How to fit correctly

After preparing the base, the rolled roll is brought into the room and left for 1-2 days. After leveling the material, cut it off and proceed with the installation of the canvas:

- Without glue: double-sided tape is attached around the perimeter of the sheet and at the base. Linoleum is laid, leveled and passed with a wooden spatula to remove air bubbles from under the sheet.

- With glue: bend the canvas (but do not bend it!) To the middle, apply the glue with a notched trowel. Before applying the material to the floor, let it stand for 1-2 minutes for the glue to show its properties. After laying, expel the air with a smooth spatula, glue the second part of the canvas.

- Sticking on mastic: the method is costly and time-consuming, therefore it is rarely used at home.

When trimming linoleum, it is required to leave a technological gap between the coating and the wall of 5 mm for free movement of the canvas during shrinkage.

What it is?

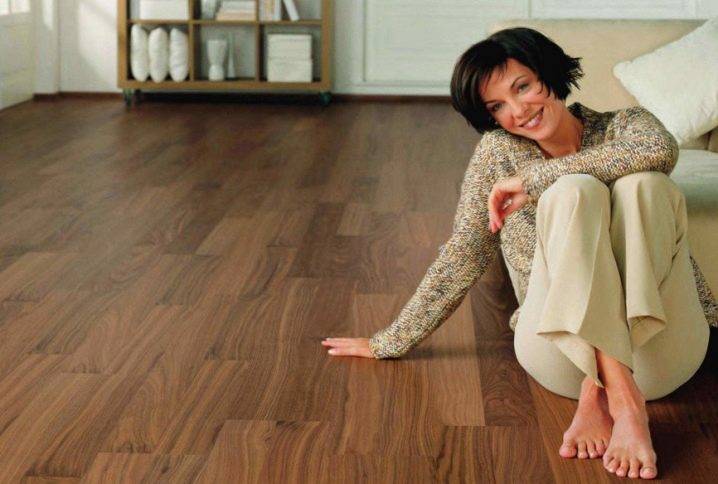

The overwhelming majority of people associate linoleum with an inexpensive, average quality coating, which is chosen by those who do not have enough money for parquet. However, this is a completely wrong opinion, because today linoleum is one of the most affordable, very durable and durable types of materials. It is easy to lay, you don't even need the help of professionals for this. The variety of colors and design options for this material will satisfy the tastes of even the most discerning buyers.

Most interesting is that contrary to popular belief, linoleum is not a cheap artificial material at all. Initially, exclusively natural, environmentally friendly raw materials were used for the manufacture of such flooring. Moreover, even the term "linoleum" in translation from Latin means "flaxseed" and "oil". The composition of natural linoleum included tree resin and flour, flax seed oil, jute, lime and cork powder.

The covering made of natural materials is completely safe for human health and the environment. Moreover, due to linseed oil in the composition, the material has bactericidal properties and has a light, unobtrusive aroma of natural oil. Such linoleum is absolutely not fire hazardous, unpretentious in maintenance, and also has a long shelf life. The cost of such flooring is by no means small, which is why natural linoleum has not become widespread, and an analogue from synthetic raw materials has replaced it.

Although modern artificial linoleum differs from natural, it nevertheless has many advantages. Most often, such a coating is made of polyvinyl chloride, but there are also alkyd, rubber, and colloxylin options. They are sold either in a roll or (less commonly) in the form of resilient tiles. This floor covering is also practical, durable and beautiful.

Linoleum marking and characteristics

To understand what types of linoleum there are, and to correctly determine the choice of coating for the house, you should familiarize yourself with the marking of linoleum, which determines their type and properties.

Symbols that can be found on the material are as follows:

- manufactured in accordance with TU or GOST, if these are products of domestic manufacturers;

- EN marking means that the products are manufactured in accordance with European quality standards and one of the foreign countries.

You can determine the quality and reliability of linoleum by a number of characteristics that cover the main operating parameters:

- coating thickness;

- the quality of the decorative layer and the tendency to fade;

- wear resistance class - tendency to abrasion;

- deformation of the material under the influence of the indoor climate;

- sensitivity to indentation;

- evaporation of toxic substances;

- ability to sound absorption and water repellency;

- the presence of an antiseptic and antistatic coating.

Outcome

So, we have determined what types of linoleum are, what are their main advantages and what are the characteristics. We hope that this information will help you find your way around the variety of floor coverings and equip a comfortable, durable and durable floor.

Varieties

To choose the right flooring, you need to know what types of linoleum are, and whether all of them can be used in the kitchen. The range of manufactured materials is quite extensive and varied, therefore it is necessary to build on the main characteristics of the products.

Natural

For production, oil from linseed crops, finely crushed lime, cork bark, powdered shell rock, pine resin and natural dyes are used. The base is a natural jute or non-woven fabric. Advantages: environmental friendliness, shape and color retention, ease of maintenance, resistance to UV rays. Disadvantages: fragility in bending, low moisture-repellent properties, high cost.

Polyvinyl chloride

For the manufacture of synthetic linoleum, a jute base, foamed polyvinyl chloride, polyester or pile is used. A special composition is applied on top, obtained by mixing plasticizers that give elasticity, cork flour, acrylates, mineral additives, stabilizers, pigments. PVC material has gained wide popularity due to its good quality and affordability. Advantages: high moisture resistance, easy to clean, easy to install. Disadvantages: sensitivity to temperature, low resistance to chemicals.

On a note! Under low temperature conditions, the elasticity of the synthetic product decreases, cracks appear. Therefore, in winter, it is recommended to choose the material in a warm store, and not in the market.

Rubber

Rubber linoleum is called relin. In its production, bitumen, recycled rubber, synthetic rubber, pigments and filler additives are used as a basis. The material cannot be called environmentally friendly due to the release of toxic substances. Relin's advantages include high elasticity and moisture resistance, but it is forbidden to lay it in residential premises.

Glyphthal

The second name of such linoleum is alkyd. The material contains alkyd resins. The advantages of glyphtal linoleum include good heat and sound insulation. But a serious drawback is the fragility and complexity of installation.

Colloxylin

Plasticizers, fillers and pigments are added to the composition obtained from nitration of wood or cotton cellulose. The result is a baseless canvas with a smooth finish. The advantages of colloxylin products are moisture resistance, fire safety. But there are also disadvantages - sensitivity to temperature changes and shrinkage.

Forms of material release

As a standard, linoleum is produced in rolls with a width of 1-1.5 to 4-6 m.But to simplify the installation process, manufacturers offer other types of material:

- Square tiles imitate a parquet floor. Due to their small size, they can be laid in different directions, to reproduce diagonal and geometric patterns.

- Long slats of linoleum look like a laminate. The material is convenient to install, it is easy to lay it even on your own. If necessary, you can easily dismantle and replace the worn out part.

- Liquid linoleum made of epoxy and polyurethane resins is laid in the form of a seamless monolithic floor. It has good waterproofing, does not deteriorate from frequent cleaning and exposure to household products.

When laying tiled linoleum, many seams are formed, so the material does not tolerate frequent washing worse, and the advantage of a liquid coating is a perfectly flat surface and the ability to change the design without dismantling.

Which is the best in quality?

Today there is a large assortment of varieties of linoleum, and it will not be possible to unequivocally determine which of them is of higher quality. It all depends on your goals and the type of premises. However, a few points are still worth highlighting.

For example, if the material has a glossy finish, it will be much easier to wash it. Also, non-slip material is much better than slippery material. The hard type of linoleum is more prone to creases and cracks than the soft one. It is also worth noting that it is best to purchase a material that will be resistant to mechanical stress and will not deteriorate if furniture will stand on it for a long time.

Choosing the right size ↑

Fortunately, its manufacturers have already taken care that we do not buy an insufficient or excessive amount of linoleum; we are only required to follow simple selection rules. The fact is that the width of all types of linoleum on sale, as a rule, corresponds to the standard width of premises in modern residential buildings. In most cases, this eliminates the need to weld or glue individual sheets of material, it is enough just to choose linoleum of a suitable width.

If even in the recent past, linoleum was laid on the floor like a carpet, and then waited for it to shrink, now this stage has been abolished. The shrinkage of modern linoleums does not occur either in length or in width, and there is no need to buy material in reserve. That is, for a room 3 meters wide, you need to buy 3-meter wide linoleum. True, with the length of the rooms in our houses, not everything is clear: the lengths of two parallel walls may differ slightly. Moreover, often such a defect is imperceptible and is found only when laying the floor covering, so that a margin of 10 cm in length when buying linoleum does not hurt.

By purchasing linoleum of standard width, corresponding to the width of the room, it eliminates the need to weld or glue separate sheets of material

By purchasing linoleum of standard width, corresponding to the width of the room, it eliminates the need to weld or glue separate sheets of material

The modern market offers the following line of standard linoleum widths: 1.5; 2; 2.5; 3; 3.5; 4; 4.5 and 5 meters. True, not all manufacturers adhere to this size range, limiting themselves only to the release of the most popular coating width of 2 and 3 meters, which is suitable for laying without joints on the floor in most rooms of modern apartments.

If you have to decide which linoleum to choose for a room with complex geometry, then in this case it will hardly be possible to do without a floor plan indicating the exact dimensions. It is good if the maximum width of the non-standard room matches the width of the linoleum: it is enough to buy a roll of material of the required length and cut it in accordance with the configuration of the room. If this option is not possible, then it is logical to choose linoleum with an abstract pattern and lay it in any convenient way, not focusing on one linear size, length or width.

Simple recommendations when choosing linoleum, which will save you from possible troubles:

- check for cracks, bulges, unpainted fragments and other defects on the surface of the material you like;

- if you buy several rolls, check the marking of each of them and the belonging to the same batch: different batches of the same type of material may have different shades;

- check if there is a hygiene certificate for the material you like;

- buy linoleum only in stores that guarantee the quality of the material.

After measuring the room and determining the required amount of linoleum, you can start choosing it by type.

Roll coverings - marking features

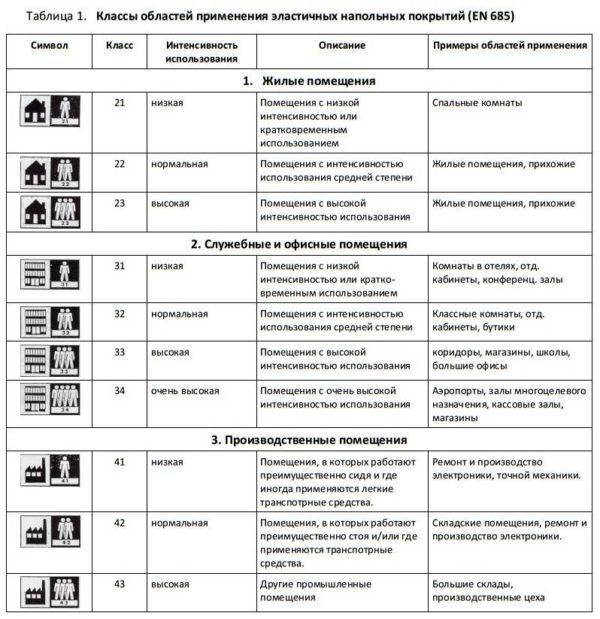

We don't shop randomly.When choosing a floor material, the store customer knows exactly where it will be installed. That is, first of all, the class of the room is determined by the operational parameters (the intensity of foot traffic, the presence of heavy pieces of furniture, etc.), and therefore the required classification feature of the finishing material.

To do this correctly, let's turn to the single European standard EN 685, which has been in effect since December 1995. It contains a unified classification system for floor coverings: laminate, linoleum, parquet boards, tiles, etc. This document is convenient in that it allows you to compare dissimilar flooring materials with each other, depending on the type of room and the intensity of the loads. For example, you can determine exactly which product is better suited for a living room or hallway - 23 class linoleum or 32 class laminate.

Of course, manufacturers label their products for a reason. The necessary tests are carried out, the results of which are summed up and, based on the results, a linoleum class is assigned.

For ease of use, a pictogram icon is assigned to each category, as indicated in Table 1.

The assigned two-digit marking is also not easy: the first number is the type of room. That is, according to the table, 2 are living rooms, 3 are office buildings and 4 are industrial facilities. The second symbol indicates the level of load carrying capacity of the coating:

- 1 - low;

- 2 - medium;

- 3 - high;

- 4 - extreme.

The above table is also true for laminate flooring. But, unfortunately, most manufacturers have significantly reduced the quality indicators of their products, and domestic and Chinese factories can not at all boast of compliance with EU standards. Therefore, Russian buyers prefer to choose 31-34 classes for home and office.

Rolled natural and PVC coatings are still holding their positions. So, linoleum class 32 is a semi-commercial and commercial heterogeneous product, used most often for commercial and commercial facilities. These products are rarely purchased for residential premises.

The wear resistance class of linoleum according to EN 649 (homogeneous and heterogeneous PVC coatings) directly correlates with such indicators as:

- thickness of the protective layer of a multilayer product (general section for a single layer);

-

assigned abrasion group.

The last parameter determines the surface resistance of the floor covering to abrasion. That is, it actually demonstrates the density of the surface, resistance to stains, dirt. Includes 4 categories:

- F - highly abrasive;

- P - moderately abraded;

- M - poorly abraded;

- T - practically indestructible.

The abrasion group is a great way to demonstrate to customers that homogeneous class 34 linoleum has a lower surface density than heterogeneous high quality 32 class T products.

If you sum up all the values, you get a single table 3, which determines the categories of linoleum, taking into account the abrasion group and thickness.

Of course, in practice, retail buyers are provided with the data in Table 1. This is understandable, because household collections of 21-23 and 31 series do not require special resistance to negative factors. But linoleum of class 33 and above must be chosen taking into account many parameters, including the thickness of the coating, the presence of special properties, etc. on a warm, felt base. But for hypermarkets or industrial premises, it is better to order a homogeneous coating with a thickness of up to 2 mm of 34 or 41-42 classes

If the room in which the linoleum will be laid belongs to category 23, it is not necessary to choose products of class 32 in the hope that it will last longer. If you buy really high quality flooring material, then it will be a waste of money.

Principles for choosing an adhesive for linoleum ↑

Simultaneously with the choice of flooring, you still need to decide what kind of glue to glue the linoleum with. As a rule, for each type of linoleum, they select their own type of glue, guided by the following principles.

Linoleum on a fabric basis is laid on the so-called cold mastic, which includes bitumen, turpentine and white spirit.

Insulated linoleum on a heat and sound insulating felt base is glued to any base with busylate-based adhesives.

Dispersion glue is considered a universal composition with which you can firmly glue any kind of linoleum to concrete, and to a wooden base, and to a cement-sand screed, and to a chipboard slab.

How to choose the right one?

Now you know almost everything about linoleum, which means that the choice of such material will not be difficult at all.

Nevertheless, once again, you should clarify what parameters you need to pay attention to when buying coverage

Room type. In most cases, this criterion is of decisive importance, because the choice of one or another type of material depends on this. First of all, it should be remembered that coatings with different characteristics are intended for household and commercial premises, and household linoleum is also divided into several types, depending on the room in the house for which it is intended.

For example, in the hall, the flooring is usually not very thick, but it must be beautiful and warm, so that it would be pleasant to walk on it. Linoleum for the kitchen, bathroom and corridor should be as resistant to wear as possible, since these premises are quite intensively used, which means that its structure should be more dense and elastic

It is also extremely important that the flooring does not deteriorate from high humidity, because the floor in such rooms has to be washed frequently. In addition, make sure that the linoleum is treated with a special anti-slip agent.

- Material size. Do not purchase a sheet of material that is too small. It is best to buy a covering that will clearly correspond to the area of the room. So linoleum will look much more aesthetically pleasing.

- A kind of backing. If you want the warmest coating that will hide small irregularities in the floor and will not deteriorate from the furniture standing on it, give preference to linoleum based on felt. This option is no worse than carpet. When you need more soundproofing, opt for a foam backing.

Advantages and disadvantages

The choice of linoleum is based on the study of strengths and weaknesses. This knowledge is necessary in order to understand the degree of appropriateness of the coating in a particular room, taking into account the traffic area and durability of the material.

Modern linoleum differs from its counterparts in the Soviet era. Whereas previously it was not given due attention, today flooring combines the best qualities of the coating with an excellent aesthetic perception. It is a repair tool and an element indicating the status of the owners of the dwelling.

The main advantages of the material include:

- simple installation and versatility of use in residential and non-residential premises (in the flooring of the living room, nursery, bathroom, toilet, study, shop, office, salon, cafe, clinic, restaurant, balcony and others);

- the variability of the width, which allows the installation of the floor without joints and scraps of a large amount of material (saving money when buying);

- a wide range of colors with realistic imitation of expensive floor materials (like parquet, parquet board, laminate, ceramic tiles, porcelain stoneware, marble chips and others) and a modest style in the form of ornaments;

- a variety of surface textures, due to which the coating can be smooth, glossy, noble matte, embossed (with a 3D effect), rough;

- the presence of an additional antistatic effect, which explains dust repellency and resistance to dirt, stain absorption;

- durability of the floor covering, which, depending on the class of material and operating conditions, can be up to 40 years without cracking and rubbing the surface;

- based on the characteristics of the composition, compatibility with the "warm floor" system, the ability to evenly distribute heat through the structure throughout the floor;

- high thermal insulation properties and noise insulation, thanks to which it is possible to reduce the audibility of annoying extraneous sounds from neighboring apartments;

- depending on the class, resistance to wear (the level of the maximum permissible weight load without punching the surface);

- resistance to moisture when in contact with the front side;

- easy care and resistance to daily cleaning (just wipe the surface with a damp cloth), as well as household chemicals;

- the richest color palette through which you can beat the lack of space or lighting, take into account practicality or demonstrate status;

- different cost of the material, based on its composition, premium level, quantity and width of the cut.

With a lot of advantages, not every type of linoleum is worth buying. Despite the assurances of sellers and promising advertisements, linoleum has disadvantages.

Among the main ones are:

- the presence of synthetic components, which does not suit every buyer;

- an increase in cost with an increase in the thickness of the protective layer of the surface;

- difficult transportation with a large volume and weight, the possibility of defects in the delivery process;

- response to constant temperature changes, which changes the structure, depriving it of elasticity and leading to the formation of cracks on the front side of the material;

- the boring look of the material of a simple class, which simplifies the general appearance of the room's furnishings, through ornaments creates a feeling of variegation and disorder;

- the complexity of the work of some types of coatings, the formation of waves after laying and gluing to the surface;

- the need for docking in the laying of spacious rooms, the area of which is much larger than the maximum production width;

- the presence of weak points (joints), which, when water gets in, can disrupt the monolithic appearance of the floor covering and require adjustment by gluing or stopping;

- the formation of mold on the seamy side with prolonged contact of the base with water without proper drying of the material;

- leveling the floor surface before laying.

Peculiarities

What is the most common and popular flooring material? - This is linoleum used both for residential premises and for public and industrial buildings.

It is so diverse in its characteristics that any buyer will find his own version on the market. You can also look at the photo to determine the color.

Choosing linoleum for an apartment, many buyers are guided only by external qualities:

- Price.

- Design (color, pattern).

- Web width.

But there are more significant parameters that are not visible, and are only reflected in the characteristics of the material.

More attention should be paid to them. And most importantly, linoleum should be chosen not for an apartment, but for each room separately

Indeed, despite the fact that all the rooms, the corridor and the kitchen are in the same apartment, they have different purposes. It's like a family. An individual family can use the services of one hairdresser, but everyone has different hairstyles. It is rare that one good linoleum is optimal for all rooms.

How to choose the right one?

The choice of linoleum depends on the purpose and place of application:

- linoleum for the kitchen must be durable, with a large layer of protection;

- it is better to put anti-slip material of a semi-commercial type or commerce in the hallway (these areas of the apartment are more passable);

- rubber linoleum is appropriate in the interior of the hallway, bathroom and toilet: it will not deteriorate from the abundance of moisture;

- the canvas in the bedroom does not need a thick layer of protection, a semi-commercial type is enough;

- household linoleum is rather weak to survive in conditions of intensive use in the nursery, corridor, living room for several years.

When choosing a material, it is important to consider the type of styling:

- the version with a jute coating is good for a concrete floor (no insulating leveler is needed);

- it is better to lay vinyl linoleum PRP on fiberboard: this way the surface will be flat;

- if special noise-insulating materials are placed under the linoleum, the installation method (glue or dry) is taken into account.

In order for the choice of material to be a rational investment of money, it is worth taking note of a few useful tips:

- the purchase is carried out in a trusted store: so the quality will correspond to the price;

- if funds allow, it is preferable to choose a natural material: it is more environmentally friendly and does not harm health;

- the color of linoleum should not conceal the degree of illumination of the room (it is preferable to exclude dark colors);

- the surface pattern should take into account the area of the room (the smaller the room, the smaller the pattern);

- if the canvas is planned to be glued end-to-end to the baseboard, you can buy linoleum in the same shade;

- accurate calculation is important: this will avoid unnecessary spending;

- good material does not exude a pungent odor (a sign of harmful toxins in the composition);

- buying a whole sheet is important: the seams are a sore spot of the coating, they will begin to flake off first;

- saving on quality is excluded: a good and durable coating is not cheap;

- if there are pets in the house, it is better to buy commerce that is resistant to the claws and teeth of animals;

- modular linoleum should be bought from one batch: this is how different shades are excluded;

- a coating with a thickness of 2 mm is excluded: it is cold, demonstrates all the subtleties of the floor and substrate.

Household linoleum

This material is intended for installation in rooms where the load level is low. The basis for the manufacture of such a material is foamed polyester.

The thickness of the household type of PVC linoleum ranges from 1-4 mm. The service life of this material is short, therefore, after 5 years, the floor covering requires a complete replacement.

Coatings for domestic use on a polyvinyl chloride basis have a somewhat more complex structure.

The advantages of household PVC linoleum:

- ease of styling;

- weakly conducts vibration and extraneous noise;

- soft;

- does not need specialized care during use;

- a wide range of colors and textures.