Rating of alkyd paints 2019

Enamels from leading manufacturers have been tested and have earned high marks from professional experts as well as ordinary consumers. On their basis, for 2018, a rating of alkyd paints was compiled, which are recommended for the use and treatment of various types of surfaces.

| Category | Name | Price | Specifications |

|---|---|---|---|

| The best alkyd paint for wood |

TEX enamel for wood and metal PROFI, 2.7 l |

RUB 949 | Durability of the coating, odorless. Low price. |

| Tikkurila Miranol, 2.7 L | 2200 RUB | The jelly-like consistency provides a low consumption of enamel, ease of application and no smudges. Virtually no, no. | |

| Dulux Domus, 2.5 l | RUB 1800 | Semi-gloss oil-alkyd paint for wooden facades. Covering in the form of a dense elastic film that cannot be damaged. | |

| Best outdoor alkyd paint | Tikkurila Unica Ulkokalustemaali, 2.7 L | RUB 2500 | Semi-gloss paint. Designed for painting wooden and metal surfaces inside and outside the premises. |

| Capadur UniversalLasur, 2.5 L | 2690 RUB | The composition contains antifungal components. The wooden covering reliably protects against mold. Without smell. | |

| Alpa Element LA-007, 1.8 L | 490 rbl. | A universal paint for the protection of any elements exposed to temperature and humidity changes. Strong, good covering ability. | |

| The best alkyd paint for interior use (odorless) | Kraffa Classic Enamel PF-115, 2.7 l | RUB 639 | Used for indoor and outdoor use. High percentage of resistance to weathering. Consumption: 0.15 kg per 1 sq. m. |

| PF 115 Triol, 2.2 L | RUB 2500 | After three layers of application, the coating is bright, high-quality, with a glossy sheen. Complete drying in 10 hours. | |

| Tikkurila Empire, 2.7 L | RUB 1,500 | When applied, the structure is dense and does not flow. Ideal for painting radiators and garden furniture. Without smell. | |

| The best alkyd paint for metal | Dulux Master, 2.5 L | 1800 RUB | The protective coating is resistant to moisture and dust. Possesses high adhesion to metal, withstands prolonged temperature exposure. Suitable for processing radiators and metal structures outdoors. |

| Heat-resistant enamel Certa, 0.8 kg | RUB 400 | The most resistant to high temperatures in the range. Withstands up to + 900 ° С. It can be applied even inside the hearth of a stove or fireplace. | |

| Alpina Heizkorper, 2.5 L | 2460 RUB | Enamel for heating radiators. Can be used for intermediate and glossy topcoats. Scope of application - radiators, hot water pipes, fireplaces. | |

| The best alkyd paint for auto | Colomix, 1 l | from 800 rubles | After processing, the surface acquires a mirror-like luster, good mechanical properties, color and gloss stability. It contains corrosion inhibitors and lightfast pigments. |

| Mobihel, 1 l | 1020 RUB | Car base paint, ready to paint, metallic effect, mother-of-pearl. | |

| Vika-60, 0.8 kg | from 570 rub. | Natural drying synthetic enamel. It is applied on anticorrosive primer in 1-2 layers with an intermediate exposure of 15 minutes. | |

| The best alkyd floor paint | Varnish PF-266, 2.2 kg | RUB 460 | Reliable floor finish that protects wood from fungal infections and mold. The service life is 5 years. |

| Enamel PF-266 Prestige, 2.8 kg | RUB 380 | Forms a durable and durable coating. Can be washed, brushed, detergent and abrasive. | |

| Betolux Aqua Tikkurila, 0.9 L | RUB 960 | Designed as protection and decoration for wooden, concrete floors and stairs. The coating is resistant to fading, abrasion and chemicals. High drying speed. |

Specifications

Almost every type of varnish goes through testing before it hits the counter. Each sample is kept under normal conditions for two weeks prior to testing. Testing consists in examining external characteristics using special devices.

The device defines the following technical characteristics:

- the thickness of the varnish when applying two layers;

- the period during which the varnish completely hardens;

- resistance to mechanical stress;

- resistance to moisture;

- consequences from contact with detergents;

- term of use.

Only those mixtures that meet the stated requirements are allowed for sale.

Customers receive a reliable and high-quality product that, after use, will significantly transform the surface to be treated. To carry out internal work, you should rely on your personal requirements, which are necessary for the implementation of a specific goal.

Typically, alkyd varnishes are used on wood surfaces.

Alkyd urethane varnish can be divided into two main categories:

- yacht;

- parquet;

Yacht material is used for painting ships. According to statistics, this product is considered the most popular. Buyers are attracted by the low cost of the product along with its increased resistance to wear and tear.

Parquet varnish is used for working with wooden floors. Both varnishes are suitable for all other wood surfaces. Yachting is often purchased to work with gazebos, verandas and other forms of architectural character.

Parquet lacquer is relevant for measures for interior treatment of premises. Besides floors, it does a good job with furniture, frames, railings and doors.

Alkyd varnishes for parquet are divided into several types.

- Water based solutions. This product is popular because it is odorless. The advantages include such properties as environmental safety and resistance to high temperatures. However, such products are distinguished by their high cost, which is not suitable for every buyer;

- Two-component. Such mixtures create a film on the parquet. They have a low cost and a pungent odor during drying. It is not possible to store the material in open containers for long, so you need to use up the varnish immediately;

- One-component varnishes. They can be stored for a long time in a closed container. Polyurethane mixtures are not afraid of contact with chemicals;

Also, such a varnish can be divided into several subtypes:

- matte;

- semi-matte;

- glossy;

- semi-glossy.

Matt products are optimal for surfaces that get dirty quickly during use, as the matte film is easy to clean.

Gloss reflects light well, therefore it is suitable for use in dark rooms.

PF-231

This varnish is considered a high quality alkyd-based product. It creates a gloss on the surface that is resistant to wear. The solution is transparent, has decorative and moisture resistant qualities. Such material is purchased for working with surfaces made of metal and wood, as well as for processing parquet indoors.

MCh-0163

Such a product belongs to the category of two-component varnishes, the composition of which consists of urea-formaldehyde and alkyd resins, acid hardeners.

If we compare MCH-0163 with the previous version, this type of varnish has improved characteristics:

- high level of water resistance;

- strength;

- resistance to the influence of abrasive substances.

EP-2146

The brand is considered a one-component alkyd-epoxy compound that has improved characteristics. The improved element is epoxy resin. The product is characterized by increased hardness, resistance to abrasives and water.

PF-283

Used for processing wood and metal surfaces. When applied, the solution forms a high-gloss layer that has good decorative qualities.PF-283 is a mixture containing alkyd resins, modified vegetable oils, fatty acids of vegetable oils, tall oils in organic solvents. Also in the composition of the components there is a desiccant. Apply the varnish with a brush or use an aerosol in a can for these purposes.

You can find out more about the varieties of alkyd varnish by watching the following video.

Types and properties

Alkyd enamels are classified by composition. Each type of coating has its own characteristics and specifications. Special-purpose paints are also available for certain types of surfaces. Each type of alkyd enamel has a special marking consisting of numbers and letters. Marking allows you to accurately determine which category a particular composition belongs to. The letters indicate the main component that was used in the manufacture of the material:

- GF - enamels based on glyphtal varnish;

- PF - enamels based on pentaphthalic varnish;

- ML - melamine alkyd compositions;

- MS - alkyd-styrene mixtures.

The first digit after the letter abbreviation plays the role of an identifier of certain properties and the purpose of the composition. It is worth considering the meanings of each digit:

- 1 - this solution can be used for outdoor construction work;

- 2 - such a composition is intended for repair work inside buildings. In this case, the absence of heating in the room is allowed;

- 3 - enamels are used only as temporary protection (preservation) of various surfaces;

- 4 - this category of alkyd paints and varnishes has a high level of resistance to moisture;

- 5 - enamels, which include special components, thanks to which the paint has a special purpose. For example, the mixture can repel rodents or have a luminescent effect;

- 6 - mixtures are highly resistant to various oil products;

- 7 - enamels that have excellent resistance to aggressive chemicals;

- 8 - such solutions are highly resistant to high temperatures;

- 9 - compositions with electrical insulating properties. Such enamels perfectly withstand voltage and current;

- 0 - the mixture is intended for priming various surfaces.

The last two numbers in the marking indicate the location of the enamel in the general catalog. And also alkyd compounds are divided according to the form of release. The enamel can be purchased in liquid form in cans or as a spray in aerosol cans. As an example, it is worth considering the most popular alkyd compounds.

- PF-115. This compound can be freely used indoors and outdoors. The enamel is used for painting structures made of metal and wood, as well as for cement, plaster and concrete substrates. The coating is applied in no more than two layers. The composition dries completely one day after painting.

- PF-133. This modification of alkyd enamel is perfect for applying to metal surfaces. The painting has a long service life, which can be 6 years. At the same time, the technical characteristics and appearance of the coating do not change. Quick-drying enamel PF-133 is applied to the surface in at least two layers. This coating dries for about two hours.

- PF-233. The composition is used for painting metal and wood. The mixture is ideal for painting heating radiators, while PF-233 enamel has excellent covering properties, it can even be applied to a layer of old paint. The paintwork material has good resistance to high temperatures. The drying speed of the coating is slightly slower than that of other alkyd compounds. Complete drying time can be up to 36 hours.

- PF-253. This paint and varnish composition is intended for painting radiators and wooden floors.Before applying the enamel to the floor covering, the wood must be pre-primed. After the composition dries, a smooth and glossy coating is formed on the surface.

- GF-230. This enamel is designed for indoor renovation work. There are some limitations in the use of this composition: the paint is not suitable for the floor, as it is sensitive to high mechanical stress. White spirit or turpentine can be used to dilute the mixture. Until completely dry, the coating has a rather pungent odor.

Views

By composition, polyurethane paintwork materials can be divided into two groups:

- two-component products requiring mixing, since each component is produced in a separate container;

- one-component paints that do not require mixing - they can be used immediately after purchase and surface preparation, since all the main components are already present in the product.

One of the cans of the two-component composition contains the hardener, the second contains the resin. This variety is much stronger and more resistant to external negative factors affecting the surface. The product is captured without the participation of water vapor from the air, which greatly expands the range of use of the product.

Classification of one-component paints by type of base

To classify one-component paints, they can be divided into three categories:

- products based on organic compounds;

- alkyd-urethane agents;

- water-dispersion suspensions.

The composition of polyurethane compositions of the first category, in addition to the main elements, includes xylene or toluene. For dilution of such materials, specialized solvents are produced. The agent reaches the solid state due to the reaction of the components with moisture from the air. Therefore, the time required for complete drying of this type of paint will depend on the level of humidity in the room.

The second type contains an alkyd-urethane varnish. A distinctive feature of this paint is a very short drying time, usually it is one and a half hours. White spirit is additionally purchased as a solvent for alkyd-urethane products.

The latter type has a similar name due to the solvent that is used for these products - during the work, you will need ordinary water. Water-dispersion paints are odorless and harmless to humans; when painting the surface with such a composition, there is no need to use additional protective equipment. They are captured by the moisture in the air.

Powder and epoxy-polyurethane paints

One more type of polyurethane painting products can be distinguished - powder formulations. They are produced in the form of a homogenized mixture, the components of which are: pigments, hardener, polyester resin and filler.

This type belongs to thermosetting dyes. They process a product or base, after which they undergo heat treatment, as a result of which a reaction occurs between the components that are fused with each other. The result of such work is a durable and hard coating. That is why powder formulations are most often used for work in mechanical engineering.

Epoxy-polyurethane paint is highly durable, therefore it is used in industry for processing various kinds of structures that come into contact with an aggressive environment to provide them with a good level of protection.

Classification by application method

Also, polyurethane compounds can be divided into groups according to the method of application to the surface:

- aerosol products;

- paint that needs to be applied with a roller or brush.

The first group of paintwork materials is used for metal products and surfaces.Automotive polyurethane paint in spray cans forms a uniform coating, which is completely free of smudges and streaks.

There are polyurethane two-component compounds for painting plastic Is a water-based base paint used for industrial painting of products.

Tips for choosing a varnish

When choosing a paint and varnish material, it is recommended to adhere to a number of criteria, the fulfillment of which in the future will allow you to get a high-quality coating:

- First of all, you need to understand how intense the mechanical loads on the floors will be. If the impacts are small (up to 2-3 people are constantly in the room), a water-based varnish will be preferable.

- For varnishing the floor in the kitchen or in the corridor, a composition with pigments is best suited. This varnish protects the surface well from dirt and dust. An anhydrous polyurethane mixture is also suitable for the kitchen floor, since it is well absorbed by the coating and does not need special care.

- If you need to varnish the floor in a room where there is a high load on the floor (office, catering, etc.), then mixtures with water-repellent properties will be the best choice.

Yacht varnish

For the processing of wooden yachts, a special (yacht) varnish is used. Also, such a composition can be used in other places, the operation of which takes place in conditions of high humidity. However, it should be noted here that yacht paints and varnishes are not intended for indoor use.

The fact is that manufacturers, striving to achieve the main qualities of yacht varnish - durability and resistance to moisture, use strong toxins for this. We are talking about such toxic components as xylene and toluene. Therefore, in order to avoid poisoning, you should not cover parquet or furniture with such varnish - it is dangerous.

Alkyd compound for metal

Alkyd varnish for metal surfaces is a mixture of alkyds and polymers. The components of the mixture give the metal a beautiful lacquered sheen. You can apply this varnish with a brush, roller or from a spray can.

The advantages of alkyd varnishes for metal include the following characteristics:

- coating strength;

- resistance to aggressive chemical media (alkali, acid, household chemicals, alcohols);

- moisture resistance;

- thermal resistance;

- resistance to wear and other mechanical stress;

- excellent adhesive qualities (the ability to adhere different types of materials);

- the ability to use both indoors and for finishing the outer part of the building.

What it is?

Alkyd varnish is a mixture containing various synthetic alkyd resins with organic solvents. The product has good adhesion and a high level of moisture resistance.

Alkyd varnishes are actively used for working with various types of surfaces.

End parquet. Alkyds do not allow the ends to stick to each other, therefore surface stress is excluded;

Parquet floors with "warm floor" system;

Parquet made from delicate woods that are highly sensitive to the environment.

When this varnish hardens, it forms a transparent and fairly hard layer. Many people say that alkyd agents harden for a long time. However, manufacturers have developed products with special additives, with which they shorten the curing time. This means that the surface can be used after a short period of time.

After polymerization, a glossy or matt film forms on the alkyd varnish, depending on the selected product. The material that you will process with such a mixture will be provided with reliable protection against irritants of any type.It is quite simple to apply the alkyd mixture, since the product has a thick consistency, due to which the product spreads well over the floor and other treated surfaces, creating a dense film layer.

How to dilute?

PF or GF enamels are sold ready for application and with the degree of density that best matches the composition of the material. However, if the formulation is to be diluted, only the smallest amount of diluent must be added, for example:

- If external painting is required, then the finished paint should be diluted by adding a thinner in an amount of not more than 3% of the total enamel volume.

- For interior work, the finished paint should be diluted with the amount of thinner no more than 5% of the total volume.

- If the composition is diluted with a large amount of thinner, then the enamel flows (in particular, from vertical planes), forms drips. In addition, the performance of the paintwork is reduced.

It should be noted that the material composition and percentage of ingredients in painting materials is not accidental and is the result of many years of experience. Therefore, the desire to improve the quality of the painted surface by adding a thinner in an arbitrary amount, often leads to a deterioration in the characteristics of the coating.

Alkyd or acrylic paint. Which paint to choose?

When choosing a paint, the consumer has the question of which paint to choose - alkyd or acrylic. Let's take a closer look at the properties and distinctive features of each of the categories.

Alkyd paints are paintwork materials, which include alkyd varnish and solvent. There are 2 types of paints in this category, the marking of which is easy to distinguish by abbreviation: pentaphthalic (PF) and glyphthalic (GF).

Alkyd paints

Alkyd enamels have found the widest use not only for interior finishing work, but also for external work. The widespread use of paints in this category is obtained due to a number of advantages.

- good performance characteristics: dense film, good covering ability.

- resistance to mechanical stress;

- weather resistance and water resistance of paint

- fairly quick drying of the coating

- low price and large selection of enamels

- a wide range of applications, both for outdoor and indoor work on wood and metal surfaces.

Despite the wide range of possibilities, these paints also have disadvantages:

- pungent, unpleasant and persistent odor. When using these paints, it is always necessary to use a respirator and, if possible, ventilate the room;

- fire hazard;

- instability to ultraviolet radiation;

- not long service life of the coating

The use of alkyd enamels will not cause you much difficulty. Even without instructions, you can do all the work yourself, using a brush, roller. Drying time is fast, but it is necessary to wait a day until the film is completely cured.

The assortment of alkyd paints offers options for a glossy, matte film. For a metal surface, it is most convenient to use a glossy paint, as it is less dirty. Matt paint is better exposed to household chemicals.

Acrylic paints

Acrylic paints are based on polyacrylic polymers, which in turn improve properties such as elasticity, degree of drying, resistance to various environmental factors.

An important advantage of acrylic paints is high adhesion and long service life of the coating. The paint is capable of adhering to foreign surfaces and at the same time retaining its properties for a long time. On plastered surfaces, the service life reaches 20 years.

Acrylic paints are UV resistant.This property of the paint makes it possible to use it for facade work, keeping its appearance for a long time.

Another important advantage of acrylic paints and varnishes is the absence of a pungent and unpleasant odor, they are not toxic and are suitable for interior work. Since there are no solvents in the paint, working with it, you do not need special protection in clothes and a respirator.

Drying time for acrylic paints is an important consideration when choosing a particular type of paint. Depending on the conditions and composition of the paint, it will take you from 30 minutes to a couple of hours to completely dry the film.

The indisputable advantage of acrylic paints and varnishes, in contrast to alkyd ones, is its simple use and the ability to correct defects in paint application at any time. It can be easily removed from the surface, without any marks or stains.

Yacht varnish which company to choose

Today, many manufacturers of paintwork materials have expanded their range of varnishes with increased moisture resistance. And to make it clearer for the buyers what properties the new product possesses, we added a loud inscription “yacht varnish” to the names of the goods.

There is no big deception here - the offered coatings really reliably protect wooden structures from water and sun. So if you do not plan to go out to sea on your summer gazebo, it is quite possible to paint it with just such a varnish. Moreover, its cost will be relatively low.

Good paint and varnish materials with a moisture-protective function are offered by the companies:

1. Poli-R

2. LLC "Taganrog paint and varnish plant" Raduga "

3. Symphony

4. LLC Polisan (TM Maxima)

5. PPPF "Enamel" (TM Rolax)

But if you want the ultimate in water resistance, or if you're really looking for a varnish to protect your boats, you need some real naval brands:

1. Caparol (TM Alpina)

2. Belinka

3. Yaroslavl paints

4. Johnstones

5. Eskaro

Pros and cons of using paintwork in the form of sprays

The benefits of using spray paints include:

- absolute readiness of the paint for application (there is no need for special preparation of the composition, it is enough to shake the can thoroughly to achieve the correct consistency);

- there is no need to purchase additional painting supplies (trays, brushes, solvents);

- high adhesion (the paint adheres well to the surface, without the formation of streaks and smears);

- the possibility of processing small parts (by spraying the composition, the paint penetrates into the smallest patterns, without leaving unpainted areas);

- the ability to create decorative effects (patina, metallic, matte or glossy surface, mother of pearl, crackle, fluorescent coating).

Among the disadvantages of aerosols when processing wood, the following can be distinguished:

- The inability to independently create the desired shade by mixing paints and tinting. Although this disadvantage is compensated for by a wide range of color palettes, including various halftones.

- If the application technique is not followed, streaks or streaks may form. However, improper staining can lead to similar problems with conventional canned colors.

- The need to use stencils to create a clear border of staining. This drawback is also controversial, because when using cans, masking tape is also used to create even processing boundaries.

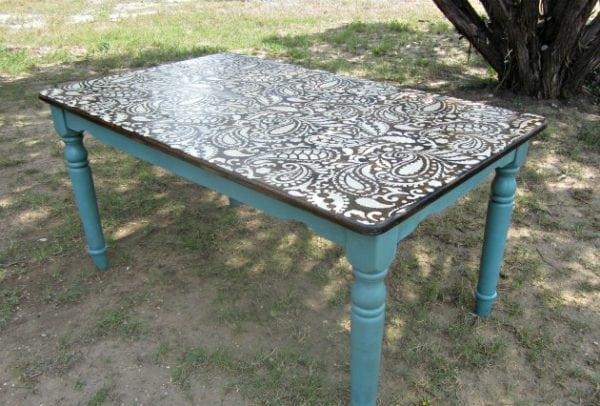

Aerosol paints for wood allow you to process products of any shape. You can use coloring sprays:

- when carrying out repairs for processing large surfaces;

- for the restoration of old products (for example, renewing old wooden furniture or window frames);

- for decoration (for example, apply an image through a stencil or simply treat the surface with a decorative coating).

Aerosols have won recognition and popularity among consumers due to their unique properties and undeniable benefits.

But with all the advantages of using coloring sprays, do not forget about additional precautions when spraying the composition.

Range of application

The scope of this type of enamel is incredibly wide. A versatile alkyd paint that can be used to paint wood, metal or concrete. This is not a complete list of surfaces and materials for which this enamel is suitable, but not all PF paints can boast such a wide range of applications.

There is PF-67 paint, which is intended exclusively for painting ship hulls. This is due to the fact that this paint and varnish material has unique properties of resistance to weathering and temperature extremes. This paint does not lose its original appearance even after several years.

Manufacturers often sell PF-1115 enamel only in two shades: gray and dark gray, but you can also find cherry. It is used, for example, for painting ship decks due to its incredibly high wear resistance and resistance to extreme temperature ranges.

Another type is alkyd-urethane paint, which is often used for floors and has increased strength indicators. It differs from alkyd by accelerated drying within 1.5-2 hours, increased service life - up to 10 years and fairly good anti-corrosion properties.

Automotive industry

For work on painting cars, a special auto enamel has been developed, which has recently become very popular. Due to the fact that a fairly large amount of solvent is added to it, it evenly and smoothly lies on the metal.

This paint has a long drying period, but manufacturers have solved this problem by adding a special accelerator to the composition, which reduces the evaporation time of solvents.

When working on painting a car, you should take into account the recommendation of specialists who advise applying the enamel in three layers. This will allow you to achieve the best quality result.

The advantages of car enamels include:

- High indicators of the quality of the coating;

- Nice shine;

- Long service life.

For household use

A wide range of paints of this type assumes the availability of enamel on the market of finishing materials, which is used specifically for painting batteries and radiators. In this variety, components are included in the composition of the paint, which significantly increase the indicators of its heat resistance.

Varieties and composition

Alkyd paint is suitable for many applications.

It is made on the basis of several main components:

- Alkyd resins. Often, the composition of paints includes varnish, which perfectly binds together all the other components.

- Solvent. Many manufacturers use kerosene (white spirit) as this element. But some also use other solutions related to this chemical group.

- Fillers. The main element here is granite or marble chips. It is crushed to the size of flour, which allows the substance to be evenly distributed in the solution.

Depending on the structure and composition, paints of this type are divided into 2 large groups:

- Oil. The main component of this solution is drying oil. There are several brands of such mixtures, among which MA-021, MA-025 and others can be distinguished. Such solutions are quite rare, as they have a strong odor when dried, and also quickly fade under the influence of the sun. But the cost of oil paints is relatively low, so many still use them.

- Enamel. The main component here is alkyd varnish, which forms a strong film on the surface after hardening. Depending on the main filler, enamels can be divided into glyphthalic and pentaphthalic enamels. The first group of solutions hardens quickly.It is advisable to use glyptal paints only indoors. Pentaphthalic compounds are more versatile and very good at repelling water. There are several varieties of paints here, among which PF-115, PF-133 and others can be distinguished.

An aerosol mixture is a great alternative for this. Spray paint is easy to apply, as it lays down in an even thin layer. However, it should be noted that not all alkyd formulations can be produced as aerosols.

To change the physical properties of paints, many manufacturers add certain substances to the composition.

Depending on this, products can be divided into several more types:

- alkyd-urethane;

- styrene;

- other.

Compatibility of paints

Acrylic paints are not recommended for use on alkyd coatings, as the result of the painting in this case cannot be predicted. After painting, the surface can be of good quality or poor (if swelling occurs). Alkyd paints and enamels applied to acrylic surfaces will flake off in most cases.

If, nevertheless, it is necessary to apply acrylic paintwork on the alkyd coating, the surface must be prepared. First, the product should be thoroughly cleaned with fine-grained sandpaper, and then treated with soil. Preparatory measures will improve adhesion of materials and reduce the likelihood of paint peeling.

It is not recommended to paint relatively fresh alkyd surfaces with acrylics, especially when it comes to metal. In these cases, dark spots are likely to appear on the surface.

There are alkyd-acrylic compounds used for painting vehicles. However, their cost is high, and such paints are not used in the construction industry.

So, according to the combination of qualities, the best choice is acrylic paint. However, if the budget is limited or the durability of the coating is not critical, you can opt for alkyd paint.