Fastening the front masonry to the wall

From all that has been said above, it is quite clear that when erecting lightweight masonry, the anchor for a brick wall is the brick itself. So, when it comes to ordinary masonry, no fasteners are needed. But to fix decorative (front) masonry to it, completely different technologies are used.

Flexible connections

In general, when performing cladding, an anchor for masonry can be any available metal material. Many bricklayers believe that all means are good for this.

For anchoring the front masonry, which is carried out simultaneously with the construction of the main wall, they use pieces of steel rods and strips of plaster mesh, and even manage to make improvised anchors from scrap aluminum profiles with their own hands.

Anchoring with steel rods

Composite rods and dowels

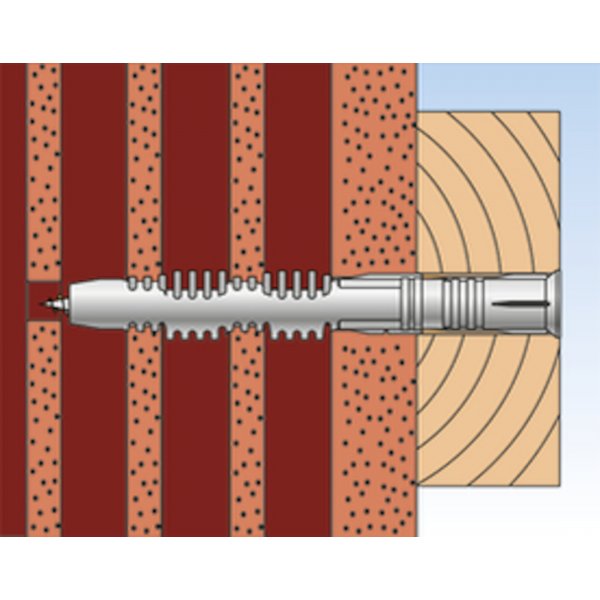

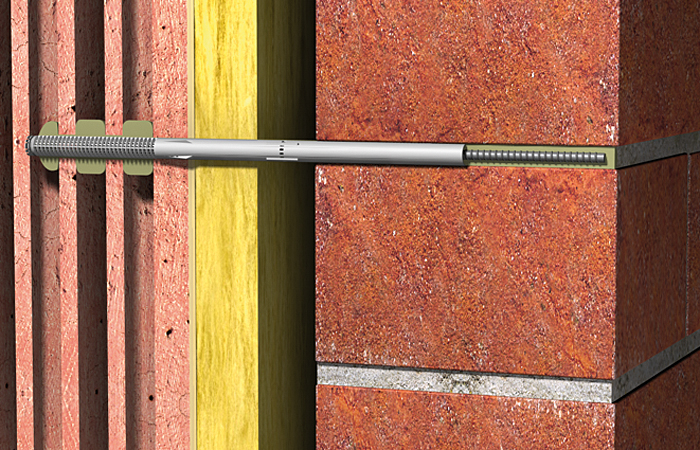

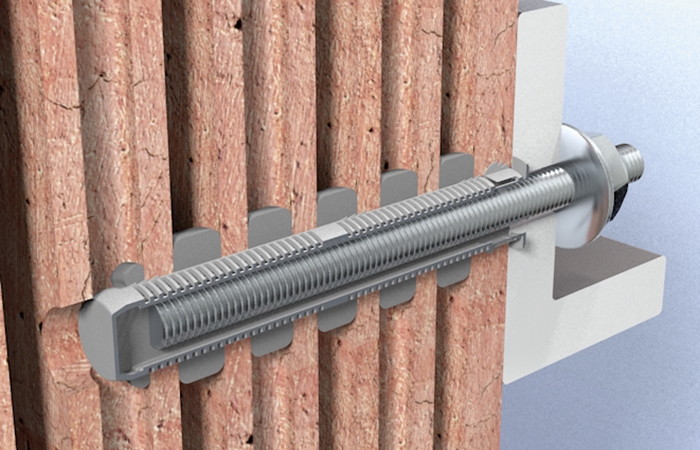

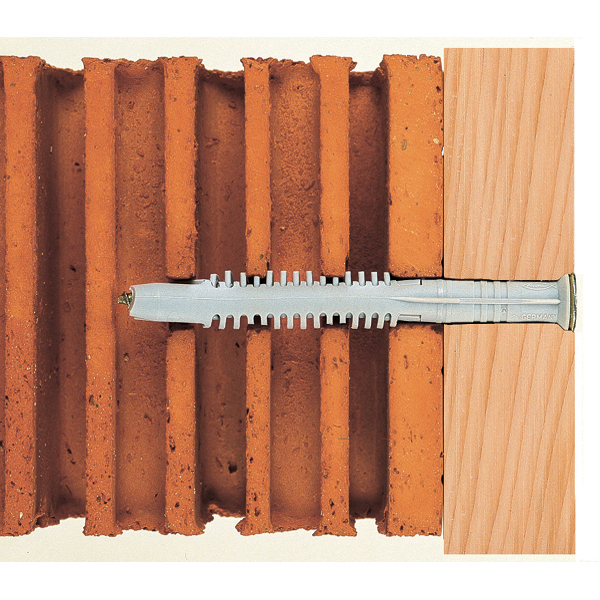

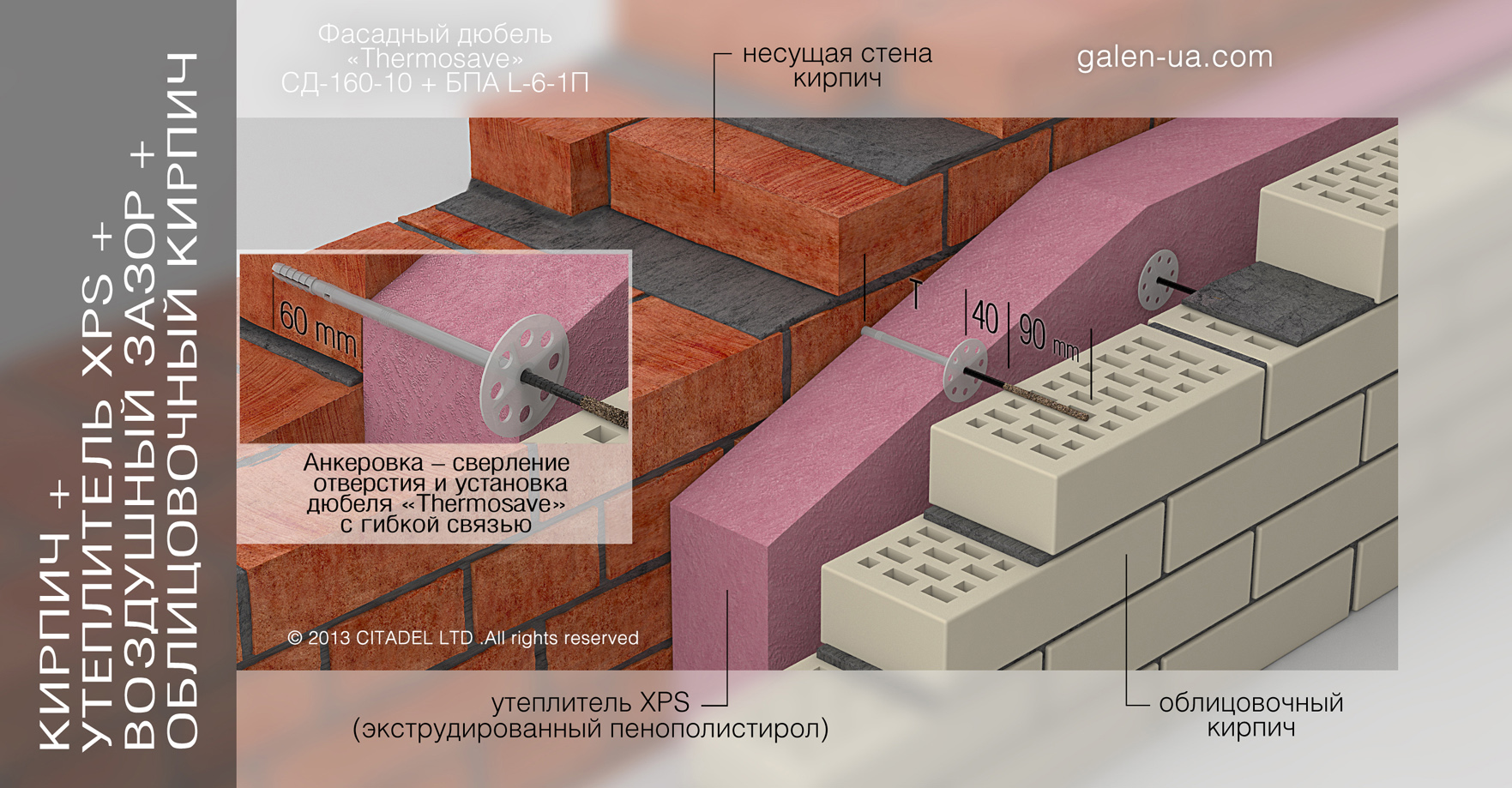

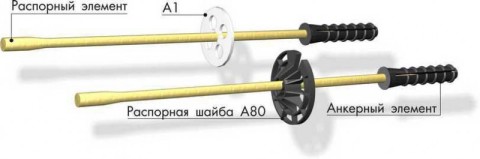

The most common are anchor rods and facade dowels with flexible connections, made of basalt or fiberglass. The rods are used for monolithic cladding - in cases where it is not possible to ligate with the load-bearing wall.

For example, when the pattern of the front masonry is formed only due to spoon rows. The rod anchors, which are shown in the picture below, can also be used when erecting a decorative wall with a ventilation gap, but without insulation.

Brick anchor: GRP rods for monolithic cladding

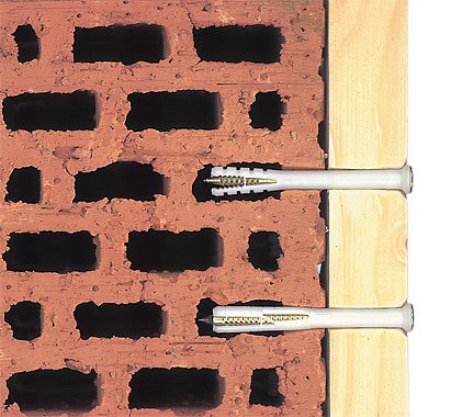

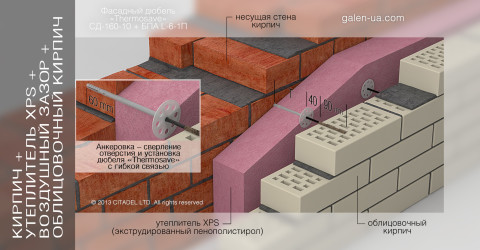

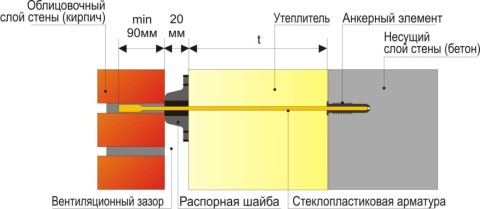

Anchors in the form of a facade dowel with a flexible connection, which you can see in the photo below, are equipped with a spacer washer. They allow not only to connect two walls together, but also to simultaneously fix the thermal insulation plates. Therefore, they are used for a bundle of three-layer insulated walls, while simultaneously performing the functions of disc dowels for insulation.

Basalt anchoring rods

On this, all the differences between rods and dowels are exhausted. All of them withstand prolonged exposure to high temperatures, and are of the highest strength. By the way, basalt-plastic is ahead of even steel in this indicator.

It is also important that it has a low coefficient of thermal conductivity, and nullifies the possibility of the formation of cold bridges. This is precisely the main disadvantage of metal rods, since they accumulate condensate and corrode, which leads to the rupture of bonds.

Perhaps someone would think that since the rod is flexible, it can easily be pulled out of the wall. However, this is not at all the case. The force that needs to be applied for this corresponds to 408 kgf (4000 Newton). Such an impact only happens during an earthquake, but when the walls themselves collapse, hardly anyone will worry about the cladding.

How to install an anchor in brickwork

- The sleeve diameter of an anchor designed for brick walls is usually 6 mm. The length varies considerably, which is why, in fact, the price of the product also depends: from 6 to 14 rubles. a piece.

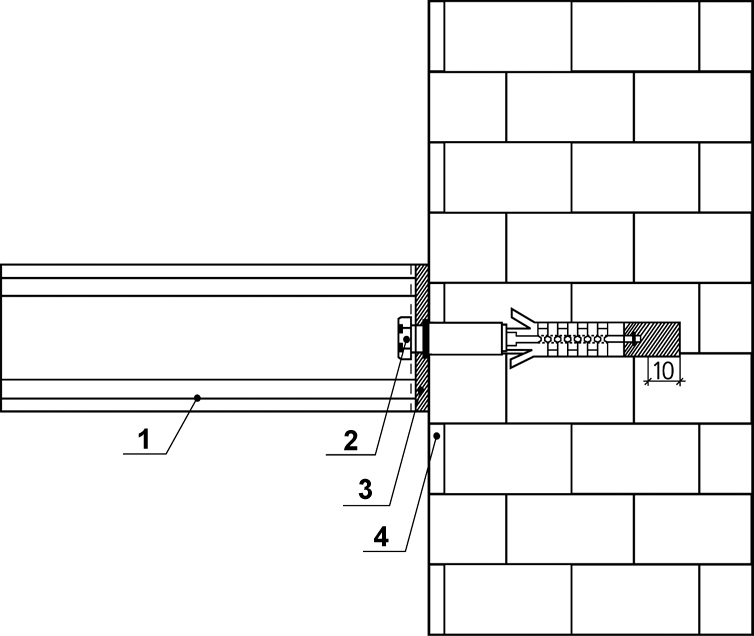

- The dowel is selected along the length so that it fits into the front brickwork by at least 9 cm (three quarters of the brick width).

- Its anchoring part is always 6 cm. Clamps for insulation are sold separately, and purchased as needed.

- There are also options for flexible connections for attaching brick cladding to bases of a different type: monolithic, aerated concrete. The exact number of connections is determined by calculation, and depends on the presence or absence of a wall of insulation in the cake.

- Its variety also matters.For example, mineral wool needs to be fixed more often than expanded polystyrene. But on average, the consumption of composite anchors is 4 pieces per 1m2. Additionally, they are installed at the corners, around openings, at the locations of expansion joints, and the spacing of the fasteners is made no more than 300 mm.

Fixing the brick cladding to the concrete wall

What else are flexible anchors good for when a brick wall is being erected with brick cladding? The fact that they allow you to connect two walls even in the case when the horizontal seams of the masonry do not match.

A flexible connection can also be laid in a vertical seam, which cannot be done in any other case. So that the fasteners do not loosen, before fixing the anchor for the brick, they mount the thermal insulation on the glue, and then, flashing it through and through, they establish flexible connections.

Hollow brick

What is this material? In modern construction, two types of bricks are used - hollow and solid. The main function of the first materials is the construction of buildings, which must be as strong and durable as possible.

This brick is good in all respects. The material is lightweight, strong, easy to install. However, it has a significant drawback. It retains heat poorly in rooms. Although hollow brick practically does not differ in strength from solid brick, it is more often used in finishing work. The internal void in such a building material can be, depending on the type and manufacturer, from 30% to 50%. Low-melting clays are used as raw materials for such blocks. It is from it that red brick is made. There is also another option. It is a silicate hollow white appearance. Let's take a look at the features and properties of mounting blocks.

Fastening the front masonry to the wall

From all that has been said above, it is quite clear that when erecting lightweight masonry, the anchor for a brick wall is the brick itself. So, when it comes to ordinary masonry, no fasteners are needed. But to fix decorative (front) masonry to it, completely different technologies are used.

Flexible connections

In general, when performing cladding, an anchor for masonry can be any available metal material. Many bricklayers believe that all means are good for this.

For anchoring the front masonry, which is carried out simultaneously with the construction of the main wall, they use pieces of steel rods and strips of plaster mesh, and even manage to make improvised anchors from scrap aluminum profiles with their own hands.

Anchoring with steel rods

Anchoring with steel rods

Note! There are many types of anchors specially designed for fastening brick cladding, which are called flexible ties. Why flexible? Yes, because part of the anchor rod is made of flexible polymer or composite material

This has its own meaning: thanks to the movable link with the load-bearing wall, cracks do not form on the front masonry when the foundation shrinks.

Composite rods and dowels

The most common are anchor rods and facade dowels with flexible connections, made of basalt or fiberglass. The rods are used for monolithic cladding - in cases where it is not possible to ligate with the load-bearing wall.

For example, when the pattern of the front masonry is formed only due to spoon rows. The rod anchors, which are shown in the picture below, can also be used when erecting a decorative wall with a ventilation gap, but without insulation.

Brick anchor: GRP rods for monolithic cladding

Brick anchor: GRP rods for monolithic cladding

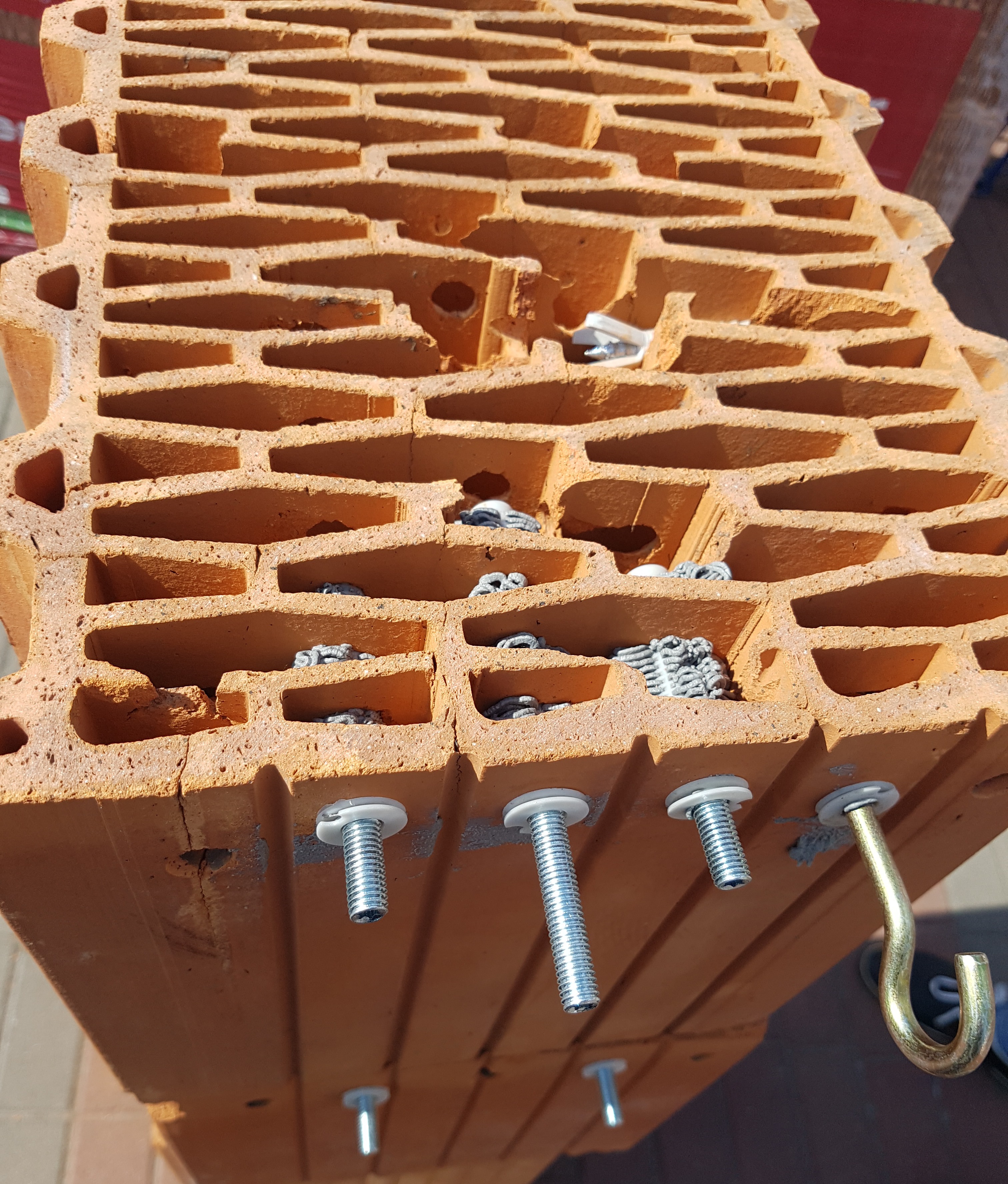

Anchors in the form of a facade dowel with a flexible connection, which you can see in the photo below, are equipped with a spacer washer. They allow not only to connect two walls together, but also to simultaneously fix the thermal insulation plates.Therefore, they are used for a bundle of three-layer insulated walls, while simultaneously performing the functions of disc dowels for insulation.

Basalt anchoring rods

Basalt anchoring rods

On this, all the differences between rods and dowels are exhausted. All of them withstand prolonged exposure to high temperatures, and are of the highest strength. By the way, basalt-plastic is ahead of even steel in this indicator.

It is also important that it has a low coefficient of thermal conductivity, and nullifies the possibility of the formation of cold bridges. This is precisely the main disadvantage of metal rods, since they accumulate condensate and corrode, which leads to the rupture of bonds.

Perhaps someone would think that since the rod is flexible, it can easily be pulled out of the wall. However, this is not at all the case. The force that needs to be applied for this corresponds to 408 kgf (4000 Newton). Such an impact only happens during an earthquake, but when the walls themselves collapse, hardly anyone will worry about the cladding.

How to install an anchor in brickwork

How to install an anchor in brickwork

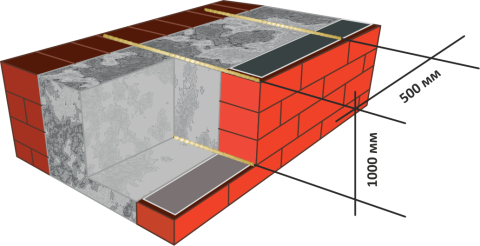

- The sleeve diameter of an anchor designed for brick walls is usually 6 mm. The length varies considerably, which is why, in fact, the price of the product also depends: from 6 to 14 rubles. a piece.

- The dowel is selected along the length so that it fits into the front brickwork by at least 9 cm (three quarters of the brick width).

- Its anchoring part is always 6 cm. Clamps for insulation are sold separately, and purchased as needed.

- There are also options for flexible connections for attaching brick cladding to bases of a different type: monolithic, aerated concrete. The exact number of connections is determined by calculation, and depends on the presence or absence of a wall of insulation in the cake.

- Its variety also matters. For example, mineral wool needs to be fixed more often than expanded polystyrene. But on average, the consumption of composite anchors is 4 pieces per 1m2. Additionally, they are installed at the corners, around openings, at the locations of expansion joints, and the spacing of the fasteners is made no more than 300 mm.

Fixing the brick cladding to the concrete wall

Fixing the brick cladding to the concrete wall

What else are flexible anchors good for when a brick wall is being erected with brick cladding? The fact that they allow you to connect two walls even in the case when the horizontal seams of the masonry do not match.

A flexible connection can also be laid in a vertical seam, which cannot be done in any other case. So that the fasteners do not loosen, before fixing the anchor for the brick, they mount the thermal insulation on the glue, and then, flashing it through and through, they establish flexible connections.

Classification

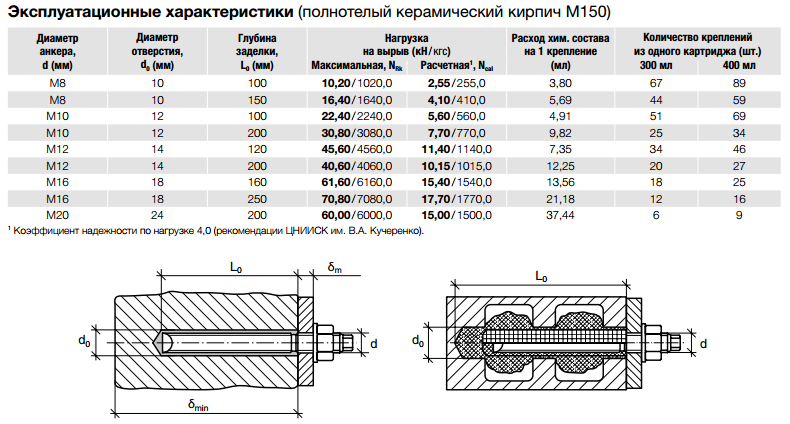

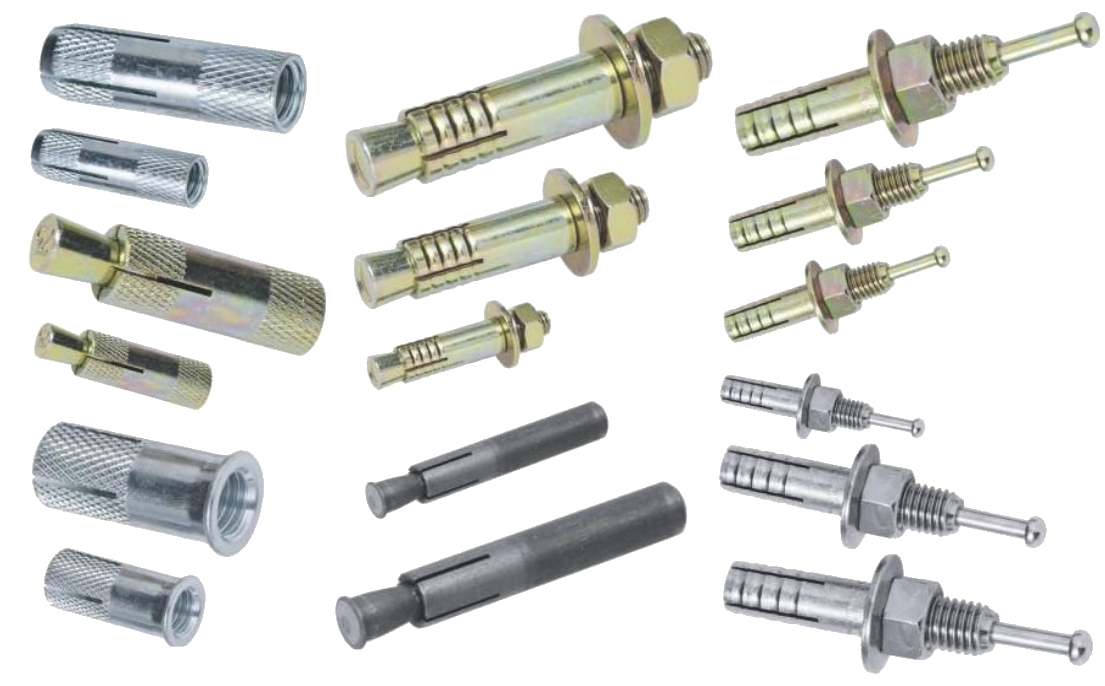

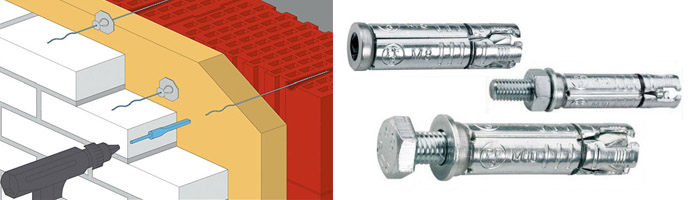

Two types of anchor systems are installed in a brick stone wall - mechanical and chemical.

The systems of the first group are more popular.

Based on the purposes of application and design nuances, anchors are divided into several types:

- hammer-in. The simplest hardware installed in monolithic block stones. Structurally, it consists of a spacer zone driven into a brick surface with a hammer, a bolt and a nut. In addition to the nut system, attachments with a hook, ring and angle are used. The ability to hold a load is determined by the parameters and the degree of reliability of the metal element. This type of anchor system is the simplest. Having installed the driven part, the element with the thread is screwed in.

- wedge. Equipped with anchoring edges that expand when screwed in and a recessed head. This type withstands significant load impacts, it is recommended for fastening directly through the part. Elements of the curtain façade, stained glass, and shelving are fastened with similar systems. The fastening system has a second name - an anchor bolt for bricks;

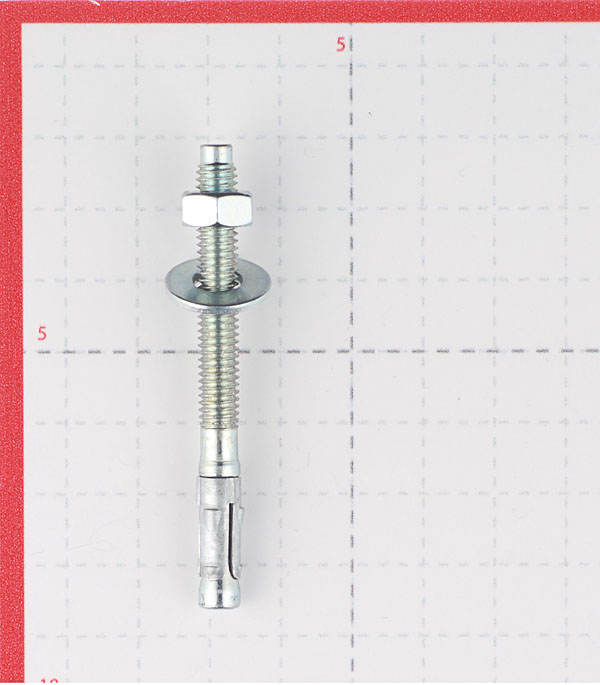

- double-spaced. They fix heavy steel reinforcement, used to create increased resistance to pull-out.Such an expansion anchor is represented by a stud with shells for expansion differing in elongation, a nut and an unpressed washer. Installed in solid solid brick material, sometimes used for hollow block stone;

- MSA is a system made of brass alloy and grooved to improve the quality of the external connection to the internal tapered cavity. At the time of installation, it expands, reliably adjoining the walls of the hole created. The maximum diameter inside is up to eight millimeters, such an anchor is used to fix not very large objects on a brick;

- anchor bolt. This fastener with a hex head is used to combine decorativeness and resistance to alignment. The disadvantage of hardware is complex installation work, for the performance of which an electric tool is needed in order for the fastener to turn out to be of high quality;

- rod retainer. Such a system is considered an extended version of the wedge anchor, used for fastenings through a multi-layer cladding. The main advantage is considered to be placement under a slight slope, but it is not recommended to use this property for brick stone. The rod is cut in length, if necessary, on the back side of the wall the system is fixed with a nut and a washer;

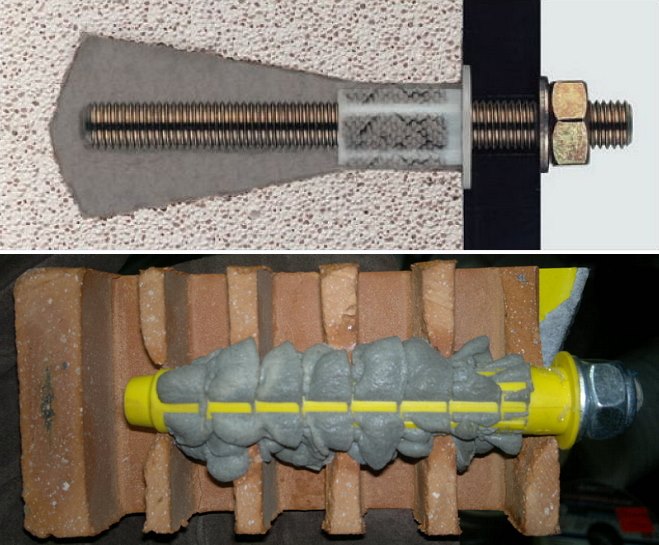

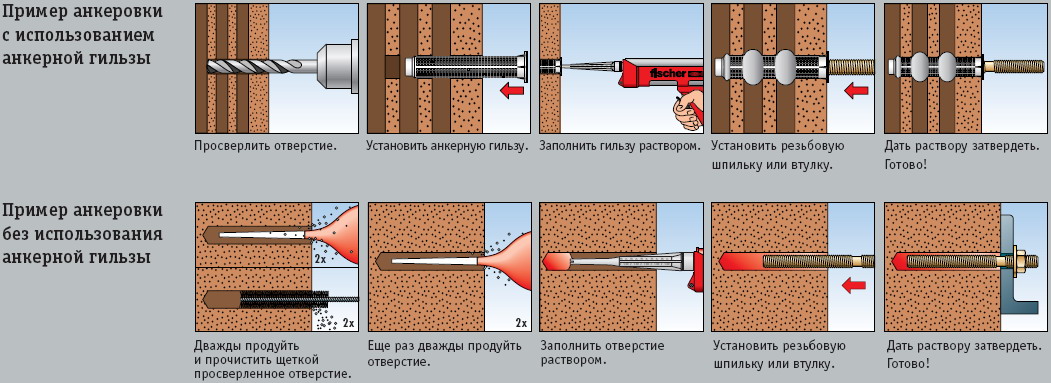

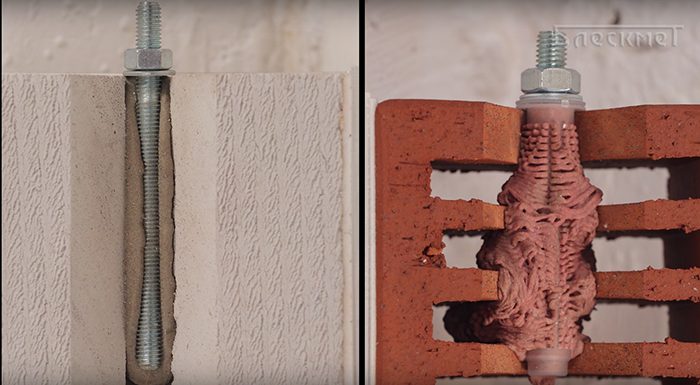

- chemical. Fixation is carried out into the prepared hole by means of a special glue that fills the internal cavity, ensuring a firm hold of the bolt. This fastener is mounted simply. A hole is drilled in the wall, a capsule containing an adhesive is inserted, a bolt is placed. Note that for the final hardening of the glue, some time is required, depending on the components of the glue and the temperature regime of the air. The information you need can always be found on the packaging material.

The review presents only the most popular anchor systems used for walls erected from brick material. Manufacturers produce a large number of anchors that have similar applications. Such systems differ in designs and technical parameters, which should be taken into account when making the final choice.

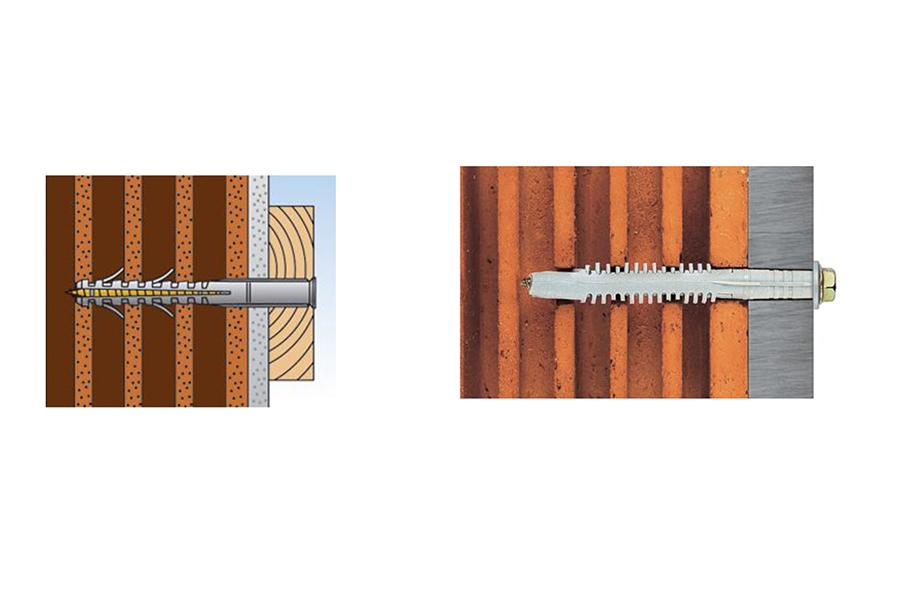

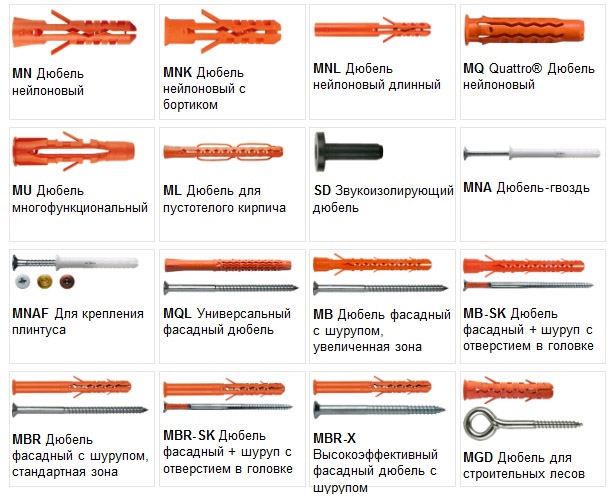

Varieties of dowels for brick walls

Dowels are used to attach furniture, paintings or other objects to brick walls, since they are capable of withstanding heavy loads. In order for the fasteners to be securely held in the base, it is necessary to select the correct type and size depending on assortment of bricks or concrete. If the dowel is not used for its intended purpose, it may not withstand the load and fall out of the hole.

Types of dowels and their features

1. Externally, the dowel is similar to a cork, has a cylindrical shape with a cavity. When the screw is screwed in, its body expands and abuts against the walls of the hole. The most common are nylon and polyethylene expansion plugs. To prevent the screw or nail from falling inside, the fasteners are equipped with a special collar equal to the diameter of the screw head.

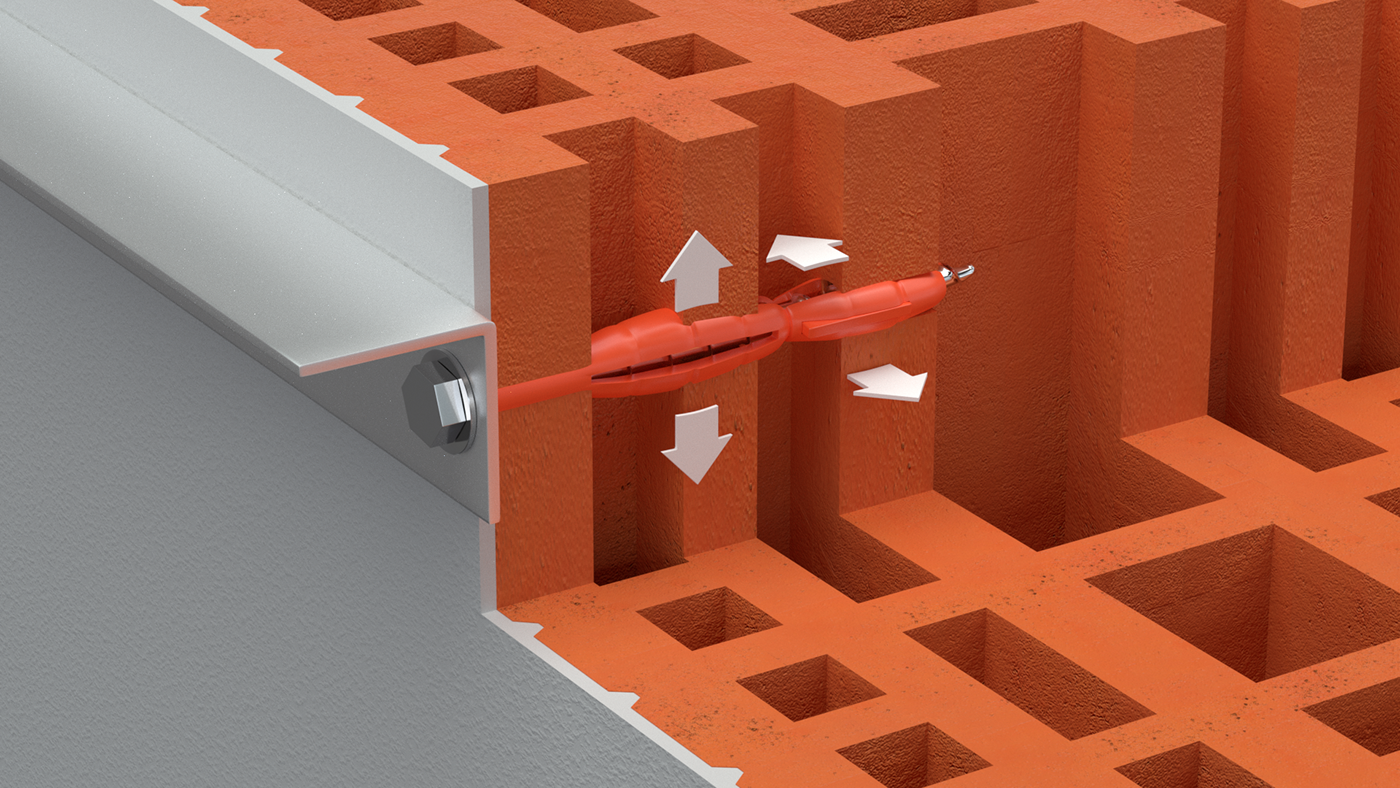

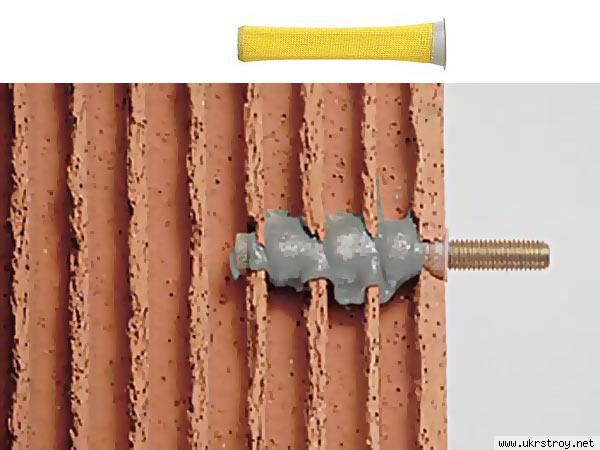

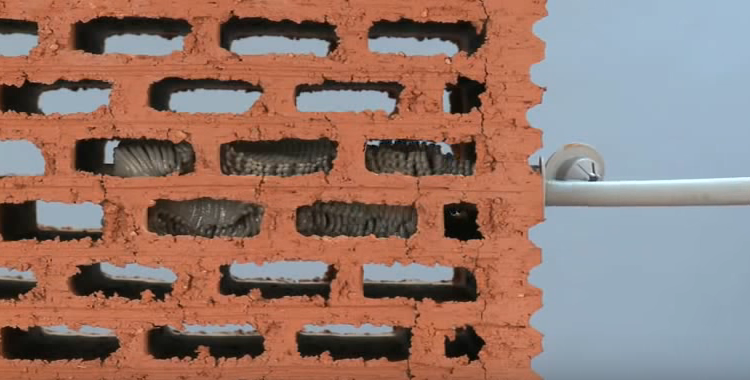

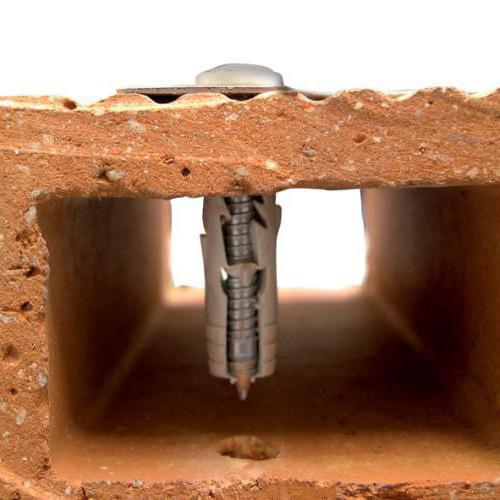

2. For walls made of porous or hollow bricks, anchor fasteners are used. As soon as such a dowel begins to be screwed into the brickwork, its end expands or twists in the form of a knot. The resulting "nut" inside the voids reliably holds any object.

3. Nail dowels are used for fastening strips under the cladding with finishing material, they are small in size. They come with a nail. Install them together through the hole in the rail and wall. Then they hammer in with a hammer.

4. Special dowels-umbrellas are used to fix the thermal insulation. An umbrella is inserted into the hole in the wall and through the insulation, and then a nail (plastic or metal) is hammered in. For heavy loads, for example, up to several tons, metal dowels for concrete and bricks.

5. For suspended ceilings, metal fasteners are best suited.In the event of a fire, the plastic will melt and the ceiling will collapse.

- reliable mount that can withstand heavy loads;

- easy to use;

- use both indoors and outdoors is possible.

Due to the presence of thorns and mustaches on them, they do not scroll while screwing in the screw.

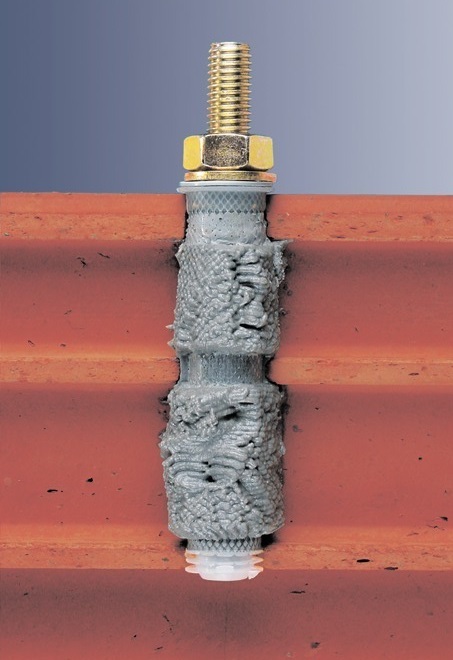

How to fix the roof base

Anchor fasteners are used for work on the base of the roof of brick houses. Anchor bolts fix the Mauerlat - one of the parts of the roof base. It is made of wooden beams and serves to evenly distribute the load of the roof over the entire surface of the building. Mauerlat fastening with anchors is a rather expensive method, but no other fastener can compare with it in terms of reliability and durability.

How the wooden Mauerlat is fixed to the brick base of the building

- To impart rigidity to the structure, a concrete belt is poured using reinforcement. The belt is poured on the upper border of the walls.

- During the pouring of concrete, anchor fasteners are mounted into it.

- After the concrete layer has hardened, the Mauerlat is tried on to the anchor bolts and markings are applied, where holes are made later.

- Mauerlat is applied to the anchors; to give the structure more strength, washers screwed on bolts are used.

In this way, the foundation of the roof is fundamentally anchored with anchoring systems.

Views

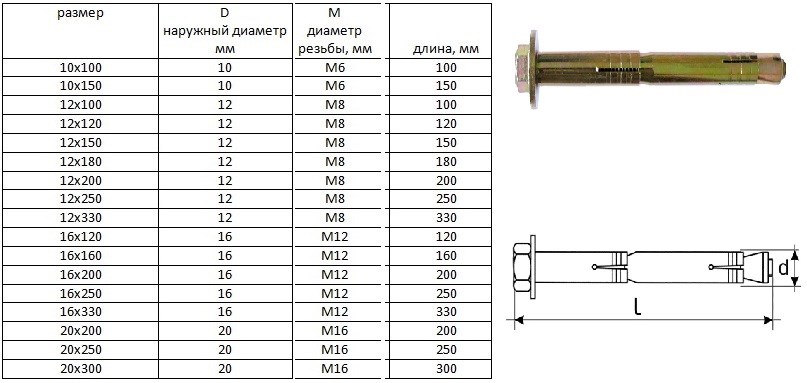

Anchor fasteners for brick buildings differ in both size and design features. They define the scope of the bolt and give it some properties. In order to achieve the best quality of fastening, the choice of fasteners must be treated with great care.

The following types of bolts are used for a brick wall:

- Driving.

- Wedge.

- MSA.

- Double-spaced.

- With a ring at the top.

- Functioning by the method of chemical fixing.

The listed options have different advantages and can be used for individual construction tasks.

Framed

Frame anchoring elements are in great demand due to their reliability and availability. However, a large number of low-quality analogs are offered for sale, which do not guarantee good fastening.

To avoid the wrong choice, you should pay attention to the following nuances:

Fastener material. In most cases, bolts are made from high strength steel and brass

When choosing an element by material, it is important to consider the scope of its application.

Hairpin length. It is determined taking into account the tasks performed.

Sleeve quality

This selection criterion is one of the most important, since it determines how long an object can be held on a brick wall. The minimum thickness must be at least 0.8 mm. If you use thinner products, the fastening will not be strong enough.

The length and diameter of the working area is determined according to some standards: the classic reading provides for a size of 8x72 mm (the first number indicates the diameter of the sleeve, and the second - to the length studs). The maximum allowable values are 8x172. Less commonly, fasteners with a sleeve thickness of 10 mm are used. They are effective for securing bulky items weighing more than 10 kg.

Drop-in anchor

Such bolts appeared much earlier than other varieties. They will be effective when hanging products on a solid brick building. To use this anchor, a place is prepared in the wall, and then the spacer is secured. Then the threaded element is fixed.

Double-spaced rods

The double-expansion anchor is equipped with a spacer sleeve. It is able to unclench in 2 places, providing maximum reliability of fixation in the wall. 1 spacer is connected to the hard surface of the masonry, which guarantees an increased degree of attachment.

For the production of double-expansion anchors, galvanized steel is used. In the upper part of the element there is a washer and a fastening nut.

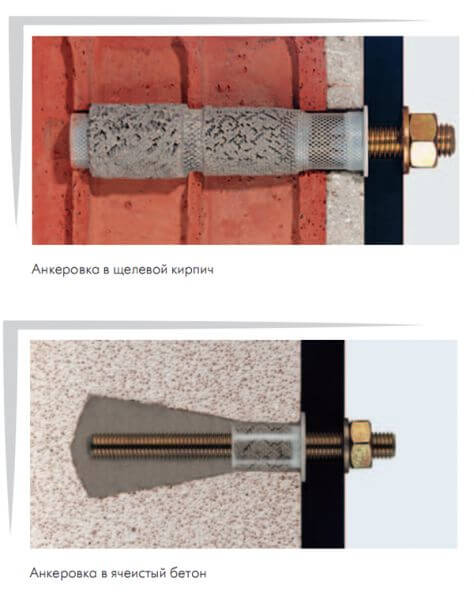

On an adhesive chemical base

Chemical anchor for brick provides increased fixing strength, since it involves the use of chemical glue. Of all the listed types of fasteners, this option has the highest reliability. The adhesive used is capable of completely filling the gaps.

The installation features provide for the observance of such rules: a place is made in the structure for fastening the bolt and is thoroughly cleaned of construction debris. Next, you should fix the capsule with the adhesive and fix the anchor.

In order for the adhesive composition to finally solidify, you must adhere to the instructions and give time to dry. It is determined by the specificity of the solution and temperature conditions. Leading manufacturers indicate the optimal interval on the packaging.

Fasteners MSA

These elements are made of high-strength brass. The outer part is distinguished by the presence of a sleeve with a large notch, which ensures a tight fixation. The allowable diameter inside the sleeve varies from 8 to 10 mm.

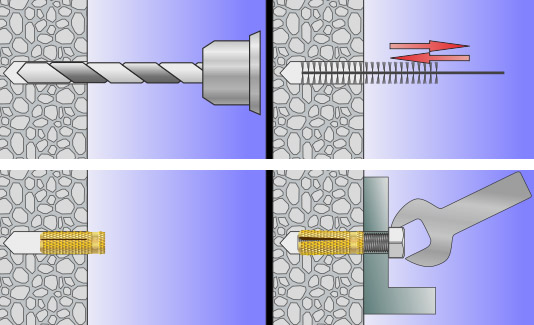

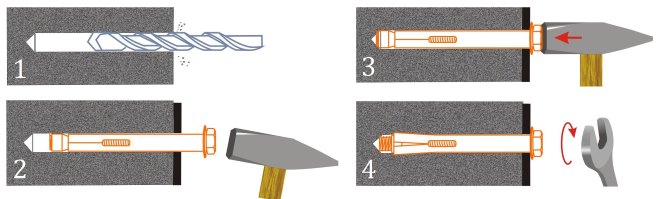

How to properly install the anchor in masonry

Anchoring products used for fastening various objects to brick structures are designed in such a way that their installation does not cause any difficulties. It is performed in the following sequence.

- A hole is drilled in the structure on which the fasteners are to be made. Its diameter should correspond to the diameter of the anchor product.

- After thorough cleaning of the hole, an anchor bolt is driven into the brick, inserted or screwed in.

- By tightening the bolt head, it is necessary to achieve maximum expansion of the spacer sleeve, which will be evidenced by the reliable fixation of the fastener in the brickwork.

Anchor installation principle

When choosing a place for drilling a hole, you should pay attention to the fact that it does not fall on the gap between the bricks filled with cement mortar. This hole should only be made in the body of the brick itself.

It is also necessary to pay attention to the state of the material from which the building structure is made, because cracks in it can significantly weaken the joint being formed.

Material composition and installation process

The chemical composition of the anchors is suitable for all types of fasteners that are made of steel. It can be used for decoration and buildings, for work in conditions with high humidity, as well as under water. Such a fastening system does not destroy the brick material, so fasteners can be installed at the very edge of the surface.

The principle of installation is that the anchor is securely fixed with a chemical compound in the drilled hole in the brick wall. Strengthening is carried out due to the solidification of the composition, which does not create stress deformations at the base of the surface. When a chemical composition solidifies, it is molecularly bonded to the material inside the hole. Due to their equal coefficients of expansion, a monolithic connection of the fastening occurs.

Hollow brick dowel - new fixing option

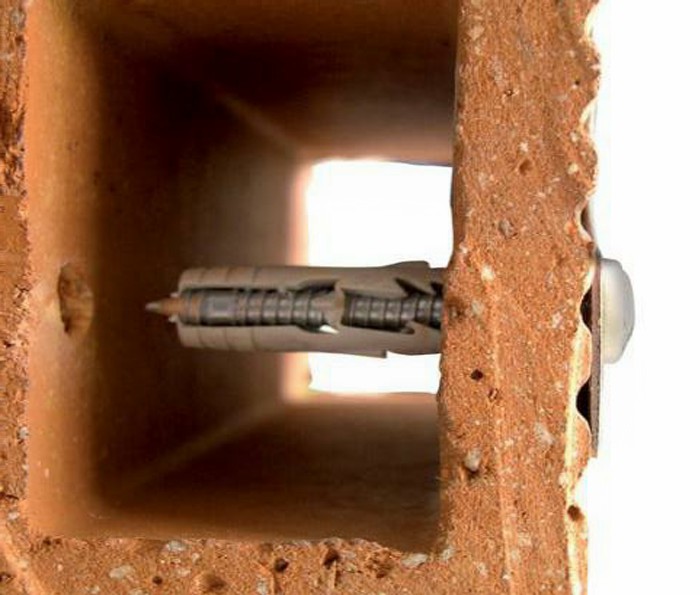

Among the building materials, there is another element that should not be forgotten. Hollow brick is also one of the problematic materials in which it is difficult to mount the mount. If, for example, you need to install an anchor bolt with a nut, then, for sure, you will be faced with the fact that the fasteners will simply rotate in the material and will dangle, of course, there can be no question of any holding force. In order to prevent this problem, there is a special dowel for hollow bricks.

What is remarkable about it, and why does it so confidently hold the elements installed on it in the hollow material? Of course, it's all about the design of the mount itself, first of all it is quite elongated, but no more than the width of the material itself. Due to the size during installation, the fastening surface will necessarily interact with the internal elements of the brick. The second, important design parameter is a significantly increased spacer part of the fastener, which additionally strengthens the fastener and does not allow it to rotate in the hole while tightening a bolt or a construction screw. The material for the manufacture of such products is usually elastic nylon, which significantly reduces the cost of the product.

As for the size range of such products, here we have a certain standard, namely the length and diameter. The main dimensions are: 6 × 60, 8 × 80, 10 × 90, and 14 × 90 millimeters, the first number is, respectively, the diameter and the second is the length of the mount. As you can see, the length of the attachment does not exceed the existing width of the brick, which is 120 millimeters by standards. This size is quite enough for the fastener to hold the structure installed on it with high quality.

Advice! The manufacturer recommends using wood screws or universal screws for installation, which ensure maximum fastening quality.