Mechanical damage

The reason for mechanical damage to the hatch door can be careless handling or normal wear and tear. This happens when heavy wet things are hung on the hatch door, lean or slam hard.

- breakage of the hatch door handle

In some cases, the machine may not block due to damage to the door handle of the washing machine door. This can happen due to improper operation. To eliminate the malfunction, the handle must be replaced.

The hatch handle is replaced with the door of the washing machine dismantled.

For this, the front clamp is dismantled - the crimp ring, which tightens the rubber cuff of the hatch. After that, the cuff must be bent and, using a wrench, fix the nuts securing the bolts designed to fix the hinge. This will allow you to unscrew the bolts with which the hinge is connected to the body of the washing machine and remove the hatch with the hinge. If necessary, at this stage, you can completely replace the door of the washing machine hatch by repeating the above steps in reverse order, but using a new serviceable hatch.

The removed door should be installed with the glass upwards on a flat surface so that access to the fastening screws connecting the halves of the plastic case is opened. Along the perimeter of the door, all screws are unscrewed and the halves are disconnected. Next, you need to remove the glass and lay the inside of the rim on a flat surface - this way you can get access to the handle of the machine. The handle is connected to the body using a pin inserted into the holes in the handle and the body of the washing machine.

To remove the handle, move the pin to the side and detach the handle, mounting spring and tongue in turn. The handle is usually supplied with consumables - tongue, pin and spring. To install a new handle, start with the spring, then install the tongue. When installing parts, care must be taken to align the holes of the parts and the body. After that, the pin is inserted and the handle is installed.

- misalignment of the fixing tongue or hinges on the door

If the door cannot be closed completely, and something interferes with its complete closing, most likely, the main functional elements of the door - the hinges or the locking tab - have shifted or failed.

If the door cannot be closed completely, and something interferes with its complete closing, most likely, the main functional elements of the door - the hinges or the locking tab - have shifted or failed.

To eliminate the malfunction, check the level of the door and the tightness of the fasteners of the hatch. If there is a visible distortion, the door must be adjusted or damaged hinges must be replaced.

Replacing the door hinge of the washing machine door is easy to do with your own hands. First of all, you should disconnect the door and hinge from the machine body.

For replacement, the hinge must be separated from the door. There are different types of hinge fasteners in different brands of washing machines. Some manufacturers (Ariston, Indesit) fix the hinges in such a way that they can be dismantled without removing the door. To do this, it is enough to unscrew 4 self-tapping screws. In most washing machines, the doors are designed in such a way that the door must be disassembled to remove the hinge.

To disassemble the door, unscrew the screws with which the plastic halves are connected, between which the glass is installed. With some effort, you should separate the halves from each other. You do not need to press too hard - this way you can break the entire door, you need to press in different places in a circle. After the plastic halves of the doors have been disconnected, you can replace the old hinge with a new one by installing in the same seat.After installing the hinge, the plastic door halves must be firmly pressed together until they click. To install the door, follow the above steps in reverse order.

To disassemble the door, unscrew the screws with which the plastic halves are connected, between which the glass is installed. With some effort, you should separate the halves from each other. You do not need to press too hard - this way you can break the entire door, you need to press in different places in a circle. After the plastic halves of the doors have been disconnected, you can replace the old hinge with a new one by installing in the same seat.After installing the hinge, the plastic door halves must be firmly pressed together until they click. To install the door, follow the above steps in reverse order.

If the door is locked correctly, then the problem lies in the locking tab. This happens in the eventif the tongue does not fit into the lock. The reason for this phenomenon may be the displacement of the metal rod, designed to fix the tongue in a certain position.

If the door is locked correctly, then the problem lies in the locking tab. This happens in the eventif the tongue does not fit into the lock. The reason for this phenomenon may be the displacement of the metal rod, designed to fix the tongue in a certain position.

To eliminate the malfunction, it is necessary to disassemble the hatch door and replace the stem in its original place. If the stem is damaged, the stem must be replaced.

- deformation of the plastic guide

In the event that the door closes normally, but without a click and the hatch cannot be fixed in the closed position, it means that the plastic guide, which is used in some models of washing machines to block the hatch door, has been deformed. It is made of a thin layer of plastic and can be washed with the use of the washing machine. To eliminate the malfunction, it is necessary to replace the part, having previously disassembled the hatch door.

Fixing the locking mechanism

If the door does not close tightly, then there is a suspicion of deformation of the latch lever. More precisely, irregularities appear on the parts, which prevent the hatch from being fixed in the locking mechanism. It's easy to fix the situation:

- remove the door according to the algorithm described above;

- we unfold the hatch with a latch towards us;

- we take a file and grind down all the existing notches and irregularities;

- we lubricate the surfaces with graphite grease for prophylaxis;

- we return the door to its place.

When problems with closing the hatch are caused by sagging hinges or loose fasteners, you need to adjust the position of the door hinges. But here everything is determined by eye: we tighten and tighten the fasteners until they fully enter the grooves.

External causes

External faults are easier to detect than internal faults. In a normally operating appliance, when the door is fully closed, a click is clearly audible. If the hatch does not close completely, the lock is not blocked, it is obvious that some part is broken, bent or warped. Usually, such a breakdown can be seen visually.

Broken door handle

The door handle is made of plastic. After several years of use or careless handling, fragile material may break. To avoid this, do not slam the door hard, hang wet things on it, let children play with the hatch, or try to open the machine before the blocking time has expired. If the handle is still broken, you can replace it with a new part.

Advice! When carrying out repair work, photograph the location of the elements. This will greatly simplify assembly.

The work on replacing the handle is carried out in several stages.

- Disconnect the appliance from the mains, remove the door from the hinges and disconnect from the machine.

- The hatch is disassembled into two parts; for this, the connecting screws are unscrewed. Using a blunt knife, separate the plastic rings and pull out the glass.

- In the door device, the handle is fixed with a long metal pin, which must be carefully pulled out. After that, the mechanism will fall into four parts: a broken plastic plate, a pin, a return spring and a hook.

They change the old part for a new one and assemble the door in the reverse order, referring to the photographs, checking the position of the parts.

Misalignment of the retaining tab or hinges on the door

If you push hard on the door of the machine, you can bend or even break the retaining hinge. In addition, the cause of such a nuisance can be the initially incorrect installation of the device, when the machine shakes and vibrates during operation, as well as low-quality components made of fragile materials.

In this case, it is necessary to visually assess the amount of skew and, if possible, adjust the position of the hinge by tightening the loose screws. If you can see that the breakdown is serious, the bearings and door trim have suffered, you will have to replace the hinge with a new one.

The work is carried out as follows.

- Remove the door from the machine.

- Unscrew the connecting screws and disassemble the door.

- Disconnect the decorative flanges, take out the glass. If the plastic parts of the sunroof are damaged, they can be replaced.

- Most often, the hinge bearings and the metal hinge break. These parts must be removed from the device and replaced.

- The assembly is carried out in the reverse order.

If, after eliminating this malfunction, the door in the washing machine does not lock, then the matter is in the fixing hook. It does not fall into the hole of the lock, which may be due to the displacement or wear of the iron rod, which fixes the tongue in the desired position. In addition, the tongue itself can break, because it is on this fragile element that the main effort is directed when closing the door.

To eliminate the malfunction yourself, you need to disassemble the door in the above way and assess the complexity of the damage. If the stem is slightly bent or flew out of the retaining groove, you can tweak the part and put it in place. A broken stem should be replaced. After such a repair, the tongue should function normally.

If the locking hook is broken in the lock device, it is better to replace the entire door handle.

Deformation of the plastic guide

In some models of washing machines, a special guide made of plastic is used to lock the hatch. Plastic parts are fragile and short-lived, easily bend and break, especially with frequent use of the unit.

In this case, it is very easy to find out about the cause of the breakdown. If the door of the washing machine hatch closes normally, but a characteristic click is not heard, then the plastic guide is bent or broken. To eliminate the malfunction, you will have to disassemble the door and replace the part.

Internal reasons

If the door of the washing machine closes perfectly, and the lock does not work, the cause of the breakdown must be looked for in the electronic device of the unit.

Broken hatch locking device

The door lock device (UBL) is a complex mechanism that is responsible for fixing the door in the closed state throughout the entire wash cycle. The device is energized for a long time, heats up and may fail during long-term operation. Unstable voltage can also damage the UBL.

Following the instructions, it is easy to replace the defective device yourself. A new device can be purchased in a store or ordered online, the main thing is that the model fits the typewriter. The work is carried out in several stages.

- Disconnect the washing machine from the mains. Make sure the hot and cold water supply is shut off.

- Open the car door. Use a Phillips screwdriver to unscrew the three screws holding the locking device inside the unit.

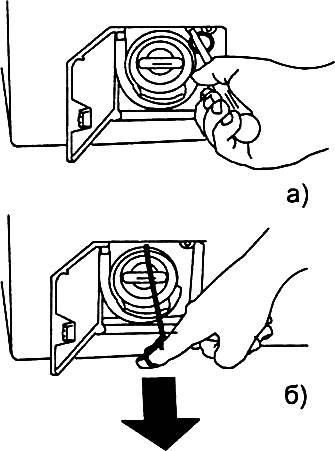

- Remove the outer spring clip located under the rubber sleeve. To do this, unscrew the rubber at the bottom of the drum, use a screwdriver to pull the spring aside and pull the clamp out of the groove.

- Slide the cuff and grab the UBL from the inside. You may need to nudge the drum a little to the side.

- Press the latches that secure the device cover and release the device that needs to be replaced.

- Disconnect the harnesses with wires from the lock.

- Connect the wires to the new UBL, close the lid and install the device in place, aligning with the holes on the case. Tighten the screws holding the device.

- Refit the rubber collar, making sure that the edge fits into the groove around its entire circumference. Install the outer spring clip (spring at the bottom of the drum).

After carrying out these simple manipulations, you should connect the washing machine to electricity, resume the water supply and check the operation of the new door interlock device.

Trash getting into UBL

Very often, the washing machine stops blocking due to debris trapped in the lock device. Threads, hair, pieces of undissolved detergent, lime and salt accumulated over the years of use of the unit interfere with the normal operation of the door locking device.

To get rid of this malfunction, it is necessary to remove the UBL from the body of the device, clean the gaps and remove dirt that impedes the normal fixation of the lock. You should also thoroughly clean the hole in the case, located in the place where the lock is installed.

Failure of the control module

The control module is a complex electronic device that is responsible for the operation of the washing machine. We can say that this is the "brain of the machine." If all of the above reasons are considered and excluded, then the malfunction lies in the control module. The device may break down due to power surges, water ingress on the board, burned out contacts, software failure, and many other factors.

To analyze the cause of the failure, you need special equipment. If there is no experience in carrying out such work, you should not try to repair the control unit yourself. This expensive device can be easily rendered unusable, after which it will be more expedient to buy a new machine than to repair an old one.

A specialist will use a multimeter to test the board and decide whether the device can be repaired or needs to be replaced. To eliminate the malfunction, you will need a complete diagram of the block and the machine as a whole. A high-quality repair is impossible without in-depth analysis.

Each owner of a washing machine decides for himself whether to make repairs on his own or call a master. If the elimination of a breakdown does not require special skills and complex tools, such as replacing a loop or installing a new handle, then it is quite possible to bring the device into working condition at home. For more serious malfunctions, when it is necessary to replace parts hidden deep inside the device, for example, replacing the UBL or the control module, it is better to turn to professionals.

Sunroof locking device

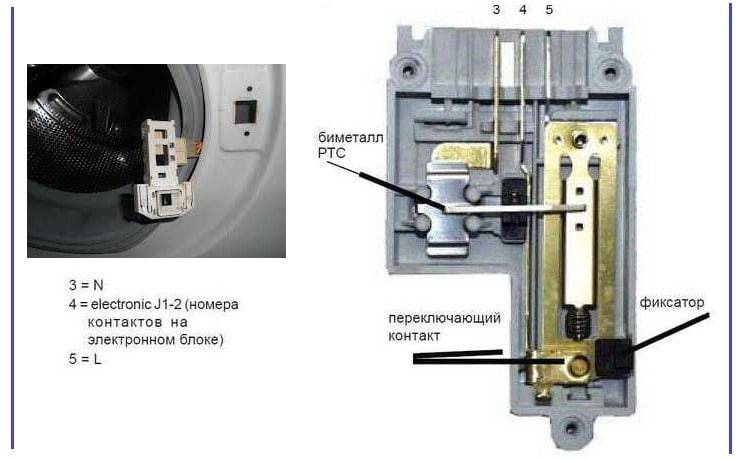

Before starting the check, it is important to understand what type of lock is installed in your model of the automatic washing machine (CMA). In older releases of the CM, manufacturers installed blockers with an electromagnet

However, they proved to be ineffective without electricity. If the electricity was cut off during washing, the door was automatically unlocked.

Another thing is the hatch door lock based on bimetallic plates. They are used everywhere due to their efficient work.

The structure consists of three main elements:

- thermoelement;

- bimetallic plate;

- fixing device.

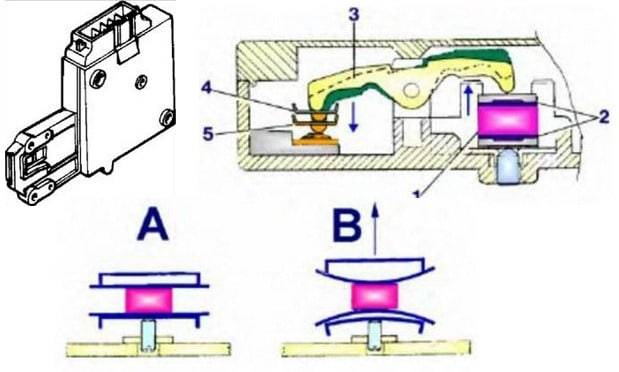

How does UBL work? Everything is tied to electronics. The electronic board supplies current to the thermocouple, which heats up quickly. He, in turn, onto the plate, which, increasing in size, pushes the retainer. Usually, when you start a cycle, a click is heard, which means the door is locked and ready to draw water.

The principle of the castle was disassembled. Now let's talk about its malfunctions: what are the reasons for the breakdown?

Causes of malfunction of the lock in the washing machine

There are two main reasons for breakdowns: physical wear and tear and electronics problems.

- Constant deformation of the plates during heating leads to damage and destruction of the element. In such cases, the commit doesn't work at all.

- Power surges can lead to breakdown of the thermocouple. Then it does not heat up, therefore, the plate remains in place. Closing the control triac results in the door not opening. The current is continuously supplied to the parts, so the latch does not disengage.

What to do in case of a problem? Check the lock of the washing machine and replace it if it is faulty.

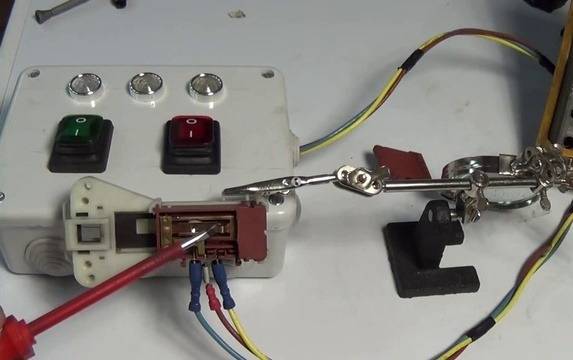

How to check the UBL of a washing machine with a tester?

The first thing that catches your eye in the event of a breakdown is the abnormal operation of the equipment. Signs of a problem with UBL include:

- The hatch does not open even a few hours after the end of the wash.

- The washing machine display shows a code that indicates a malfunction of the blocker.

- The door is not unlocked even after disconnecting the equipment from the network.

- During start-up, the lock does not work, the hatch does not close.

Most often, either the element itself or its wiring and control module fail. A multimeter will help to accurately determine the cause of the breakdown.

To perform diagnostics, you need a wiring diagram for the device. It can be different for each model, because manufacturers arrange contacts in their own way.

What you need to find out:

- Where is the "neutral" contact.

- Where is the "common".

- Where is the "phase" located.

Prepare a multimeter, adjust it to measure resistance. You can get to the castle in the same way in all front models:

- Open the door.

- Remove the two mounting bolts.

- Fold back the sealing lip.

- Run your hand behind the body.

- Get the UBL.

- Disconnect the wiring.

Now attach one tester probe to the neutral contact, and the other to the phase contact. Three-digit values are considered normal.

Next, lean one probe against the neutral contact, and the other against the common one. The device is considered broken if the values are 1 or 0.

The tester did not find a breakdown, but the blocking does not work? Examine the lock itself, perhaps the reason is just the wear of the bimetallic element. The lock cannot be repaired, you must immediately replace it. Buy an identical part from a store, connect the wires and install it in its original place. See the video for details:

How to diagnose if the hatch is blocked? There is a simple way to open it:

- Take a thin ribbon.

- Pass it between the door and the CMA body.

- Pull firmly at both ends.

- The latch should give way.

Last but not least, the control board is examined. Its triacs often suffer from oxidation and burns. This is due to unstable voltage in the network and high humidity in the room. It is better to entrust the repair of the module to a specialist.

To maintain the functionality of the washing machine electronics, connect the appliance through a voltage regulator. Disconnect the plug from the outlet before starting repairs.

Badly

7

Interesting

18

Super

We test UBL and change it

But not always a door that does not close requires an instant replacement of the UBL. Before changing the blocker, you must make sure that it is faulty. To assess the performance of the device, you will have to remove the device, inspect and check with a multimeter. We act like this.

- We disconnect the Indesit washing machine from all communications, including the sewerage and water supply.

- We open the hatch. As a rule, if the mechanics worked perfectly, then the door remains closed. Then we unlock it manually: we unscrew the top cover, tilt the washing machine back, put our hand to the lock and try to move the latch to the side with our index finger. In a similar way, you can act from below, after removing the bottom.

- We loosen the outer clamp on the cuff and tuck the elastic into the drum.

- We find the lock, loosen the retaining screws and take it out.

- Disconnect the wires connected to the UBL.

- We take out the UBL.

Taking the blocker in hand, you can start checking. First of all, we take the factory instructions and study the electronic circuit of the part. We turn on the multimeter to measure the resistance, bring the probes of the device to the "phase" and "zero", and then evaluate the result on the scoreboard. If a three-digit number appears on the display, then the UBL works without interruption, otherwise, it will have to be replaced. It is also recommended to continue testing by moving the ends to grounding and common contact.When the screen lights up "0" or "1", everything is definitely in order.

No need to try to fix a faulty UBL. First, it is useless with disposable bollard parts. Secondly, the new device is inexpensive. In order not to be mistaken with a replacement, you need to tell the Indesit serial number in the store. Installation will not cause difficulties: it is enough to act carefully, do not forget about safety measures and follow the instructions described.

UBL with temperature sensor

When electricity is supplied, the UBL locks the hatch in the closed position. It closes the contacts of the switching device and signals that the wash can be started. A special lever mechanically fixes the lock. This will last the entire washing time.

And at the moment when electricity stops being supplied to the blocking device, you need to wait about 2-3 minutes. Then the catch is removed and allows you to open the door.

How does the locking device work?

A resistor is involved in the work of the UBL. Its resistance increases as its heating increases. This effect leads to the fact that the two plates, which are located in the block, change their shape. This produces a shift in the lever. The lever closes the contacts of the switching device.

A resistor is involved in the work of the UBL. Its resistance increases as its heating increases. This effect leads to the fact that the two plates, which are located in the block, change their shape. This produces a shift in the lever. The lever closes the contacts of the switching device.

At the same time, the latch, connected to the contact plate, makes a movement that creates the fixation of the hatch door. The whole process takes place a few seconds after the electricity is supplied. When the electricity supply is cut off, the temperature sensor is cooled down. It takes 1 to 3 minutes to cool. Then the plates take their normal shape. The contact is no longer closed and the latching stops.

The main causes of problems with opening the washing machine and their solutions

One of the most common breakdowns in washing machines is the problem with opening the door after the end of the wash program. At the same time, many users of the device try to make an effort to get to the laundry, which only aggravates the situation.

One of the most common breakdowns in washing machines is the problem with opening the door after the end of the wash program. At the same time, many users of the device try to make an effort to get to the laundry, which only aggravates the situation.

Why doesn't the machine open and how can you solve this problem yourself?

Sunroof locking device

The main reasons for the breakdown are problems with the operation of the device, which automatically block the hatch, as well as the breakage of the handle itself.

If the malfunction is associated with the operation of the hatch locking system, then most often this device cannot be repaired and requires a complete replacement.

In order to make this replacement, it is necessary to remove the top cover of the machine, and unscrew the screws that secure the device. To get to the screws and unscrew them, you need to open the locked hatch. To do this, tilt the washing machine slightly and stick your hand in to unlock the door manually.

Sunroof locking device

The locking device must be removed and replaced. To do this, it is necessary to remove the rim-clamp that fixes the door, and disconnect the right side of the door cuff. A hand should get through the hole to unscrew the external screws. Before you get the lock, remember, or better write down the order in which the automatic locking device was connected.

To install a new automatic locking system, follow the same steps, only in reverse order. After all the parts are installed and everything is screwed, you can proceed to the test. To do this, plug the machine into a power outlet and start a wash program. During the operation of the device, the door must be locked, and after the end of the program, open after a few minutes. Although some manufacturers of washing machines install an automatic lock on their machines, which turns off immediately after the end of the washing program.

Another common reason why the washing machine won't open is a broken handle.

Washing machine door

The easiest way to solve this problem is to completely replace the handle with a new one.

The easiest way to solve this problem is to completely replace the handle with a new one.

Replacing the handle is easy. Any car door consists of plastic rims that surround the concave glass. The halves of the rims are attached to each other and to the machine itself using self-tapping screws and special latches. In order to work with the machine more conveniently, it is necessary to remove the device door from the hinges.

After that, you should unscrew the self-tapping screws that connect the parts of the rim to each other. Next, very carefully detach the halves of the bezel from each other. The handle of the washing machine is attached to this half of this rim, which needs to be replaced. And a tongue is attached to the handle, which fixes the door.

It is important to remember how the mechanism works, so that later there will be no problems with installing a new handle and assembling the washing machine. Therefore, write down the sequence of actions and when installing a new handle, follow it in reverse order.

After the replacement of the faulty handle is made and the machine is fully assembled, you can connect it to the network and check the operation. It is very important that the door of the appliance not only unlocks after the end of the wash, but also locks in place.

Blocking the door of the washing machine can be caused by a simpler reason that does not require expensive repairs. This could be due to clothing falling into the castle. If this happens, do not break the lock trying to get to the washed laundry. Open the top cover of the washing machine after disconnecting it from the power supply. Locate the automatic door interlock device and use a screwdriver to remove the hook from it. If you are not sure that there is no water left in the machine, it is better not to tilt it too much or turn it over. If at the same time water gets on the electrical module of the device, then it may burn out. At the same time, repairs will be very expensive or become, in principle, unprofitable.