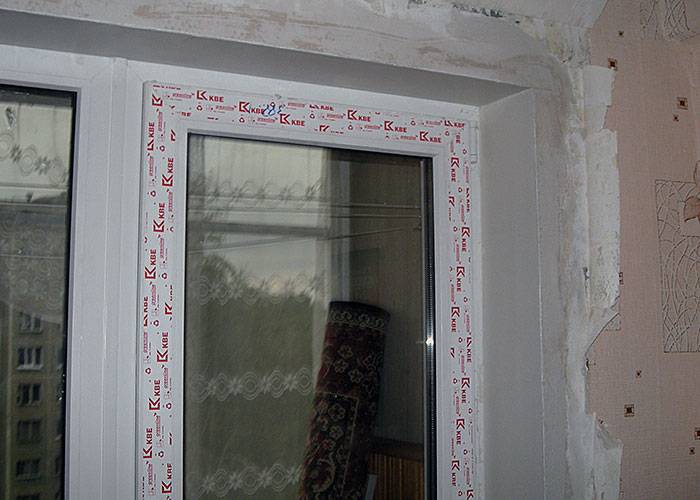

Installation on polyurethane foam

Fastening window slopes to foam

Fastening window slopes to foam

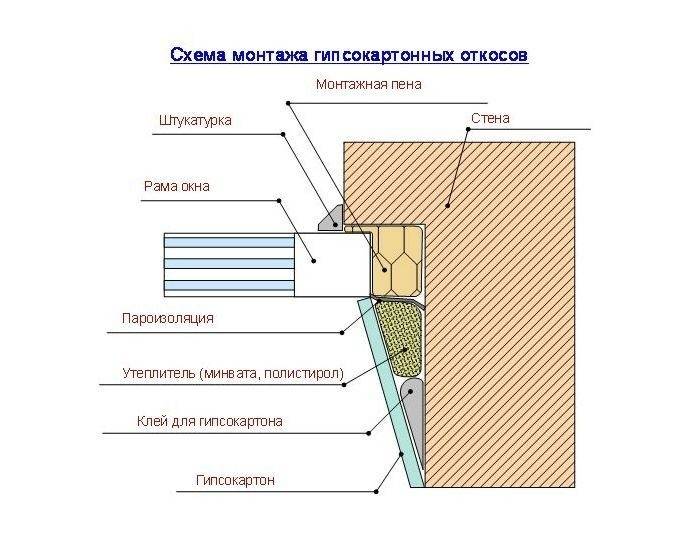

The slope can be closed by fixing the drywall with polyurethane foam. The sealing is very simple, but it is used if there are few defects on the slopes and the pits are small in size, up to 3 cm.With large sizes, the defects must be repaired with foam before installation, the correct method of sealing potholes is using cement mortar or a starting type of plaster. You need to sew like this:

- Dismantle the old coating, plaster and foam residues. Further, large potholes are filled.

- When the pits are dry, the polyurethane foam is applied to the drywall from the back of the material. The layer of foam is not more than 1 cm. The application of the material is done in the form of a snake.

- Plasterboard material is placed on the slope and pressed against it. The pressure on the drywall must be strong so that the foam grabs onto the slope.

- After that, the drywall comes off, and foam remains on the slope and finishing material. After 10 minutes, the foam will increase in size.

- The drywall is re-mounted in the slope and pressed against the wall. If necessary, the material is fixed with spacers and left for up to a day without continuing work.

- The next step is to seal drywall seams on slopes with plaster.

Puttying a window slope

Puttying a window slope

The disadvantages of this design of door and window slopes are quite large. The biggest disadvantage is that the surface must first be leveled, otherwise the drywall sheet will not become. Drywall on slopes can bend during installation. Voids remain on the door / window slope, due to which the fixation is not very reliable. But this is the fastest method for finishing the slopes with plasterboard. When a window or doorway is sewn up with plasterboard, according to any described method, the opening is finished with various materials. But before finishing the slopes, you need to do the following:

- The slope is puttying with a thin layer.

- On the outside of the opening, protection is placed and a corner is formed using a plastic perforated corner, which is closed with putty.

- Another layer of putty is laid in order to finally even out the surface.

- Finishing material is selected.

The painting is not durable, therefore, for the slopes of the part, a panel type of materials is used, for example, plastic for the slopes, instead of drywall, PVC panels and other materials, this is a good material made in accordance with GOST, it is distinguished by its durability. The video shows step by step work with drywall, you can use the method for doors and windows:

Installation technology

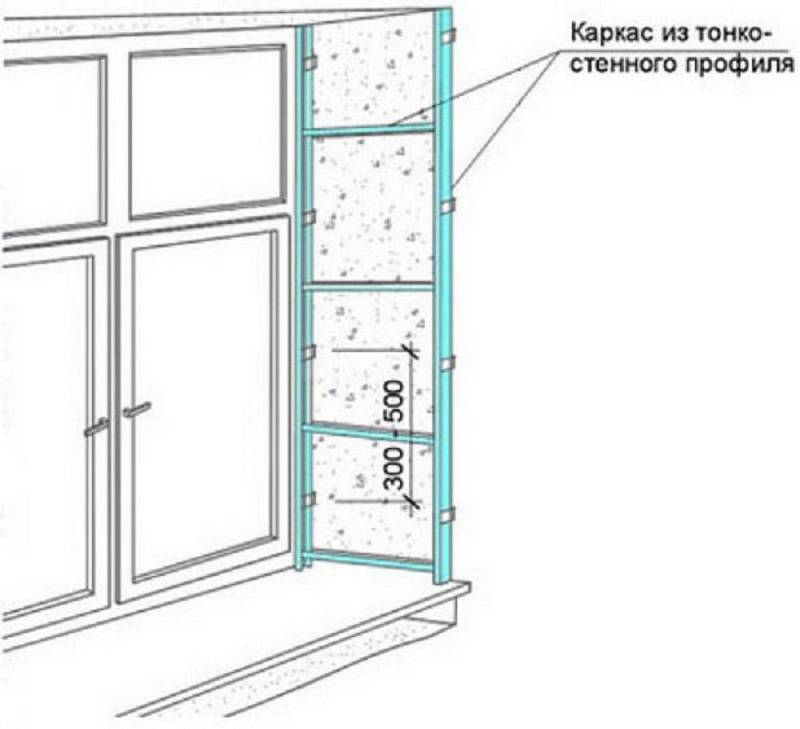

The main difficulty of the technology is that the frame is constructed for a specific window with specific wall defects. If you work according to a template, without taking into account the specifics of the situation, the construction may turn out to be skewed. Therefore, all work should always begin with careful measurements and drawing up.

The creation of the structure should be carried out from the frame to the wall. First, you should make sure that the window structure itself is inserted vertically into the opening, without distortions.

The structure of the frame must be rigid enough so that the sheet does not "play" under the fingers after installation. Therefore, it is worthwhile to determine the number of jumpers in advance. You will need one in each plane at the corners, and jumpers in the middle of the plane are placed as needed, depending on the width of the slope.

Read the series of articles on drywall: Drywall: types, properties, installationCircular drywall wallHow to level the walls with drywallInstallation of drywall partitions indoors

General requirements for window slopes

The slope is considered to be the outer or inner part of the window opening, which is created due to the difference in the thickness of the wall and the window frame.

Slopes give the windows an attractive appearance, and also protect the room from cold and dampness

In order to decide in what way you will trim the slopes (it does not matter for wooden or plastic windows), you need to take into account the following conditions:

- the surface of the slope must have good resistance to weather conditions and mechanical stress, i.e. not flake off over time, not get wet, not change color under the influence of moisture and sunlight;

- have good thermal insulation, which will prevent the formation of condensate on the surface of the slopes;

- slopes must have good steam and moisture resistance in order to ensure high operational properties of the assembly seam, which is achieved by installing windows in compliance with all the requirements of GOST;

- the surface of the slopes must be resistant to wet cleaning and cleaning so that the outer surface does not delaminate and does not appear on it.

Often, after installing windows, apartment owners ask the question: Is it necessary to finish the slopes? There can be only one answer: you cannot leave the windows for a long time in the form that remained after the work of the installers. And it's not just a bad aesthetic appearance. There are at least two reasons to make window slopes:

1. Mounting foam, which is used when installing windows, gradually deteriorates during operation under the influence of sunlight. In addition, during hardening, the foam increases by 5–10% in volume, that is, it squeezes itself, as it were. This leads to the formation of a gap between the frame and the foam, therefore, the heat resistance is reduced.

Installation foam, which fills the voids between the opening and the window frame, needs protection

Installation foam, which fills the voids between the opening and the window frame, needs protection

2. Foam is not a waterproofing material, it collects moisture, which, if frozen, can damage the integrity of the material. Therefore, the foam must be immediately protected from negative influences.

Stage five. Installing sheets or how to make drywall slopes

When the solution is ready, they proceed to the installation of blanks in the window opening. To do this, on the reverse side of the mounted sheet, an adhesive composition is applied with tubercles up to 100 mm high and 100-150 mm in diameter. Moreover, the step of the location of these bloopers is taken equal to 250-300mm.

Then the panel (first, the top one) with the applied solution is installed in the opening and pressed against the base plane until the marks on the side walls correspond to the level of inclination of the sheet. Excess material, squeezed out, is leveled with a spatula along the end of the slope. The side panels of the structure are mounted in the same way.

When performing these works, a number of recommendations should be followed:

- Perform work together (while one is holding the top panel, the second is installing the side ones);

- Check the correct installation of the panels by visual inspection, or using a level or plumb line;

- After the glue has previously hardened (15-20 minutes), fill all the voids between the drywall and the base plane with the same composition.

Installation of plasterboard elements

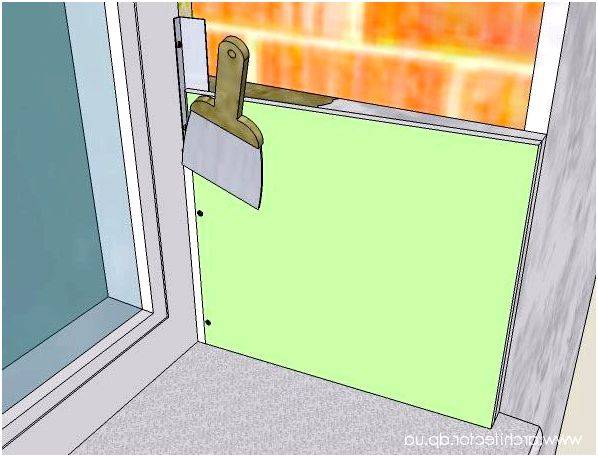

From a whole sheet of drywall, which you have already smeared with a primer and allowed to dry, you need to cut off the upper part of the slopes. When you cut out a piece of drywall that matches the parameters you calculated that you indicated in the diagram, you can start installing it. Check all length and width parameters carefully before cutting the part. No need to waste extra drywall.

Transfer all the calculated dimensions to the plasterboard immediately. Use a regular ruler and pencil for this. You cannot start cutting without marking the cutting line in advance.

Use a construction knife to cut the top part straight along the lines you have drawn.To do this, attach a ruler to the lines and cut the cardboard along it on one side. Then, with a light blow of your fist from the back of the cut, break through the drywall, as if bending it along the line of the cut.

Before installing the cut-out part, check that you have all the necessary materials and tools.

Level plank

It is important that it is the same length as the panel you are going to install;

Putty knife. It is needed to apply and distribute the mixture over the surface;

Cut drywall board;

Glue.

Now let's start applying the glue. It is best to apply it around the perimeter, and also make several separate islands of the mixture in the center of the plate. Thus, the plate will be fixed much better, because the edges will be securely fixed, and the glue located in the center will be evenly distributed over the void under the drywall.

Once you've applied the glue, you can secure it. This is not an easy matter and not because it requires physical effort. It is necessary to install the plate evenly so that it coincides with the intended drawing.

The slope must be strictly horizontal. In order to achieve this, you need to check its location after installation. This is done using a level in two directions. But this technology is applicable only to the upper part of the slope.

If it becomes necessary to bring a certain area closer to the wall, then you can lightly hit the drywall. This is unlikely to hurt him unless you apply too much force. However, you should not pull the part back. This is fraught with serious consequences. Drywall can simply crack. Based on this, it is more advisable to apply a little more mixture. The excess substance can then be simply distributed by filling the empty space.

Craftsmen often additionally secure the upper part of the slope with dowels or create various supports to fix the angle in a suitable position, but this is not urgently necessary. The slope can easily be held due to surface tension alone. It will not allow the drywall to move in space.

As soon as the glue mixture that holds the top plate hardens, you can proceed to the installation of the side slopes. The side panels are mounted in exactly the same way as the top. Cut out the desired shape and size from a primed drywall sheet. Mix the adhesive mixture and apply it to the joints using the same technology. Install the plasterboard part in the desired location so that it matches the intended drawing. Using a spirit level, adjust the panel to the desired location indicated by the marking lines. However, this time, the level check is different. The difference is that the check is carried out with a level only vertically in one direction.

Then comes a very crucial moment. Wait for the glue mixture to completely harden. After that, take the same mixture and coat all the cracks in the drywall structure. This is a very important and necessary step.

After the design of the slopes has been completely mounted, you can proceed to putty the surface of the drywall. Putty is the final stage of installation of any plasterboard structure. If you are going to make slopes with your own hands, you cannot do without it.

After you have carefully plastered the slopes, the work can be considered finished. However, this is not all. Although the structure is made up, and the room is protected from the cold outside, the window remains in an extremely unpresentable form. Therefore, it needs finishing. In order to prepare the slope for cosmetic finishing, it is lubricated with a finishing putty. Only then can you start painting or any other type of finish.

Preparation for work

Before installing drywall slopes, you need to prepare a workplace - free up the area near the window. If there is furniture in the room, then it should be covered with polyethylene to protect it from dirt, dust and moisture. Drywall work is a "wet" type of work.

Slopes for entrance doors with plasterboard, like window doors, can be mounted in several ways - using glue, foam, putty or a metal frame.

When fixing elements to the wall surface, an adhesive mixture based on gypsum is used, followed by coating with a finishing putty.

Polyurethane foam

This material is used to securely fix the window structure and to protect the assembly seam from moisture from the street. The device of drywall slopes is performed to protect the polyurethane foam from moisture and sunlight, as this leads to its destruction and loss of performance.

Excess construction foam is removed with a clerical knife

Excess construction foam is removed with a clerical knife

Due to its expandability, the foam can protrude beyond the boundaries of the assembly seam. Before installing slopes on drywall windows with your own hands, you need to cut off excess foam using a clerical or construction knife.

Measurement

In order to make high-quality slopes on the door with your own hands, you need to remove the exact dimensions and cut out the details in accordance with them. In this case, it is necessary to take into account the need to create allowances, since adjustments may be required in the process of work.

When measuring the niche of a window opening, the slope is taken into account, so the height is measured twice - near the window and near the wall.

Surface preparation

To ensure maximum adhesion of the adhesive to the surface, it is necessary to thoroughly clean the base from dirt, dust and fragile finish, which crumbles with minor mechanical stress.

After cleaning the surface with a brush or brush, wash it with water to maximize dust removal

In this case, it is important to remove the old plaster layer or paintwork. In case of significant violation of the integrity of the wall in the window niche, it must be restored and leveled

Before installing drywall on slopes, it is necessary to clean the surface

Before installing drywall on slopes, it is necessary to clean the surface

Finishing window slopes at the leveling stage can be done with ordinary putty.

If the installation of drywall slopes is carried out using a metal frame, then with minor surface errors, alignment can be omitted. The main thing is to remove the damaged plaster layer.

Before making the slopes, the surface must be treated with a primer with antiseptic additives to avoid the appearance of mold and mildew. It is necessary that the slopes dry out.

Antiseptic primer prevents mold on slopes

Antiseptic primer prevents mold on slopes

The plasterboard slope should be fixed with glue perpendicular to the plane of the window. Fixing the slopes of plastic windows on the walls is carried out in compliance with their exact horizontal and vertical position. Therefore, before installing drywall slopes on windows, it is necessary to indicate their location using a marker and a corner.

The place of installation of the future slope is marked with a marker or pencil

The place of installation of the future slope is marked with a marker or pencil

Instruments

From the tools, you will need to prepare drywall, glue, a primer, fasteners in the form of self-tapping screws, materials for thermal insulation, a small spatula, a screwdriver, rags and a container for water, foam and a profile. You will also need metal scissors, a level and a tape measure.

How to cut drywall

If it is necessary to cut off part of the drywall in a straight line, then draw it along the marked line with the edge of a sharp clerical knife. Then lightly tap on the surface of the sheet, attaching a meter ruler to the line. As a result, the drywall breaks off along the notch line, leaving the board to be cut on the other side.

The panels are cut with a clerical knife.

The panels are cut with a clerical knife.

If you need to cut out a curly element, then use a hacksaw for metal with small teeth. Using an electric jigsaw can speed up the work, but you need to be prepared for a lot of dust.

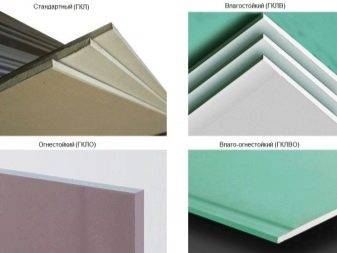

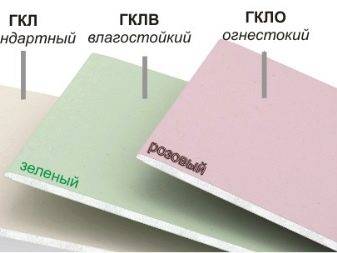

For the device of slopes on windows and for interior doors, it is necessary to use gypsum plasterboard of the GKLV brand.

Features of drywall

Usually, the design of slopes with plasterboard is chosen by people who want to carry out repairs on their own without the involvement of experienced specialists. The result is an aesthetic appearance of a sloped window. This is due to some of the advantages of GCR.

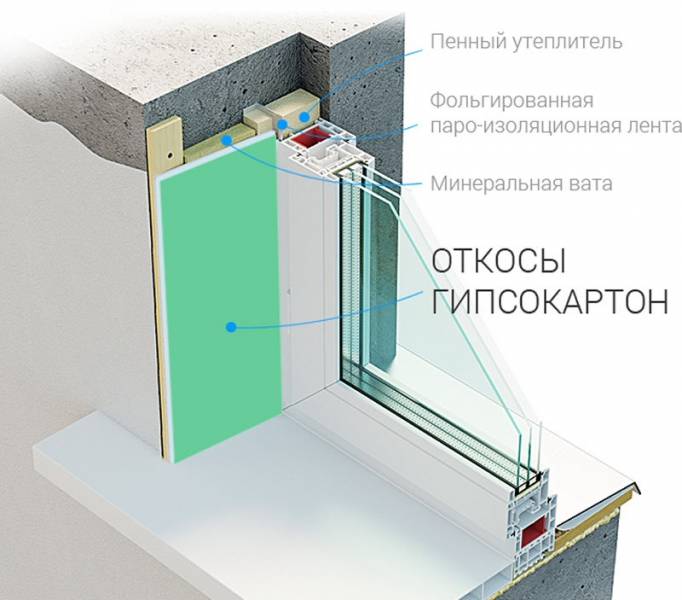

- Thermal and sound insulation properties. If you want to additionally insulate the room, you can install double slopes with special insulating material.

- Light weight, which allows you to make only the frame for installation without additional reinforcement.

- A perfectly flat surface when using sheets of gypsum board contributes to an accelerated finish.

- The ability of drywall to "breathe", that is, when temperature drops or changes in humidity levels, there is no need to fear deformation of the sheets.

- Environmental Safety. Even in combination with other additives, slopes do not emit harmful gases into the environment.

- As a result of the work, minimal waste is obtained.

However, one should also take into account the disadvantages of the material during installation work:

- it is necessary to carefully handle drywall during repairs, to avoid any damage;

- it is necessary to additionally protect the surface from high humidity, since even moisture-resistant material will become vulnerable after a while when exposed to moisture.

Depending on the room where you want to install the slopes, choose a material from a certain type:

- with an average level of humidity in the room (up to 70%), standard drywall is suitable;

- in conditions where the humidity is more than 70%, gypsum boards with antifungal and hydrophobic additives are used;

- in conditions of increased fire hazard, gypsum boards with additives such as fiberglass and mineral wool are suitable, this option is used extremely rarely, but its equally important advantage is its high strength to mechanical stress.

Preparatory activities

Take all measurements first. In the process of preparing sheets of material for the design of slopes, leave small allowances.

Measurements

Regardless of the chosen method of finishing the slopes with plasterboard, carry out preliminary preparation of the surface to be decorated. Be sure to remove the existing plaster coat.

Remove old plaster

In the case of using the gluing method, the surface must be carefully leveled. To do this, you can use an ordinary putty.

Leveling the Slope Surface

When using the wireframe method, pre-alignment can be dispensed with in most cases. It is enough just to get rid of the crumbling areas of the plaster coating.

Treat the base with an antifungal agent.

Antifungal primer

After completing all the preliminary activities, you can proceed directly to the fastening of drywall sheets according to the selected method.

Plastic slopes

On sale there are special plastic panels for finishing slopes. This method is even easier than installing plasterboard slopes. Plastic slopes are undemanding to maintain, moisture resistant and durable. There are panels in various colors.

There are several types of such slopes:

- made of foamed PVC;

- made of plasterboard-based plastic;

- sandwich panels.

On the rough surface, fit the guide rail at the window frame. Fix the plastic slope in it. The opposite side is attached to the outer corner or also to the profile.

An additional plastic panel is installed for corner decoration. Thus, conventional plastic slopes and models with a plasterboard base are installed.

Installation instructions for gypsum board slopes

Elements cut from drywall can be installed:

- on polyurethane foam;

- on putty;

- on the frame.

On polyurethane foam

Anyone can "glue" drywall to foam

It is very easy to fix the cut-out sheets on the polyurethane foam. But this can be done immediately if there are no large holes on the slopes. If the depressions are up to 3 cm, you can install the slopes immediately, only the largest potholes should be pre-filled with foam (do not apply much, about 1/3 of the volume of the excavation).

If irregularities are deeper than 3 cm, it is better to pre-seal them with cement mortar or a compound for starting plaster.

The procedure for installing drywall door slopes on mounting foam is as follows:

- Having prepared the site (removing dust and falling off pieces, filling too large recesses with foam), apply polyurethane foam to the back of the drywall blank with a thin (1 cm no more) snake.

- Install the element in place, press it against the wall, the way this fragment should stand.

- Tear it off and set it aside for 5-8 minutes. The foam remained both on the wall and on the drywall sheet. In a few minutes, it increases in volume.

- Set part of the slope in place and press well. Leave in this state until the foam is completely hardened (for 12-24 hours).

- Fill up the gaps between the plasterboard elements and the wall with plaster.

The slope is made of plasterboard, finishing work remains.

The disadvantages of this method are quite serious. Firstly, the side and vertical surfaces must be leveled beforehand, otherwise you will not be able to align the elements. Secondly, there is a possibility that the workpiece will bend / bend. Third, there are voids. Well, and the most important thing is that the mount is not the most reliable. But the door slopes are made simply and quickly.

On putty

Instead of polyurethane foam, you can "glue" the cut fragments onto the diluted putty:

- On the sheets, cakes are applied from a composition diluted to a paste state for working with drywall (better - finishing, it is more "sticky"). They should be located around the perimeter and here and there in the middle.

- Spray the slope cleaned of dust and cracked old plaster with water from a spray bottle.

- Place the workpiece in place and press it well. You can rest your palms on the plane and "shake" the fragment from side to side. Feel that the plaster has begun to blur and the piece of drywall is stuck.

- If the fragment is tight and does not move, you can leave it until the putty seizes (for a day, sometimes two). If the element is not held firmly and can move, it needs to be supported with something. Preferably around the edges and in the middle. Leave in this form for at least 10-12 hours. Then the props can be removed and the putty is completely dry.

The methods of applying "patches" from the putty can be different. The main thing is that the element holds well.

The disadvantages of this method are the same. It is only necessary to say that the slopes on the windows in our apartment are made in this way. It was already 9 years ago, and so far - no problems.

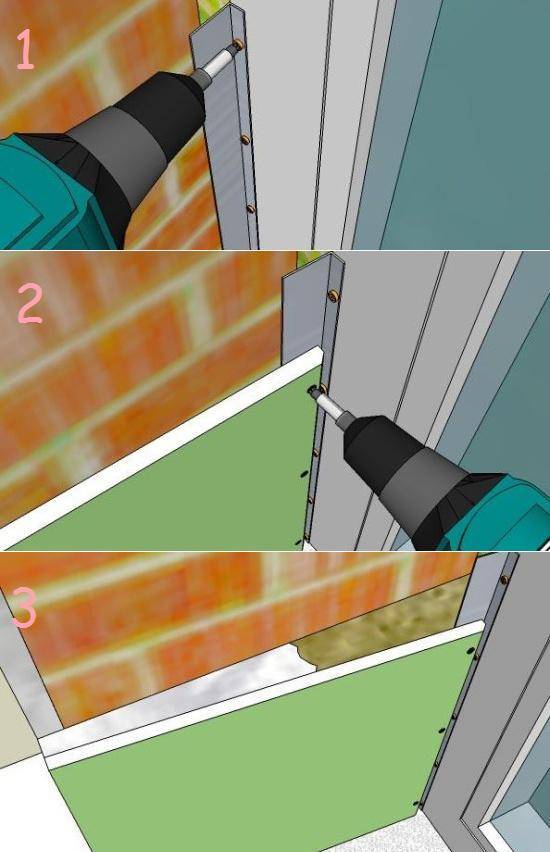

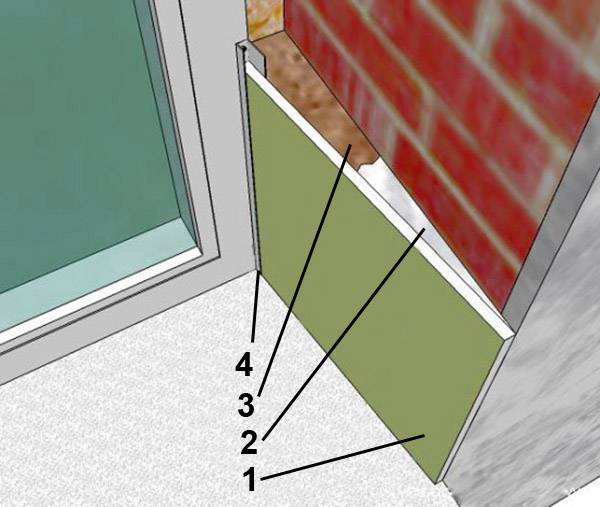

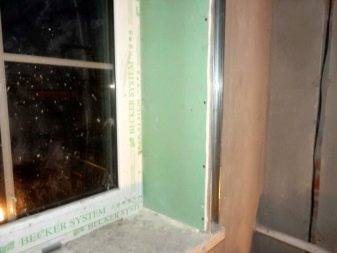

On the frame

A more laborious, but also more reliable and versatile method of installing drywall slopes is on the assembled frame. The frame is made of wooden blocks or special profiles.

The guides are positioned vertically along the doorframe and at the corner. Small transverse jumpers are placed between them, at a distance of 50-70 cm.

To install drywall slopes with your own hands, the frame is first assembled. It can be made from profiles or wooden blocks.

With this method, there is one feature: measurements are taken after the frame has been installed. The cut parts are put in place and secured with self-tapping screws.

If the frame is assembled from profiles, self-tapping screws are needed for metal, if from bars - for wood

In any case, you need to twist carefully: so as not to tear the cardboard.If overtightened, the plaster may even burst or crumble.

A large number of rejects of this kind will lead to the fact that the drywall slope will not adhere well.

Preparatory work

The reliability of the fastening and the durability of the entire structure depend on the quality of surface preparation. At this stage, it is necessary to lay communications (mainly wires) under the future structure. You will also need to remove excess polyurethane foam on which the window is attached, seal the cracks with putty and remove traces of mold. After that, you need to clean the opening of debris.

Taking measurements of the window

To make the structure as flat as possible, for this, using a metal square, you need to measure the distance from the window to the wall. The procedure is recommended to be carried out along the entire perimeter, marking the length at each of the corners and in the center at the top and bottom.

Plasterboard sheets should be adjacent to the window. That is, it is necessary to ensure the coincidence of the planes of the slopes and the plastic frame. To do this, on the window sill and window, you need to apply the appropriate marks along which the drywall sheets will be installed.

Preliminary surface preparation

At this stage, it is necessary to remove foam and debris that interfere with the installation of slopes. You should also apply a coat of primer to prevent future mold growth. Without the last procedure, after a few years, you will have to break the structure and re-treat the surface. The primer is also recommended to be applied to the back surface of drywall sheets.

Removing the plaster layer

Installation of slopes is recommended to be carried out on "clean" walls. That is, the metal frame, on which the gypsum plasterboards are fixed, should be installed on a surface previously cleaned of plaster. This procedure is due to the fact that the cement mixture collapses over time, which in the future will lead to a violation of the integrity of the slopes. The plaster layer is removed with a hammer and other tools such as a chisel.

Leveling and filling

Before installing the slopes, it is necessary to close up the defects of the walls, which can become "bridges" of cold. In winter, frost penetrates the apartment through similar holes in the walls. To seal such defects, ordinary putty is used.

Leveling the surface is necessary in cases where drywall is attached to an adhesive or polyurethane foam. This step can be neglected if the work is carried out using a metal profile. However, the frame itself also needs to be aligned to the building level.

Material selection criteria: PVC, plaster, drywall

What to make the slopes from the inside of the room, what are the options?

Sometimes the choice still depends on the initial data, for example, for a reinforced concrete opening, it is plastic materials that will be most suitable, since the concrete itself easily accumulates and retains moisture. Or a very poor quality of brick laying, which is often observed in "Khrushchevs" - sometimes there is almost through blowing of the wall, and freezing in general is quite common. Moreover, quite often all this has already been eliminated by the repair of premises and there are no obvious signs. It is here that the danger lies in wait - drafts in the openings, which should be eliminated. And for an additional effect, the slopes are made of insulated plastic.

Of course, you can turn to the masters. But if you decide to make the slopes of plastic windows with your own hands, then by and large it all depends on your preferences and skills in working with materials. The main conditions: high-quality preparation of the opening - elimination of all cracks, and competent installation of a window with a window sill

After that, it is no longer important how to arrange the slopes, any material convenient for you will provide a good result. And there are few technologies for the device of slopes: plastering and finishing with sheet materials

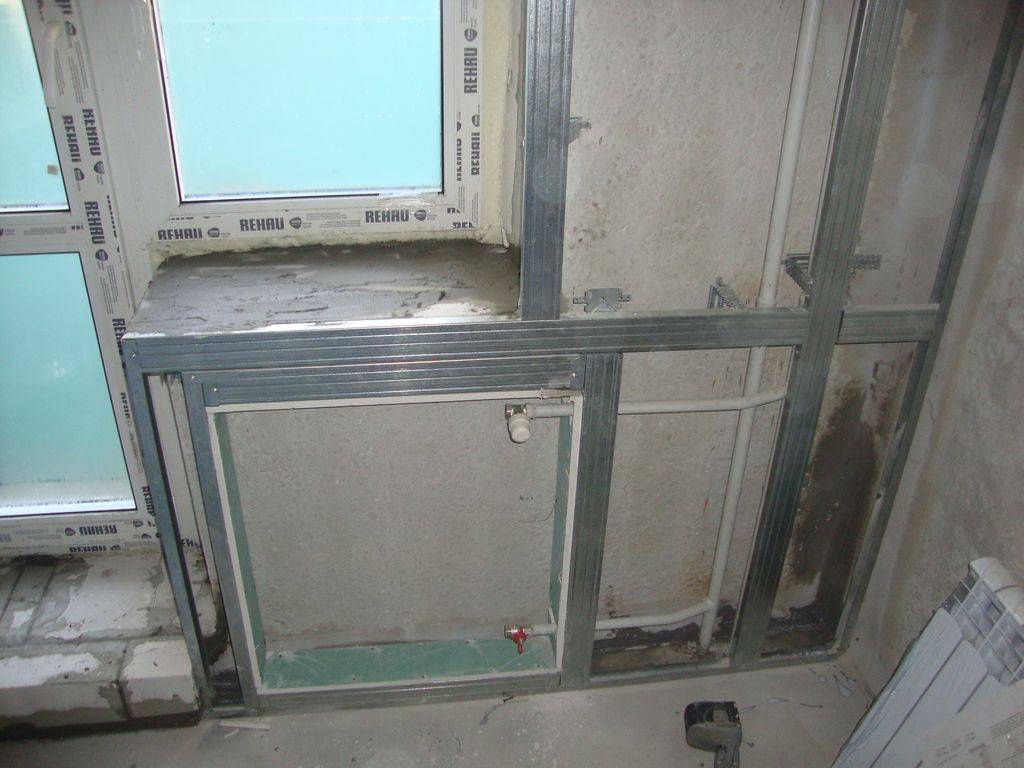

Installation of slopes on a frame made of profiles

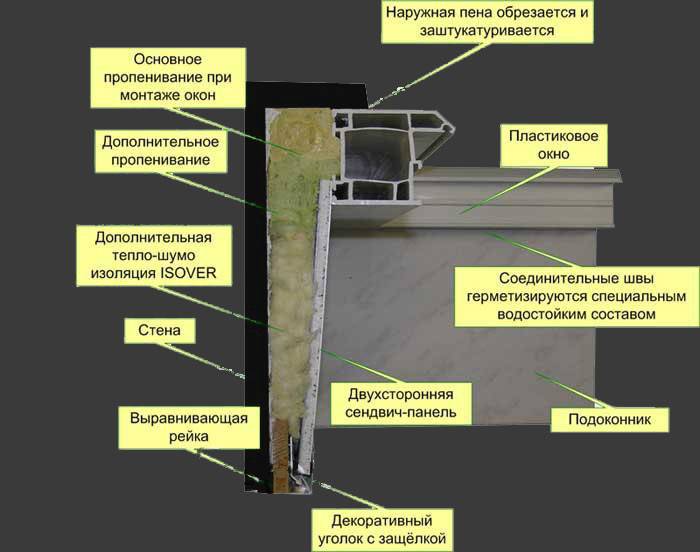

Modern models of plastic windows in most cases are made on the basis of frames, structurally providing for the installation of a special profile for fixing slopes. In this case, it is enough just not to forget about this profile when buying a window, install it in the corresponding groove on the frame and insert the slope cut out of the drywall sheet in advance. The technology for cutting out slopes from a solid sheet of drywall in this case will not differ in any way from the one discussed just above.

If the design of the window frame does not provide for the possibility of using profiles for slopes, then it is not difficult to make them yourself. As a basis, you can use galvanized or plastic L-shaped profiles. These profiles should be screwed to the inside of the window frame along the lines along which the slopes will be in contact with the window.

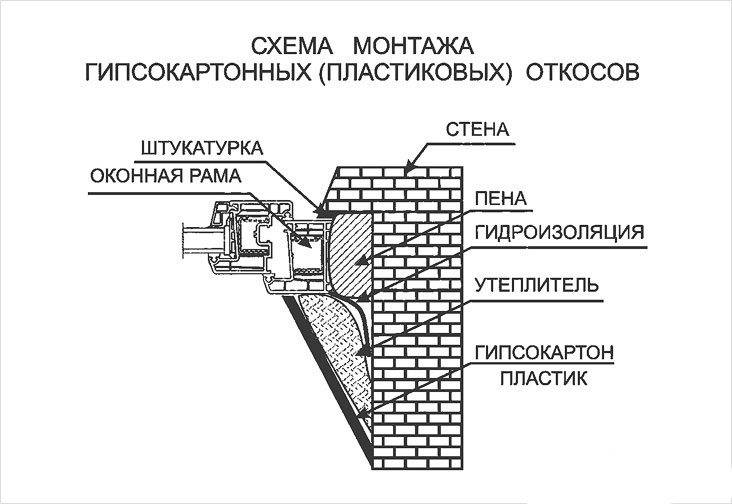

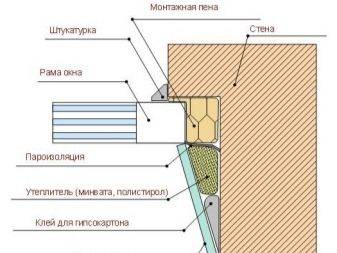

Scheme of mounting slopes on a frame made of profiles

Along the outer edges, the plasterboard slope is attached to the edge of the wall either with self-tapping screws or by means of glue, which depends on the type of walls, the type of surrounding finish, and other similar factors. It should be borne in mind that before the final fixation of the slope, it will be necessary to fill with foam all the cavities formed between it and the surface of the window opening.