What to do if the washing machine freezes

Since today the models of washing units have become "smart", then during their operation, problems associated with the computer, which are responsible for the modes of washing, spinning, rinsing and drying, are not excluded. If your machine does not stop, i.e. there was a failure in the program, and it continues to rinse the items loaded into it, then you need to turn it off.

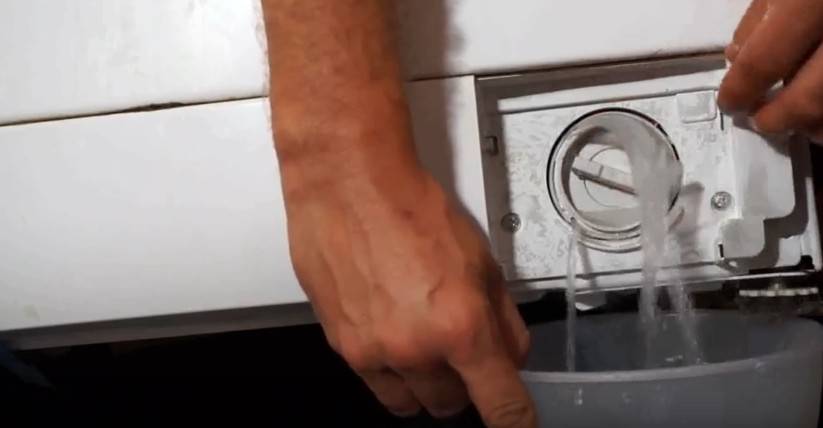

In such a situation, you need to eliminate the electronics failure by turning off the unit from the mains and draining the liquid from it yourself through a filter or emergency drain. As a rule, the washing machine freezes on rinsing because it is clogged, which prevents the normal passage of water. This problem is eliminated by cleaning the filter or replacing it. If everything is normal with the drain, then the reason lies in a malfunction of the control board, motor brushes and even engine breakdown.

Features of the problem

A washing machine is a rather complex unit. It works according to a clear scheme, which is set by the program. In order to better understand the situation, it is necessary to determine all the specifics of the operation of this technique. The user selects the program he needs, then the washing machine executes the command and monitors the process. If there is any deviation from the set parameters, the electronic unit determines the failure of any program. The washing time increases.

The washing period takes from 30 minutes to 2 hours and depends on the selected program. It is often a mistake to think that the process has been delayed. First of all, you need to make sure that the standard program is selected, which does not involve additional soaking and rinsing. In order to be completely sure of a malfunction of the equipment, you need to run some program and observe. Such tactics will allow you to understand at what stage the malfunction appeared.

Note! In addition to the fact that the machine washes longer than the stated time, the transition to rinsing and spinning may not occur.

Washing machine draws up a lot of water

If your washing machine overflows. That is, it collects too much of it, then the following malfunctions are possible:

- Failure of the water inlet valve, in this case the water continues to fill up all the time.

- The level sensor (pressure switch) has broken. This can also lead to this malfunction.

- Also, this problem can occur during the very first wash. In the event that your washing machine was transported in a horizontal position.

- Incorrect setting of the washing machine.

Eliminating the malfunction

You can find the exact information on how high from the floor the drain and inlet hoses can be found in the instructions for use of your household appliances.

After checking, you can proceed to the next stage - pour and pour water from the tank two or three times. This is done using buttons or other controls on the car.

The washing machine does not heat the water: reasons

If, as a result of the check, the heating of the machine door is not observed and the meter does not respond to the switching on of the household appliance, then this "behavior" of the washing machine may be caused by the following malfunctions:

- Incorrect connection of the household appliance.

- The wrong wash program has been selected.

- Heating element burned out.

- Thermostat is defective.

- Control box defective.

If a household appliance has just been purchased and this is the first launch, then a factory defect is possible or the wires could come off during transportation. Such a malfunction is eliminated by contacting a trade organization to replace or repair the washing machine.

Many washing programs have a limitation on the maximum heating of the water, therefore, the choice of such an algorithm for the operation of the device may lead to a false determination of the inoperability of this function. To eliminate this possibility, additional testing of the technique should be performed by repeating the procedure, but choosing a different washing program.

The heating element can burn out in almost any washing machine, but especially often such a nuisance happens with Indesit equipment. In addition, frequent washing in hard water without the use of special softening chemicals can also provoke a breakdown of the heating element. It is almost impossible to reliably identify the malfunction of the heating element without removing this element from the household appliance, therefore, if there is no experience in repairing complex household appliances, then you should contact a specialized workshop or call a specialist at home.

A faulty thermostat can also cause the washing machine to not heat up. To check the performance of this element, you also cannot do without removing it from the housing of a household appliance.

The malfunction of the control unit belongs to the category of complex, but it is necessary to start diagnosing the program module only after the heating element and thermostat have been checked. In some cases, you can independently eliminate the malfunction of this element, but if the control program has "flown", then the restoration of the washing machine will be impossible without the involvement of a qualified specialist.

Intake valve breakage

The machine Indesit, Samsuns, LG, Bosch and many others can hum without allowing water to drain, and vice versa. As mentioned above, the washing machine does not pick up water well, because the coil at the valve could burn out or the filter could simply become clogged.

If, with the latter option, water is not drawn into the machine due to a blockage that can be easily removed, then in the first case, the valve will have to be completely changed. Before replacing, people who are versed in electronics can check the performance of the coil with a multimeter or apply current to the sections.

So what not to do if a coil problem is found? Replacing it and leaving the old valve will not be the best option. If the unit does not pick up fluid due to a valve malfunction, then it is better to replace it as a whole, and not in parts.

Heating element malfunction

If the washing machine washes without stopping, then this indicates a malfunction of the heating element. With prolonged use of household appliances, scale forms on the heating element, so it takes more time to heat the water. If the temperature does not correspond to the specified parameters, then the wash does not start. In order to clean the heating element from scale, it is recommended to start washing without laundry in the drum, and pour citric acid instead of powder. You can also use a special descaler. If this method does not help, then it is recommended to replace the heating element.

If the heating element is defective, then the washing time changes, which requires repair or replacement of this part. It can be done independently using a flat and Phillips screwdrivers, a tester, silicone, a 10 mm socket wrench.

When replacing the gas-filled thermostat, the machine is disconnected from the power supply and the water is drained from the tank. The self-tapping screws are unscrewed and the cover is removed, the heating element fastenings are loosened. It is necessary to remember the features of fastening the wires, and then disconnect them from the thermostat. The heating element is carefully removed so that the rubber seal is not damaged. In the next step, the temperature controller is removed from the control panel. If the need arises, then a sealant is used to treat the place of its installation. Reinstall the new thermostat in reverse order.

When replacing the gas-filled thermostat, the machine is disconnected from the power supply and the water is drained from the tank. The self-tapping screws are unscrewed and the cover is removed, the heating element fastenings are loosened. It is necessary to remember the features of fastening the wires, and then disconnect them from the thermostat. The heating element is carefully removed so that the rubber seal is not damaged. In the next step, the temperature controller is removed from the control panel. If the need arises, then a sealant is used to treat the place of its installation. Reinstall the new thermostat in reverse order.

When replacing the bimetallic thermostat, the machine is turned off, the water is drained, the cover is removed and the fixing point of the heating element is loosened with a key. after that, it is disconnected from the wires and the resistance is checked using a tester. Install the heating element in reverse order. To check its performance, you need to run the washing machine at a 40-degree mode. If the water heats up, you can continue to operate.

Wiring faults

To understand why the washing machine does not add water, it is recommended to check the wiring, conduct a thorough diagnosis of the mechanism. Sometimes malfunctions of the device are caused due to damage or loosening of the wire contacts connecting the internal elements of the case. It is better to entrust the wiring check to specialists.

For diagnostics, the wizard uses a multimeter that measures the current strength. If the indicators are underestimated, then the terminals should be tightened. Potentially damaged wire sections. They must be wrapped with electrical tape to avoid short circuits. If the wires are in disrepair, they cannot be repaired. It is necessary to carry out new wiring in order to extend the operating life of the equipment.

The information provided will help you understand why water in small quantities or slowly enters the washing machine. If you want the equipment to serve for a long time, you should not do the repair yourself, contact the service center.

Malfunction of the level relay (sensor) or its tube

Most often, this breakdown manifests itself as follows: water continues to accumulate after the machine starts working and does not stop. In order to make sure that the damage lies precisely in the sensor, it is necessary to remove the sensor tube and examine it for damage and holes. If it passes through the tube, then it must be replaced with a new one. If the level sensor itself is faulty, then you should change it.

You can watch the video instructions for replacing the level sensor (relay) below:

We wish you success in self-repair and a long life for your household appliances! Have a good day!

6 reader comments

lussol:

I have an automatic machine. She worked flawlessly for several years. Today she began to wash, and she constantly draws water, without stopping. How to independently determine the health of the water level sensor itself before changing it. After all, it may not be the case.

Outwardly, it looks strange, the water level in the washing machine does not increase, but you can hear how it enters the tank. Often the cause is an incorrect position of the drain hose. Or it happens that even without starting the wash, with the washing machine turned off, water is drawn into it and the tank overflows.

Manifestations:

- water is poured without filling the tank;

- the water level in the tank rises very slowly;

- water, filling the tank, flows out of the washing machine.

Causes:

- Wrong position of the drain hose;

- Uneven pressure in sewer pipes;

- Blockage in the water intake system;

- Clogged or defective intake valve;

- Damage to the tube of the water intake level switch (pressure switch);

- Defective pressure switch.

Repair:

Disconnect from the network.

Disconnect the washing machine from the power supply.

Drain hose position.

Check the position of the drain hose, it should rise at least 60 cm above the ground. Many people believe that there is a certain valve on the drain, in the washing machine, which supposedly should hold back water and open at a certain time. But this is not so, the drainage of water from the washing machine is limited only by the height of the drain hose.

position of the drain hose

It happens that when moving or moving the washing machine, the hose goes down, the water starts to flow out by gravity and the tank does not have time to get to the desired level. To eliminate the malfunction, it is enough to raise the drain hose to a height of at least 60 cm relative to the lower level of the machine.

Spontaneous draining.

It happens that even with a properly positioned drain hose, water is collected and immediately leaves by self-draining. In this case, the reason is that the pressure in the sewer system is rarefied and water is sucked from the machine into the sewer. To eliminate the malfunction, it is necessary to install an "anti-drain" valve in the break of the drain hose, which equalizes the pressure and prevents spontaneous drainage of water from the washing machine.

Water supply system.

Check the water supply system: the presence of the required water pressure in the system, whether the tap is open, whether water comes from the inlet hose, the inlet valve mesh.

Leaks inlet valve.

If water is poured into the washing machine even when it is turned off, then the inlet valve is definitely faulty, which is not tightly closed due to blockage or damage to the membrane. In either case, for the stable operation of the machine and for your peace of mind, it is better to replace it. After all, a faulty intake valve can cause severe leakage. Then the washing machine tank will overflow, and water will begin to flow onto the floor, and in case of your absence, it will flood the apartment and the neighbors below.

Water level switch.

If, after starting the wash, the water level rises higher and higher, and its flow does not stop, then the most likely reason is a malfunction of the water level switch (pressure switch) or damage to its tube.

To check, you need to disconnect the rubber tube of the pressure switch and check its tightness, even with the slightest hole in this tube, the rising water level will not create pressure in the tube and, as a result, the water will not be turned off. Replace the tube or pressure switch if necessary.

Burned out ten

When an electric heater fails, it cannot perform its functions of heating water, as a result of which the temperature sensor refuses to work. If you look at the heating element with a flashlight through the sieve of the drum, you may notice that there is scale on it. If you are sure that it is precisely because of the heating element that water does not enter the washing machine, then you need to change it.

For this:

- We unscrew the back cover of the machine.

- Disconnect the ground and the sensor from the heating element located under the tank at the very bottom.

- Next, we take out the heater using a socket wrench, freeing the seal from the nut and gum.

- We buy a new heating element and repeat the procedure in reverse order.

If you are not sure that you can independently determine why the vending machine does not collect water and change the heater, then it is better to contact a workshop.

The breakdown is to blame

The situation can be much more serious if a hidden breakdown of the washing machine is the cause of the bad wash. Not all washing machine models have a high-quality self-diagnosis system. For this reason, users learn about serious breakdowns when the equipment has already spoiled things and caused moral and material damage to them. The quality of the wash is reduced, usually, the following breakdowns:

- a failed heating element;

- stretched drive belt;

- worn bearings.

So, if you take out obviously cold and not washed laundry from the drum of the washing machine, and the hatch sweats during washing and rinsing, it is very likely that the wash is carried out in cold water. First of all, you need to check the heating element of the washing machine. Since the machine does not heat the water, it means that it will not be able to wash things normally. The problem is solved:

- replacement of the heating element;

- replacing the heating element sensor;

- replacing the control triac.

The washing performance may gradually deteriorate due to a stretched drive belt. If you have a modern direct drive washing machine, then this information is irrelevant for you. Well, if in your washing machine the drive is carried out by means of a belt, then you will have to remove the back wall of the machine, remove the old belt and install a new one.You can read about how best to do it yourself in the article How to change the belt on a washing machine - video.

To understand that the problem is in the belt, you need to observe the washing machine. Namely, how she turns the drum during washing and spinning. When the belt is stretched, the revolutions are unstable and may suddenly drop, from this spinning and washing will be carried out at a low speed, which means that the quality of washing will suffer.

Washing machines that have been in operation for more than 5 years can often experience more serious breakdowns associated with the drum mechanism. One of the most unpleasant failures is bearing destruction. When the bearings are destroyed, the drum begins to knock and creak when rotating, and the stronger the damage, the more terrible sounds the washing machine will make. As a result, the drum will not be able to rotate at the speed required for high-quality washing, and the machine will no longer wash the laundry well.

Dirt has accumulated

Dirt, mildew and water stone are the scourge of the washing machine. The inside of the washer is damp and warm, ideal for mold growth. Over time, if nothing is done, the mold will grow so much that it will remain on the clothes you put in the drum for washing. The machine will stop washing your clothes and will stain them. Why this is happening is understandable, but what should be done?

- Remove the dirty laundry from the drum of the washing machine;

- Take out the powder cuvette and rinse it from dirt;

- Unscrew the trash filter and clean it.

- Purchase a special detergent for washing machines, add it to the powder dispenser, and then run the wash program in hot water without putting the laundry in the drum and turning off the spin.

- If the car is heavily overgrown with mold and water stone, then the procedure will have to be repeated twice, or even three times. After that, the quality of the wash will increase.

Features of technology

Modern washing machines have dozens of different programs and functions in their arsenal that allow you to flawlessly wash things from various, even problematic, fabrics. However, users, sometimes not wanting to read the “multivolume” instructions, begin to study their new washing machine “by typing” and, of course, make mistakes when choosing a washing mode or when turning on any function.

Then there are angry calls to sellers in the store, calls to service centers with questions why the machine does not wash some things and assumptions about a factory defect. You need to understand that any technique in work has features, a complex technique with electronic control, even more so. Before connecting such equipment to an outlet, you need to carefully read the instructions for use, and only then take any action.

So why doesn't the washer wash your favorite item, and the overall wash quality is pretty bad? To answer this question, you will have to "turn on the logic" and sort out a lot of potential reasons for such an outcome, until you stumble upon the true reason. And the information in this article will help you. Good luck!

Why doesn't my washing machine rinse my laundry well?

Once again, while washing your clothes, you suddenly find that the rinsing is not being done properly. Why it happens?

Failure of the heating element

The reason the washing machine does not completely rinse the detergent out of the clothes can be one of the following:

- The washing machine is overloaded. If the laundry was put into the drum more than the norm declared by the manufacturer, the washing powder will clog into the folds of the clothes and remain on it, since water practically does not get into them.

- More powder was added than needed. In this case, the powder does not rinse well because the amount of rinse water prescribed in the program is too small for the amount of detergent that has entered the drum.

- Insufficient water pressure.First, you need to understand what its reason is: either this weak water pressure is associated with manipulations at the pumping station, or the problem is directly with the water supply hose going to the machine (the filter or the hose itself is clogged). In the first case, the remains of the powder on the laundry is a temporary inconvenience that will disappear by itself after the pressure in the water supply is normalized, the second requires cleaning the hose or filter mesh.

- Water drainage problem. In this case, the waste water, which still contains powder, is not completely poured out of the drum of the washing machine. These residues are mixed with the clean water added for the rinsing and, accordingly, pass through the fibers of the fabric again. This may be due to a clogged drain filter, a broken drain pump, or a kinked or clogged drain hose.

- The heating element is out of order. Over time, the heating element becomes covered with scale and rust due to hard water. Then the washing machine stops heating the water normally and the detergent does not dissolve in full.

Checking the hoses of the machine

Will Calgon protect my washing machine from damage?

In advertising they assure that only he will protect. And if Calgon is not used, then the uncle from the service center will load the poor car on a cart and take her somewhere or worse - take a chainsaw and make a "horror movie." People watch ads, and on a subconscious level, they form an opinion: "To keep the machine from breaking, we need Calgon." But it does not protect against breakdowns, but only prevents the formation of limescale in the washing machine. Note: it does not get rid of scale, but only prevents its formation!

Calgon and others like it, products only soften the water, which prevents the formation of limescale, but not one hundred percent. That is, if the water is very hard and the wash is carried out at a high temperature, Calgon will not be able to provide ideal protection.

If there is already scale in the washing machine, then “it's too late, uncle, to drink Borjomi”. If a washing machine has served you faithfully for 3-5 years without any "calgons", then you shouldn't change anything. It will be cheaper to clean the heating element - with your own hands, if your hands are growing from where, or with the help of specialists. Service centers provide such a service, and it costs a penny. Adding Calgon with each wash will cost more - that's for sure.

The newspaper "Komsomolskaya Pravda" once carried out a calculation of the money going from a medium-sized family to Kalgon. It turned out that in five years exactly as much money is spent on this product as a new washing machine costs! So is it worth the effort? It's up to you, of course.

By the way, a water softener is also added to good washing powders. That is, pouring Calgon into a good powder is almost the same as adding sugar to tea with honey. True, the amount of "water softener" in powders is much less, but it is for the better, judging by the statements of the manufacturers of washing machines. They argue that products like Calgon, of course, protect against the formation of limescale, but at the same time have a detrimental effect on other parts of the washing machine. It turns out that we treat one thing and cripple the other?

The machine does not draw water or wash

The causes of this problem usually lie in the following:

No water pressure. Then the machine hums, but the tank does not fill up. In this case, it is recommended to pause the wash.

It is very important not to turn on the machine immediately as soon as the water pressure appears, since

it may be rusty at first due to worn metal or cast iron water pipes. The feed valve is closed. The machine also hums, but at the same time it turns the drum, as if filling with water, and a corresponding error appears on the screen. In this case, it is enough to open the tap all the way. The inlet valve filter is clogged. It is located in the area of the inlet valve and serves to retain small and large particles.When it clogs up, the machine first picks up little water, and then stops altogether. The additional water filter is clogged. Its location is in the area of the inlet hose. The hatch door is not closed. Modern washing machines give a corresponding signal at the same time, an error is displayed on the screen. Water supply will not start until it is open. Breakage of the retaining tab on the hatch door or falling out of the stem, which serves as its attachment to the machine. This reason is connected with the weakening of the hinges, as a result of which the hatch is warped. Broken door lock. For the safety of users, engineers have developed a system for locking the door before washing. If there is this problem, the program does not start, and water does not flow into the tank. Inoperative inlet valve. Its location is behind the car, and its task is to supply fluid to the machine immediately after the module signal. Malfunction of the program module. This is the most complex part of the device, which is commonly referred to as the "central computer". It initially contains washing modes, and its main task is to control all sensors. The breakdown of the programmer is the most serious. But in most cases, the above malfunctions are the cause.

| Cause | How to remove |

|---|---|

| Weak water pressure. | Call the local housing office, find out when they will give water. If after a couple of hours - you can wait, temporarily suspending the program, if much later - it is advisable to cancel the wash, and disconnect the machine from the outlet. |

| The water tap is closed. | Open it up. If it is open, but not completely, turn it all the way. |

| The inlet valve filter is clogged. | It is recommended to clean it to fix the problem. The procedure consists in the following algorithm of actions:

disconnect the machine from the power supply; find the inlet hose at the back of the machine and unscrew it counterclockwise; close the hose with a rag, since water may spill out of it; remove the mesh filter with pliers, which also requires cleaning; install in place; screw the inlet hose to the machine clockwise, making sure that the connection area is securely tightened; open the water tap in order to check the correctness and tightness of the hose connection; restart the program. |

| The additional water filter is clogged. | Procedure: remove from the inlet hose, clean inside and out, dry and reinstall. |

| The hatch door is not closed. | Close it. |

| Locking tab breakage or stem falling out. | If the locking tab is skewed due to prolonged operation or the metal rod falls out, the hatch door is dismantled, and the rod is installed in the desired place. After eliminating this problem, a thermal lock is activated, which serves as protection against opening the door during washing. |

| Broken door lock. | If the bimetallic plate is worn out - the door is not blocked, the vending machine stops the included program at the initial stage. You can fix the problem only either with the help of the wizard or in the service center. |

| Inoperative inlet valve. | Responsible for the supply of water and its shutdown when filling the tank to the desired level. Most often, this is facilitated by a burned-out coil, which can be determined by ringing the valve. It cannot be repaired, only replaced with a new one. |

| Malfunction of the program module. | To determine that it is he who is the reason for the termination of the water supply, you first need to use the exclusion method, because this is the rarest type of breakdown. If, nevertheless, the problem lies precisely in it, then you should call the wizard, who will determine whether it can be repaired or whether it must be replaced. |

1 Reasons for breakdown

An automatic washing machine rarely fails. The reasons for its breakdowns are not always human negligence and poor water quality. Like every technical tool, the machine needs maintenance and inspection.If it is carried out regularly, the failures will decrease significantly, but often this does not happen, and if some details do not fail, then they get upset. This also happens when the machine refuses to wash, being already filled and filled with water.

There are 5 reasons why this can happen:

- The drive belt has fallen off (however, on some models it is not).

- The electric motor is broken (so the drum cannot start rotating).

- Teng burned out (water does not heat up and the machine does not start automatically).

- The control board burned out, broke down, out of order.

- Clogged filter.

Causes of breakdown of the washing machine

Drive belt and breakdown of the electric motor or heating element

The first reason is the most favorable, since in this case the machine can be returned to good condition with your own hands in a short time. On the other hand, some typewriters are not in danger of such a development. These are the models that have a direct drive, which means that there will be no belt on it.

If the mechanism has a belt drive, it is better to start checking the machine with the belt. It is located, as a rule, behind the back or side cover of the case. Depending on the type of loading the machine has. When loaded vertically, the belt will be on the side, and when loaded at the front, it will be at the back.

In case of improper transportation, excessive vibration, the belt can simply fly off, and sometimes it is enough to just put it in place to fix it. In some cases, especially if the washing machine has been operating for many years, the belt may wear off, then you will need to purchase a new one. The side or back panel on a typewriter can be removed very easily and does not cause any difficulties.

Diagnostics of the washing machine

If the belt has fallen off, it must be removed from the machine, checked for damage and replaced if there are a lot of them. When installing, the belt must first be pulled over the engine, then put on the pulley. No need to stretch the belt

Rotating the pulley gently counterclockwise, tighten the belt onto the wheel

If many washes are performed at a time (within 2-3 hours), then the engine may overheat elementary. In this case, you just need to give the machine time to rest.

Stopping the engine is associated with wear of the brushes inside it. It is enough to simply replace them yourself. To do this, you need to remove the electric motor. It is often attached with two bolts. Disconnect the belt and sensors attached to it and, with a screwdriver, remove the terminals one by one from the brushes. This can be done with a small plate.

After the old brushes are removed, you need to put new ones. This is also easy to accomplish. New brushes are placed in the brush holder, the springs are pressed and fixed with plates. Then the terminals are put in place, and the engine is placed back.

Checking the drum of the washing machine

The machine works as a single system, that is, the failure of one element simultaneously stops the entire operation of the product. Teng, heating water for washing, can simply burn out and thereby block the operation of the entire machine.