Installing and securing anchor bolts

Several special steps are required to secure the anchor to the base

To begin with, it is very important to choose the right anchor bolt in terms of size and weight.

Remember that the finishing material is not able to withstand this mount, so it must be screwed right through to the concrete or brick base.

Thus, calculate the thickness of the coating and take into account the immersion of the bolt into the concrete by another 50 mm. In this case, the anchor will be installed correctly.

The drill, which will make the hole in diameter, should be about half a millimeter smaller than the bolt itself. This is done so that the anchor bolt is installed into the wall with little effort and the fastening is therefore more reliable.

Find the right drilling equipment. To do this, be sure to consider the type of base. Next, you need to drill holes in the marked places.

Clean the surface of the base and the hole itself from dust and dirt. Insert a sleeve into the hole and drive it there. Then insert the stud into the sleeve and screw the nut onto it. Tighten very carefully, as soon as the nut reaches the sleeve, secure it with a special wrench.

Anchor packaging usually indicates how many turns of the wrench are required to securely tighten without causing damage. In some cases, it is permissible to completely immerse the nut into the cladding layer to the base. But for this, only specialized nuts are used.

This information will also appear on the bolt packaging. In this way, the anchor bolts are fastened.

Main characteristics

A stud anchor is an element that is intended for the installation of structures of heavy or medium weight to the base surfaces of concrete or natural stone. After a positive test, the stud anchor can also be used for fastening in solid brick.

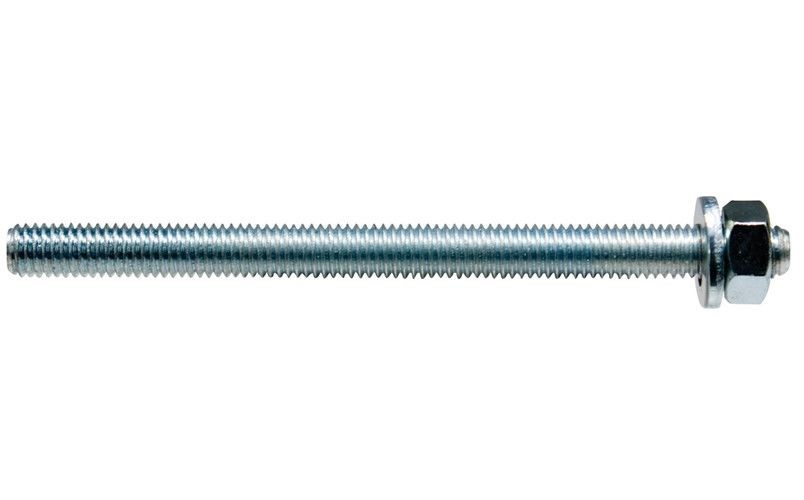

The design of such an element is a threaded rod and a spacer-type coupling. The scope of delivery also includes a nut that matches the diameter. As a rule, such elements are made of carbon steel having a zinc coating with a thickness of 5 μm. But in hardware stores there are also stainless steel anchors. Some manufacturers, such as Hilti, provide anchors for concrete that is in tension or compression. Products of this type differ from ordinary ones by the presence of markings on the hairpin.

The range of sizes of stud anchors is quite extensive. So, indicators thread diameters vary from M6 to M24, and length indicators can be from 40 to 300 mm. These parts help to mount elements with a thickness of 5 to 130 mm and an impressive weight.

The principle of operation of the presented anchors is simple: after being placed in a prepared hole when tightening the nut, the stud with a spacer helps to wedge the outer shell of the fastener. This allows you to reliably mount this element.

How the stud anchor works in a concrete base

The fields of application of this type of anchors can be very diverse. They are used for the installation of cables, antennas, heavy structures, load-bearing consoles, and various types of fences.

Stud anchors have many advantages over alternative fasteners, namely:

- a high degree of reliability due to strong fastening at the base;

- through installation, characterized by sufficient convenience;

- the possibility of remote installation due to the elongated thread;

- low cost.

Peculiarities

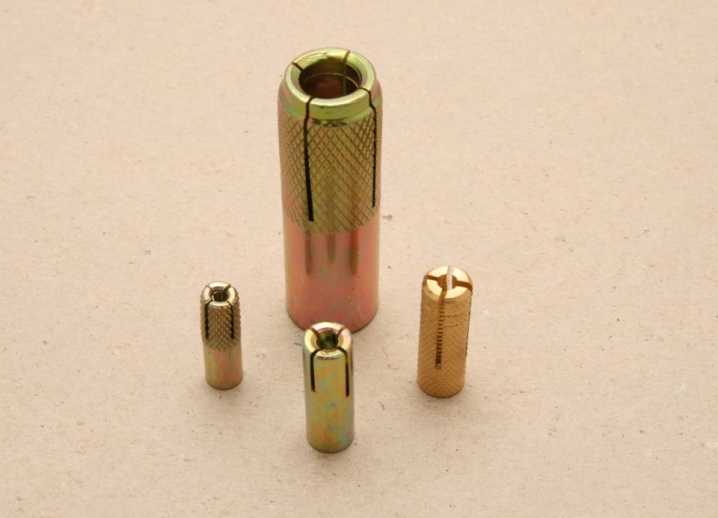

Expansion (self-expanding) anchors are the same self-supporting expansion bolts.They are made of high-strength, durable metals: galvanized carbon steel or brass. This is how they differ from the dowels, which are mainly made from plastic polymer compounds. The zinc layer creates an effective protection of hardware against corrosion, usually the coating has a yellow or whitish tint.

The active part of the self-expanding bolt resembles a sleeve, longitudinal cuts are provided on the sidewalls - they form expanding petals. A spacer is built into the sleeve body part - in the process of hammering the hardware into the hole, it squeezes its "petals" and thereby makes the fixation of the hardware product as reliable and durable as possible. The top of this mount looks like a stud, with a washer and an adjusting nut on the threaded side. The operating principle of the spacer bolt is simple. When a nail, located inside the nut, is driven into the base, the bottom of the bolt expands and it is fixed to this very base. Such an anchor is easy to install and fixes without any problems.

The main advantages of self-expanding anchors are:

- high strength and bond strength;

- resistance to external mechanical damage and adverse environmental factors;

- ease of use;

- high speed of creation of effective fastening.

How is it indicated in the labeling?

In order to avoid constant measurement of anchors during selection or work, markings are applied to their sleeve using a stamp, allowing you to quickly orient yourself. Here is an example of marking a domestic anchor: М12 16x150. In this case, M12 is the thread size, 16 is the diameter of the sleeve and drill that needs to be drilled, 150 is the maximum depth to which the material must be drilled, corresponding to the length of the hardware. The markings may differ slightly from manufacturer to manufacturer. In addition to the above information, the marking can also indicate the maximum thickness of the material to be fixed.

How to twist?

Installation of the stud anchor is no different from the installation of other types of these hardware or dowels.

- First you need to drill a hole in strict accordance with the diameter of the fastener. Then remove material chips and dust from the recess. Thorough cleaning is not required.

- After completing these operations, an anchor is installed in the prepared place. You can hammer it with a mallet or hammer, through a soft gasket, so as not to damage the product.

- At the end, the anchor pin is connected to the attached object. For this, a special nut is used, which is present in the design of the product. When it twists, it opens the petals in the locking cylinder and locks into the recess. In this case, the required item is securely attached to the surface.

Key points to pay attention to when installing

- Insufficient tightening of the nut will cause the cone to enter the spacer sleeve incorrectly, as a result of which the fasteners will not take the desired position. In the future, such fastening may weaken, and the entire structure will become unreliable. But there are times when the stud anchor still achieves maximum firm fixation in the material, but already with an offset from the desired position.

- Overtightening the nut also has a negative effect. If you tighten it too much, the cone fits too tightly into the expansion cylinder. In this case, the base, into which the stud anchor enters, may collapse. This can happen even before the force begins to act on the hardware.

Not all workers are aware of the possible dangers associated with non-compliance with the tightening rules.

It is very important to control how tight these fastening systems are. There is a special tool - a tightening control module, with which you can adjust the forces

He is able to document his actions for subsequent checks.

In the next video, you will find examples of the installation of various anchors.

Characteristic

The anchor-stud (wedge) consists of a threaded rod, at the end of which there is a cone, a spacer cylinder (sleeve), washers and nuts for tightening. It is a widely available and widely available product. Their assortment is quite wide. Zinc-coated carbon steel products are most commonly seen on the shelves, but stainless steel anchors can also be seen.

Anchor rod is one of the important details in construction work. Their reliability and the required amount significantly affect the strength and safety of building structures.

This type of mount has numerous advantages:

- the design is very simple and reliable;

- excellent bearing capacity;

- high speed of installation, no special skills are required for installation;

- widespread, you can always find the right option;

- affordable price.

There are also disadvantages, and they are as follows:

- due to the design features of the product, it is not recommended to use it in soft materials (wood, drywall);

- it is necessary to observe high accuracy when drilling holes;

- after dismantling the product, it will no longer be possible to use it the next time.

Varieties

There are several varieties of this type of fastening systems for solid bases, such as spacer, spring, screw, hammer, hook, frame. Their main purpose is to attach various objects to a concrete or natural stone base. You can also find a threaded rod collapsible anchor, it is mainly used for anchoring in suspended ceilings or hollow partitions.

Anchors are not very suitable for installation in wood, since when screwed in, they violate the structure of the wood, and the reliability will be very small. In some cases, when it is required to fasten boards for formwork, anchors with a replaceable spring are used.

All products can be divided into 3 subgroups according to the material of manufacture:

- the first is made of galvanized steel, it is recommended for installation in concrete;

- the second is made of stainless steel, it does not require any coating, but this group is very expensive and is made only by prior order;

- in the production of products of the third group, various alloys of non-ferrous metals are used, the parameters of the products are determined by the characteristics of these alloys.

There are also additional properties. For example, reinforced studs with increased tensile strength can be produced.

Types of stud anchors

We will talk about the most common Hilti stud anchors on the market. The entire range of these products is divided into several types:

- HST;

- HSA;

- HSV.

Each of them has its own nuances, characteristics, standard dimensions and has certain operating criteria.

Hilty fasteners have a reliable design that inspires confidence

HST

This stud anchor is intended for the installation of structures in specific areas and is used in tension and compression types of concrete. HST is available in carbon steel, stainless steel or highly corrosive steel.

This type is the only manufacturer's stud anchor that is approved for use in cracked concrete.

All the named types of these elements are used for the installation of beams, floors, various equipment, columns, as well as structures that constantly experience shock loads.

This high quality stud anchor features stainless steel spreader bars with anti-corrosion coating. Due to the presence of a series of highly corrosive material, the presented type of fastener can be used in an aggressive environment.

The main advantages of HST are:

- minimum center distance and length to edge;

- the presence of a head on the threaded part for additional protection;

- a wide range of diameters from M8 to M24;

- matching the length of the drill and anchor.

The design of the anchor is simple

HSA

This mechanical fastener has a unique spacer structure. It is pre-connected with a nut and washer. This type of fastener is suitable for work on a concrete base without flaws, as well as on natural stone.

Due to the presence of additional markings, during installation, you can monitor the immersion length of the fastener. This makes it much easier to meet the planting requirements. This type of stud anchor is sized to match the length of the Hilti drill.

The advantages of this type of anchor products are:

- difference in diameters from M6 to M20.

- the choice of the type of coating: galvanized or stainless steel.

- the ability to withstand both standard and reduced planting depth.

HSA series anchor with length marking

HSV

This is a stud anchor of the "Standard" type for installation in concrete and natural stone. A distinctive feature of this model is that it is used for medium-type loads and has a high level of flexibility.

HSV is manufactured from carbon steel and is equipped with DIN 125, DIN 9021 nuts and DIN 127b spring. Due to the production of steel by the cold forming method, the possibility of fracture during bending is excluded.

This type of fastener differs from those presented in smaller diameters. He has them ranging from M8 to M16.

Features of HSV:

- saving time due to the possibility of assembling fasteners in advance;

- the presence of a mark to control the planting depth;

- protection of the threaded part with a head with large dimensions;

- zinc coating of the surface with a thickness of up to 5 microns;

- the ability to apply a load immediately after installation.

Studs with head threads may only be used in dry conditions. They can be installed through or pre-assembled.

Galvanized fasteners with pre-assembled nut and washer

Views

The development of anchor fasteners has led to the emergence of several varieties of it. With a countersunk head for a Phillips screwdriver, they are usually used for mounting frame structures. With a nut at the end, it can be used for fastening objects and equipment with mounting holes. For heavy equipment, bolt head anchors are often used.

An anchor bolt with a ring can be either reinforced or bent. A slightly shorter ring forms a hook. The hook anchor is indispensable if you have to not only fix the object, but also mount and dismantle it. A kind of development of the hook was a simple bend at the end of the hairpin. Such an L-shaped anchor - a crutch - also has a wide range of applications. The working part is no less varied, the one that is fixed in the drilled hole.

The most common expansion anchor bolt has already been described above, there is no need to repeat it. The original solution - the duplication of spacer sleeves - led to the development of a special design of the anchor, called two-spacer and even three-spacer. These fasteners can be successfully fixed even in porous material.

For reliable fixation, the spacer part can have a folding spring mechanism, not just expanding the fasteners, but creating an emphasis on the inside of the coating, for example, a plywood or other partition, for which other fasteners of adequate reliability simply cannot be used due to the characteristics of the material.

Features and scope

Fasteners in wood structures have never been difficult. Even a simple nail is quite suitable for this, let alone a fastener that has a screw thread - screws or self-tapping screws do an excellent job with fasteners in wood. Can be fastened to wood and fasteners with hooks or rings. In this case, the reliability of the fastening will directly depend on the thickness and quality of the wooden structure in which the fastener is carried out.

The main elements of the anchor mechanism, which ripples the anchor fastener in the drilled hole, are a metal sleeve-sleeve with slots dividing it into two or more petals, and a cone nut, which, being screwed onto a rotating pin, opens the petals, which, in fact, holds the fasteners. This simple scheme is successfully used for concrete or solid bricks.

For hollow and hollow material, an anchor with two or more sleeves can be used, forming several anchorage zones, significantly increasing its reliability.

Why do you need such a clever fastener when there are cheaper screws and dowels? Yes, indeed, in some cases, fastening with a self-tapping screw and a plastic dowel is quite justified, especially if you have to use fasteners at many points, for example, when installing cladding or decorative materials. You can also resort to this method if increased requirements are not imposed on the fasteners: installation of shelves or wall cabinets, frames or paintings

But if you have to fasten rather heavy and bulky objects, it is still better to pay attention to the anchor bolts

Crutches or L-shaped anchors will be indispensable for hanging the boiler. An anchor with a hook at the end can be useful if you need to hang a heavy chandelier or punching bag. Fasteners with a ring are useful for securing cables, ropes or guy wires.

Types and models

Self-expanding bolts in accordance with GOST can have different markings, usually due to the presence of a metric thread, it contains the letter "M", as well as the diameter and length of the hardware. For example, expansion bolts M8x100 mm, M16x150 mm, M12x100 mm, M10x100 mm, M8x60 mm, M20.10x100 mm, M12x120, M10x150 mm, M10x120 mm, and M12x100 mm are widely used.

Some models are marked with a single diameter, for example: M6, M24, M10, M12, M8 and M16. Also on sale you can find products containing markings of three numbers: 8x6x60, 12x10x100, 10x12x110. In this case, the first number indicates the outer diameter of the anchor, the second - the inner size, and the third characterizes the total length of the product.

There are several types of spacer bolts.

- With washer - includes a wide washer, thanks to which the mounts are pressed as tightly as possible to the wall or some other base.

- With a nut - used to secure heavy structures. They are inserted into the hole, and the nut is screwed on, so there is no need to hold the hardware on weight.

- With a ring - such fasteners are in demand when pulling a cable, rope or cable. They are also necessary when you need to fix the chandelier to the ceiling.

- With a hook - a curved hook is provided at the end of such hardware. These models are indispensable in the process of hanging water heaters.

- With impact spacer - used for fixing structures made of natural material by through mounting.

- Double-expansion anchor - has a pair of spacer sleeves, due to which the surface of "implantation" of the hardware into a solid base is noticeably increased. Widely in demand when working with stone and concrete.

How to use it correctly?

Installing the stud into the glue mass is not difficult, however, in the implementation of this task, several important conditions must be fulfilled. Installation begins by making a hole in the base. For this, a punch with a drill is used (its diameter should be about 2-3 times larger than the size of the metal stud).

The next step is to thoroughly clean the resulting hole from dust and dirt. If you neglect this work, the adhesion of the adhesive and the material will not be so reliable. You can use a vacuum cleaner to remove dust from the hole.

Following actions.

- Inserting a mesh sleeve into the hole (its use is mandatory when working with cellular materials and hollow bricks). It must be installed before the introduction of the adhesive mass.The use of a mesh sleeve promotes an even distribution of the composition along the length of the hole and on all its sides.

- To fill the hole properly, a special dispenser should be used. The mass should be filled in the entire volume of the hole.

- Manual insertion of the stud. If the length of the product is more than 50 cm, it is advisable to use a special jig, which feeds the rod under pressure. When using ampoule liquid dowels, the pin must be clamped into the drill chuck and the fasteners must be inserted when the equipment is operating at medium speed.

After inserting the anchor bolt into the hole, the compound hardens. Basically, the glue dries in half an hour. The squareness of the metal rod should be checked immediately after it is inserted into the hole. After a few minutes, due to the polymerization of the composition, it will not be possible to change the position of the pin.

How to install a chemical anchor, see below.

Dimensions (edit)

GOST dimensions (length and diameter) of anchor bolts do not exist, the alloys from which they are made are subject to mandatory standardization. However, all manufacturers adhere to the regulations dictated by the technical conditions. And here it is already possible to distinguish a number of size groups that divided the fasteners first by diameter, and then by length.

The smallest size group is made up of anchors with a sleeve diameter of 8 mm, while the diameter of the threaded rod is smaller and, as a rule, is 6 mm.

The smallest anchors-hooks and rings have very modest dimensions and corresponding strength: 8x45 or 8x60. Not all manufacturers produce such fasteners, since it is often successfully replaced by a plastic dowel with a self-tapping screw that has a ring or hook at the end.

The size group of products with a diameter of 10 mm is somewhat more extensive: 10x60, 10x80,10x100. Stud thread is standardized with M8 bolt. On sale, such consumables can be found much more often than the previous group, since their field of application is much wider, manufacturers are more willing to produce just such anchors.

Anchor bolts with a diameter of 12 mm (12x100, 12x130, 12x150) and a diameter of a threaded rod M10 have practically no competitors at all. The unique fastening properties do not allow replacing them with plastic dowels. It is in this size group that double-expansion reinforced anchors can be presented.

Real fixing "monsters" are anchors with stud diameters M12, M16 and more. Such giants are used for serious construction and installation work and are usually not used in everyday life, therefore they are very rarely represented in hardware stores. Even less often, you can find fasteners with a stud diameter M24 or, even more so, M38.

How to choose?

There is no universal fastener, so you need to select wedge anchors based on the following conditions:

- size (thickness of the part that will be attached to the base, and the depth of immersion of the anchor into it);

- how it will be located (horizontally or vertically);

- calculate the expected loads that will affect the hardware;

- the material from which the mount is made;

- the parameters of the base into which the stud anchor will be installed.

Also, before buying, you need to check the documents and certificates of conformity for products. This must be done because anchors of this type are used in the installation of important structures, and not only the integrity of these elements, but also the safety of people, largely depends on their reliability.

Materials (edit)

The material of the anchor can also be different:

steel;

It is clear that each material has its own advantages and disadvantages. Steel fasteners with high strength cannot be used in aggressive environments, including high humidity. Galvanizing significantly extends the life of the steel fastener, but also increases its cost. Stainless steels of grades A1, A2 or A3, used for the manufacture of anchor bolts, do not corrode, have high strength, but are distinguished by high cost.Brass, despite not the best strength characteristics, can be used not only for fasteners in a humid environment, but also under water.