Articles

Alkyd or acrylic primer: which one to choose?

15.05.2014

Surface preparation before finishing with any materials is extremely important. Priming helps to save you money, significantly improve the quality of repairs and extend its service life. How to choose the right building materials and carry out the work?

The primer is used for all types of substrates: metal, wood, concrete, brick, plaster, drywall, putty. Its main purpose is to provide a strong "seizure" of finishing materials, be it wallpaper, paint, varnish or tile, with the base. Paint and varnish technologies do not stand still, now you can find a primer that will protect wood from rotting and the formation of fungus, metal - from corrosion, plaster or putty to give special strength due to deep penetration or even color.

The choice of primer should be based on the type of substrate and the properties you want to give it. Today, a large assortment of acrylic and alkyd materials is presented on store shelves.

What is the difference between alkyd paint and acrylic paint

The former are used for almost any reason. Their main advantage is that they are odorless. When renovating in small spaces, an acrylic primer is indispensable. However, if you need to carry out work on metal, then only alkyd material will help here. It reliably protects the iron from rust. Experienced builders prefer alkyd primers to acrylics for outdoor work.

The most common among alkyd is the GF-021 primer. Its anti-corrosion properties can significantly extend the service life of metal products. In addition, the primer is often and successfully used for other types of substrates, for example, for wood, drywall, brick, plaster. The technical characteristics that the manufacturers indicate on the labels give the right to call the GF-021 primer universal. In particular, this term appears on the bank of the Yaroslavsky Kolorit trademark. If you are in doubt about which primer to buy, then you can safely choose the GF-021 primer. Specifications, including consumption per m2 and drying time, vary across product lines. Before buying, be sure to read the instructions for use.

Traditional colors for alkyd primers are brown, red-brown and gray. The palette of this material does not always play a big role, since it is most often applied under finishing materials. When absorbed and dries, the primer becomes dull, however, it can affect the color of the future coating. If you choose a primer for light wallpaper, then alkyd will not work for you.

Among acrylic materials, deep penetration primers stand out. They are designed to strengthen loose and fragile substrates. Among them can be concrete, plastered, wood, cement, gypsum, plasterboard, previously painted surfaces. This type of primer penetrates as deep as possible into the substrate and reduces its absorbency, allowing significant savings in subsequent painting work. You will find such a primer in the lines "Yaroslavl Coloring" and "Norm".

The "Braska" line also includes a deep penetration primer, but it has additional properties that are valuable for repairs. It contains a fungicide, a chemical used to fight fungal diseases. The primer is ideal for woodworking, protecting the substrate from mold and harmful bacteria.

Acrylic primers, in contrast to alkyd, colorless, some of them are used as an independent coating. This is your option if you are looking for a primer for gluing light-colored wallpapers. This type of primer can be used both indoors and outdoors.

You do not have to worry about the quality of the coating formed by the primer, if you chose it taking into account the existing base and finishing materials. In this case, the soil will responsibly fulfill all the duties assigned to it.

Types of paints for metal

Paints are classified according to composition, purpose and properties. For metal, not only specialized coatings are suitable, but also some universal ones, which can also be used for painting wood, concrete and other types of surfaces. The basis for the manufacture of the coating is of paramount importance - it determines the strength, durability and heat resistance of the composition.

The composition of the following types of paints is distinguished:

- Epoxy. They are extremely toxic, therefore they are not used for internal work. Produced on the basis of silicone resins with a hardener. The coating withstands high temperatures well.

- Oil. Less toxic. The composition is based on natural oils or drying oil. They are used for interior work, as they are unstable to large temperature ranges. Not able to protect metal from corrosion. Therefore, the surface to be painted must be primed.

- Alkyd. They have a low level of toxicity. Used for interior work. They adhere well to the surface even without priming. Cannot withstand strong heating, combustible.

- Acrylic. Non-toxic, odorless. Produced on the basis of polymers. Diluted with water. Versatile in application. Suitable for painting parts that are exposed to heat. Provides protection against corrosion.

- Rubber. These paints are ideal for metal roofs. Toxic, suitable for outdoor use only. Provides additional protection against leaks. Easily removable if necessary.

There are specialized coatings for metal, they are divided according to their properties:

- Anti-corrosion - compounds that protect the metal from moisture and oxygen. Does not require a primer coating.

- For rust - applied directly to oxidized iron. Such paints significantly reduce the time and financial costs for metal processing. Quick drying. Produced on the basis of synthetic epoxy resins with the addition of anti-corrosion pigment.

- Hammerheads - when dried, they form potholes on the surface, similar to hammer blows. They can be produced on an alkyd, acrylic, epoxy base with the addition of small particles of glass and aluminum powder. Resistant to mechanical damage.

- Primer-enamels are formulations that combine the properties of a primer, an anti-corrosion coating and an enamel.

- Nitro paints - such compositions are most often produced in spray cans. They are toxic, so the paint in spray cans is used only for outdoor work. Its advantage is that staining does not leave streaks.

- Blacksmiths are made on the basis of polymers. One of the most durable. They have the highest adhesion rates to the base surface.

As a rule, the more expensive the composition, the longer it will last. The most affordable - oil ones - can lose their appearance and crack in just a couple of years. Nitro paints fade in the sun in one season. The hammer has the greatest durability - even after 10 years of operation, it will not change its appearance, but if necessary, it is almost impossible to remove it. The best paint for metal is blacksmith paint, but given its high cost and high consumption, it is not always advisable to use it.

When choosing, be guided by the following indicators:

- Purpose (for indoor or outdoor use);

- Toxicity;

- Consumption and cost;

- Duration of operation;

- The need for preliminary preparation of the metal.

The condition of the metal surface is also important. If it is required to paint ferrous metal with rust, the choice of compositions is narrowed

Also in the case of products that will be exposed to heat or weather conditions.

Features of use

Enamel paints in spray cans are easy to apply and give the desired effect, subject to a number of nuances. Remove dirt and dust from the surface to be treated. Then, the metal is degreased. As a rule, white spirit is used for this. If necessary, the surface is sanded, putty and cleaned.

For better subsequent adhesion of the paint and varnish material to the surface, the latter is primed. For this, it is advisable to use aerosol primers. In order for the primer to be combined with the paint, choose funds from one manufacturer.

For better subsequent adhesion of the paint and varnish material to the surface, the latter is primed.

For better subsequent adhesion of the paint and varnish material to the surface, the latter is primed.

Shake the can of paint before application. Trial testing is carried out on a test surface. The distance from the surface to the spray should be at least 25 centimeters. Spray paint gently without creating smudges. After applying the first layer, the paint is allowed to dry (at least half an hour). After that, the next layer is applied. On average, the paint dries completely after 6 hours.

The distance from the surface to the spray should be at least 25 centimeters.

The distance from the surface to the spray should be at least 25 centimeters.

Advantages and disadvantages

Acrylic enamels have gained wide popularity relatively recently.

Their advantages include the following:

- acrylic mixtures are very wear-resistant and durable. On metal coated with this type of paint, corrosion does not form until 10 years;

- even after many years, the coverage will not require regular updates;

- the light white coating will not turn yellow over time and will not lose its former shine;

- paints of this type are not afraid of temperature changes; after complete drying, the coating will not be afraid of any changes in the weather;

- since the paint does not contain any harmful and toxic substances, pipes, gas storages and some other types of industrial stations are often painted with it;

- metal paints can withstand extreme temperatures up to 120 degrees. In special formulations, there may even be silicone resins that can withstand even higher temperature conditions.

Despite all the advantages, acrylic enamels also have some disadvantages:

- All manufacturers say that paints dry very quickly, but it can take up to one month for the final formation of the mixture on the metal. Moreover, in this period, the coating will be the most vulnerable to various damage from the outside;

- For some, this is a minus, but for others it is not, but the palette of acrylic enamels is not as extensive as, for example, in other varieties;

- The cost also belongs to a small disadvantage, but it cannot be said that it is much higher than the usual options. Nevertheless, some consider it a significant disadvantage.

Latex varieties

This product is an improved water emulsion formulation with many benefits. Acrylic-based paint is used for interior painting of textured wallpapers and walls, thereby emphasizing the beautiful pattern of the picture.

Elastic latex paints can be applied to the surface very easily, forming even layers. When dry, a strong film coating is formed that can protect the treated surface from various damages.

Manufacturers produce latex-type products for painting wall and ceiling bases with decent indicators of reliability and quality.

When choosing a paint, you need to carefully read the instructions, since paints and varnishes for painting walls and ceilings may differ in their characteristics and properties.

White water-based paints Latex-based ceilings are used to paint ceilings as they tend to be less negatively affected by pollutants. Latex wall paint, due to its water resistance, better tolerates the negative effects of moisture.

Manufacturers also produce a range of semi-gloss and matte paints, which, when dried, create a coating with an appropriate effect. At the same time, semi-gloss paints and varnishes are not classified as a universal finishing material, since instead of hiding, on the contrary, they emphasize the existence of defects on the surface of the base. If semi-gloss latex paint will be used, the base must be carefully prepared beforehand.

Matte paints are considered universal; they are used for finishing various types of surfaces. At the same time, if we compare the parameters of water resistance and abrasion, matte are significantly inferior to semigloss compositions. A huge plus is the possibility of multiple repainting of the matte surface, so you can quickly and easily update the interior of the room by giving the walls a different color.

Varieties of paints and varnishes

Paints and varnishes contain binder, fillers, pigments, solvents / thinners and additives. In order to correctly apply paintwork materials during repairs, you need to know exactly their composition.

Main components

Oil paints based on drying oil.

All paints are divided according to the type of binder used and the type of solvent.

- The binder determines the main qualities of the paint, the service life of the coating and the speed of its drying. There are 4 types of binders used for paintwork materials: alkyd and epoxy resins, oil (on drying oil), latex, acrylic polymers.

- Dissolving components are divided into proper solvents and diluents. The former reduce the fluidity and viscosity of the material. Thinners only reduce the viscosity of the paint.

- To improve the characteristics of paintwork materials, additives are added to their composition: stabilizers, emulsifiers, fungicides, antiseptics, etc.

- Special paints belong to a separate category. These are anti-corrosion coatings such as Zinga conductive paint. Analogues with antiseptic properties that protect the base from mold and decay. Compositions for removing small defects (irregularities, scratches, cracks), etc.

Oil and enamel compositions

Pictured is acrylic enamel.

Materials based on alkyd and acrylic resins include oil and enamel paints.

They are suitable for painting metal, wood and plaster surfaces.

After drying, they are non-toxic, light and moisture resistant.

- Oil paints are made on the basis of drying oil. White Spirit, gasoline, turpentine or solvent naphtha act as thinners for them. The price of the compositions is not high, but they dry for a long time (up to several days). The main disadvantage is that the coating turns yellow over time.

-

Lacquer is added to enamel compounds as a binder. It gives the coating a gloss and aesthetics. The instruction recommends using such paints for external and internal finishing work on metal, wood, concrete, plaster.

Enamels are moisture and lightfast. They also have anti-corrosion resistance.

Emulsion and dispersion materials

Water dispersion composition.

Such paints are diluted, but do not dissolve with water. In them, the binder and pigment particles are distributed in a liquid medium, thus creating a stable emulsion.

When the coating dries, it will not wash out with water.

- Emulsion compositions are economical, have environmental friendliness and fire safety.

- Fits well on almost any basis.

- Dry quickly, do not have a pungent odor.

Many people think that water-based and water-dispersion compositions are the same.

However, they are different.

- Matt emulsions wash off over time.The dispersions are waterproof and suitable for use in damp rooms.

- Water-dispersion compositions are usually white, water-based analogs have a variety of colors.

- Dispersions cannot be used at temperatures less than +5 degrees. However, when modifiers are added, they are thermally stable. Such are, for example, fire-retardant paints for metal Polistil.

- Such compositions are frost-resistant after they have completely dried.

- They are vapor permeable.

- Suitable for alkaline substrates (concrete, plaster).

- These paints are excellently tinted.

- Resistant to ultraviolet light, retains its original color for a long time.

- They have the ability to repel water.

- They have high mechanical resistance.

About paint compatibility

First, an epoxy putty must be applied to the old coating.

Based on everything written above, we will answer the main question of the article - is it possible to paint with acrylic paint on enamel and vice versa.

- Based on their composition, acrylic paints and varnishes lie only on the same old coating. They cannot be applied over alkyd enamels due to incompatibility of thinners / solvents. The new coating will simply fold (lift) the enamel.

- In addition, it is undesirable to apply emulsion and dispersion compositions to old glossy and adhesive paints. The same applies to lacquered substrates.

- But, after emulsion and dispersion materials, you can use any enamels and paints.

Now how, without removing the enamel, apply a coating of acrylic paint with your own hands.

After the putty, an acrylic primer is applied.

Nowadays, many liquid putties and primers are sold that have the described composition.

One of the best materials is Inter Troton Spray.

- First, apply a liquid putty over the enamel.

- Next, coat the surface with acrylic primer.

- Then you can paint the base.

Tips and tricks for use

Depending on the surface on which the enamel will be applied and the composition of the paint, which choice to make will depend. To protect wooden products from mold and decay processes, use water-based, dispersion and universal enamel.

Protective components against corrosion are added to the enamel for painting metal structures. A fire retardant, acrylic urethane blend will do the trick.

Enamel, which can be wiped down with a damp cloth, is advised to buy if you need to color the floors. In addition, such paints dry quickly, do not attract dust, and retain their gloss for a long time.

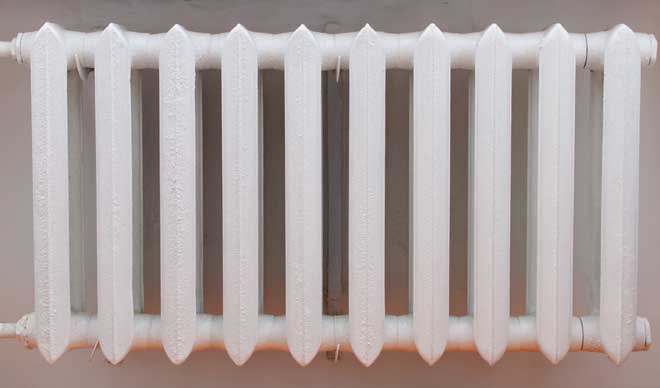

As a rule, plastic objects can also be painted with acrylic paints - however, a primer is applied to the object first. Heat-resistant products are intended for finishing radiators. It can also be used to paint brick, concrete and metal structures.

Water-dispersion enamel, which contains antiseptic components, is relevant in bathrooms and kitchens, since the paintwork can be easily wiped off, moreover, it is not afraid of moisture.

Applying acrylic paint to oil

It is not recommended to apply acrylic on old oil paint, as in this case good adhesion of the materials cannot be expected. It is much preferable if acrylic is used as the bottom layer, and an oil solution is applied on top.

However, if desired, you can still treat the old oil layer with acrylic. However, in this case, you need to thoroughly prepare the surface.

The preparatory work is as follows:

- Sand the surface with a layer of old paint. For sanding, we need a fine-grained sandpaper.

- We remove dirt and dust from the processed material, and then degrease the surface.

- We are waiting for the surface to dry.

- Apply 2-3 layers of acrylic solution.

However, preparatory work alone does not yet guarantee a successful application of acrylic to an oil base.To achieve the desired result, the acrylic composition must be quite thick, that is, diluted with water in a proportion not exceeding 1 to 1.

Sometimes the oil composition eats into the surface so firmly that it is not possible to remove it. In such cases, paints with specially enhanced adhesive qualities, for example, "Master-121", will help. Such paints are able to adhere even to moderately oily surfaces.

Unfortunately, water-based paint is not always good, and if you are already disappointed in all its charms, you can return to a well-tested oil paint.

Please note that even in advertisements, it is written: "water-based paint is in no way inferior to enamels", is not inferior, and therefore no better than oil enamels. And in practice, when you paint old windows, doors or other buildings with nails, water-based paint, after a year the nails will rust and rust will indicate their location.

This is due to the fact that the water-based paint "breathes", which means it passes moisture to the iron and it rusts.

So it turns out that when painting surfaces without iron elements with water-based paint, it is good. But if there are old windows or doors with old non-galvanized iron elements, it is better to use proven oil enamel. But the question arises, is it possible to paint with water-based paint, oil? And forget the stories that water-based paint is erased with water. Forget it with a damp cloth, you won't wipe off high-quality water-based paint. So the answer is simple - you can, because the composition of the water-based paint is similar to the composition of the putty, on wood, so clean it a little with sandpaper, remove the excess and you can paint, but it is better to soak first with a deep penetration primer, which improves adhesion (adhesion of new paint) and strengthens the surface . Author of PBT

Acrylic paints were introduced to the market half a century ago. It is safe to say that this is a real breakthrough in the construction and repair industry. Today this type of coating is preferred by most consumers.

The composition of this material is simple. Consists of three elements: resin (binder), water and coloring pigments. Those who are not yet familiar with this coating are interested in whether it is possible to paint a tree with it? The answer is undoubtedly yes. Moreover, this option has many advantages over similar formulations. How to paint wood with acrylic paint and how to choose the right product?

What it is?

The chemical composition of acrylic paints includes acrylic, a polymeric substance that is obtained during the cleavage of acrylic acid. For this, water is used in a mixture with ethanol or chloroform. The resulting substance will be completely transparent. It is a colorless synthetic substance.

Acrylic has good technical characteristics and a wide range of applications. Paints based on it are now used for both indoor and outdoor work. In addition, they are used in art painting. Such formulations can be diluted with water. Acrylic paints differ into types and types according to certain letter designations. So, many trains have the VD-AK marking and a digital index. This means "water-dispersible acrylic paint", followed by the number of the paint composition.

Acrylic paints are fairly durable and strong when dry, while their texture is light. Such compositions can have bright saturated shades, while they do not fade at all, since they are resistant to ultraviolet rays.

For the preparation of such paint, acrylic and dispersion plastic are also used. This composition is quite thick, therefore it is often dissolved with water. This type of paint coating is characterized by film formation.Thus, the painted surfaces will be protected from external factors, the paint will remain stable for a long time, and its color will not change.

Each acrylic paint consists of several elements:

- binder;

- filler;

- colored pigments;

- solvents and other additives.

Binders connect all paint components. Thanks to them, the adhesion of the coating to the surface on which they are applied is improved. Typically, the composition of the binders are presented in the form of a polymer dispersion. In turn, it is made from acrylic resins. This component determines the strength and long term and operation of the coating, its stability and indestructibility.

The role of the filler is usually performed by a composition consisting of acrylic inclusions. It is necessary for the surface to be painted over well and with high quality. It makes the paint more viscous and also improves adhesion to painted surfaces. The filler holds the composition together and at the same time performs protective functions.

Colored pigments are necessary for the paint to have a certain shade. They are formulations in the form of a powder that uniformly fills the entire composition. Pigments can be:

- organic;

- inorganic;

- finely dispersed pigments of piece origin;

- natural.

A component such as a solvent is necessary so that the paint is not too viscous and can cover surfaces well. With the help of various additives, manufacturers change various quality and functional characteristics of the paint, making it more viscous or, conversely, more liquid, change its brightness, as well as other properties.

This composition is made according to the following technology:

- first, an acrylic compound with a coloring pigment is placed in a large container;

- after that, connecting substances and solvents are added there, and then the composition undergoes intensive and high-quality mixing until a homogeneous consistency;

- after that, each manufacturer will check their products for compliance with quality standards;

- then, from a large container, the formulations are filled into small containers for sale.