Selection recommendations

When choosing a sealant for seams in a wooden house, one must focus on the properties of reliability, flexibility, shrinkage properties, adhesion, etc.

Log sealants

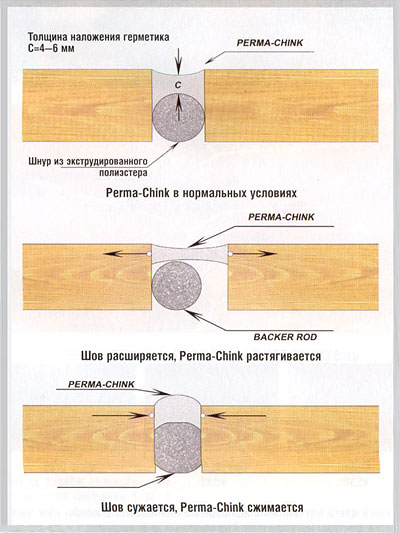

A log house is a material that is subject to deformation over time. Therefore, a sealant for a log house must have properties that are able to take the desired shape. That is, it must be flexible, withstand stretching, compression.

The mass should lay down easily, evenly.

For sealing joints in a wooden house

There is a lot of sealing work inside a wooden house. Taking into account the nuances of the room, a sealing substance is selected.

If the gaps in the floor are closed and in a conspicuous place, then it is better to immediately acquire a lot of the desired shade.

Popular sealants for timber and logs

- Acryl 100 is a premium class log house sealant. Suitable for indoor and outdoor use. The surface can be painted with water-based paint. Working temperature 5-40 degrees. Before the film dries (10 min – 1.5 hours), the treated area must be protected from moisture. Complete drying will occur in 7 days. 15 shades.

- Perma-Chink is a compound for wider joints with increased flexibility. High adhesion to wood, a strong film is formed. Does not lend itself to sunlight, moisture, temperature extremes. 10 shades.

- Eurotex is a one-component, highly flexible wood sealant. It is produced for sealing inter-joint seams. It has high vapor permeability, heat-insulating properties, does not give further crack propagation, does not flow down from vertical planes, etc. No toxic elements are included, therefore it is safe for the body.

- Energy-Seal is a sealant for a wooden house. Closes gaps up to 2.5 cm on natural wood surfaces. Works are carried out inside and outside the house. The product is specially designed for the deformation conditions of wooden houses. The material can stretch and shrink several times without loss of properties, cracking. Maintenance is minimal, it is enough to wipe with soapy water. 12 shades.

- WepostWood is a high quality sealant for seams in a wooden house. At the same time, there is no heat loss and penetration of wind, humidity. One coat is sufficient for durability. It is unacceptable to carry out work during precipitation on the street. 6 shades.

Can you do the sealing yourself?

The creation of warm seams is performed once for many years, therefore it requires special care and strict adherence to technology. Amateurs, beginners and those who ignore important rules often make mistakes that entail a serious decrease in the quality of the finished seam. The most common missteps are:

- incorrect selection of sealant;

- work in damp, cold weather;

- application of seams of low thickness;

- poor foundation preparation;

- making rough, intermittent seams;

- poor-quality smoothing of joints.

If the technology is violated at any stage, the sealing layer may crack, rupture or swell. This will cause depressurization and the ingress of cold air into the wooden house. Also, moisture will penetrate into the cracks, which will provoke rotting of the material and the appearance of mold, mildew.

The conclusion is this: if you fully follow the technology and purchase only high-quality formulations, you can do the work yourself. In the absence of time, skills and desire, it is better to invite professionals to create warm seams.In this case, you will not have to redo the work, which is even more costly and difficult, and the finished seams will serve faithfully for decades.

Types of wood sealants

Wood joint sealants are available in tubes, file bags and buckets. A special gun is used to apply the product. The sealant in buckets can also be applied with a spatula.

The following sealing compounds are distinguished:

- Acrylic.

- Silicone.

- Polyurethane.

- Bituminous.

To decide how to close the seams in a wooden house, let's get to know each of them in more detail.

Acrylic sealant

- Has good adhesion to wood.

- It is a plastic material, forms an elastic film on the surface that is not subject to deformation during the shrinkage process.

- Waterproof, resistant to high and low temperatures.

- The product contains fungicides that prevent the formation of mold and the penetration of insects.

- It is characterized by color fastness, does not fade under the influence of ultraviolet radiation. It can be used to cover seams in direct sunlight.

- The composition is easy to apply, it can be plastered and painted in any color.

Acrylic sealant can be used to seal the internal and external seams of a log house, but there are some limitations in its use:

- when applying the product, dry warm weather should be above +10 degrees Celsius.

- it is unacceptable to seal the outer seams in the rain.

- it is not recommended to use acrylic sealant on joints constantly in contact with water.

Silicone sealant

A silicone-based log sealant is a versatile tool that can be used to seal the joints outside and inside a wooden house. Silicone sealants are considered the most durable of all existing means, they can last up to forty years without losing their properties.

The disadvantage of silicone sealants is the impossibility of staining them, but today compositions of different colors are produced, so it is not difficult to choose a product of the desired shade.

Polyurethane sealant

The material perfectly withstands the deformation processes taking place in the wood during the shrinkage period, while remaining unchanged. However, since polyurethane sealant contains poisonous components, it is recommended to use it only for sealing external log joints.

Bituminous sealant

They are rarely used to seal the seams of log walls. It is impossible to seal the ends with bitumen-based mastic, since the product completely clogs the capillaries of the wood and the logs can crack.

You can also make your own grout by mixing clay, sand and cement together. This composition has good water resistance, but lacks elasticity. If the wood is deformed, the seal may crack.

Advantages of warm seam technology

Any defect in the interpanel seam immediately affects the microclimate of the room, and this applies not only to temperature conditions, but also to the level of humidity. The "warm seam" technology allows you to completely solve the issues of heat and waterproofing, provided that all stages of the process are followed closely. According to the “warm joint” standard, the space between the panels is sealed from the outside of the building. An independent fulfillment of this task is theoretically possible, but it is limited by the multi-storey structure of most panel buildings.

Sealing the seams between the joints of a wooden house is equally important. If you do not perform this task qualitatively, potentially warm, natural walls will bring the owner a lot of trouble: from significant heat leaks to rotting wood here and there. The "warm seam" shows the best performance on log walls with two-sided sealing: both from the inside of the building and from the outside. In some cases, only internal processing is acceptable.With regard to wooden buildings, the technology is much more likely to be self-realized, since special climbing equipment is not required to process a one-two-story house.

"Warm seam" for a panel house

The first and most necessary condition for creating a high-quality "warm seam" is a thorough cleaning of the joint from traces of previous insulation, sealant, paint and other contaminants. In addition to the complete reconstruction of the seam, restoration work is allowed when only some of its sections that have suffered as a result of any mechanical impact are cleaned and processed.

The first layer of "warm seam" is a sealing compound, usually on a polyurethane base. It is filled with a dry, clean seam about half the depth. This layer of sealant acts as the basis for subsequent ones and closes access to the room for external moisture. Its heat-insulating properties are not very high, but the ability to expand allows the composition to penetrate into irregularities and cracks, to fill the volume of any configuration as much as possible.

A filling heat insulator is placed on the sealant, which is a hollow or porous material. It is desirable that it has sufficient elasticity for dense installation and is located slightly deeper than the plane of the facade.

The final layer is sealing the joint with polymer mastic, comparing it with the plane of the facade. The mastic has high elasticity and, when cured, is resistant to both high and low temperatures. Thus, the access of moisture, air and sunlight to the inner, more delicate and unstable layers of the "warm seam" is closed.

All work on cleaning the interpanel space and on filling it is carried out exclusively by hand, therefore the quality of work directly depends on the qualifications of the performer. Treatment with sealants is possible in the temperature range from –15 to +35 ° C, but it is better if the outside temperature is positive.

"Warm seam" for a wooden house

A house made of logs or a bar is folded, like a layer cake, from individual crowns. The space between them - the gaps are sometimes very wide - must be well insulated in order for the house to become truly warm and cozy. Traditional materials, used for many centuries, show high thermal insulation properties, but have low elasticity, as a result of which the seam quickly deforms and requires repair.

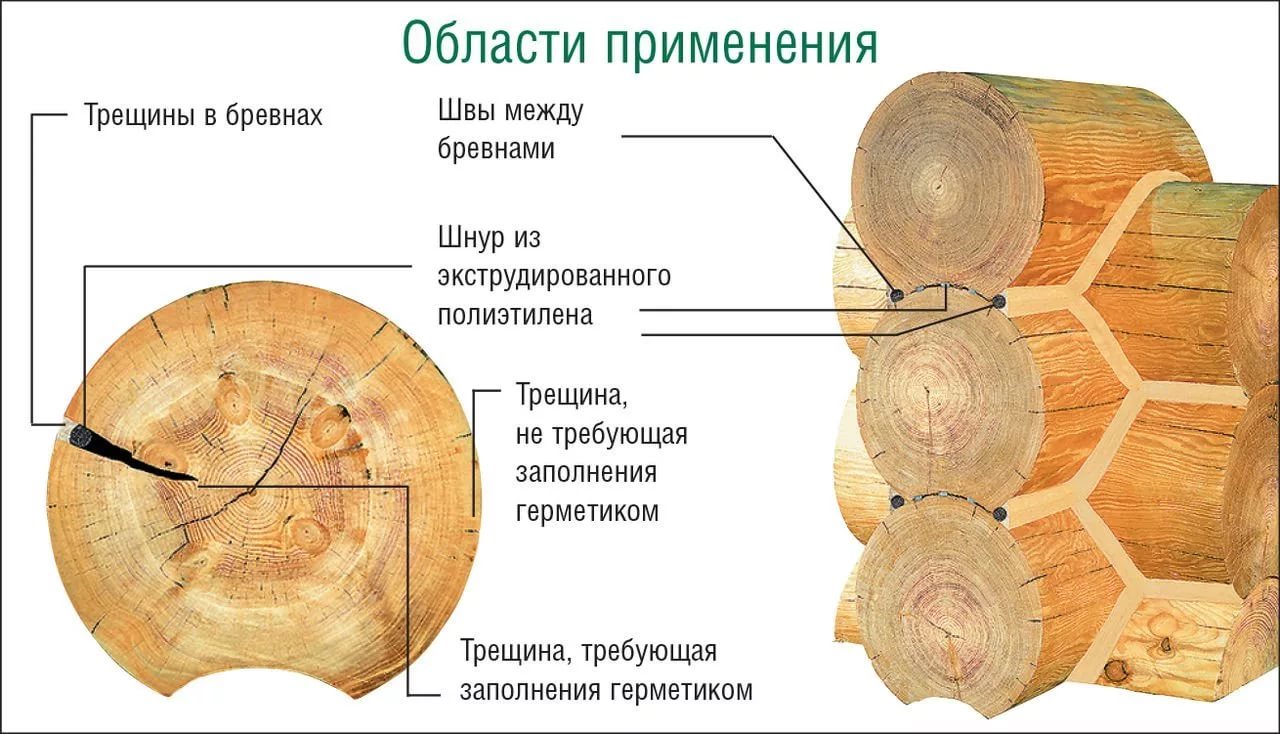

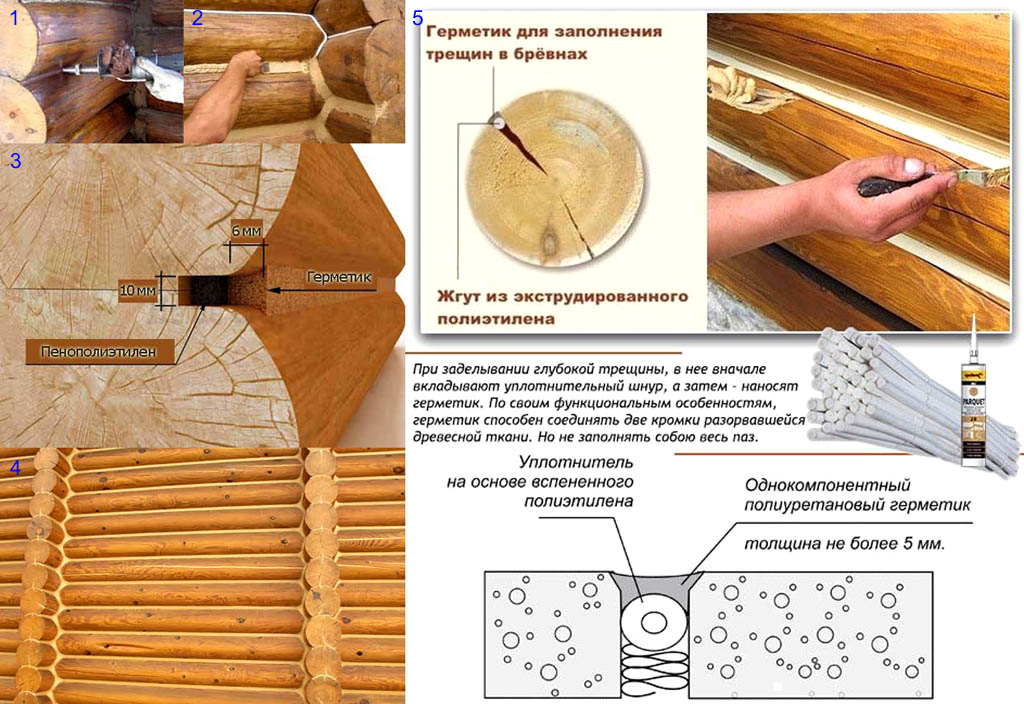

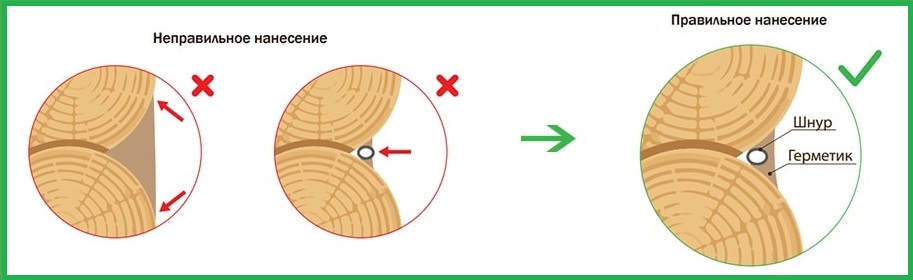

With regard to a wooden house, there are options for sealing technology, depending on the width of the gap or crack. For wide gaps, the technology is in many ways similar to the one described above, when first a heat-insulating material is placed in it - most often it is a cord of one of the suitable diameters on a self-adhesive base. Then the space between the logs is filled with a sealant (usually acrylic) to a certain thickness. The material is pliable until it hardens, so it can be easily smoothed even with wet hands. Fine cracks are immediately filled with sealant without the use of additional materials.

The water base and the use of components that are safe for health allow the use of acrylic sealants not only outside buildings, but also inside them. However, the water base limits the use of the sealant to exclusively positive temperatures of +5 ° C. It should also be noted the variety of possible shades of this material, which determines their high level of aesthetics.

Consumption

To calculate the amount of material necessary, you should determine the scale of work - measure the depth and width of the gap or crack. The flow rate can be calculated by multiplying the width of the work area by its depth. For triangular joints, the flow rate must be divided by two.

In addition, information on the consumption of material per linear meter is always attached in the instructions for the product.

The values obtained can vary based on the density level of a particular composition.Some manufacturers suggest using online calculators to calculate the amount of material.

What is important to know when choosing formulations

Solutions are produced in different containers: these can be plastic buckets, tubes, briquettes or tapes (the total weight of the product depends on the choice of container).

If the seams are very long, it is best to buy a tape sealant.

When buying silicone joint sealants, it is important to consider that they can be of poor quality. The point is not only in manufacturing defects, which are also common, but also in the initial dilution of the material.

Be sure to ask to show the certificate for the product.

The low cost indicates that the solution contains cheap organic compounds (kerosene, oil and other cheap thinners). Manufacturers may not indicate the presence of additives in the characteristics, which means that the marking will indicate "sealant - 100%".

But the more impurities, the lower the quality of the product - poor adhesion to surfaces, insufficient elasticity, and shrinkage over time are noted. Wood house sealant may fade or turn yellow.

Main color: white, mahogany (rich brown), gray, larch and oak.

Verified brands: Moment, Quadro, Econ, Soudal.

Cons of sealants, regardless of the type:

- Most of them repel moisture, which is a plus and at the same time a minus: because of the water-repellent properties, hermetic compounds do not accept coloring pigments (the solution to the problem is a wide range of shades). It is high-quality sealants that do not lend themselves to staining.

- Insufficient adhesion to plastic.

- Sometimes the composition "grasps" poorly, in places it smears.

Warm seam for a wooden house

A warm seam for a wooden house makes it possible to insulate a log house once and forget about the cold for life! The Warm seam technology (insulation of wooden houses with a sealant) is completely harmless, like natural insulation, and without new cracks and protruding rags inherent in them. Sparrows will not take them to their nesting sites under the eaves!

Warm seam for a wooden house, the price of work

|

Types of jobs |

Unit. |

Cost, rub. |

|

Sealing "Warm seam" for rounded logs and timber |

m. | |

|

Sealing "Warm seam" for a log house |

m. |

Warm seam for a wooden house, turnkey price

|

Types of jobs |

Unit. |

Cost, rub. |

|

Sealing "Warm seam" for a house from a bar |

m. | |

|

Sealing "Warm seam" for rounded logs up to Ø220 |

m. |

|

|

Sealing "Warm seam" for rounded logs from Ø220 to Ø280 |

m. |

|

|

Sealing "Warm seam" for rounded logs over Ø280 |

m. |

|

|

Sealing "Warm seam" for a log house |

m. |

|

|

With a volume of up to 500 meters, the delivery of scaffolds is paid separately |

7000 | |

| Sealant consumption calculator, Measurement online |

The prices are indicated for a complex of turnkey services: measurement, Remmers sealant, delivery, installation of scaffolding, work!

Remmers warm seam technology advantages:

Remmers' excellent elasticity and adhesion of the warm joint ensures a stable seal regardless of seasonal fluctuations in the gap between the joints and allows you to speed up the commissioning of a new house without the use of primary caulking.

Sealing a wooden house completely eliminates heat loss through inter-crown gaps and cuttings, which reduces heating costs.

Vapor permeable, moisture resistant, which increases the comfort of living.

Warm seam Remmers is made in Germany and meets the most stringent environmental standards.

Sealing the seams at home has a variety of colors and textures, allowing you to choose the most effective color combination for the crowns and seams ..

| View all works |

Do-it-yourself sealing of log seams using Remmers technology, is it possible?

The effectiveness of Remmers technology is ensured not only by the unique composition of the used sealants, but also by the exact observance of compatibility with other wood processing and surface preparation products. If you have a lot of free time to learn Remmers technology, and you are ready for the same tedious work, success will be assured too.

Sealing the seams of a wooden frame begins with preliminary work.

1. Grinding the log house: removes dirt, old protective layer.

2. A Vilatherm sealing cord is installed in the gaps.

3.Remmers sealant is applied to the top of the laid cord.

4. Level the sealant layer with a spatula and remove excess.

All stages of sealing a wooden house must be done efficiently and professionally, otherwise the house will have to be insulated again and will cost even more.

It is better to entrust this monotonous occupation to our teams, where responsible people were selected who knew how to enjoy such work. In addition, they apply their styling know-how, developed over the years.

Examples of poor quality work and violation of technology Warm seam

|

|

||

| Poor quality materials, improper application of sealant | |||

| Application of paint without primer on bleach against blue stain without subsequent drying of the log | Incorrect storage of wood after the construction of the walls, no subsequent treatment with antiseptic compounds |

| Improper insertion of the Vilatherm sealing cord leads to the buckling of the cord through the sealant |

Views

Sealants for sealing joints in floors, ceilings, walls and for protecting end elements are divided into four types. Each material has its own unique performance characteristics.

Wood joint sealants are sold in tubes, bags and buckets, applied with a special gun or spatula.

To determine which remedy is best for you for sealing seams and joints, consider each of them.

Acrylic

Acrylic based sealants are the most sought after and readily available for home use. They are practical, durable, easy to handle, and provide a high degree of adhesion to surfaces.

For the manufacture of acrylic sealants, harmful components and solvents are not used, so they are safe enough for internal work.

Acrylic wood sealant has many advantages:

- provides good adhesion to a wooden surface;

- promotes the formation of an elastic protective film that is resistant to deformations that are possible during shrinkage at home;

- shows resistance to high moisture and temperature extremes;

- has powerful antiseptic properties;

- provides resistance to fading under the influence of sunlight;

- easy and quick to apply, plaster and paint.

This is an excellent material for sealing seams on the inside and outside of a log house, which is still not without significant drawbacks:

- applied only in warm weather at an air temperature of up to +12 degrees;

- not used for sealing joints in bad weather conditions;

- it is not used to seal the joints between the joints, which are exposed to constant exposure to excess moisture.

3> Polyurethane

Polyurethane based sealants basis are among the most durable, wear-resistant and expensive materials that are used for sealing seams in window and door structures, roofing elements, corner joints in log houses. They are distinguished by high adhesion, resistance to mechanical damage and good elasticity.

Polyurethane wood sealant has the following positive characteristics:

- resistance to increased moisture, chemical components and biological contamination;

- resistance to shrinkage during polymerization, deformation and mechanical damage;

- ease of application to a wooden surface;

- the possibility of grinding and staining.

Among the disadvantages of the material are high cost, limited color palette and susceptibility to UV exposure.

Silicone

Silicone-based wood joint sealant is a versatile product that is designed to seal the internal and external seams of a wooden structure. Such materials are distinguished by wear resistance and durability, the service life of which reaches 35 years.

The distinctive characteristics of silicone wood sealant include:

- good elasticity and adhesion to wood surfaces;

- resistance to ultraviolet radiation and temperature extremes;

- resistance to high moisture and dampness.

The material does not lend itself to staining, which is its main drawback. Colored sealants are already on the market today, so you can easily choose the right shade.

Silicone wood sealants can be used to seal internal wall joints and gaps in the rafter system, handle railings, slopes, door and window structures in a wooden bath or house.

Silicone based sealants are divided into the following categories:

- neutral - the most environmentally friendly materials, but susceptible to weathering;

- acidic - compounds resistant to temperature extremes. They are distinguished by an unpleasant chemical odor and drying time;

- sanitary - antibacterial compounds that prevent the formation of mold and mildew.

Bituminous

Bitumen and rubber based sealants are the most durable and reliable. Such compositions are suitable for inter-seam processing of structural elements in the rafter and drainage system of the house.

The main advantages of bituminous wood sealants include:

- high level of waterproofing;

- resistance to temperature extremes and ultraviolet radiation;

- ease of application to treated surfaces.

Bituminous mastics are not subject to staining, moreover, they are toxic, therefore all work is carried out using personal protective equipment - gloves, a respirator and overalls.

How to seal the seams in the bath correctly and accurately.

So you have come to the conclusion that it is time to build a bathhouse. The bathhouse has been built. But here a natural question is raised, how to cover up the seams in the already built bath, which are very visible. No matter how tightly the timber or frame is laid during the construction of the bath, the seams still remain. But through them just that precious heat will go, without which comfortable conditions for the visitors of your bath are impossible. It follows from this that in the winter period the heat in a log bath can be preserved only if all joints, cracks and seams between the crowns are sealed.

Wood, by itself, due to natural features, can deform, changing its volume and size. And in the bath itself, due to constant temperature changes, this will be especially noticeable, since cracks appear on the logs themselves, and gaps are most likely formed between the blocks. All this will lead to the fact that the bath itself as such becomes very unprotected from natural phenomena. This problem is completely solvable, and modern means for insulation will not require large material costs. But the insulation begins even during the construction of the bath, when the initial sealing and sealing of the joints of the bath is carried out. And from that moment on, a completely natural question arises: "How can you cover the seams in the bath and ensure its thermal insulation?" As thermal insulation, you can use traditional materials that are used when the crowns are laid: tow, moss. And also for sealing external seams in a bath, modern materials are suitable, which provide thermal insulation in wooden buildings.

Modern materials - acrylic sealants for wood.

Modern heat-insulating materials are resilient and elastic, therefore they are widely used. The peculiarity is that it is easy to work with acrylic sealants, they dry quickly and it is possible, if necessary, to apply several layers, which is very convenient and profitable. All modern hermetic materials have high adhesion, which has a positive effect on thermal insulation properties, they are not afraid of changes in air temperature and humid environment. But they have one more of the main properties - vapor permeability, which allows the tree to breathe.Acrylic sealants are used not only to seal the joints of the bathhouse, but also for any splits and cracks that form in the wood over time.

Among modern materials for keeping heat in a bath, special sealing tapes should be noted. They need to be distributed in the space between the timber. They are almost non-caking, which means that you do not need to use other hermetic materials, which creates additional savings. In addition, the sealant changes its shape when the logs begin to deform during the natural shrinkage of the bath.

- They include only natural materials, to which ecologists cannot make any claims.

- Moss and jute keep warm air out of the room and keep cold out.

- They have excellent absorbent qualities, which is very important in constantly damp bath rooms. Therefore, there is no need to worry about the walls starting to rot.

Characteristics and properties of wood sealant

Like most acrylics, VGT sealant is an environmentally friendly product that is safe for humans and pets. It is odorless, non-flammable and poses no fire hazard.

Appearance and composition

VGT sealant has a pasty appearance. It is non-flowing, easy to apply to the surface and easy to level. This is a one-component product, completely ready for use, does not require dilution with any liquids.

Adding water, solvents or other liquids to the sealant can completely spoil the product and become unusable.

The composition of the VGT suture material is environmentally friendly. The sealant is based on an aqueous dispersion of a polymer and other ingredients:

- filler;

- pigment;

- modifying components.

Product consumption

The approximate material consumption for a seam section of 1 cm2 is about 140-150 g per 1 linear meter.For more accurate calculations, how much money will be required per running meter of the seam, you can use the formula Mp = btV (kg / l.m), where :

- b is the joint width (m);

- t is the thickness of the material layer (m);

- V is the specific gravity, which for this sealant is 1500 kg / m3.

Drying time

The final drying time of the applied composition depends on the environmental conditions. Under optimal conditions (temperature about 20 degrees and humidity 60%), it takes about 24 hours for a 2 mm thick layer of sealant to cure completely.

Sealing instructions

High-quality insulation of a wooden house is possible only with strict adherence to the technology, which includes the preparation and the main stage for sealing the cracks.

Materials and tools

For work, you should buy a sealant in a cartridge or another form that works well for the assembly gun. You also need to prepare:

- foamed polyethylene in the form of a cord;

- narrow spatula;

- paint brush;

- water;

- rag;

- masking tape;

- soil for wood;

- spray.

You can also apply sealants manually, but using a gun will make your work faster and more comfortable. In addition, the assembly gun helps to squeeze out the product in a strictly metered, even and beautiful strip, while without it it will be difficult to achieve a similar effect.

Preparation

In older buildings, there is most often a rough caulk. It is better to remove it to reduce the risk of mold and insect nests. After the blockhouse is cleaned of dirt, dust, the old paintwork is removed, and in the presence of oil impregnation, the base is polished.

The wood is treated with degreasing compounds, then primed, allowed to dry well. If you ignore the preparatory measures, the sealant will lie unevenly and its adhesion to the substrate will decrease.

Further, a special polyethylene cord is laid in the seams between the logs.It is designed to fill the gap between the joints, since it is expensive and ineffective to completely seal the entire gap with a sealant. Too large joints are first caulked with tow, jute, then a cord made of expanded polyethylene is attached with metal staples. Both surfaces of the joints are pasted over with masking tape so that the sealant layer is even.

Sealing compound application

The warm seam creation agent is applied with an assembly (glue) gun. It is necessary to act in this way:

- cut the tip of the tube at an angle of 45 degrees;

- insert the tube into the pistol;

- pour the agent not packaged into cartridges into a special gun designed specifically for such sealants;

- press the "trigger", applying the sealant with a flat tape of the required thickness (the layer of the product should capture the logs by 0.5-1 cm on both sides);

- sprinkle the seam with water from a spray bottle, then level it with a spatula and remove the excess;

- moisten a small brush, finish the joint;

- remove stains, drips with a rag, then remove the masking tape without waiting for the sealant to dry.

Typically, for complete polymerization, the sealing compound needs from 2-4 days to 2 weeks, depending on its type, brand, weather conditions. Only after the end of this period can the seam be dyed.

Material consumption

Sealants are produced in tubes of 300 and 600 ml, as well as in plastic buckets of different sizes. Consumption varies greatly depending on the width and depth of the joint. For example, with a standard seam 5 mm deep and 20 mm wide, 200–250 g of the product will be needed per 1 running meter.

Drying time

It is necessary to work with sealants using the "warm seam" technology in dry weather at temperatures within the range of + 5 ... + 35 degrees. The optimum humidity for work is 60%, the temperature is + 20 ... 23 degrees. Under such conditions, the agent cures at a rate of 2 mm / day, and the primary film appears after 30-60 minutes. In wet, rainy weather, sealing a wooden house should not be carried out, as well as during snow. This will adversely affect the quality of the resulting seam.

Corners and cuts

The most difficult job of forming warm seams concerns the joints between wooden walls. To seal corners, overhangs, a polyethylene cord of the required thickness and length is inserted into the cracks, pushed through with a spatula. Usually this process is time consuming, laborious and painstaking. After the sealant is applied, its layer is leveled with a wet spatula.

If the corners were previously treated with oil impregnations or fire retardants, you will have to first grind the wood with a grinder, otherwise the sealing compound will not achieve the desired adhesion.

Storage conditions of the sealant

The product must be stored at temperatures within + 5 ... + 30 degrees without access to the sun, protected from moisture. The sealant can withstand up to 7 cycles of freezing and defrosting (the duration of each is no more than a day, the temperature is not lower than –18 degrees). Before use, the frozen composition is kept at room temperature for at least a day.