How to understand that the pump is faulty, the reasons for the breakdown?

Before you rush to disassemble the washing machine with your own hands and change the pump, you should accurately determine the cause of the breakdown. It is very possible that the reason is not at all in the pump, here you need to understand as thoroughly as possible. Let's proceed as follows.

- First you need to listen to the pump.

- Open the drain filter and clean if necessary.

- Check and clean the drain hose.

- Check the rotation of the pump impeller; there may be a jam.

- Check the sensors and contacts going to the pump.

Some malfunctions can well be localized by ear, without being an expert, so go to the washing machine during operation and listen. Wait for the moment when the machine starts to drain or fill water, following the program. If the pump hums, tries to work intensively, but water does not flow into the tank or the pump does not make any sounds at all, consider that the malfunction is localized.

After you have made sure that the pump is not working as it should, you should determine exactly whether it needs to be replaced or whether it can be repaired on your own. First of all, we open the drain filter and clean it from debris with our own hands.

If cleaning the filter did not help, check the drain hose for blockages. To do this, the hose must be dismantled and rinsed with a jet of hot water. Replace the hose and run a test wash. If the pump continues to be "capricious", then you need to look further.

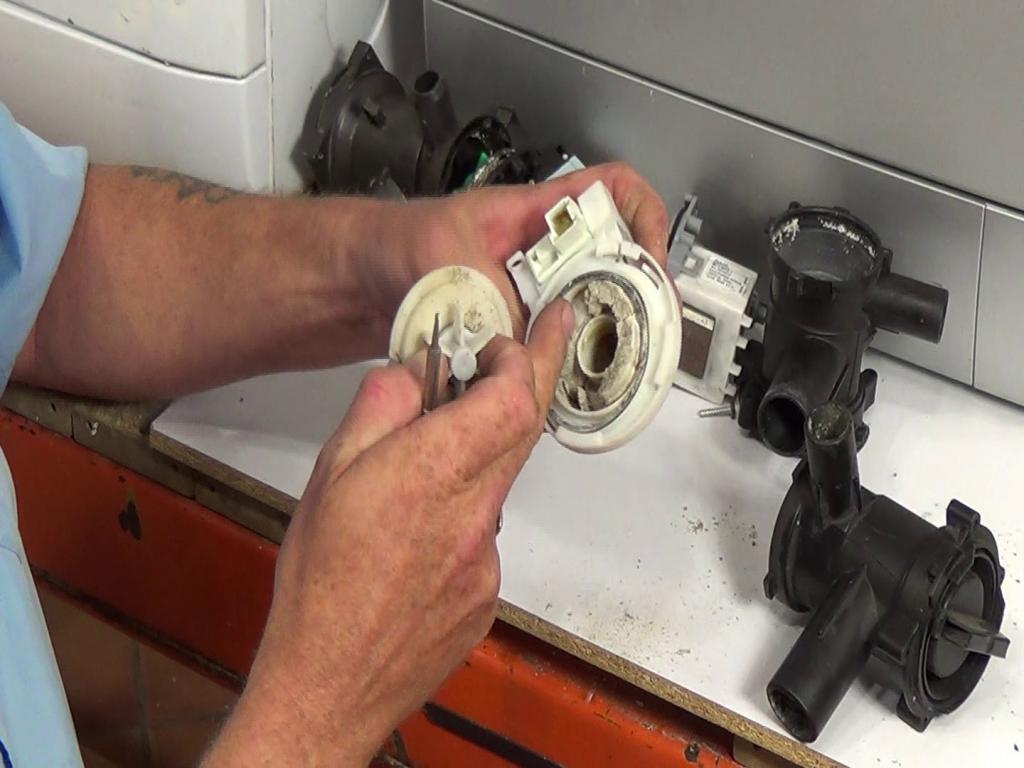

Next, you need to check the rotation of the impeller of the drain pump of the washing machine. The impeller can be reached even without disassembling the machine, through the drain filter, which must be unscrewed. To make it more convenient, get a flashlight and shine into the hole from which you unscrewed the plug.

In the hole you will see the pump impeller. Put your hand through the hole and turn the impeller with your fingers, checking how it works. If the rotation of the impeller is difficult, try to feel for foreign objects that are interfering (very often these are threads, pile, wire, etc.). If the impeller rotates freely or the reason for the difficult rotation has not been found, you will have to disassemble the washing machine with your own hands.

Having reached the pump, we check the impeller. If necessary, the drain pump can be dismantled and inspected more thoroughly. If there are no threads and lint, and the impeller still does not spin well, then the reason is in the mechanism and the pump must be disassembled. If the impeller rotates normally, but it works every other time, then the problem is in the burnt contacts, sensor or control unit.

We select tools and accessories for repair

The composition of the necessary tools and accessories will depend solely on the nature of the problem, so we will describe the option, as they say, to the maximum, if everything is completely bad with the pump. In this case, the repair of the washing machine may require the following components:

- drain pump assembly;

- impeller;

- axis;

- cuff;

- pad;

- pulley;

- drain pump sensor;

- contacts.

Purchase a new pump and parts for it with caution. It is best to take an old unit, take it to a retail outlet that sells similar products, and a sales assistant will help you make a choice. The same should be done with accessories. Bring the pump disassembled to the store and you will be given the right part for it.

With tools, things are easier. In most cases, it can be removed with a Phillips screwdriver and a pocket knife. However, if there is a need to check the performance of an electrician (sensors, contacts, wiring), you will need to get a multimeter.

Repair and replacement of the pump

After the part is disconnected, it is required to check the pump of the washing machine. Before disassembling the part, inspect the impeller and all holes to make sure they are not clogged, hair, threads, wool and other debris are not wound around the blades. You need to pull out the drain filter and inspect the part visually, and then try to turn it. A working unit should rotate with pauses due to the coil installed on the magnet. If there is no debris, the impeller rotates with difficulty, the device will need to be disassembled. This requires:

- Remove the pump cover by unscrewing the fasteners or turning it counterclockwise.

- Pry off the impeller housing latches to disengage the impeller.

- If the cross does not give in, you need to warm up the shank with a hairdryer, and then pry it off with a screwdriver.

- Remove and clean the impeller magnet.

- Remove the magnet from the shaft, a bearing will appear.

- Apply pump grease to keep the bearing functioning properly. If it is deformed, install a new element.

- All rubber gaskets should also be inspected. If they are noticeably damaged, they will need to be replaced with new ones.

- Assemble the pump in reverse order.

Next, you need to ring the pump. Procedure:

- Take a multimeter and set the voltage measurement mode.

- Put the test leads on the pump contacts.

- If the display shows "1" or "0", the unit is faulty and the pump needs to be replaced.

- If the value consists of several digits, this indicates that the pump is intact, and the malfunction is in something else, possibly in the control unit. For accurate diagnostics and subsequent repairs, it is recommended to contact a professional.

If the drain pump needs to be replaced, a new part will need to be purchased. This can be done at a service center, a specialized store or via the Internet. In order not to be mistaken when buying, you need to tell the seller the exact brand and model of the washing machine, or bring a faulty unit. The same should be done with other components to be replaced.

Washing machine pump repair

From life

A breakdown of a washing machine is like snow on your head. Everything happens suddenly and rapidly. You arrive home late at night after work. Tired, no strength. At work, it does not work out with the boss, and with colleagues too

not really. You turn on the TV. A plate under the nose. You try to look at the screen with one eye and ... instantly your face is in food. You sleep and see already the tenth dream. You wake up and then it starts ...

You remember that you forgot to wash your shirt. You scold yourself that you are a "bad person." You quickly put your shirt into the drum of the washing machine, pour the powder with trembling hands, put it on for 30 minutes. Bam! The car "stalled" - in the language of avid motorists. Panic, horror, thoughts of reprimand at work! What to do? How to be?

Real-time repair

The company will never leave its customers in trouble, even in the most critical situation. We will promptly help you to eliminate any breakdown.

Within a short period of time after your call, the master will arrive at the place. The specialists of our company will carry out preliminary diagnostics of the device and make repairs.

Below, you can learn more about the pump function and find out what it is.

What is a pump?

water pump in a washing machine is a very important element. It is a miniature pump located at the very bottom of the device. During the operation of the machine, all used water goes to the sewer. It is the pump that allows you to speed up this process and quickly drain excess water. There are two types of pumps:

In our time, with an impeller, as a rule, they are no longer installed. But they can still be found on the older Ariston and Indesit models.

If it so happens that water remains in the drum during washing, the reason most likely lies in the pump. How to independently conduct pump repair read below ...

"Attention! We do not recommend doing self-repair. You'd better entrust this business to professionals. " DIY repair

DIY repair

Remember! All of the following applies only to a pump with an impeller mechanism. "

What do you need? Honestly, except for the usual knife and Phillips screwdriver - nothing. So let's get started right away.

2) Next, you need to remove the back wall of the washing machine. As a rule, all fasteners are held on ordinary self-tapping screws. After that, having carefully examined the device, we find the pump itself in the lower corner. We open the wires coming from it, unscrew the pump, remove the hoses.

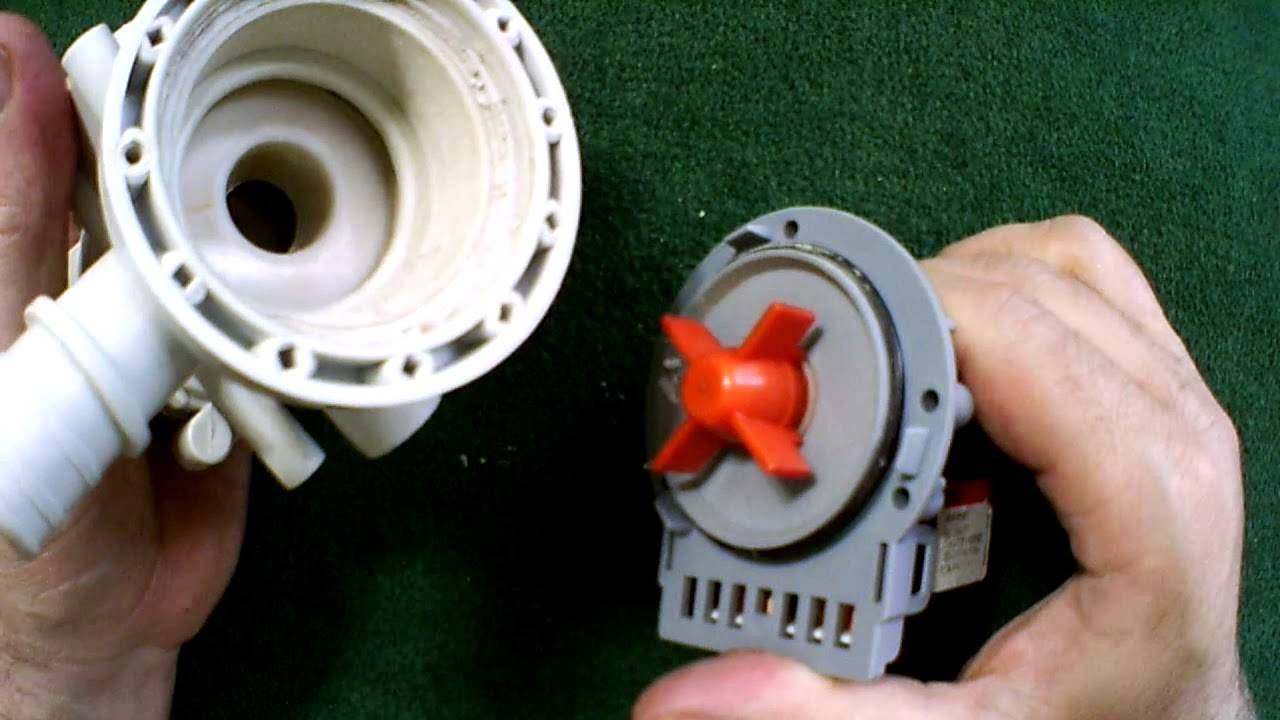

3) After that, you need to disassemble the pump itself. To do this: unscrew the pump snail from the pump body itself. We write down in what order the engine was. Then we carefully take out the engine with the impeller from the snail itself. We check if everything is in order. We manually scroll the impeller blades, as a rule, they should spin easily (intermittent movement is allowed.)

4) Basically, breakdown occurs due to the fact that in the process of using the washing machine, under the influence of hot water, the casing is deformed. Therefore, the impeller blades touch it freely and breakage occurs.

"Warning! Don't cut too much. If you remove the excess, the pump performance will drop. "

6) Then we collect everything in the reverse order and start the car.

If you succeed, congratulations. If not, then there is only one option - purchase new pump... You can install and purchase a pump in our company at a reasonable price. See below for more details ...

Once again about us

Be sure, using the services of our service center, you can forget about problems. We work from 9.00 to 21.00, and around the clock. Who said Saturday and Sunday are days off? Caring for our customers is more important than rest. We will draw up a schedule for the arrival of a specialist individually for you and select the right day.

We guarantee you quality and reliability. All parts for repair are purchased from our German partners. Therefore, the part installed in your washing machine can serve for many more years.

The company maintains a transparent pricing policy. And for our regular customers there are various discounts and promotions. Read more

Hurry up! Make an order right now and get a discount on 3 services!

Restoring the base of the impeller

Half of the work has been completed, now a logical question arises, how to restore the base of the impeller? If you managed to correctly disassemble the structure, then it will be easy to assemble it back. So, you need to do the following:

Half of the work has been completed, now a logical question arises, how to restore the base of the impeller? If you managed to correctly disassemble the structure, then it will be easy to assemble it back. So, you need to do the following:

- insert the metal shaft into the plastic impeller; for a tight connection, you can press it into the seat with a screwdriver;

- lubricate the rubber strips of the structure with lithol;

- attach the shaft with the impeller to the rubber part;

- clean the inner cavity of the pump (where the impeller base will be inserted);

- install the structure inside the pump (it will be attracted by a magnet).

- coat the cavity in the area of the upper plastic part cut off from the impeller with sealant.

This will replace the pump impeller. The process is fast enough, it will take about one hour to complete the work. The main thing is to prepare all the tools necessary for the repair, and imagine what the essence of the upcoming manipulations is.

Diagnostics

The first step in diagnostics is to check for signs of pump malfunction. Before disassembling the structure, you need to make sure that the malfunction is associated with the pump. You can determine the breakdown by the following symptoms:

- the water drain mode was activated, but the pumping system does not function;

- in the process of draining, loud noise and buzz are heard;

- the pump pumps out water, but more slowly than initially;

- during washing, the machine turns off spontaneously;

- the hum of the pump motor is heard, but the water does not drain.

In the presence of one of the listed failures, it is highly likely that the pump will need to be repaired. Before proceeding with dismantling and repair, you need to carry out diagnostic actions. To check, remove and clean the drain hose to get rid of the blockage, and then rinse the filter. Next, they include a test wash for rinsing and draining, and if the steps taken did not help to fix the problem, you should proceed to repair work.

Diagnostics

Most modern models of Bosch washing machines, for example the Maxx 5-6-7 series, are equipped with a self-diagnosis system, which greatly simplifies the identification of faults. In order to establish the nature of the breakdown, it is not necessary to contact the service center, it is enough to perform a few manipulations, and your machine itself will "tell" what the problem is. So, let's start executing the service test:

- Close the door, move the program selector to the "Off" position.

- Pause for 2-3 seconds, set the switch to "Spin" (clockwise).

- When the "Start" LED blinks, press and hold the "Mode RPM" button. Follow the "Start" - it should start flashing again.

- Turn the selector switch to "Drain" (clockwise).

- Release the "Regime Turns" (you have not forgotten about holding this position?).

- Next, put the switch in the position corresponding to checking any part of the washing machine (3 - engine, 4 - drain pump, 5 - tubular electric heater (TEN), 8 - main wash water inlet valve, 14, 15 - quick automatic test). Below is a diagram of the switch and the location of the numbers that correspond to the position of its knob.

Here is a schematic image of the switch and the decoding of the positions of its handle

Here is a schematic image of the switch and the decoding of the positions of its handle

Some models differ in command numbering: for example, in a Bosch Logixx 8 washing machine, the engine is checked at the 4th position (by the way, in this washing machine, you can carry out a quick diagnosis by setting the switch to 3). When the test is completed, the display will show an error code, which will help the instructions to decipher. In older models without a display, the error can be recognized by the glow of the LEDs, after which it will be possible to start repairing the Bosch washing machine.

In the photo - the control panel of the Bosch Logixx 8 washing machine; diagnostics of breakdowns in it is carried out according to the Bosch Maxx principle, only the numbering of commands is somewhat different

In the photo - the control panel of the Bosch Logixx 8 washing machine; diagnostics of breakdowns in it is carried out according to the Bosch Maxx principle, only the numbering of commands is somewhat different

Owners of the older generation of models are somewhat more difficult - they will have to determine the breakdown based on its symptoms.

Symptoms of malfunctions and their causes

Devices of earlier years of release, for example Bosch WFT 2830 or Bosch WFF 1201, cannot diagnose problems on their own, so the user will have to do this based on their characteristic signs:

- water is collected slowly or not at all. This is due to the accumulation of debris in the inlet filter, a malfunction of the filler valve. The culprit of the breakdown may also be a water level sensor - a pressure switch;

- water does not drain well. The problem most often lies in the clogging of the drain filter, failure of the drain pump or pressure switch;

- the water does not heat up. The heating element is almost always to blame for this. The heating element burns out for two reasons - normal wear and tear or the formation of limescale. Sometimes there is no heating due to a malfunction in the control board or a malfunction of the temperature sensor;

- the drum is not spinning. By means of a belt drive, torque is transmitted from the engine to the drum. If the belt falls off or breaks, the drum will not move. A more serious option is engine breakdown;

- loud noise during spinning. This is usually due to bearing failure.

In the photo Bosch Maxx 4 WFC 2060 - a model equipped with a self-diagnosis function

In the photo Bosch Maxx 4 WFC 2060 - a model equipped with a self-diagnosis function

Any of the listed malfunctions can be caused by the failure of the control module (electronic controller).Unfortunately, it is very difficult to repair this unit on your own, it is better not to try. Contact a Bosch washing machine repair service at home. The specialists will re-solder the board or replace it with a new one.

Is it difficult to find a pump?

The location of the drain pump is standard in almost all LG models, regardless of whether it is a direct drive in a typewriter or with a belt drive. Moreover, it will not be difficult to get to the place of malfunction - you will not have to completely disassemble the case. Also, there is no need to even unscrew the back wall, top cover, pallet or front panel. Finding the pump is many times easier, as it only requires a series of simple steps.

The location of the drain pump is standard in almost all LG models, regardless of whether it is a direct drive in a typewriter or with a belt drive. Moreover, it will not be difficult to get to the place of malfunction - you will not have to completely disassemble the case. Also, there is no need to even unscrew the back wall, top cover, pallet or front panel. Finding the pump is many times easier, as it only requires a series of simple steps.

- Disconnect equipment from electricity.

- Drain the waste water from the drum using the emergency drain.

- Shut off the water supply, disconnect from the sewer.

- Tilt the body back, placing old rags under the machine.

Everything. We look under the bottom and get free access to the entire drainage system. There is another way - move the machine to the center of the room and put it on the left side.

How to properly disassemble a washing machine pump

The pump in the washing machine is responsible for pumping water for washing and for pumping it out of the tank after the end of the cycle. Usually, water changes are carried out before and after rinsing. But what if there is water in the tank and the car buzzes? Then you need to know how to disassemble and check the pump of the washing machine.

In the article we will tell you how to get the pump out of the CM case, disassemble, clean and check for serviceability.

The device and types of pumps in the washing machine

The drain pump device is simple. It consists of an impeller, a stator and a permanent magnet rotor. The rotor can rotate in any direction, therefore, when the impeller is blocked by a foreign object, it can jerk in one direction or the other.

There are two types of pump in washing machines:

- Circulating pump for supplying water during washing and rinsing. This type of pump is installed on expensive washing machines such as Siemens, Bosch and Hansa.

- Drain evacuation pump. Drains waste water from the tank. Also, the pump removes water from the tank after spinning. The characteristics of the pump are as follows: power from 20 to 30 W, capacity 20 liters per minute.

Where is the pump in the washing machine? The exact location depends on the CMA brand. In the Whirlpool, Samsung, Ariston, Beko, LG, Indesit models, the pump can be conveniently reached through the bottom, which does not require additional disassembly.

In automatic machines "Electrolux" and Zanussi, it is enough to remove the rear panel. And in the CMA brands AEG, Bosch and Siemens, you will have to completely disassemble the front panel.

Symptoms and causes of malfunction

Before disassembling the water pump, pay attention to the main symptoms of a problem:

- When filling and draining water, the machine hums and hums strongly.

- The washer does not respond to installed programs.

- Not enough water is entering the drum.

- Water remains in the drum after washing.

- The drain mode is on, but the water is draining very slowly.

You must immediately exclude possible causes of the malfunction, such as:

- Clogged drain filter or hose.

- Electronics problems. If the contacts going from the control board to the pump are broken, then the pump does not receive a signal to start work.

Also, the reason that the drainage pump does not do its job well may be a jammed impeller. Often, when the impeller rotates, threads or hair are wound around it. As a result, it gets jammed, water pumping stops.

What can be done to check

Checking the drain system is easy. You need to start with the drain filter, which serves as a kind of pump plug. You don't have to disassemble anything for this. Do this:

- Turn off the water tap.

- Prepare a flat container.

- Use a flat screwdriver to release the latches on the door that covers the drain filter.It is located below the front panel.

- Unscrew the filter, drain the water and inspect it for clogging.

- To check the impeller, shine a flashlight into the filter opening.

- Inspect the impeller for foreign matter. Also see if it spins while working. If everything is in order, reinstall the filter.

Preparation for work and disassembly

Prepare what you need to repair or replace the water pump.

Components:

- New pump that fits your washing machine model. Before going to the store, you can remove the old part and show it to the seller. He will suggest a suitable replacement. If you decide to buy components on the Internet, an individual number is indicated on the pump, which should be guided by.

- Rubber gaskets.

- Impeller (in case of malfunction).

- Pulley and axle.

- Sensors and contacts for the pump.

Instruments:

- Crosshead screwdriver.

- Knife.

- Multimeter.

Disassembly instructions for the pump

After you have pulled out the pump for disassembly and inspected the impeller, check the condition of the rubber seals. If there is working off on their surface, replace them immediately.

To disassemble, you need to remove the cover of the pressure boosting pump. Do this:

- Let's immediately consider how to remove and install the impeller if it breaks down.

- First, the pump snail is removed - you need to unscrew the screws.

- Mark the position of the motor in relation to the volute and remove it together with the impeller.

- Now cut the impeller blades with a sharp knife and install everything in the reverse order.

During assembly, you can use a special pump lubricant.

To check the pump winding for serviceability, use a multimeter. How to ring the winding? Apply the test leads of the multimeter to the winding while measuring the resistance. If the winding is defective, then the part cannot be repaired. A complete replacement is needed.

Did the article help you?

Not really

How to choose a drain pump

More details about the drain pump: where it is located in the washing machine, the principle of operation and the device, you can read in this article: what is a water pump for a washing machine

When replacing the drain pump, it is necessary to choose a complete analogue in terms of device and technical parameters. All drain devices differ both in power and performance, and by fastening method... You should choose only from proven and reputable manufacturers. Sometimes it happens that the connection of electrical wires to both the drain pump and the circulation pump may have a different location than those that have failed. This nuance usually does not matter and does not affect the installation of the element in its original place. All replacement operations are carried out in the reverse order of dismantling, with a mandatory check of the quality of all fasteners and connections.

Self-repair of the pump

If the drain pump in the washing machine fails due to a burnout of the electrical winding, then the part must be replaced. In other cases, it is often possible to restore the full performance of the device, for which, first of all, the impeller and filter should be cleaned. To clean the impeller, you will need to disassemble the device case. The two halves of the working cavity of this part, as a rule, are fastened with 3 screws, so it is enough to unscrew the hardware fastening the pump parts to gain access to the impeller.

We disassemble the drain device

The reason for the deterioration in the performance of the drain mechanism, as well as complete jamming of the working shaft, may be threads, hair or long hair. It is necessary to carefully inspect the impeller and shaft and, if such contamination is found, clean them with a thin screwdriver. The inside of the snail also needs to be wiped to remove soap deposits on its walls.

When the parts are cleaned, rinse the two halves in water without immersing the engine.Then you need to assemble the body, connect the pipes and electrical clamps to it and install it in its original place.

When the process of installing the cleaned pump is completed, the machine is turned on in rinsing mode and the operation of the drain mechanism is checked. If the device is operating normally, then no more

measures are not required, if it was not possible to repair the pump in this way, then it is necessary to replace the electric drain pump in the washing machine.

4 Impeller malfunctions

The pump impeller is one of the fragile elements of the mechanism. If things with pockets filled with small change are put into the washing machine, coins can quickly knock off the impeller blades or bend the stem. In non-separable pumps, the solution to the problem is radical. The mechanism changes completely. A collapsible pump with broken impeller blades does not need to be completely changed. It is enough to replace the broken element.

Some owners of washing machines have to face the problem of stopping the drainage of water during the washing process. It can be solved by simply blowing the drain hose, but after a while, the problem again makes itself felt. The cause of the breakdown lies in the development of the seat and the "fatigue" of the metal rod (photo 7).

One of the reasons for the breakdown: the development of a footprint

One of the reasons for the breakdown: the development of a footprint

Breakage of the L-shaped part under the impeller

Breakage of the L-shaped part under the impeller

With prolonged work, it gets jammed, it cannot scroll. Accordingly, the discharge of the waste water is stopped. Such a problem also arises due to a broken L-shaped part located under the impeller in the rod (photo 8).

Because of this, the impeller itself scrolls around the axis. The problem is typical for Samsung brand pump pumps. In any case, the professional masters of the service center recommend replacing the device completely, since the repairs made will only prolong the equipment's performance for a short time.

Check for contamination on and under the stem sleeve

Check for contamination on and under the stem sleeve

If the pump stem is not very worn out, but the device still functions intermittently, it is worth checking for contamination on the stem coupling and under it, as well as on the stuffing box (photo 9).

If found, the mechanism is thoroughly cleaned and washed. After the procedure, check the degree of depletion of the stem. If it is large, it is better to replace the pump. The oil seal must remain in place. Finally, lubricate the stem elements and put the whole mechanism back.

Pay attention to the polarity of the collapsible pumps

Another interesting nuance concerns the polarity of the collapsible pumps. On sale there are models of pumps with poles combined together or separate, located on the back of the pump at the bottom (photo 10).

The latter are separated from each other at a decent distance, so if water drops get into one of the "nests" the second will remain intact. In pumps with combined poles, the electronics fail more often precisely due to the ingress of water on the working elements. In conclusion, it is worth noting that collapsible pumps for washing machines are electromagnetic, so the order of connection to the poles is of no fundamental importance. The device will work correctly in any case.

If you want to buy a new pump for your washing machine, give preference to a quality product from a trusted brand. Remember that Chinese pumps are cheap, but they often break. A typical problem for them is the breakage of the impeller blades.