Properties

All the positive qualities of an anaerobic sealant are achieved through a chemical reaction between the substances that make up it. It consists of oligomers or polymers from the acrylic group (giving the required consistency and viscosity) + initiation substance (providing accelerated polymerization).

Getting on a metal surface, the mixture fills even the smallest and most insignificant cracks, and after that, quickly solidifying, forms a kind of rubber layer. Under this layer, the polymerization process takes place with the help of radicals. The sealant hardens gradually, starting from the moment oxygen ceases to flow to the seam. One of the main advantages of such a sealant is its high vibration resistance, which prevents the thread from loosening its fixation.

Using many years of experience in the construction industry, manufacturers have managed to create a material that has a number of undeniable advantages:

- reliable fixation of plumbing pipes;

- high strength and wear resistance;

- resistance to vibration vibrations, which are often the underlying reason for the destruction of communications;

- safe in contact with drinking water;

- after the glue hardens, it is no longer possible to dissolve it in water;

- connection of materials of different structure;

- ease of use - even a person without any experience can handle the application;

- resistance to high atmospheric pressure - no more than 50 atmospheres;

- immunity to aggressive substances, solvents, paints and oils;

- protects metal from corrosive changes;

- long service life, which even in the worst conditions lasts up to 4 years;

- high temperature compound that does not degrade even at temperatures of + 300 ° C.

However, not everything is perfect here either. Having a wide range of advantages, the sealant still has some disadvantages:

- The communications fixed by this composition are very difficult to disconnect or dismantle. Sometimes, to remove the sealant, it must be heated with direct fire. In contrast, an ordinary fum-tape or tow will be cleaned much easier.

- High cost price. Quite often, consumers refuse to buy an anaerobic sealant due to its high price. But if we take into account the sufficient economy of consumption of the composition, then the money spent will be justified

- The sealant from different manufacturers will not be identical, their composition will differ in the volume of the active component.

You need to work with the sealant strictly following the instructions. Do not handle wet joints, as the desired effect cannot be achieved.

Therefore, it is important to completely dry the work surface and remove all moisture. There is also a limited diameter of the processed communications - pipes should be no more than 10 cm in diameter, wider parts are more difficult to process and dry longer

Advantages and disadvantages

The application of anaerobic sealants has many benefits. The main advantages of using them:

- anti-corrosive action, the ability to work on metal;

- no need for additional tools;

- elasticity of the seam, which prevents cracking;

- safety for humans, the environment;

- ease of use, no need for skills;

- high-quality fixation and sealing of elements;

- wide scope of use;

- mechanical resistance;

- comfortable consistency, ensuring optimal penetration and distribution of the composition;

- economical consumption, the ability to transfer the crawled out tool to another connection;

- large assortment and affordable price.

Varieties of anaerobic sealants

All existing anaerobic products can be divided into two broad categories: one- and two-component formulations. The former are intended for sealing joints in a domestic environment, the latter are suitable for industrial use and have improved technical properties. Also, all sealants, depending on the type of their composition and strength indicators, can be designed for a specific narrow or wide scope of application.

Depending on the type, the products are divided into:

- Low Strength Substances - Used to seal threads subject to standard or high stress.

- Medium strength polymers are suitable for the provision of services, reinforcement of joints, and can be used for further dismantling of joints.

- High strength gels require one solid connection, without further dismantling of the structure.

According to the degree of strength, anaerobic compounds are divided into three groups:

- Standard ones are used for those materials that are always in vibration-free conditions and do not need periodic dismantling and disassembly of structures. This type of sealant is easier to remove without the use of special tools. Value 4-9 Nm.

- Medium sealants are used in structures that are exposed to atmospheric pressure and are also exposed to vibration. To remove the substance from the threads, it is necessary to use special tools or apply heat. Its value is 15-22 Nm.

- Raised ones are used for those threaded connections that no one will dismantle for several years. It has the highest degree of strength among other anaerobic sealants, therefore it is able to withstand even the strongest vibrations and atmospheric pressure. To separate the joints, a force of 55-60 Nm is required.

Anaerobic sealants can also be found in any suitable color. The anaerobic composition can be yellow, orange, red, green, blue, or white.

Depending on the scope of application, sealants are divided into the following groups:

- Those that are used in the systems of laying communications, heating systems, pipelines. They are combined according to their ability to perfectly withstand the effects of high temperatures of air and water, for them the limit value is + 120 ° C.

- Anaerobic compounds, which are completely insensitive to aggressive environmental influences and chemicals, are not afraid of the temperature range from -60 to + 150 ° C.

- Adhesives with instantly fast curing times, have high adhesion properties to any type of surface.

Adhesive sealants are appreciated by all craftsmen and professionals for their excellent consistency and fluidity. But depending on this, they can also be divided into different categories, including:

Tips & Tricks

If it becomes necessary to separate the fixed parts, the sealant can be removed immediately after work or some time after hardening. For dismantling, you will need an adjustable wrench and a hair dryer if the composition is strong.

Removal instructions:

- we turn on the construction hair dryer and direct a hot stream of air to the seam;

- wait until the mass begins to crumble and then remove it with an ordinary rag;

- with an adjustable wrench and disassemble the connection.

There is no need to completely clean off the residue, a new layer can be applied directly over the old one.

When choosing a sealant, consider the following:

- operating conditions of the connection;

- any thread features;

- at what temperature the gel will be used;

- what are the requirements for the strength of the future connection;

- how often it will be necessary to disassemble the connections;

- what material the thread is made of.

For the pros and cons of anaerobic sealant, see the following video.

Scope of application

Oxygen-free sealant adhesives are widely used in various fields:

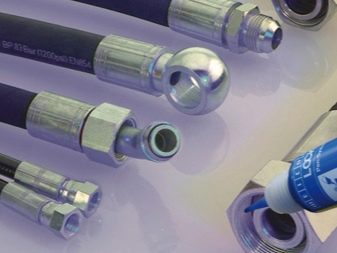

- For locking and sealing threads, replacing various mechanical devices. At the moment, the composition is the simplest and most reliable way to strengthen threaded connections against the effects of shock, shock and vibration. Due to its semi-liquid consistency, it completely fills the entire space and is able to evenly distribute the load along the turns, preventing the leakage of gaseous substances or any liquid.

- For blocking and securing sliding joints. This includes all metal connections such as bushings and bearings. Oxygen-free gels allow parts to be seated with a gap, without heavy deforming stress, while maintaining ultimate shear strength.

- Reinforcement of various pipe connections: flanged and threaded. Unlike mechanical devices, which over time are destroyed by vibration and stress, decompose in an aggressive environment and pollute the surrounding space, the sealant is able to remain in its original state for a long time and firmly fix the pipe elements.

- Impregnation of porous material, welded seams and pressed products. The gel perfectly removes small pores, cracks and other defects in the field of welding, casting and pressing.

Main characteristics and scope

Anaerobic sealants differ from analogues in a number of properties and application features. They are great for metals, as they are acid-free and non-corrosive. The compounds show the highest adhesion quality for the following metals:

- of stainless steel;

- carbon steel;

- cast iron;

- brass;

- bronze.

The adhesion of clamps to chrome and chrome-plated surfaces, aluminum, alloy steel, galvanized bases, plastic is somewhat worse, and yet these materials are also suitable for work. Other features of anaerobic sealants:

- excellent tolerance to liquids and gases under pressure up to 100 bar;

- no damage caused by vibration, lubricants, fuels, weak acids, alkalis, solvents;

- the ability to operate at temperatures of -90 ... + 300 degrees, maximum efficiency when working in the range of + 18 ... + 30 degrees;

- curing time - 5-60 minutes (depending on the specific brand).

Anaerobic sealants are applied only after careful preliminary preparation, otherwise the quality of the joint will decrease. If the work is done correctly, the finished joint receives a strength comparable to the characteristics of the welded seam. Immediately after application, do not allow the sealant to come into contact with alkaline agents or acids.

These properties allow the use of anaerobic compounds in a variety of areas and industries. They provide the impermeability of injection units, welds in metallurgy and mechanical engineering, military and aerospace industries, and are widely used for the repair of water supply, sewerage, heating, and gas supply systems.

Anaerobic clamps help to secure various threaded joints, flanged joints, tubular elements. They can replace simple gel or rubber gaskets, which is very important in auto repair.

Application

Typically, the glue is sold in flat-necked tubes. This allows even small threaded connections to extract the correct amount of sealant. With the same neck, if necessary, it is distributed over the surface. Some manufacturers attach a small brush to the tube, which further simplifies the process of using the composition.

The procedure for using the gel looks like this:

- shake the package before use;

- open the tube and apply glue at the joints;

- fix the parts and hold them in this position for 20-30 seconds;

- remove any excess sealant that has come out by wiping the surface with a clean cloth.

To obtain a better fastening, work should be carried out on a dry and degreased surface. For these purposes, a solvent can be used, which should be allowed to dry completely.

The curing time of the sealant is usually 15 minutes. For formulations from different manufacturers, the polymerization time can vary (from 5 minutes to an hour, depending on the brand and purpose of the gel). The optimum temperature for work is + 15 ... + 25 ° С.

The sealant demonstrates its maximum properties on pipe joints with a diameter of no more than 8 cm. Better adhesion is demonstrated when applied to rough rather than smooth and polished surfaces. It is possible to apply over contaminated surfaces, but if possible it is still better to clean and degrease them.

If it becomes necessary to separate the parts glued with sealant, special keys and a construction hairdryer should be prepared. The latter should be turned on and the sealant layer should be warmed up. After that, it will begin to crumble. When the threaded connection is freed from the bulk of the glue, the parts are disconnected using a plumbing wrench. If further use of the parts is expected and their fixation with an anaerobic sealant, the old layer of the composition can not be completely removed, but a new one can be applied on top of it.

You can learn how to use anaerobic sealants in the video below.

Manufacturers

There are a huge number of brands that produce anaerobic sealants in modern markets. It is necessary to choose among them worthy of attention, based on the following criteria:

- The sealant must be suitable for the material to be worked on.

- You need to choose an anaerobic composition based on the features of the thread.

- Meet the temperature conditions in which the substance will be used.

- Meet the requirements for the bond strength of the elements.

There are brands that have managed to win the trust of buyers, thanks to the high quality of their compositions. Current list of manufacturers:

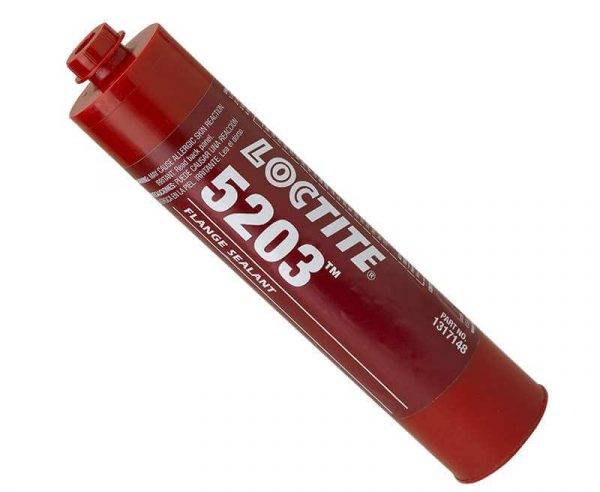

- Loctite - the manufacturer's assortment includes anaerobic sealants of various consistencies, as well as liquid gels, sealing threads and other substances for different types of work. Loctite anaerobic sealant is distinguished by its durability. The price of Loktayt substance with a fast setting speed is 1700 rubles on average. The same view from the line with reduced viscosity will cost 100 rubles. more expensive for a package of 50 g.

2. "Anaterm" is a domestic manufacturer that asks for a very affordable price for the excellent quality of its products. The manufacturer's assortment includes various sealants with special compositions that are used for assembling parts, hardening joints, eliminating small irregularities and cracks. There are types of material for steam lines, as well as those used in the repair of mechanisms and assemblies. A tube of 200 g will cost an average of 2500 rubles.

3. "Santekhmaster" is a brand of anaerobic sealants also from a domestic manufacturer, which is used to ensure flange connections, thread hardening, adhesion of parts. Plumbing glue is devoid of a specific and sharp aroma, it is easy and convenient to apply, and it is not afraid of temperature extremes, high pressure, harmful chemicals. Santekhmaster anaerobic sealant can be used even under extreme conditions. But there is also a minus of such an anaerobic composition - you need to apply it with your hands, which is not always convenient. The master needs to ensure that the substance does not remain on the skin. Available in small 15 ml tubes, the manufacturer claims this should be enough to handle 30 0.5-inch fittings. The price of a tube is within 150 rubles.

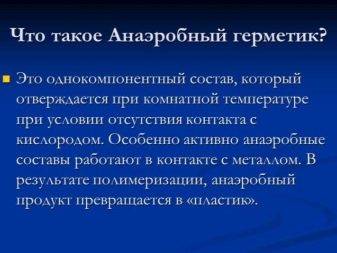

What it is?

Anaerobic sealant is a polymer gel used to seal the thread and also provide corrosion protection. It provides absolute sealing of threaded connections, therefore it is used primarily in the military and aerospace sectors. If we talk about domestic use, then this is plumbing work - water, gas and heat supply networks.

The polymer has a liquid consistency, thanks to which it manages to fill all the recesses and spaces of the working base. In conditions of contact with metal surfaces in the absence of air, the gel solidifies, providing a reliable seal. Anaerobic glue is a type of sealant, the main difference of which is the provision of super-strong fixation.

In contact with air, the polymer does not freeze, so excess composition can be easily removed from the surface of parts. From the inside of the pipeline, they will simply be washed off with water. And inside the parts, in the place of the thread, the gel polymerizes, reliably seizing the elements and ensuring their tightness.

The principle of operation is based on a polymerization reaction and can only take place in an anaerobic (airless) space. This process involves several stages. First of all, free radicals are formed between the parts to be bonded. Further, the ions of the metal surfaces start the polymerization process, as a result of which the sealant begins to solidify.

Rating of the best anaerobic sealants

Some formulations in hardware stores can be bought without fear - their quality remains at a very high level.

Permabond

This is a line of medium and high strength products that can easily tolerate even very strong vibrations and shifts. Such compositions can be used in the repair of transmissions, pumps, cylindrical blocks, they easily replace various gaskets on industrial equipment.

Loctite

The range of the manufacturer includes several anaerobic sealants in the form of pastes and gels. There are also special tools that are created for gas pipes, which are characterized by increased wear resistance and durability.

LOXEAL

Professional products of this brand are designed for sealing threaded pipe joints, for securing bearings, strengthening flanges, replacing gaskets. Sealants are characterized by work in a wide temperature range, resistance to aggressive substances and vibration.

"Santekhmaster"

The product of the Russian manufacturer is practically odorless, is not afraid of temperature changes, pressure surges, and is resistant even to the action of antifreeze, gasoline, and other chemicals. It can be used in harsh and extreme conditions for sealing threads and flanged joints, as well as for anti-corrosion purposes.

Siseal

It is a medium strength sealing gel that is well suited for water supply and sewage systems. It is undesirable to use it where there is a risk of increased oxidation of materials. Available in white.

"Catch No. 3"

A sealant under this name was created specifically for domestic use: working with pipes, heating systems, gas supply. The product protects metal from rusting and is suitable for repairing cracks of any size.

"Anaterm"

Brand sealants are of high quality and low price. They can glue parts, strengthen joints and threads, eliminate pores, cracks, and various defects. The line includes clamps for repairing steam lines and automotive mechanisms.

How to use anaerobic adhesive sealant - instructions for use

The adhesives are sold in flat-necked packages. Additionally, a brush may be included. The glue is squeezed out of the tube and distributed over the surface with it without the use of additional tools.

The procedure for using the tool:

- shake the package

- open the package and apply a dense layer of glue to the thread,

- connect parts,

- remove any excess glue with a cloth or transfer to another area with a brush.

To obtain a quality result, it is important to apply an anaerobic thread sealant to the entire surface, both inside and outside, and also to ensure that the sealant is distributed over the entire area of the joint.

How to dry anaerobic adhesive fixative

To dry the product, a temperature of about + 15C is required. Under these conditions, the glue will dry in about 15 minutes.

Operating procedure:

- shake the package to mix the contents,

- open the tube and apply the product with the neck (the dense consistency of the glue will not let it spread, the product does not drip by),

- leave to dry for 15-20 minutes (it is not necessary to use a tightening wrench, the glue polymerizes even when wrapped in just a few turns),

- check the connection under a pressure of 10 atmospheres.

If no leaks are found, a second check can be carried out within a day under a working pressure of up to 40 atmospheres. If the room temperature is below + 15C, heating of the joint will be required to speed up the drying process of the glue.

The total curing time depends on the diameter of the joint, as well as the characteristics of the material and the ambient temperature.

In addition, nothing is required to add to the sealant, since anaerobic adhesives are already completely ready for use. The only recommendation is to pre-clean the surface, degrease it, and then apply glue.

How to remove thread sealant

If it becomes necessary to disassemble the glued joints, this can be done both immediately after the connection and after it has hardened. This will require a key and a hair dryer (if the gel is very durable).

The procedure for removing the glue:

- turn on the construction hairdryer and direct it to the connection,

- wait until the glue begins to crumble, remove it with a regular cloth,

- use the key to disassemble the connection.

It is not necessary to completely remove the remnants of the old adhesive-sealant, a new layer of the product can be applied directly on top of it.

Rating review of anaerobic sealants

Many companies are involved in the production of anaerobic sealants

When choosing an adhesive, it is important to rely on the operating conditions of the future connection, as well as on the following factors:

- thread feature,

- temperature conditions in which the sealant will be used,

- requirements for the level of bond strength,

- the need to disassemble joints,

- materials from which the thread is made.

Consider the popular options for anaerobic sealants on the Russian market

VIDEO ON TOPIC

1. Loctite anaerobic sealant is available in different model options - in the form of sealing threads, liquid formulations that prevent liquid and gas leaks. The use of adhesives of this brand can significantly increase the strength of pipelines.

2. Anaterm sealants have similar properties. They are used for fixing threads during assembly, eliminating small cracks and pores, fixing welds, porous casting, instant and durable gluing of parts, repairing steam lines, restoring and repairing mechanisms and assemblies. Prices for Anaterm products start at 2,400 rubles per 200 g package.

3. Anaerobic sealant Santekhmaster is another popular domestic product. It is produced by the Region Spetstechno company. It is an innovative adhesive for sealing flanged and threaded metal connections. The adhesives are resistant to gasoline, alcohol, antifreeze, and retain their properties under extreme conditions, at high temperatures and pressures.

Prevents corrosion. The composition is non-toxic, does not have an unpleasant odor, can be applied by hand, but prolonged contact with the skin is still not recommended. Economical consumption of funds makes it profitable for purchase and use. So, a 15 gram package should be enough to process 30 ½ ”fittings. The cost of a 15 gram tube starts at 145 rubles.

Pros and cons of anaerobic glue

Among the benefits of anaerobic glue are the following:

- preservation of properties in a wide temperature range,

- resistance to mechanical damage,

- large viscosity range,

- vibration resistance,

- economical consumption,

- high tightness after use,

- ease of use,

- affordable price.

What are the pros and cons of anaerobic adhesives

It is important to note that the liquid consistency of the glue allows it to penetrate into the narrowest places. The tool grasps any metal surfaces, and also allows you to easily fix parts without the use of special keys

The absence of special requirements for the use of sealant makes it available to any craftsman without skills and experience.

Anaerobic sealants have become a worthy alternative to obsolete seals, gaskets, press fit. Of the shortcomings of anaerobic adhesives, it is worth highlighting a very strong fixation of parts. To separate them, you will need strong heat and additional tools.

VIDEO INSTRUCTION

TU 2257-274-00208947-96 (amendment No. 1-6)

| product details | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Application: For fixing, locking, sealing and sealing threaded and smooth joints in industry and everyday life when assembling vehicle units operating in various environments, when installing hot and cold drinking water supply systems in connecting elements (couplings, flanges, etc.) ... Anaerobic adhesive-sealant of high strength ANATERM-111 cures in narrow gaps of metal products when contact with air oxygen is broken. Special properties

Temperature range

Terms of use

Certification Material development and production are certified in accordance with GOST R ISO 9001-2008 (ISO 9001: 2008). Certificate No. ROSS RU.IF05.K00093. Liquid material properties

Polymerization time

Properties of the cured material

Chemical resistance of the cured material

Safety requirements

Transport and storage

Shelf life and conditions

Recommendations for use and storage The working surfaces of the parts must be cleaned and degreased with gasoline, toluene or acetone, nitrite-free substances. The adhesive sealant is a finished product and is applied to the bolt thread in the amount required to fill the thread profile. You can use a bottle dropper, a brush, special dispensers. It is allowed to pour the sealant from the manufacturer's packaging into a clean working plastic container. As the glue-sealant is consumed, it is supplemented with the next portion. Reverse draining of the product from the working container into the manufacturer's packaging is prohibited. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Other retainers for cylindrical connections: |

|

Anaerobic sealants Anaterm and Unigermixers of cylindrical jointsAnaerobic high strength adhesive sealant ANATERM-111

The use of anaerobic compounds

Typically, sealants are sold in small tubes with a thin neck, through which it is convenient to squeeze them out even into hard-to-reach places. Also on sale there are products in bottles equipped with a brush, which also makes the work simple and quick.

Application technology

Before using the anaerobic fixative, all surfaces are cleaned of dirt, dust, and degreased. They must be dried without fail, since this type of product does not hold well on wet surfaces. A solvent (acetone, white spirit or any other) is excellent for processing materials.

The sealant should be applied to the joint on both sides - inside and outside - or on two parts. This will allow the composition to be distributed in an even layer and eliminate the appearance of unlubricated areas. The procedure will be as follows:

- Shake the package, then open it.

- Apply a thin layer of sealant.

- Fix the parts, hold for 30 seconds.

- Remove the crawled composition with a soft cloth.

- Leave the products until the sealant hardens completely (the time is always indicated on the package). You can use the details after a day.