Advice

You do not need to have professional skills to apply the composition

It is important to pre-clean and dry the surface of the seam, then fill it with a sealant, squeezing the latter out of the gun or immediately from the tube

Seams that are too deep require more compound, which entails additional costs and increases the curing time of the seam. This can be avoided by first placing an elastic seal in the form of a polyethylene cord on the bottom of the deep gap.

To achieve the optimal positive result will allow following certain recommendations when applying the composition:

- Work can be carried out at a temperature of -40 ... +120 degrees, while the temperature of the working surfaces should be within + 4 ... +32 degrees.

- The sealant is suitable for gaps between 6 mm and 5 cm wide.

- When applying the sealant in conditions of high humidity at the time of solidification of the composition, it is better to cover the working surface of the polyethylene.

- When applying the composition in a humid environment, you can use the room only after the joint has hardened. At the time of solidification, the effect of moisture on the seam is unacceptable - the liquid will simply wash it out.

- For staining the seam, latex compounds should be selected, the staining procedure can be performed 21-30 days after using the sealant. It is recommended to sand the surface beforehand. Only a completely dry seam can be skinned.

- It is better to use the opened packaging completely. It is permissible to store the composition in a closed form if the original packaging is broken for 2-4 days. After this time, the properties of the sealant deteriorate.

- It is not necessary to add solvent or other components to the acrylic sealant, if this is not provided for in the instructions. A two-component composition is kneaded from 2 components, while in most cases it is necessary to mix both compositions completely, without leaving a part for subsequent use. Violation of the proportions in this case entails a deterioration or complete loss of its properties by the sealant.

The shelf life of the composition in sealed original packaging is one year at a storage temperature of 20-22 degrees. Freezing of the product and its subsequent use is inadmissible.

If the product gets on adjacent surfaces, they can be immediately washed off with a damp cloth. If you haven't and the sealant remains, you can use a razor blade or a utility knife.

Place the tip parallel to the sealant mark and carefully cut it off. No need to drive the tip over the surface - scratches will appear

The remains of the composition are washed off with a damp cloth.

In addition, you can dissolve stains with special products for acrylic compounds. Manufacturers advise using a mask and gloves during work. Typically, the solvent is applied to dried spots and left on for 30 minutes. After the specified time, the stain is removed with a damp cloth.

To do this, apply a small amount of solvent to the sample or in an inconspicuous place. If after half an hour no negative impact is found, you can use the composition on the main area.

For information on how to use acrylic sealant, see the next video.

Specifications

Composition

Accent 125 is a non-viscous, thixotropic polyacrylate based paste.

The following ingredients are included in the sealant:

- Water dispersion of acrylic polymer.

- Special auxiliary substances that improve the properties of the material (to accelerate the film formation process, improve adhesion, extend the service life, etc.).

- Coloring pigments to give the sealant a specific shade.

- Filler to create volume.

Drying time

After applying the sealant, a film forms on the surface after an hour. It will take a day for a material with a thickness of 2 mm to harden. Full polymerization occurs within a week. The sealant can be applied at temperatures of - +5 - +35 degrees. Optimal weather conditions: temperature - +23 degrees, humidity - 60%. The sealant begins to perform its main functions already during the solidification period.

It is not recommended to treat the surface under the following conditions:

- temperature is below +5 degrees;

- humidity - above 80%;

- in very hot and dry weather;

- during the rain;

- in direct sunlight.

High humidity and low temperatures can lead to longer drying time and washout of the sealant. Too dry weather promotes accelerated film formation and the appearance of bubbles and blisters on the surface.

Consumption

Sealant consumption depends on a combination of three indicators:

- seam width;

- the thickness of the sealant;

- specific gravity.

So, with a material thickness of 5 mm and joint width 10 mm per 1 r.m. you need 100 g of sealant. The instructions provide a formula for calculating the material, as well as a consumption table for standard seam indicators.

The sealant is sold in 310 and 600 ml cartridges, as well as in 5 and 10 liter buckets. On average, one 5 liter bucket is enough to cover 70 running meters.

Service life and storage

The sealant forms a strong and durable coating that perfectly withstands any whims of the weather. The manufacturer guarantees the service life of the sealant for at least 20 years.

You need to store the product in a tightly closed container at t +4 - + 40 degrees. Expiration date - 2 years from the date of manufacture.

The sealant can be subjected to repeated (up to 7 cycles) defrosting / freezing, provided that the cycle is no more than one day. In this case, the limiting temperature should not be lower than -18 degrees.

A single long (up to 7 days) freezing of the product is also allowed. Defrosting should be carried out in natural conditions without heating at a temperature of + 22 degrees.

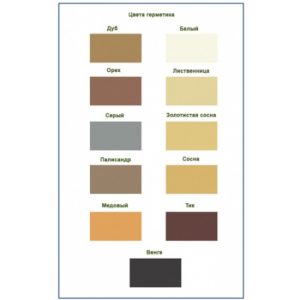

Color palette

The manufacturer offers 13 natural shades, from light larch to dark brown teak and wenge. A wide range of colors allows you to choose a tone for any design and color of the frame. If the buyer does not find anything suitable in the catalog, then you can order a custom tinting.

Color palette Accent 125

Views

Acrylic sealant is divided into 2 large groups - one-component and two-component composition. The first is the ready-to-apply mass. The second one includes 2 components, which must be mixed until a homogeneous consistency before use.

The one-component composition is universal, while it is afraid of exposure to moisture, cracks at low temperatures. It is best used for sealing joints exclusively indoors with normal humidity levels. Such seams are optimal for painting, the coloring composition lays down in an even layer, without changing the shade during the drying process.

To obtain a composition with higher technical properties, it is possible to add other components to it, primarily silicone or latex, as well as hydrophobizing compositions. For example, the presence of latex in the acrylic sealant makes it possible to obtain a frost-resistant product. This makes it suitable for outdoor use.

The siliconized two-component sealant is characterized by increased adhesion. The silicone in the composition allows for bonding surfaces with smooth, sliding surfaces. First of all, it is plastic.

The advantage of acrylic-silicone compounds is also their increased resistance to precipitation and temperature extremes. The presence of silicone increases the elasticity of the sealant by about 20-25%, so it better tolerates low temperatures.In this regard, this composition is also suitable for outdoor use.

The addition of organic extenders allows the addition of organic extenders to prevent excessive viscosity of the composition with silicone, and the introduction of fungicides can increase the resistance of the sealant to aggressive environmental influences. The result is a more durable joint that is not only resistant to weathering, but also chemically inert. In this regard, such a sealant was named "professional".

Other types of two-component sealants with improved technical characteristics are also considered professional. As a rule, they are more difficult to apply, have a higher cost, therefore, their use for domestic purposes is irrational.

They show good adhesion to surfaces made of concrete, brick, plastic, glass, as well as on plastered surfaces, and are suitable for repairing window and door frames. After curing, they can be painted latex or oil paints.

In addition, acrylic sealants are water-resistant and non-water-resistant. The latter are absolutely safe from the point of view of environmental friendliness, but are only suitable for dry rooms. They cannot be used in joints subject to thermal expansion and deformation.

The water-resistant composition has special additives, which is why it cannot be called 100% natural (however, it is suitable for use in residential buildings). Demonstrates high adhesion to most building materials, including textures of different composition, as well as in sedentary structures. It can be used in high humidity conditions, but not in direct contact with liquid.

Usually, antiseptic additives are present in the composition of moisture-resistant acrylic sealants, which prevent the appearance of mold and microorganisms on the surface of the seams.

Another criterion for dividing acrylic sealants into groups is the presence or absence of pigment in them. The standard composition is transparent or white. If a certain pigment is added, then the shade can be any. Such a paint sealant allows you to quickly eliminate small cracks without using other compositions.

Acrylic-rubber sealant is used for filling joints on wooden surfaces, and is also suitable for use in inter-row joints of log houses. It allows you to get a warm and reliable seam, is not afraid of temperature changes in the geometry of the wood. As a rule, such a sealant is laid on top of the mezhventsovy insulation. Its shade is matched to the frame.

When added to the composition of fire retardants and other components, it is possible to obtain a fireproof sealant. As you know, the acrylic one-component composition itself is non-combustible, however, the presence of certain additives in its two-component analogue can change the situation. A feature of a fire-fighting (both one and two-component) composition is its ability to localize the spread of flame.

Differences between sealants Accent 125 and 136

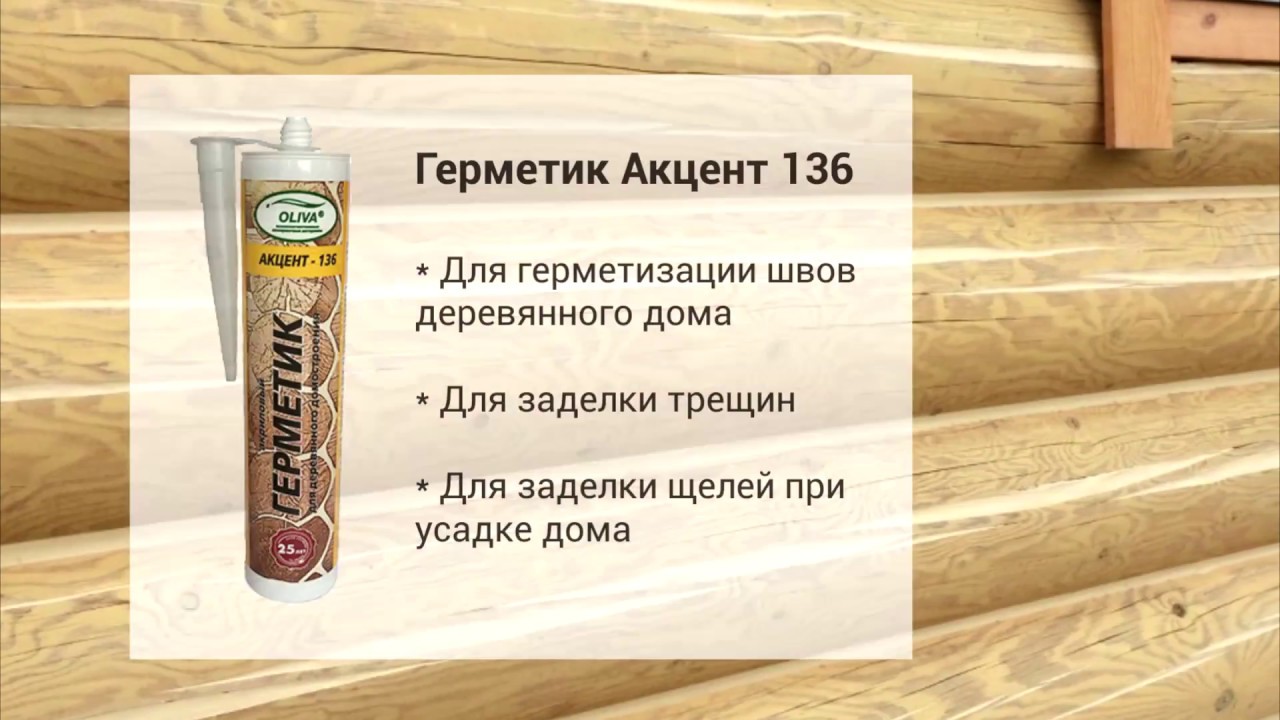

Accent 136

In the manufacturer's catalog, the Accent series is represented by several sealants designed for sealing joints in various building structures. Accent 136 is very often used to seal houses made of timber and logs using the "warm seam" technology. Both sealants are very similar in properties and composition, but there is still a difference.

Differences between sealants are shown in the table:

| Properties | Accent 125 | Accent 136 |

| Elongation at break,% | 500 | 600 |

| Density, kg / l | 1,5 | 1,36 |

| Predicted service life, years | 20 | 25 |

| Deformability,% | 20 | 25 |

As can be seen from the table, in terms of elasticity and durability, Accent 125 is slightly inferior to sealant 136, but its density is slightly higher. In addition, the Accent 125 has a lower flow rate at equal rates. So, with a joint width and a sealant thickness of 5 mm, Accent 125 consumption will be only 37.5 g, while Accent 136 will need 50 g.

And one more significant point: the price of the Accent 136 is 25% higher than the 125.

Consumption

To calculate the exact amount of sealant required for operation, you need to know the dimensions of the joint that must be filled. The seam depth is multiplied by the width of the future strip and the consumption value is obtained. Consumption is taken per meter and is expressed in grams. If the seam is planned to be triangular, then the flow rate can be divided by two. This case is suitable for processing the connection of perpendicular surfaces.

To seal the crack, it is necessary to take a sealant with a margin, since it is almost impossible to find out the exact dimensions of the crack. To process a seam with a length of 10 meters, you need to spend 250 grams of silicone. The sealant is produced in tubes of 300 grams - this amount is enough to process this surface. It is better to purchase a colored sealant of one brand and one batch, since the shade of the product may vary.

The use of a sealant does not require additional devices and special skills. The material does not have a strong odor and does not irritate the skin. Work can be performed without special respiratory protection and skin protection. The composition can be easily washed off with warm water from hands or tools.

When treating surfaces with a sealant, some rules should be followed. Do not change the humidity and temperature in the room until the composition is completely dry. Do not use water in the bathroom or kitchen if the surface of the sealant has not hardened. Otherwise, there is a high risk of erosion of the adhesive.

The hardening process of the sealant is conventionally divided into two stages. First, the surface is covered with a strong film. This stage lasts no more than three hours and allows for adjustments. Then the sealant sets completely, but this stage lasts several days. With the onset of the second stage, the masters do not recommend influencing the layer of material. Interference can affect the structure of the solidified composition and reduce its physical and mechanical properties.

The sealant is applied with a special gun or spatula. Most often, the finished substance is sold in a special dispenser. After opening the package, it is recommended to use the product to the end. The sealant cannot be stored after the first use - it loses its basic properties. For large volumes of work, the masters are advised to purchase a sealant in buckets, since the use of a tube in large areas is problematic.

Before applying the adhesive, the rough surface must be carefully prepared. Dust, dirt and material residues are removed from the seams. The space to which the sealant will be applied must be degreased. If you skip this stage, there is a risk of impairing the properties of acrylic. The required adhesion will only be applied to the previously treated dry surface.

You can reduce material consumption and save money by using a sealing cord. Experts use this method when installing windows, skirting boards, laying large ceramic fragments. The cord can reduce the consumption of adhesive by 70-80 percent, as well as increase the pace of construction work. The cord also acts as an insulator and prevents heat leakage.

Accent 117

Multifunctional acrylic sealant with high adhesion to concrete, aerated concrete, brick, stone, plaster, PVC, wood, metal (including tin and zinc).

It is weather-resistant, UV-resistant, used for outdoor and indoor use.

The material is completely ready for use. After applying the sealant, due to the evaporation of water, an irreversible vulcanization process begins. After curing, an elastic rubber-like material is formed.

Application area: ACCENT 117 is used in the construction and repair of residential, industrial buildings and structures, as well as in individual housing construction and repair.

• Long-term sealing of expansion joints in building structures with a deformability of up to 15%.

• Sealing joints, cracks, openings outside and inside the premises.

• Sealing of air ducts, standing seam roofs, etc.

Due to its high thixotropy, the sealant can be applied to horizontal, vertical, inclined surfaces with positive and negative inclination angles.

White, gray (other colors on request)

air dry

Skin formation time

1 hour (at + 23 0 С and humidity 50%)

Curing time at a layer thickness of 5 mm.

24 hours (at + 23 0 С and humidity 50%)

Shrinkage, no more

Application temperature range

from - 17 0 С to 0 0 С and from +5 0 С to +35 0 С

Operating temperature range

from - 40 0 С to + 80 0 С

Elongation at the moment of rupture, not less

300% (on seam samples) 700% (on shoulder blades)

Conditional strength at the moment of rupture, not less

Predicted service life

at least 10 years

Instructions for use:

Preparation for use.

Sealant ACCENT 117 is completely ready-to-use. At low temperatures, the viscosity of the sealant increases, therefore, before use, we recommend keeping the sealant in a heated room for at least a day.

Dilution of the sealant with water is NOT RECOMMENDED - this can lead to a change in the properties of the sealant (reduced adhesion, loss to thixotropy, etc.), cracking is possible!

The surfaces to which the sealant is applied must be cleaned of dirt, dust, grease, loose particles of cement mortar residues, residues of previously used sealing materials, etc. When working in winter, clean the surface from ice and frost. It is possible to apply the sealant to both dry and damp surfaces. The presence of drip moisture is unacceptable.

DO NOT apply sealant during rain and snow!

To maintain the design thickness of the sealant layer, it is recommended to use anti-adhesive harnesses foamed polyethylene Vilatherm.

In hot weather with low air humidity, surfaces can strongly absorb moisture, and the sealant dries out at a faster rate at the contact points. The sealant does not have time to wet the surface and “rolls” over it. In this case, it is recommended to pre-moisten the surface with water using a spray gun.

The sealant is applied to the prepared surface with a spatula or pistol (when using cartouches). Voids and leaks are unacceptable. The surfaces of the applied sealant are given the required shape using special spatulas. Use soapy water to prevent the sealant from sticking to the tool. To obtain a neat seam, we recommend protecting the front edges of the structures with adhesive tapes. After applying the sealant, the tapes are removed.

Package - plastic bucket - 7 kg, 15 kg., File-package 600 ml., Cartridge 310 ml.

Storage - the guaranteed shelf life is 12 months at a temperature of +5 0 С to + 30 0 С in undamaged original packaging.

Security measures - avoid contact with unprotected skin and eyes. Do not ingest. Not explosive, in an uncured state it can be washed off with hot water and soap. In a vulcanized state, it is removed mechanically.

• contact with drinking water is inadmissible;

• not recommended for use in closed rooms with a relative humidity of more than 90%

• it is not recommended to use the sealant at temperatures from 0 0 С to +5 0 С at a relative humidity of more than 90%

Transportation and storage of the sealant at low temperatures is possible. Withstands up to seven freeze-thaw cycles.

Purpose of sealants and what to consider when choosing

The main purpose of the material:

- sealing joints and crevices in wooden floors, walls, etc .;

- protection of the end parts of wooden structures;

- processing of joints of any parts;

- filling cracks;

- other repair work.

The building materials market is overflowing with all sorts of sealant options for a variety of purposes. Sometimes such an abundance of compositions is confusing, because the buyer does not always know which option to choose.

When choosing an acrylic wood sealant, consider:

- intended place of use and type of surface. They produce compositions for external and internal work, universal use, for windows, roofs, etc.;

- environmental features and factors affecting the structure treated with acrylic lubricant. From the general group, heat-resistant, fire-resistant, sanitary and compounds are distinguished, the list of which is only being replenished;

- composition of the sealant.

The company "Master Srubov" - quality and reliability

Our company is an official dealer of Oliva and recommends Accent 125 sealant to all its customers. We have been working with sealants from this manufacturer for many years, during which they have shown themselves to be the best.

Hemetik Oliva meet the highest customer demands for quality, safety and reliability. We offer our clients the best conditions when ordering sealing with this material. You can buy it with good discounts. By ordering the insulation of your wooden house in our company, you will receive high quality workmanship and excellent service.

We have created all the conditions for the convenience of our clients. You can check the quality of our work online using daily photos and video reports from the facility. We set fixed prices, which we do not revise in the course of work.

We produce insulation of wooden houses in Moscow, Moscow region and surrounding areas. You can leave your application in the "Contacts" section.

Calculate the cost of painting and insulating your home right now

Do you have accurate measurements at home?

Measured by myself There is a project of the house The measurers came I want to call the measurer

By clicking on the button, you consent to the processing of personal data

Thermal insulation of a bath inside and outside - materials and technologies

Features of the use of teak oil in the processing of wooden houses

Tikkurila oil impregnations - protecting your home

Features of Varathane tinting compounds

Specifications and properties

Accent 136 is a UV-resistant, non-flowing thixotropic paste with a uniform tear strength of at least 10 kg / cm².

Composition

In the production of this sealant, German-made raw materials are used:

- aqueous dispersion of polymer;

- modifying additives;

- pigment;

- filler.

Shrinkage factor

In technical documentation and instructions for use, the material is often referred to as "dry residue" and is measured as a percentage

For example, when sealing joints between logs, when the construction of a log house is underway, it is important to know how the material will change after drying. Acrylic wood sealant Accent 136 has 72%

This is the average value for all similar premium materials, which are used in the work of the company "Master Srubov".

Consumption

The consumption of funds per running meter depends on the depth, thickness and length of the seam and is calculated using a special formula:

Mp = b × t × V (kg / l.m.), where:

b - joint width (m),

t is the thickness of the sealant layer (m),

V - specific gravity (1500 kg / m³).

Acrylic sealant consumption table Accent 136:

| Sealant thickness, mm | Joint width, mm | Consumption, gr |

| 5 | 5 | 37,5 |

| 5 | 10 | 75 |

| 3 | 5 | 22,5 |

| 3 | 10 | 45 |

Drying time

This parameter is usually divided into two periods: drying time and hardening time. Drying means the formation of an outer protective film. For most of the formulations, including the Accent 136 sealant, it is 1-2 hours. Curing is the main parameter - this is the time during which the sealant will fully gain useful properties. Depends on joint thickness and temperature, but the average value usually does not exceed 24 hours at a thickness of 2 mm.

Life time

The indicator determines how long the sealant will maintain its operational characteristics: it will not crack, it will not burst. For high-quality acrylic materials, it is 20 or more years, for Accent sealant 136 - 25 years.

Flammability and hazardousness

All wood sealants are combustible. They will continue to burn even after the ignition source has died out.At the same time, acrylic sealants are fire and explosion proof.

There are no solvents in the composition; under the action of fire, they do not emit harmful compounds.

Palette

The standard Accent 136 palette includes 13 shades: white, beech, golden pine larch, pine, honey oregon, walnut, rosewood, oak, teak, gray, wenge.

Sealant palette Accent 136

It can also be tinted in other colors. Acrylic sealant can be painted and then sanded.