Detailed instructions and ordering

It is easier to build a fireplace with your own hands if there is a detailed description and photo of each stage of installation. There are several stages that are followed during construction. Carrying out the work step by step, you can fold the summer cottage fireplace with your own hands.

Drawing creation

Regardless of the shape and configuration of the structure, the first thing they do is create a sketch and drawing of the future fireplace. Adhering to the scale on a piece of paper, draw a structure, indicating all the elements of the device

It is important at this stage to choose the facing. For example, if they plan to embroider the outer part, then you will need a ceramic red brick

And if the facing will be carried out with tiles, then they choose a more economical option.

What are frame houses and what are they built from

Preparatory work

When installing a fireplace in a living room, all furniture and the floor are covered in advance with plastic wrap. If the premises are not residential, then they do not do this, and after construction work, they just thoroughly wash and clean everything.

The next step is the construction of the foundation, on which the reliability of the structure depends. The foundation is made separate for the fireplace, and not shared with the house. If the construction is done in a residential building, then carefully remove the floor in the place where they plan to build the fireplace. It is made 6 cm larger than the structure itself.

They dig a hole 60 cm deep, cover it with 15 cm rubble, fill it in and form a base. The foundation is given 7 days to dry. Before erecting a fireplace, first the bricks are laid out without using mortar, in a dry form.

Note! In the process of laying out bricks "dry", each stone is numbered. This will build the fireplace faster.

Laying out the fireplace

As soon as the foundation has dried, roofing material is laid out in two layers. For the first row of masonry, cement is added to the solution in a ratio of 20% of the total volume of the solution. The first brick row is laid with an edge. The equality of the diagonals is determined using a tape measure.

Solid rows are built using a trowel. The chimney and firebox are built by hand. The mortar is applied to the middle of the brick. With an excess solution, it is removed with a damp cloth immediately, before it dries.

After the foundation, a firebox is made. A grate is laid on the bottom, then rows of the firebox are erected and the door of the fuel chamber is fixed. To securely fix it, the door is placed on a metal mustache and laid between the rows. The blower is built on the fifth row.

The next step is the arch. Regardless of the design of the fireplace, steel corners are used in the construction of the arch. Bricks are attached to them, and when facing, they hide. When erecting an arch, bricks are placed in a wedge.

Chimney construction

It depends on a well-built chimney whether smoke will enter the room or not. If the chimney is round, then the draft is better, and if it is square, it is worse. The walls are made smooth so that soot does not form and smoke easily passes through the pipe. The chimney itself is made vertical, less often at an angle. In this case, the angle of inclination is not more than 30 ° С. The size of the pipe depends on the size of the structure and the outlet. The minimum section is 14x27 cm. A cap is installed on the top of the chimney, which protects it from the ingress of precipitation and other details.

Facing works

If they build a regular or mini-fireplace with their own hands, then finish it with cladding. They decorate the outer part of the structure in several ways:

- Plaster. First, the mesh is pulled, the U-shaped brackets are installed. Linseed oil is applied to protect against corrosion. The first layer of 5 mm plaster is applied to a warm wall. The second layer is applied after the first has dried. The thickness of the layer is made thicker than the previous one. The third layer is made with a thickness of up to 15 mm.

- Coloring. Use a chalk or glue solution.

- Drywall. It gives the fireplace a rectangular shape. First, a frame is made of metal, and drywall is sewn onto it.

- Decoration.

Note! When painting the outside of the fireplace in white, it is recommended to add blue to the paint. Then the paint will be more snow-white.

With the help of cladding, flaws that have arisen during the masonry process are hidden. With high-quality work, the cladding may not be done.

Construction work

Since the masonry of the structure is made with wet bricks, it must be dried before heating the fireplace. This is done for 6-7 days. The furnace door and ash chamber are opened. Then the fireplace is heated to dry, but the temperature is not brought to the maximum. During the second week, the structure is warmed up every day, while not raising the temperature to the maximum.

Chimney installation

Any stove with a brazier or barbecue must have a chimney. In the case of an outdoor fireplace, it is best to use modular elements that will ensure high efficiency of the device and are quite easy to install.

Do-it-yourself chimney construction principles:

- start installation from the body of the fireplace;

- connect all the elements together very tightly. The formation of cracks is not allowed;

- the fixing depth of the chimney parts must be greater than their radius.

Chimney for a stove with barbecue or barbecue can be made of bricks.

Chimney brickwork

At the final stage, an outdoor fireplace can be tiled with decorative stone or tiles. Also install cooking grates.

If you want to build a portable fireplace, then make a small metal box with legs, which should be equipped with a mesh lid. It will act as a hob and will prevent the spread of flames and ash.

Varieties of brick structures

Before you build a fireplace in the country with your own hands, you need to choose its type. There are several types of contraction, which depend on the installation method:

- Built-in.

- Wall mounted.

- Corner.

- Island.

The style and appearance of the hearth depends on the desires of the owner of the house and on the area of the room in which the structure will be erected.

Built-in type

A fireplace for a summer residence of this type is built immediately upon the construction of a wall or column. If you make a built-in structure already in a built house, then the costs will be higher. Since you will have to make a hole in the wall for the chimney and portal.

Of all types, it takes up the smallest space. The portal or firebox is chosen in accordance with the area of the room. This is a size of 70x60 or 80x70 cm. The portal itself is framed with masonry or brick. If the area of the room is small, up to 20, then the size is 60x50 cm.

Wall-mounted type

It is installed against the wall, where the chimney can be built into the wall or partially protrude. You can build it in a house with a ready-made renovation, since it does not require a wall to collapse. It is considered one of the popular types. It takes up a lot of space, so it won't work in a small room. The cladding is made of stone, tile, brick or other similar materials.

Corner type

They are popular because they are conveniently located, do not take up much space, and there is a lot of free space in front of the fireplace. The chimney of the structure is built into one of the adjacent walls. The part that remains open is made of concrete or metal. The very front part is plastered or covered with decorative brick or stone. This type of fireplace creates additional comfort in the house, since you can place chairs near it in a semicircle.

What to consider when designing a house from a profiled bar

Island type

In this case, the structure is erected separately from the walls, in the center of the room. Then the heat spreads evenly throughout the room. Its feature is an open firebox. True, sometimes an open space is covered with glass. Island fireplaces look impressive, but take up a lot of space.Therefore, they are installed exclusively in large rooms. Then they do not block the light and look appropriate and neat.

Tools and materials

To build a fireplace stove for a summer residence with your own hands or a chimney, they use red ceramic bricks. It can be solid and hollow. For the focus, take material without internal cavities. It has no pores and does not deteriorate from heat. To equip the base, you will need a cement mixture. It costs more than concrete, but more practical. It is made from 300 grade cement.

A sheet of galvanized metal is laid on the base. Then make hydro and thermal insulation. Additionally, fireclay plates are used to protect the base of the firebox from cracking. Instead, masonry is made of refractory refractory bricks.

Roll cardboard impregnated with resin and sprinkled with sand is placed as thermal insulation. For this, roofing material or roofing material is suitable. The insulating material is placed on a layer of tar or bitumen mastic. A metal pipe is installed for the chimney. To make the brickwork strong, monolithic and smooth, the elements are fastened with a clay-based mortar. It is supplemented with fine sand from rocks. Such a solution will withstand the heat of burning wood well.

For the construction of the portal, different materials are used, since the mouth is subject to thermal stress and exposure to open fire:

- Marble adds elegance, looks expensive and pretentious. The marble fireplace is suitable for classic interiors. In combination with simple wall and floor decoration, it looks out of place.

- Granite is suitable for a Gothic or Scandinavian interior, as for marble, but in darker colors.

- Tiles are used for facing fireplaces in Russian or ethnic style. They are made of earthenware or ceramics, decorated with drawings. For laying the tiles, a special viscous mixture and special tools are used.

- Ceramic tiles are suitable for cladding fireplaces and, if necessary, replace tiles.

- Natural stone is used to decorate the hearth in the style of chalet, rustic, country. The material is suitable for building and decorating a fireplace in the country with your own hands.

- Artificial stone performs the functions of natural, but costs less.

- Facing bricks come in different shades. It is used for finishing the facade of the portal.

- Natural wood is used only for exterior decoration. More often, carved portals are made of precious woods of a dark shade.

- The galvanized profile is suitable for creating a rough finish in the style of a Scandinavian castle or in modern loft-style interiors. When using forging, grates or volumetric elements, the fireplace is decorated in a Victorian style.

- Plaster parts are used to create an imitation of stucco molding. The decor is done in a classic or baroque style.

- Mini fireplaces are decorated with parquet boards. Narrow slats are not suitable for decorating wide and high portals with a shelf.

Advice! If the fireplace has a closed firebox, the door must be cast iron or glass with fireproof properties.

Calculation of basic dimensions

As noted earlier, the correct operation of the fireplace primarily depends on the size of its firebox and the section of the chimney. If the parameters do not match, the thermal efficiency of the heater will significantly decrease, or the stove will emit smoke into the room. When designing a fireplace, you should adhere to the rules:

- The section of the furnace window should not exceed 2% of the total area of the room. The height of the working chamber is chosen so that it does not exceed the depth by more than 2 times.

- To determine the quadrature of the hearth of the furnace, the area of the mouth is multiplied by a factor of 0.7.

- Firebox dimensions: the width should be 20–40% greater than the height.

- To calculate the depth of the working chamber, multiply its height by a factor of 0.5–0.7.

- If the design of the fireplace assumes the presence of bottom blowing, then the area of its channel in the light should be at least 200 square meters. cm.

As for the parameters of the chimney, its cross-section cannot be less than 10% of the area of the combustion window. When building a chimney, experts recommend observing the conical shape of the opening. In any case, the dimensions of the smoke channel must be at least 140x270 mm for a brick structure and Ø150 mm for a round riser.

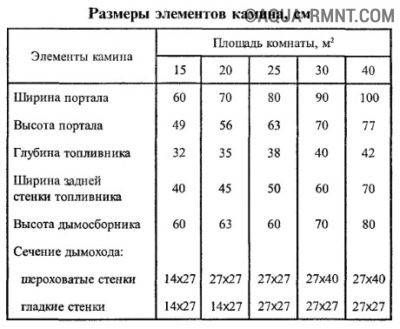

There are many programs on the network for calculating the basic parameters of corner fireplaces. In addition, you can use ready-made tables, which indicate the design parameters of their constituent parts, depending on the area of the heated room. One of them is shown below.

Basic table sizes of corner fireplaces depending on the area of the heated room

You can use the diagrams and orders of existing heating devices.

Orderings of a simple corner fireplace

The exact amount of material required depends on the design of the fireplace and its dimensions. To calculate the number of bricks, it is advisable to use the ordering scheme. In this case, each half or three-four indicated on the diagram is considered a whole brick, and the value obtained as a result of calculations is multiplied by a coefficient of 1.2. This will allow you to make a small margin in case of marriage or damage during transportation and unloading. As for the mortar, to make seams with a thickness of 5 mm, you will need 1 bucket of ready-made masonry mixture for every 50 bricks.

Fireplace types

Before building a brick fireplace with their own hands, they think over the place of its installation. The heat source is not installed opposite the entrance to the room. Otherwise, cold air masses impede the movement of warm streams. Choose a place away from the entrance, where there are no drafts. There are several ways to locate the hearth.

With a central location, the fireplace is installed in the middle of the room. He is the main object in the interior. The hearth in the center effectively heats the entire room, since the heated air moves freely. This arrangement is not suitable for small rooms as the heat source takes up a lot of space and impedes movement.

A wall-mounted fireplace is more common. It does not take up extra space in the room, it warms well. A separate recreation area is arranged next to it. When arranging such a hearth, enhanced fire-prevention measures are required. The wall adjacent to it is laid with non-combustible material.

Corner fireplaces take up very little space. Therefore, they are often made in country houses. In terms of its effectiveness, it replaces a wood-burning stove. The hearth has a simple ordering scheme. Therefore, its construction is within the power of beginners in the construction of furnaces. The corner design conceals all the inaccuracies and unevenness of the masonry. With the correct implementation of the frontal zone, other flaws are covered with finishing materials.

Features and benefits of corner fireplaces

Placing a fireplace in the corner of a room dates back to the times when it played more of an applied role than a decorative one. Since it was necessary to heat several rooms with a heating device, the location at the intersection of the walls was the most advantageous both from the point of view of heating technology and from a purely practical point of view. The corner fireplace could be installed in a small room, where a full-fledged heating unit simply could not fit.

Corner fireplace creates an atmosphere of comfort, warmth and well-being in the house

In addition, homeowners were attracted by the cost of building a heating device, which was significantly lower than when installing a classic fireplace. This is due to the fact that the corner structure requires the construction of only one facade, while the wall models also need side walls. Of course, in the first case, much less material will be needed, and the construction time is reduced by almost half.Although in our time the fireplace has lost its exclusive purpose, the tendency to optimize space and costs during its construction has persisted.

All corner fireplaces can be divided into two groups:

- symmetrical designs;

- fireplaces of an asymmetric type.

Symmetrical fireplace with semicircular portal

In the case of a symmetrical installation, the bisector of the angle runs exactly in the center of the portal of the heater and visually divides its firebox into two equal parts. In this case, the front panel can be laid out both in a straight line and in the form of an arc or a broken line.

The combustion chamber of an asymmetric fireplace is shifted to the side and often turns out to be opposite one of the walls. The heater itself resembles a wall stove with an open or closed firebox, and its portal is complemented by a side wall. Often it is replaced by a metal or stone column, resulting in a unique design.

Corner fireplaces have practically no drawbacks, while their features predetermine a number of design and operational advantages.

- Versatility. Heating devices of this type can heat rooms with an area of more than 100 square meters. m, therefore they are suitable for small country houses and large country cottages.

- Saving space. Installing a wood-burning heat generator in the corner of the room will significantly save space. Symmetrical models with a concave portal type allow you to maximize the space.

- High heat output. The heat from the fireplace is distributed not only by convection, but also due to radiation. This allows you to raise the air temperature in the room from 0 ° С to + 20 ° С in just 1–2 hours.

- Installing a heater in the corner allows you to heat three rooms in the house at once.

- The possibility of constructing a furnace of any configuration.

As you can see, this design has many advantages. As for the negative aspects, the corner models in this regard are no different from the wall ones. An open fuel chamber does not allow for a full-fledged smoke circulation, since the thrust is only enough for the removal of combustion products through a direct channel. Due to the fact that most of the heat goes outside along with the smoke, the efficiency of corner fireplaces rarely reaches 20%. There can be no talk of heat accumulation - when the wood burns out, the walls of the stove quickly cool down.

Asymmetric corner fireplace looks stylish and elegant

The fireplace is simply irreplaceable on rainy autumn days - its ability to pass a large amount of air through itself will keep the room humidity within optimal limits.

Required tools and materials

You will need a minimal set of tools, which, most likely, every home craftsman will have. Here's a complete list of everything you need:

- rammer for soil compaction;

- bayonet shovel;

- rule for leveling the foundation;

- mooring cord, which will allow you to make the laying perfectly flat;

- hammer;

- building corner, plumb line and level;

- buckets for solution and water;

- jointing for masonry;

- a mason's hammer, or, as it is also called, a small pickaxe;

- trowel (trowel);

- roulette;

- mallet with rubber striker;

- angle grinder;

- cutting wheels for work on stone and metal;

- pliers.

For laying a fireplace, you will need tools that every owner will have.

In the process of building a fireplace, you will need to equip a reliable foundation. To do this, you need to prepare:

- roofing material or any other roll material for waterproofing;

- construction mesh with cells of 100 mm in size for reinforcing the foundation slab (other materials that can be found on the farm can also be used as an armored belt - pieces of steel bar and reinforcement, pieces of pipes, corners, etc.);

- sand;

- crushed stone (fraction 20-30 mm) or coarse granite screening;

- lumber for arranging the formwork (it is best to use wide edged boards, but various scraps are also suitable, as well as used wood materials);

- cement grade M-400 or higher;

- nails for formwork assembly;

- steel wire, if the reinforcement belt will be knitted from reinforcement or bar.

High-temperature zones of the furnace and chimney are laid out with fireclay bricks

List of materials:

- refractory brick - any one can be used, but for the convenience of work it is better to take fireclay brand SHA-8 with standard dimensions;

- red fired brick, grade M-150 and above;

- facing brick (it is used for masonry of external surfaces, unless another method of finishing is expected);

- cement;

- clay;

- sand;

- steel corner with shelf dimensions 50x50 mm or 60x60 mm (needed as supports to overlap the hearth and arch of the firebox);

- boards, rail and plywood for making a template, if the overlapping of the fuel chamber will be in the form of an arch;

- a special type of metal gate valve - with a long handle;

- fireplace cassette, if it is planned to install a factory-made firebox;

- heat-resistant thermal insulation made of asbestos or basalt;

- Decoration Materials.

Masonry mortar can be prepared from commercial mixes

We'll have to take care of the chimney too. In the case of making a brick chimney, it is necessary to think in advance about the safety of its operation. Since a feature of the heater is an almost straight gas channel, it is not uncommon for burning particles of ash and soot to fly out of the chimney during intense combustion. The design will comply with fire safety standards if the chimney is equipped with a spark arrester. A deflector will be needed to protect the vertical gas duct from atmospheric phenomena and increase traction. Additionally, it will protect the structure from the wind, preventing the formation of turbulent flows at the upper cut of the pipe.

Barbecue oven safety requirements

Having conceived the equipment of a recreation area with a barbecue on your site, first of all you need to choose a place for its placement

At the design stage, it is important to take into account building codes and fire safety requirements for this structure.

For the laying of the furnace, refractory bricks are used, which are resistant to prolonged exposure to high temperatures and conduct heat.

The stove gets very hot, so no wooden structures are allowed at the back of the stove. Buildings on the site must be at least 5 meters from the place of the future installation of the furnace.

There should be no flammable materials or substances near the barbecue area.

When equipping a recreation area or a summer kitchen, it is recommended to use bricks, tiles, and impregnate wooden structures with a special fire-fighting solution.

The design of the recreation area should be provided with an exhaust hood, and the stove itself should be provided with a well-designed chimney.

The barbecue oven should have an optimal height of the countertop and working areas for ease of cooking on it, without sharp corners and protruding parts.

DIY step-by-step technology for building a fireplace

It is possible to equip a corner fireplace with your own hands in a different interior of a private house. The main thing in the construction process is to observe the design and brickwork features. We have collected for you several videos that answer the basic questions about arranging a fireplace area.

Video: laying a fireplace

Brickwork on video is a laborious process that requires certain rules to be followed. We suggest you watch a video on this topic.

Video: interesting design corner fireplace "Annushka"

The corner fireplace "Annushka" is very popular among modern cottage owners.It exhibits a luxurious look that suits all design styles. The design features are discussed in the following video.

The construction of a corner fireplace structure requires specialized knowledge and skills from the master. It is necessary to be careful and comply with the developed design project, then the finished product will delight households for a long period of time.

Building a fireplace inside the gazebo

A wood-burning fireplace, covered with a gazebo, is a stationary structure that cannot be moved and disassembled for storage during the cold season. Therefore, its construction must be approached with the utmost responsibility.

Particular attention should be paid to the foundation, as it must withstand a heavy hearth. Below is a detailed plan that will help you create a cozy corner where you can cook your favorite meals outdoors at any time of the year.

Here's how to make a 3 × 4 gazebo out of wood.

Laying the foundation

Dig a trench under the base, no more than 0.5 m deep. Fill the recess with gravel approximately halfway. Then compact the gravel thoroughly. As a result, you will end up with a kind of pillow.

Then, along its perimeter, it is necessary to install the formwork. Next, mount the reinforcement, which can be iron rods or steel mesh. Next, concrete must be poured into the formwork. After about three days, as soon as the concrete hardens and dries, you can remove the restrictive elements.

Important! Make sure that the reinforcement never protrudes beyond the upper edges of the formwork.

Woodshed and portal masonry

A stationary fireplace is usually a two-tier structure. The first tier is a woodshed, which is placed directly on the base under the stove. Dry logs should be stored here. Bricks and concrete base should be cleaned from dirt before laying. This measure guarantees reliable bonding of bricks to the concrete plane.

Moisten the base with water, then apply the fixing agent and lay the initial row of bricks. Lay the masonry using a proven method: on the edge and at a distance, approximately 10-11 tiers.

Moisten the base with water, then apply the fixing agent and lay the initial row of bricks. Lay the masonry using a proven method: on the edge and at a distance, approximately 10-11 tiers.

After completing the construction of a place for storing firewood, isolate its upper border from the second row. A steel corner and an iron lattice can serve as a delimiter. The spacers should be flush with the top bricks.

Important! It is unacceptable to use a sand-cement mixture as a connecting solution. It does not resist high temperatures when in contact with an open flame.

The second building level is a portal

To lay the bottom of the portal, use a fire-resistant material, placing it on a metal grate. Fill the joints between the bricks soundly with fireclay clay. You should get a completely flat, stable surface. Then lay the first tiers of the rear and two side walls of the portal.

We suggest that you familiarize yourself with the information on how to build a gazebo from 4x4 wood.

Fireplace tooth

Having coped with the first two rows, proceed with the laying of the fireplace tooth. This element represents the rear wall of the portal, assembled at a slope of approximately 60 °. Its presence is necessary for the complete removal of volatile carbon monoxide substances.

For this purpose, process the chimney tooth with a grinder. From each building element of the first level, saw off some part at the required slope. The geometry of the sidewalls must correspond to the slope of the tooth and form a single whole with it. Place the top row just above the portal arch. In this position, it will ensure the escape of volatile combustion products into the pipe.

Also find out how to build a gazebo with your own hands in one day.

Chimney installation

Also lay out the channel for the removal of combustion products from refractory bricks. During installation, do not allow cracks and cracks - seal them in time with clay.

Observing this technology, you will provide the stove with excellent traction and protect the surrounding space from the effects of smoke. Another important point is the height of the chimney - it should be enough to prevent corrosive gases from entering the windows of neighboring buildings.