Recently, the fashion for two-story houses has become firmly entrenched in society. And in this case, it is not so much about luxury as about practicality. Indeed, on a small garden plot, a full-fledged one-story house rarely fits, therefore it is quite logical to build a small two-story house, in which everything you need can easily fit.

When planning the construction of a two-story house, you should not least of all think about the stairs, determining its type, material and dimensions. In this article we will talk about staircase fences, which are not only decorative, but also important functional elements of modern staircases.

Stair rails

SNIP on stair railings specifies that any staircase with more than three steps must have a rail for safe and comfortable use. All staircases, without exception, are subject to this requirement.

The staircase railing consists of two elements:

- Balusters - supporting vertical posts, which, in addition to their functional component, are also the most beautiful part of the staircase.

- Railings - are located on balusters, being in direct contact with the hand of someone walking up the stairs.

Today, the shape of handrails and balusters can be very different, just like the material used to make them. However, there are several requirements spelled out in the SNIP that must be observed when installing the fence.

SNIP requirements for the dimensions of fences for flights of stairs

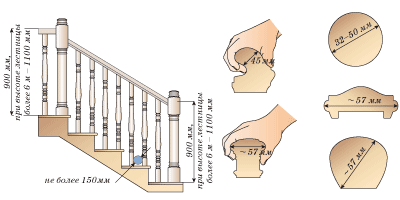

- The height of stair railings must be at least 90 cm. This requirement applies to all railings: lattice, combined, screen. The height of the stair rail has no upper limit.

- The presence of handrails on the stairs of public and residential buildings is mandatory.

- The presence of edges and sharp protrusions on the protective elements is unacceptable.

Advice! The handrail can be of any shape: square, round, rectangular or curly. However, the main requirement in this case concerns the dimensions that are convenient for a hand grip, since, first of all, it is a functional element.

- These elements are subject to certain requirements regarding fire resistance, prescribed in GOST.

- The distance between the balusters should not exceed 150 mm.

- The width of the staircase also has its own requirements:

- The staircase in width should be no less than the width of the exit to the staircase located on the most populated floor.

- In buildings where the room can accommodate 5 people at the same time, the width of the flight of stairs should be from 0.9 m.

- If the building accommodates from 5 to 200 people, then the permissible minimum is 1.2 m.

- More than 200 people - 1.35 m.

Staircase materials

The following materials are most often used for handrails:

- Wood.

- Metal.

- Glass.

- Stone.

- Plastic.

- Ceramics.

Consider some of the features of the above materials:

- Wood. As a traditional material for making stairs, wood has retained its leadership in this industry today. Today, most of the staircase structures in private houses are made of wood, due to fashion trends regarding environmental friendliness and naturalness.

In addition, natural wood compares favorably with its counterparts in price, excellent appearance, flexibility of do-it-yourself processing, strength and durability.

Advice! One of the most important benefits of wood is that wood elements look great in combination with any material. Therefore, deciding on a combination of wood with metal, plastic, forging or ceramics, you can rest assured that your efforts will certainly be crowned with success.

- Metal. The main criterion for such fences is increased wear resistance. Therefore, all-metal structures are most often installed in crowded places: shops, sports clubs, as well as swimming pools, where such handrails have already become a kind of classic.

Most often, these products are made of steel (stainless) and aluminum. These are lightweight structures that are not afraid of temperature extremes, cold, dampness, corrosion, they are durable and very easy to maintain.

- Glass. Glass elements are also very popular. They are used in all types of grand staircases, including spiral ones, perfectly fitting into modern interiors in combination with stainless railings. The glass thickness in this case is from 8 to 12 mm.

There are several options for securing glass between the posts. The simplest of them involves the use of clamping glass holders. At the same time, there is no need to drill glass, and therefore this method is cheap and practical.

- Stone. Stone stairs are a symbol of luxury and prosperity. They were present in castles, museums, noble houses, etc. Basically, railings in such structures were made of marble. Nowadays, in order to emphasize the luxury of the cottage, marble staircases are also installed in it, the structures of which, in most cases, are completely made of this stone.

- PVC staircase railing. The most common imitation of natural wood. Such products are quite durable, but only handrails are made of PVC, since this material is unreliable for balusters.

Plastic is easy to care for, is not afraid of dampness and has an excellent appearance. The elements are very easy to install, thanks to the careful fitting of the parts. Also, plastic is characterized by low cost, ductility and impact strength. Like wood, it is warm and pleasant to the touch.

- Acrylic. First of all, such products are characterized by an excellent appearance. Transparent handrails are a great alternative to glass, while providing greater strength and safety.

The most interesting option is the illuminated railings. In this case, the backlight passes along the end of the handrail, shining through it along the entire length. This is especially convenient in low light conditions.

We install the fence with our own hands

Having completed the design of stair railings, you should proceed to their manufacture and installation. If we are talking about wooden products, then you can make them yourself or contact a specialized workshop.

Both the manufacture of stair railings and their installation can be carried out by you yourself. Installation of stair railings is a simple procedure, but it requires diligence and accuracy from you.

The instruction consists of several stages:

- Installing balusters on a bowstring using pins:

- We drill holes in the middle of the lower end of each column, with a diameter of 12 mm and a depth of 80 mm.

- Next, you should "adjust" the column to the angle of the bowstring, making the lower and upper cut.

- We glue the studs into the holes made. For this, standard galvanized studs with M6 threads are used. We glue on PVA. At the same time, the ends of the studs should look out from the edges of the product by 6-7 cm.

- Now we drill holes in the string, about 100 mm deep and 14 mm in diameter.

- We install wooden balusters with hairpins into the holes in the bowstring.The outer racks should be installed first, and then all the others.

Advice! Before gluing, check that all the posts are perfectly "adjusted" to the bowstring slope, otherwise the railing may be skewed.

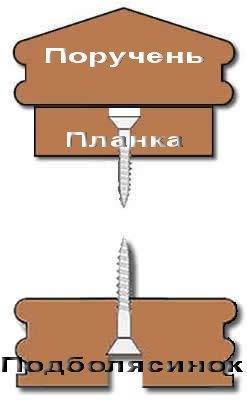

- The racks are fastened to the railing in the same way (in the rail groove or under the rail). The sub-sill is a wooden plank that must be glued into the railing groove from below.

There is another, simpler method of fastening, which involves the use of self-tapping screws:

Fastening is carried out directly to the treads. This makes it possible to exclude work on adjusting the balusters, it is enough just to carry out an even cut at a right angle.

This option is best suited for installing a structure on stringers.

- From the inside, we screw the self-tapping screws into the tread. Their tips should protrude from the outside by about half.

- We make a mark in the middle of the lower cut of the column.

- Gently screw the support onto the self-tapping screw.

- We install the railing in the same way, only in this case it is necessary to screw the self-tapping screw into the under-rail.

Conclusion

In this article, we examined several of the most popular types of fences. Most of them can be installed with your own hands, without resorting to the services of specialists. In the video presented in this article, you will find additional information on this topic.