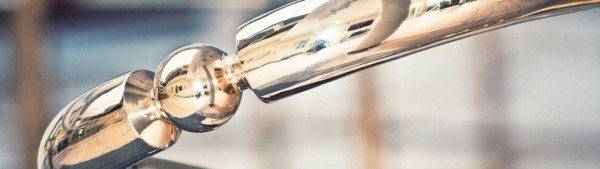

Stainless steel, or as it is often called "stainless steel" in construction circles, is widely used in other areas. However, it is in plain sight that this material as railings and fences for a wide variety of staircase structures manifests itself in all its glory.

A strong handrail is a must

Moreover, the stainless steel stair railing is perfectly combined with many materials of the flight of stairs. Of course, first of all, we are talking about glass, with this combination, an initially classic high-tech style is obtained, however, design solutions allow using stainless steel in working with concrete and wood (see also reading We make stainless steel stair rails).

Each material always has its own list of advantages, and stainless steel also has it:

- Lifetime... This is a fairly long period, up to 50-80 years, with no change in external qualities.

- Ease of manufacture... Thanks to modern processing methods, the metal can be cut, welded and shaped at will.

- High threshold for corrosion resistance... Here you can clarify that low-grade steel calmly resists weathering, and high-grade steel resists aggressive compounds that may be present in the air.

- Strength... The mechanical properties of stainless steel allows you to reduce the thickness of the sheet, while not losing the quality of the product. Acting as accessories for stainless steel stair railings, the material fully complies with safety requirements.

- Hygiene... Stainless steel is recognized as one of the most hygienic surfaces, on which there are no pores, cracks, notches, and, accordingly, there are no places where bacteria can breed.

- Appearance... A huge number of words have already been said here, examples are given, etc.

Important! Returning to hygiene, it is worth clarifying that this is an even more significant remark in relation to the railings, which are constantly in contact with human hands, and, accordingly, can be a potential carrier of bacteria.

The need for a product and technical points

First of all, stair railings and stainless steel are required to fully ensure safe movement along the flight of stairs. However, railings are installed both on balconies and on observation decks, for example.

Based on the main function of the fence, it can be recalled that the dimensions of the products are always clearly regulated by GOST. Thus, the optimal height for balcony railing is 1200 mm and for stairs 950 mm. Dimensions take into account the average height of a person, and his center of gravity.

All parts of the product can be distributed as follows:

- Handrails, elements that are located in a horizontal plane.

- Vertical racks. These are a kind of supporting structures that not only support the handrail, but also give rigidity to the entire structure.

- Filling between the uprights. Here you can use the material of your choice, ranging from plastic and glass to decorative stone.

It is also worth noting that the manufacture of stainless steel stair railings involves the use of a round metal pipe of a certain section. This is an important point, since it is the pipe that lends itself best to both processing and bending with a pipe bender.

In addition, during the assembly of the entire structure, the pipe can be welded by argon welding, or assembled mechanically, in which the elements are attached to each other with bolts.

Assembly

The assembly always takes place according to the project, and assumes that all structural elements are initially already fitted to each other. In this case, it remains only to tighten everything with your own hands and not to confuse the location of the element (see also the article Accessories for stainless steel stairs: structural elements and their characteristics).

It should be noted here that argon-arc welding remains the most preferred assembly method. It allows you to connect all parts of the structure with virtually no visible seams. This makes it possible to create a stylish fence that looks incredibly good on the outside.

But as for the second method - bolted assembly, it is simply more suitable for self-assembly. At the same time, outwardly, this method looks interesting in the general interior, as a point hint at the technical, rough component of the interior.

When it comes to filling the space between the racks, it all depends on the customer and the project. All racks are equipped with special fasteners specifically for the filling material. The easiest way to install is glass, plastic, wood. These are lightweight materials, and the instructions only require installation by nests and that's it.

Citing stone, marble, granite as an example, you will need at least minimal knowledge in working with this material.

You can also note the option of a stainless steel filling device: a pipe of a much smaller section is selected, and installed either in a vertical or horizontal position.

It is worth clarifying that we are talking about the final assembly. The main parts are done in production and everything is assembled on site.

The cost of a running meter of such a structure can start from 4-5 thousand rubles. Price always depends on many factors, including size and overall design.

This also includes the cost of not only the main material, but also all components, accessories, as well as filling the fence. In principle, such a cost is quite adequate, and it can even be attributed to the category of product advantages, because thanks to the relatively low price, it is possible to create very interesting designs.

In the video presented in this article, you will find additional information on this topic.