Determining the error code in a car without a display

Manufacturers produce various models of washing machines, some of them are not equipped with a special display for displaying information about the state of the unit. The presence of a display greatly simplifies the diagnostic process.

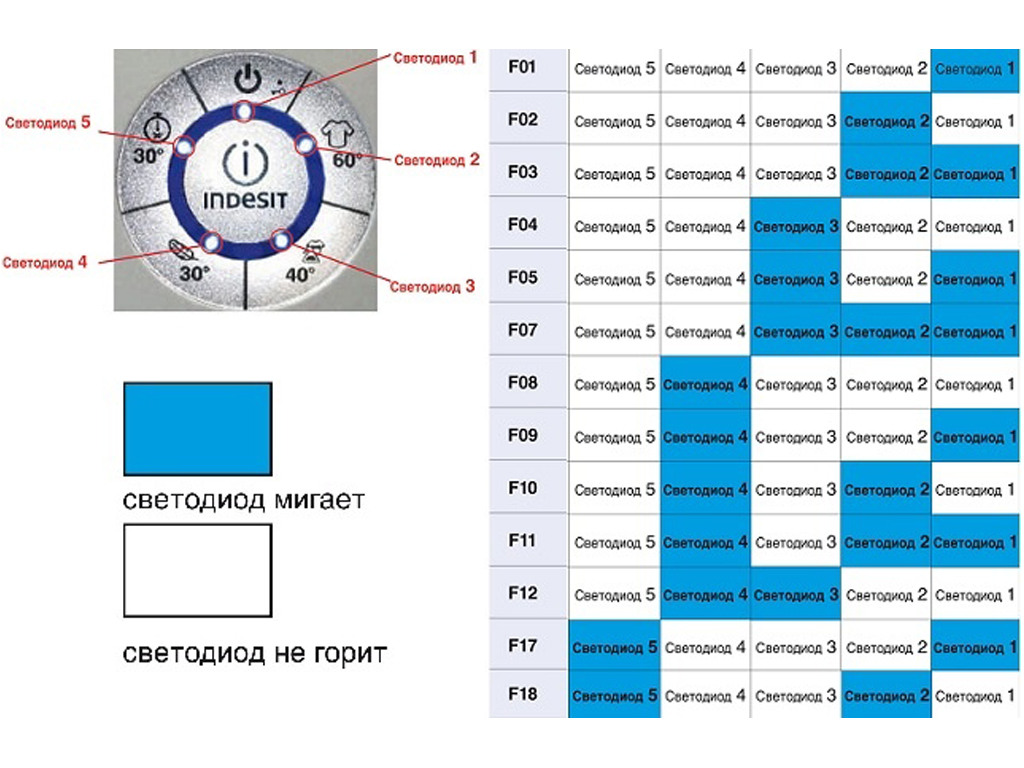

Units without a display are also capable of performing a self-diagnosis process. In this case, the LED indicators located next to the function buttons flicker.

To start the testing process on machines without a display, it is necessary to perform several preparatory operations:

- Completely remove water from the washing machine tank.

- The wash mode switch is set to off.

- The special button for additional functions must be pressed and held.

- Next, set the wash program switch to the first position.

- After five seconds, all LEDs on the machine panel should light up.

- After the lights come on, release the button for additional functions and press "Start".

The number of blinks of the indicators (before the pause) indicates the nature of the malfunction of the washing machine. Having counted the lights up, it is easy to determine the error code. So, if there were three fires before the pause, then this indicates the presence of an error E03 in the Candy washing machine.

Errors in the system that you can fix yourself

If a breakdown occurs during operation, the Kandy washing machine will inform the owner in one of two possible ways:

- If the display is present, the Activa technician will display an error in the form of a digital code.

- There is no display in Aquamatic models, the machine will inform you about the malfunction using a blinking light on the front panel. By the number of times the light flashes, you can judge the malfunction that befell your washing machine.

Error code E01

The unit cannot lock the door closed before starting washing. The appearance of the E01 error on the vehicle display may be the result of a loosely closed hatch. The first step is to check if the clothes are stuck in the gap. If this is not the problem, the door lock may have broken. It is also necessary to inspect the wiring for integrity. It is also possible that the electronic controller does not work.

E02 code

Water intake error. By the appearance of such a code on the display, the machine notifies that, after a set time, its level is below or above the nominal mark.

If the problem was not found, then, most likely, the filling valve, which is responsible for taking water in the required quantities, has failed. Perhaps the code was highlighted due to a malfunction or an electronic controller.

Error E03

Indicates that water is drained from the drum very slowly, which does not meet the technical requirements (more than 3 minutes), or does not drain at all.

It is necessary to inspect the hose and make sure that it is not pinched or clogged anywhere, and that the drain filter and siphon are not clogged with scale. It is likely that the problem is caused by a faulty drain pump or pressure switch.

Be careful, as some of the errors displayed on the display arise through the fault of the owners of the equipment.

- If, check, there may be a complete power outage in the whole house, or you did not insert the plug into the outlet.

- Water is not poured into the drum, because the delayed start mode is set by mistake.

- much stronger than usual. Probably, the vibration is caused by the imbalance of the unit relative to the floor surface, or the laundry is unevenly placed in the tank during the rinsing process.

- The appearance of copious foam can be associated with the use of detergent for hand washing.

- At the end of the working cycle, the technician does not drain the water and does not squeeze out - it is possible, due to inattention, the mode "without draining the water", "light ironing", "without spinning" is set.

- All indicators are on or blinking - this may be due to a malfunction of the equipment. Reboot the machine by turning it off for a couple of minutes and then turning it back on.

Washing machine engine tachogenerator

A small remark. Attempts to restart the car were unsuccessful. Water is poured and drained, only the drum does not spin, since the engine does not start.

To diagnose a tachometer generator, you can, in principle, not remove the engine, but only throw off the contacts with the loop. But since.

the reaction of the washing machine was a little embarrassing, it was decided to carry out a full engine diagnostics. And she worried because if the tachogenerator malfunctioned, the motor had to try to start, which did not happen.

So, when ringing, it turned out that the resistance of the tachometer is 45 ohms - this corresponds to the norm. It does not penetrate the body, and when the motor shaft is cranking, it produces a constant voltage of about 0.2-0.

4 volts. What's the matter? Is the machine giving an error code incorrectly?

The engine has been completely checked. Rotor and stator resistance is normal. No leaks were found on the hull. Turn-to-turn short circuit in the motor windings was not found.

Top-loading washer

Let's start with an example of a Kandy washing machine. She has a rare self-diagnosis system, which includes the code E16 of interest to us - the Candy CTD8766 washing machine. This is a pretty stylish top-loading machine with electronic controls, a simple backlit display and a maximum load of 6 kg.

How does the E16 code stand for such a washing machine? Literally decoding sounds like this: "... there was a short circuit in the heating element circuit ...". What does it mean?

- The heating element of the washing machine simply burned out due to scale or short circuit.

- The wiring is burned out or the contacts are oxidized, due to which the heating element does not receive power.

- The triac of the control board, which is responsible for the heating element, is out of order.

In rare cases, a short-term failure in the control board can cause such an error. You can fix this failure by restarting the washing machine. If disabling and re-enabling the home assistant did not help, you will have to resort to repairs, the nuances of which we will talk about a little later.

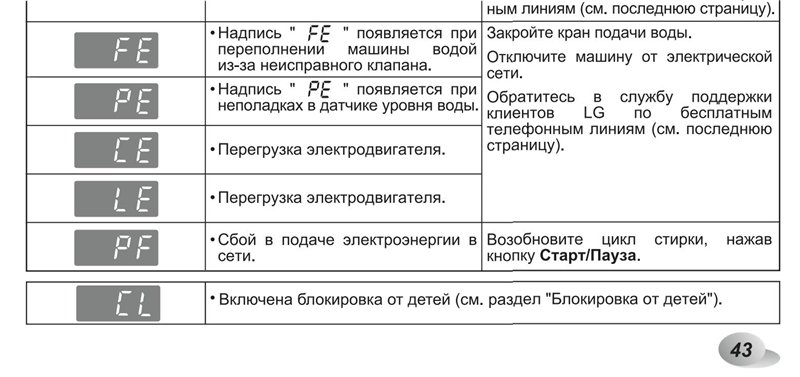

On washing machines of the Aquamatic series

Washing machine Candy Aquamatic series, of course, will not show you the code E16, since this washing machine does not have a display. And those Aquamatics that have a display also cannot show this code, since it is not built into their self-diagnosis system. However, non-display Candy Aquamatic displays error 16, which is similar in nature to error E16.

Error 16 is also deciphered, a heating element malfunction (short circuit, open circuit, insulation damage), but it is not so easy to recognize this code. To determine this or that error on the Candy washing machine without a display, you need to count the number of flashes of the special indicator, which is located in the lower left corner of the machine's control panel near the toggle switch. If the washing machine stops working and the indicator flashes 16 times, this means that the machine is displaying error 16.

How do I fix the error?

To eliminate the E16 error on top-loading washers, you will first have to check the heating element and the electrical communications that fit it. First, as usual, you will need to open the case and inspect the part of interest visually, and then check it with a special device - a multimeter. So, let's do the following.

- Disconnect the washing machine from the water supply, sewerage and electricity, then push it out and turn it to its right side.

- We unscrew the two self-tapping screws that hold the right side wall of the machine, and then remove this wall to the side.

- Next to the large pulley at the bottom of the tank, we see the contacts of the heating element, to which the bundle of wires fits, however, working with the heating element is inconvenient, since the drive belt interferes. With one light movement, pull the belt off the pulleys.

- We take pictures of the location of the wires so that later we do not forget how to connect them.

- We remove the wires and inspect them, as well as the contacts for melting or oxide.

- We measure the resistance of the heating element with a multimeter.

- We take out the old heating element and put a new one in its place.

- Putting the machine back and connecting it to communications - you can check!

Candy of the Aquamatic series is repaired in about the same way, only in order to get to the heating element, you will have to remove not the side wall, but the back one. If you are interested in other malfunctions of washing machines of this brand, read the publication Kandy Washing Machine Error Codes.

In conclusion, we note that a rather rare error E16, nevertheless, can spoil a lot of blood for the owners of Candy washing machines, especially when you consider that it is rather difficult to find its decryption on the Internet. But we tried to rectify the situation by writing this short article, we hope the information it contains will be useful. Happy renovation!

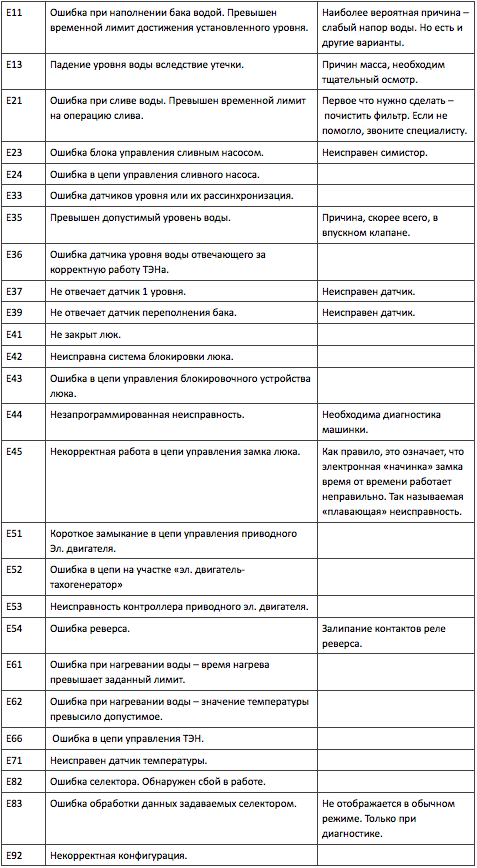

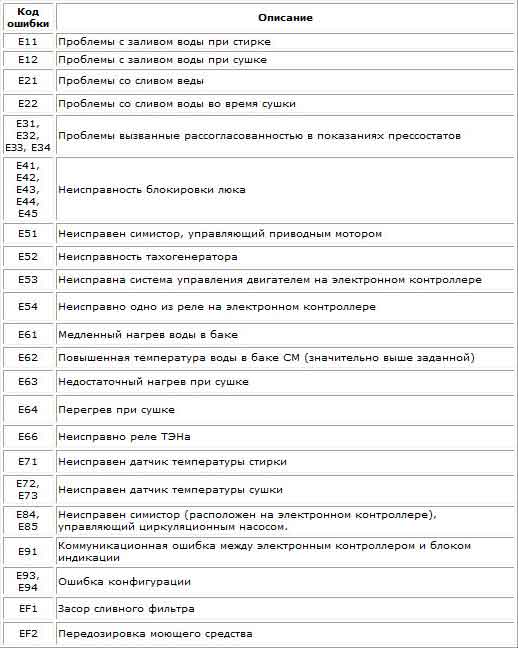

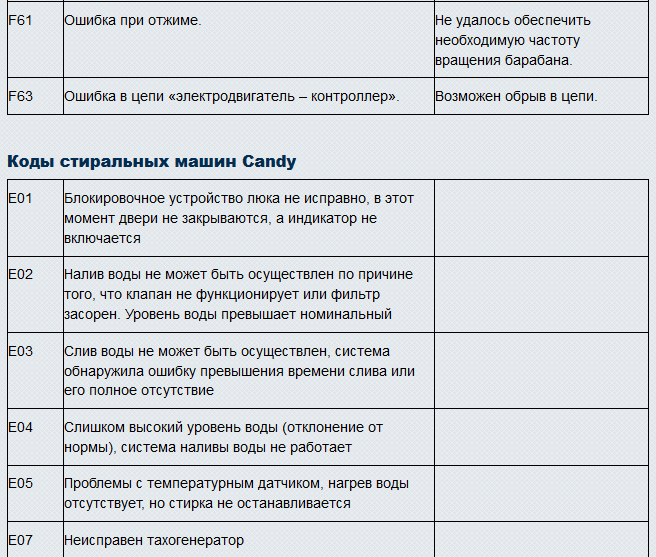

Error codes

Washing machines with display

|

Code |

What does |

What happens to the typewriter |

Reasons for the error |

What to do |

|

E01 |

The problem with blocking the hatch |

The door is not locked and there is no button indication. |

The blocking device does not work or there are malfunctions in the operation of the electrical controller. Wiring failure is also possible. |

Check the sunroof lock and wiring, and then examine the electrical controller. Repair or replace non-working parts. |

|

E02 |

Water overflow problem |

Water is not poured into the machine at all, or its level does not reach the required parameters in 210 seconds. Also, this error is displayed when the water level is very high, which does not allow the command to be executed. |

Inlet valve not working. The electrical controller has ceased to function. Clogged inlet strainer. The pressure switch stopped working or there was a leak in its pipes. |

Check the condition of the valve, the function of the pressure switch and the functionality of the controller. If necessary, clean the filter in the filling system. |

|

E03 |

Water drainage problem |

The water does not drain at all, or it is discharged from the machine for more than three minutes. |

The drain pump does not work or contacts in its circuits are broken. The pressure switch has become unusable. The drain line is clogged. |

Check the pipes and hoses of the drain system, as well as the pump and water level sensor. Replace defective parts with working ones. |

|

E04 |

Filler valve problem |

The volume of water inside the tank is higher than the required parameters, as a result of which the pressure switch signals the overflow of the tank. |

The filler valve has broken (it remains open all the time) or the electrical controller is damaged (often the triac is to blame for the malfunction). |

Check the triac and the bay valve by repairing them or replacing them with serviceable parts. |

|

E05 |

Water heating problem |

The water does not heat up. |

The temperature sensor, electrical controller or heating element does not work. The motor of the program selector is out of order or the circuits of the control unit are broken. |

Evaluate the performance of the heater, measure the resistance of the temperature sensor and the motor of the program selector. It is also worth checking the electrical circuits and the performance of the controller. Replace defective parts with new ones. |

|

E07 |

Engine problem |

The engine spins quickly and sharply. After three attempts to start it at the maximum speed, the wash stops. |

The tachogenerator does not work (most often the problem lies in its core). |

Check the resistance of the tachogenerator winding, and if it is faulty, replace this unit. |

|

E09 |

Engine problem |

The shaft stops rotating. |

The entire control unit does not work or the triac has burned out. |

Assess the operation of the control unit and the condition of the triac, and if faulty parts are identified, replace or repair them. |

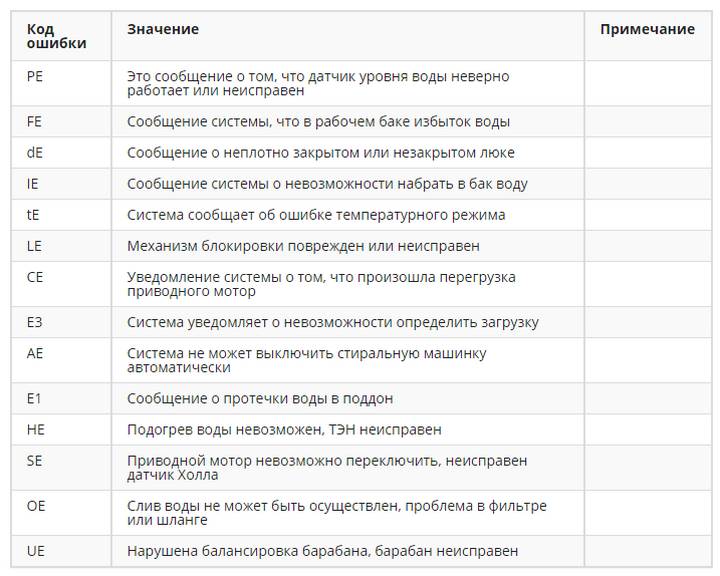

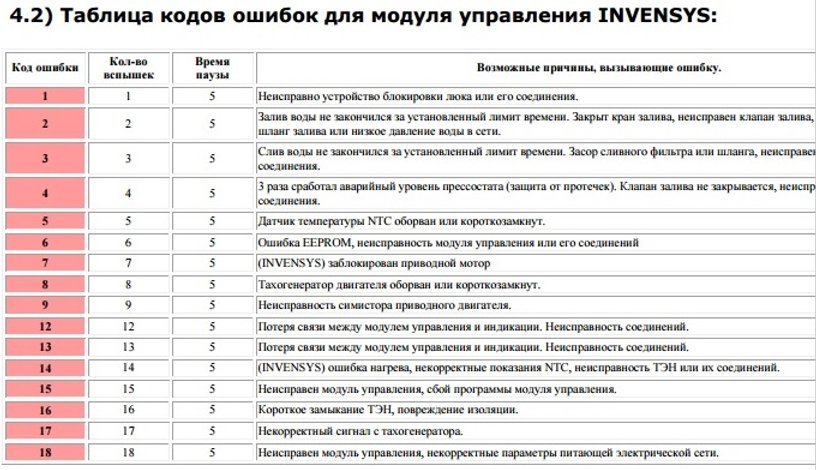

Washing machines without display

In models without a display, errors are determined by the number of flashes of the indicator located at the bottom left:

|

Code (number of flashes) |

What does |

Reasons for the error |

|

The indicator is always on |

Control module problem |

The control module does not work or its program has failed. |

|

1 |

The problem with blocking the hatch |

The interlocking device does not work or there is a wiring fault. |

|

2 |

Problem with filling the machine with water |

The bay valve or pressure switch has become unusable. The inlet hose is dirty or kinked. The water pressure in the pipes is too low. |

|

3 |

Water drainage problem |

The drain pump does not work or the contacts in its circuits are broken. The drain line is clogged. |

|

4 |

Bay valve problem |

The valve has become unusable (does not close). The pressure switch does not work or its wiring is broken. |

|

5 |

Temperature sensor problem |

The sensor has become unusable due to a short circuit or an open circuit. |

|

6 |

EEPROM memory problem |

A memory error has occurred or the Control Unit is not working. |

|

7 |

Engine problem |

A blockage of the drive motor has occurred. The hatch lock is stuck (the hatch is closed). |

|

8 |

Tachogenerator problem |

The tachogenerator has become unusable due to a short circuit or an open circuit. |

|

9 |

Drive motor problem |

The triac burned out. |

|

12 and 13 |

Communication problem |

Lost connections associated with the control unit. |

|

14 |

Control problem |

The Control Unit does not work or its wiring is faulty. |

|

15 |

Control problem |

The control unit is not working or its program has crashed. |

|

16 |

The problem with the heating element |

The heater is damaged due to a short circuit. The insulation is damaged. |

|

17 |

Tachogenerator problem |

The tachogenerator transmits incorrect signals. |

|

18 |

Control problem |

The control unit does not work or the parameters of the power supply are unsuitable for the operation of the machine. |

Reasons for the appearance

The most common reasons that CM gives an E03 error are the following:

- clogging of the drain hose from the pump to the siphon or other equipment used to connect to the sewer system;

- breakdown or complete exit from the operating state of the pump;

- damage to contacts in the water level sensor - pressure switch.

A breakdown of E03 in CM Candy may also indicate an interruption in the heating circuit. Often the cause of the error is a malfunction in the control unit. The E03 error often appears due to the negligence of the users of the washing machine, when the washing mode is set incorrectly. To eliminate such a problem, you just need to make sure that the selected program is correct before pressing the "Start" button.

How to fix it?

To fix the problem, it is necessary to carry out repair work depending on the cause of the problem.

Broken valve

In the production of Candy brand washing machines, original filling valves are used, which are not similar to the elements in the products of other companies.

A malfunctioning valve can be associated with the following problems.

- Clogged filter located between the hose and the valve. This is a small mesh that prevents debris from entering the water.

- In some cases, a special coil located on the valve burns out. It needs to be rewound or replaced.

- Dense plates are used to control the fluid pressure. During operation, they can shift and fall out.

Problems with the pressure switch or module

If the error appears due to incorrect operation of the sensor responsible for the liquid level, you need to do the following.

The first step is to find a pressure switch. It is located in front of the washing machine.

Diagnostics begins with checking the tube, its integrity and tightness. If there is a defect, this element must be replaced.

Using a special tester, the pressure sensor contacts are checked

It is also worth paying attention to the serviceability of the wire through which the power goes.

Pay

The control boards also fail. The individual elements located on it are responsible for filling the tank with water and draining. They must be checked for serviceability, but only a specialist will find the necessary elements on the board. It is better to entrust the repair to a professional. If you carry out repairs yourself, you can ruin the board.

In the production of equipment, the company uses boards of different models, so this part may differ in different washing machines.

General troubleshooting tips

- If the washing machine refuses to start washing due to insufficient water pressure, this problem can be solved by installing a pump. Its installation is easy to cope with even without professional knowledge. The nanos will maintain the required pressure. If the insufficient level persists, you should contact the water utility to solve the problem.

- When taking in water, the shut-off valve must be fully open. Close it only after a complete stop of the wash program.

- Check the integrity of the water supply hose. Any leak must be repaired.

- If the mesh filter becomes dirty, it must be carefully removed, washed and reinstalled.

- As a preventive measure, experts recommend periodically cleaning household appliances inside and out. Remember to thoroughly rinse the compartment for detergent and other chemicals.

- If the water in the water supply system is saturated with heavy metals and other foreign impurities, you need to use special softening compounds. Modern household chemicals stores offer a wide range of products designed specifically for automatic washing machines. Compliance with this simple rule will significantly increase the service life of the equipment.

- If you notice that the washing machine began to draw up water more slowly, you need to diagnose the equipment as soon as possible. If the problem is not corrected in time, malfunction may cause other malfunctions.

- Re-flashing can help to eliminate malfunctions of the control board, but only a qualified technician can do it. In the event of a serious breakdown, you will have to replace part of the microcircuits or purchase a new board.

To find out how to identify errors on the display in the Candy washing machine, see below.

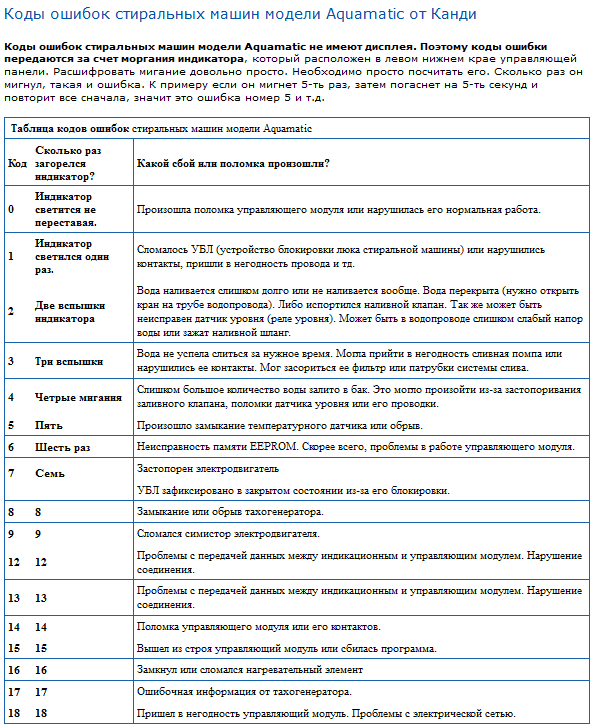

How to identify an error in typewriters without a display

The Candy Aquamatic series does not have an informative display, which usually shows an error message. In this case, the problem can be recognized by the blinking of the lower left indicator. The user needs to count the number of diode flashes in one of the series, the interval between which is 5 seconds.

In cars without a display, you can determine the nature of the breakdown by the glow of the indicators

In cars without a display, you can determine the nature of the breakdown by the glow of the indicators

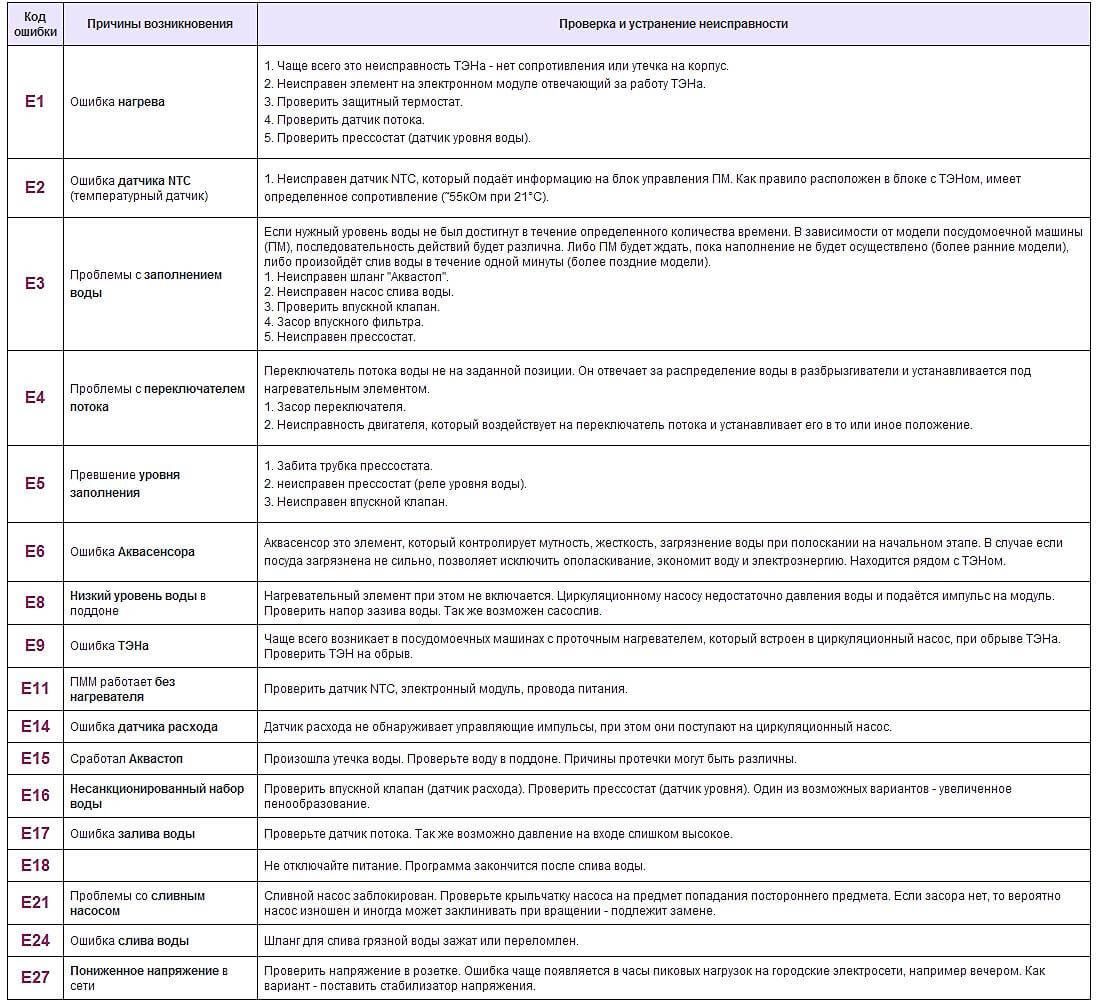

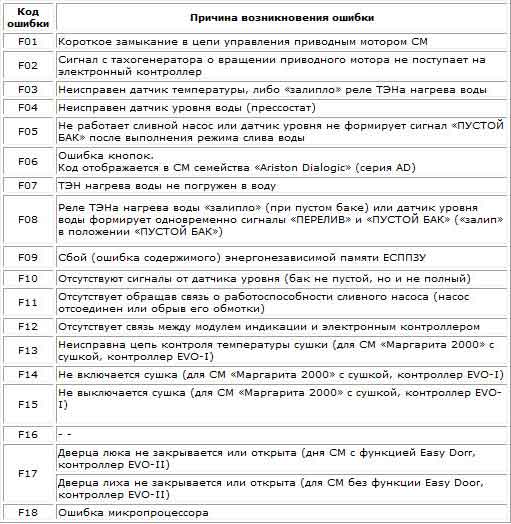

Information on the causes of errors is summarized in the following table.

| Number of indicator flashes | Possible causes of the malfunction |

| 0 (permanently on) | Malfunction of the control module, failure of the program of the electronic module |

| 1 | Violation of the connections of the UBL contacts, breakdown of the blocking device |

| 2 | Lack of water gulf. The filling tap is closed, the pressure in the water supply is low, the solenoid valve or pressure switch is out of order, the intake hose is kinked or damaged |

| 3 | Lack of drainage of water. Clogged drain hose or filter, breakage of the drain pump, lack of contact in the pump connections |

| 4 | Activation of protection against leaks (emergency level of the water level sensor). Breakage of the filler valve, pressure switch or its contacts |

| 5 | Failure of the temperature sensor (NTC), short circuit of the temperature sensor, malfunction of the program selector |

| 6 | Failure of the EEPROM memory, failure of the control module or its contacts |

| 7 | Based on the MDL control system - motor blocking.Based on INVENSYS - jamming when closed sunroof locking devices |

| 8 | Short circuit or breakage of the tachometer |

| 9 | Breakage of the triac of the drive motor |

| 12, 13 | Lack of contact between the control unit and the display module. Lost connections |

| 14 | Failure of the control module or its contacts (for MDL system) |

| 15 | Control board program malfunction, control unit malfunction |

| 16 | Insulation failure, heating element short circuit |

| 17 | Wrong tachometer signal |

| 18 | Incorrect parameters of the power supply network, breakdown of the control module |

Above are the general values of the codes for cars without a display. Before fixing the problem, it is best to check the decoding for your specific Candy model. The values may differ depending on the characteristics of all modifications of the unit. You can find reliable information about fault codes in the official user manual for your washing machine.

Step-by-step verification of details

In principle, any error can cause an elementary failure. Try restarting it. A few minutes after stopping work, hold down the off button and unplug the power cord. Then put everything back in place and try starting the wash again. If nothing works, then something is really wrong.

Alternatively, the cord itself or the outlet may be faulty. Check them with a tester. Although rare, it happens. Analyze the appearance of your “home helper”. It is possible that some defects will surface during visual inspection. If not, you will have to diagnose the insides of the unit.

- You should start with the engine. It is placed in a special hatch by the Kandy manufacturers. Open it up.

- Support the drive and turn the pulley in parallel. In this way, the belt itself will be removed from the large and small pulley.

- Take an 8mm wrench and remove the motor mounts.

- Before removing the motor completely, free it from all wires. It is advisable to somehow fix their location.

- Examine the motor. Surely you see two bulky plates. So, this is the engine brushes, remove them.

- Carry out a thorough inspection of the brushes. If they have severe abrasions or other visible faults, then it is necessary to replace them with new ones.

- Reassemble in reverse order and test the unit.

After replacing the brushes, the machine sometimes makes a cracking sound during washing. This is where the plates slide into place and rub against each other. The problem does not always lie in the brushes, for example, the control module can fly. What to do then? Here you cannot do without the intervention of a master, but you can diagnose a breakdown with your own hands. Just take a multimeter and check all the elements of the control unit.

Occasionally, the winding of the motors burns out. Repair in this case is extremely unprofitable, experts say that it is cheaper to purchase a new washing machine. However, it is worth noting that for Kandy machines, the situation with a motor breakdown is extremely unusual.

Checking the tachometer and engine

Unfortunately, the attached instructions do not include a detailed description of the E08 error. It only contains information that it occurs when the motor tachogenerator breaks off, or when it closes. It can also occur when the engine fails, and less often when the control module breaks down. Based on the information provided, first of all, you should check for operability such details as:

- motor;

- tachometer;

- control module.

Verification requires adherence to a certain algorithm. At the first stage, a motor with a tachogenerator is removed, and after that, steps such as:

- disconnecting the machine from the power supply;

- removal of self-tapping screws from the back panel;

- dismantling the panel itself;

- removing the drive belt while simultaneously pulling on itself, and scrolling the pulley.

Then the engine should be removed.To do this, it is recommended to mark the wires extending from the motor in order to prevent difficulties in connection. Then we unscrew the bolts that hold the engine, and take the last one out of the case. Now we are examining the Hall sensor in the machine: strong vibrations could lead to a loosening of the fastening, or weakening of the contacts. In such a situation, you only need to tighten the mounting bolts and restore the connections.

If this was not the problem, you will need to check the resistance of the tachometer. There are two methods for this.

- Setting the tester to resistance determination mode. It is necessary to unclench the wire connectors and remove them from the sensor contacts. Then the probes are fitted to the contacts to test the resistance. The normal range is considered to be from 60 to 70 ohms.

- Switching the tester to voltage detection mode to understand if current is being generated or not. To check, the probes are superimposed on the sensor contacts while the engine is running. If the values change (approximately 0.2 Volts), then the part is in working order.

It is imperative to check the integrity of the wiring, because often it is she who leads to a breakdown of the tachogenerator. And if the part is in a faulty condition, it will need to be repaired or completely replaced.

If the breakdown has not yet been identified, you should start checking the motor. At the initial stage, we check the brushes, and if it turns out that they are worn out, we replace them.

So, using a multimeter, we check the wiring supplying the tachometer and the motor for breakdown. If no breaks are found, a rotor and stator resistance test will need to be performed. Then we check if there is a current leakage to the case, followed by testing the turn-to-turn short circuit in the winding. A breakdown means that the engine cannot be repaired due to the high cost of repairs, and the best option would be to install a new engine.

Frequent Kandy washing machine error codes

Any machine can fail. The cause of the breakdown can be different, commonplace or, on the contrary, quite serious, leading to expensive maintenance of equipment. To understand exactly what happened, a professional diagnosis will help. However, often, such diagnostics can be done on your own, the main thing is to listen carefully, take a closer look, and have everything you need to troubleshoot at hand. What breaks in Kandy Grand Evo washers most often?

The reasons for the breakdown of the Kandy washing machine can be different.

The reasons for the breakdown of the Kandy washing machine can be different.

The wizards identified a number of faults:

- Blockage of the drain system or its technical breakdown. In case of a blockage, the machine does not drain the water and gets up after the wash cycle, spinning does not occur. If there is no tightness of the connection of the nozzles, hose or drain pump, leaks may occur when the laundry is wrung out. In addition, a peculiar noise during draining of water indicates problems with the drain system, usually this is due to a clogged pump.

- The moving parts of the Kandy washing machine are worn out. Parts that are under serious stress all the time when the machine is in operation wear out faster. Such parts include oil seals, bearings, shock absorbers, and an electric motor. Failure of these elements manifests itself as follows: the machine vibrates strongly when it is running while wringing out the laundry. You can also notice the characteristic drumming or rattling of the drum.

- The heating element (ten) is broken. This malfunction usually occurs on some older Kandy models. The water does not heat up during washing, or the machine (SMA) does not want to wash at all.

Malfunction of electronics and electrics, another common cause of failure of the Kandy washing machine. Electric wires and the places where they connect to the sensors can cause the machine to fail. This usually happens due to the fact that the terminals are oxidized, from moisture ingress. However, it also happens that electric wires burn out due to high voltage.