How to make and assemble a sandwich pipe by yourself?

The finished sandwich chimney consists of segments, each of which has a length of one meter and is inserted into the other during installation. And how exactly to assemble a sandwich chimney and from what materials, now we will figure it out.

So, the construction of a chimney sandwich is as follows: it is an inner and an outer pipe, between which there is a layer of thermal insulation. The inner tube is made of stainless steel, while the outer tube can be made of a wide variety of materials, even copper and brass. But it is not recommended to take galvanized pipes for the chimney: in the heating-cooling mode, it will change its diameter, while there is practically no stainless steel.

Most often, basalt fiber or mineral wool, which has good thermal insulation properties, is used as a heater. Experienced stove-makers, for example, advise taking Rockwool WIRED MAT 80 basalt wool as thermal insulation. Its thickness can vary from 25 to 60 mm.

Expanded clay and polyurethane are also used as internal insulation of such pipes. The only problem when laying thermal insulation between the outer and inner pipes is that the material has to be overlapped with a half-thickness undercut and an overlap of 10 cm. Or completely fill everything by hand, if it works out neatly.

Sandwich pipes are also connected in different ways: flanged, bayonet and cold bridge, and also under smoke and condensate. "Through smoke" the chimney is collected in order to fully guarantee that no carbon monoxide gases get inside the house or bath. And "condensate" - so that the condensate formed due to the temperature difference can freely flow down the pipe.

In the first case, the smoke does not encounter any obstacles and, under the action of traction, quickly goes out, but condensate can get inside the sandwich if the joints are carelessly sealed. Why the inner insulation will suffer a lot. But in the second method, the inner pipe of the sandwich goes into the bell of the lower one, and moisture cannot get into the pipe in any way. But the smoke, if it finds even the slightest crack, will find a way out for itself. What should you choose? Gas is harmful to human health, and condensate is harmful to the durability of the chimney. The only way out - with any method, carefully seal all the cracks and joints, and that's it.

For the inner pipes of the chimney sandwich, we recommend the installation "by condensate" so that it does not fall on the pipe seams and there is no leakage. And, despite its double layer, sandwich pipes still need high-quality insulation from those areas that are most fireproof - from beams, roofs and ceilings. And the sandwich cannot be used as the first pipe that connects directly to the oven.

So, knowing the technology, you can easily make a high-quality sandwich chimney with your own hands - from materials you personally purchased (preferably with quality certificates).

Professional advice

When installing a chimney, it is worth taking the advice of experts to make the perfect smoke outlet. The tube that goes from the outside is collected by condensate. If you follow the smoke procedure, condensation can seep into the sleeves. The insulation cannot be wetted, in this situation the pipes will be poorly insulated, and the outer sleeve can provoke a fire when the wall structures are heated. In addition, the freezing of liquids can cause the formation of holes on the tubes, and the acid inside the condensate substance provokes a burnout of the liner from the inside. Smoke outflow in open spaces is not dangerous, it can be eliminated if the joint parts are additionally lubricated with a sealant.

It is not recommended to reduce the diameter of the chimney opening, this can provoke a stoppage or decrease in draft.The chimney duct must be cleaned of soot twice a year, and the head part from ice, snow or condensation frozen on it. Sandwich pipes do not need additional insulation, except for the passage through the partition or wall. For this purpose, it is better to use refractory insulation and exclude the use of glass wool. The section in which the pipe runs through the wall must be insulated with ceramic or basalt wool, asbestos or foamed vermiculite. The use of asbestos does not cause problems; at the final stage, the product will not begin to dust and release hazardous substances.

When working with walls made of wood, it is necessary to remember the danger of fire, therefore it is much more difficult to install chimneys in such buildings when compared with brick ones. When the chimney is taken out through a wooden wall, it is necessary to strictly observe the distance from the pipe to the wall, it should not be thicker than 260 mm. Additionally, you need to take care of the heat-insulating part and treat the walls with fire retardants. When installing a chimney in such a structure, it will be necessary to isolate the surfaces of the walls near the monotube and the outlet from the heat generator. This insulation is created using combustible materials such as tiles, plaster, stone or metal sheets.

Preparatory work

Before proceeding with the installation, it is necessary to clarify several main factors. When choosing a channel, you need to take into account the features of the height of the building, the diameter of the future channel, and others. Give a special role to the installation site and the location of the heating equipment. Installation of a sandwich chimney, like any other, can be done in two main ways:

- Internal.

- External.

For example, in case of internal placement, the installation of a chimney sandwich is carried out directly in a heated room, and in this case additional sealing is not required. But, there is a nuance, if the attic is not heated, in this case, it will be useful to additionally insulate the pipe during installation and seal it in order to prevent exhaust gases from entering the rooms with the ensuing consequences.

In addition, at the initial stage, consider what to do with those materials, walls, next to which, in contact, the chimney will pass. Surfaces should be treated with special fire retardants.

DIY chimney sandwich installation

DIY chimney sandwich installation

As for external systems, the assembly of the external chimney sandwich must be carried out taking into account the mandatory insulation. These types are much safer, since immediately during installation they bring the pipe out, reducing the likelihood of exhaust gases entering the premises.

What type and shape should you choose? Here it is worth giving preference not only to aesthetic indicators, but also to functional ones. Consider the feature that fixing or securing a square chimney is simple, it is quite easy to operate, does not require special skills during installation. But, the main drawback of such a system is the accumulation of condensate and other unnecessary dirt and dust inside.

Round elements in this part are much preferable, given their shape, they much less trap not only various debris that can get from gusts of wind, but also form less condensation, naturally, taking into account proper insulation. The only thing is that such systems are difficult to install and you need skill.

Also, do not forget to prepare the necessary tools for installation in advance. So, the tools necessary for the chimney device:

- Drill, grinder.

- Jigsaw, screwdriver.

- Hammer.

- Screwdrivers.

- Protective ammunition.

- Spatula and chisel.

Fastening

The maximum length of the chimney, starting from the grate and ending with the deflector, can reach 5-6 meters. At the joints of the pipes, it is necessary to use a heat-resistant sealing material that can withstand temperatures up to 1000 ° C. Upon completion of the installation, it is imperative to remove the protective film from the structure.

For further cleaning of the chimney from soot in the body of the pipe, an audit is provided - a tee with a door on the side. This element cuts directly into the channel.

For reliable support of the chimney, you can make your own bracket from steel corners with a size of 30x50 mm. To do this, you need a drill, grinder and M10 bolts. The latter is optional as the bracket frame can be electrically welded together.

Safety rules

The likelihood of a significant increase in pressure in the channel provides for the closure of the joints with specially designed couplings. It is advisable to seal joints on steel pipes with heat-resistant sealants. Complete insulation of the chimney contributes to the correct draft.

Sandwich panels with good thermal insulation characteristics do not exclude the possibility of overheating and possibly ignition of materials located near the chimney. To prevent such a situation, it is recommended to increase the thermal insulation layer at the joints of the structure.

Subject to the main safety rules, it will not be difficult to install the chimney. In addition, it is necessary to provide high-quality maintenance of the canal, including its regular cleaning. This will become a kind of prevention of accidents during the operation of the oven.

Installation technology

Higher requirements are imposed on buildings made of combustible materials. When removing the chimney through a wall in a wooden house, all fire safety standards must be taken into account.

Step-by-step instructions on how to make a chimney correctly:

- For a pipe, a passage is punched through the wall in accordance with SNIP standards. The distance from the pipe to the wall erected from fire-resistant building materials is at least 25 cm. To the surface made of materials liable to combustion is 45 cm. In the second case, it turns out that you need to punch a fairly large hole. To make the hole for the chimney through the wooden wall smaller, the surface is sheathed with metal or other fire-resistant material. A 25 cm hole is made, since the surface is isolated from fire.

- A metal box is mounted in a hole in the wall.

- The pipe is led through a metal box, fixed in the middle, taken out. The pipe must be solid, it is impossible to join the elements inside the wall, it will be problematic to service them.

- All free space in the wall is filled with non-combustible heat-insulating material.

- The hole on both sides is closed with metal or other heat-resistant raw materials.

- Outside, a support platform for external pipes is mounted, which is held by metal brackets attached to the wall.

- An adapter in the form of a tee is installed on the outgoing segment.

- The lower part is removable. It functions as a condensate collecting glass. Some models are equipped with a fitting with a tap, to which a hose is connected, through which the accumulated water is poured out.

- A chimney is connected to the upper part, which is brought out to the desired height. To prevent debris from getting inside the pipe, a cap is installed on it.

The pipe brought out to the outside is attached to the wall using stainless steel clamps.

In a frame house, it is recommended, instead of a support platform, to build a small foundation that will hold the outer pipe in order to relieve the load from the wall.

In more detail, how to install a chimney through a wall, you can watch the video:

Stainless steel for sandwich pipes

The table shows the most commonly used stainless steel grades and their characteristics:

| AISI brand | Application | Specifications |

|---|---|---|

| 430 | For outer shells of sandwich pipes | Belongs to economy class. It reacts poorly to high temperatures, has sufficient resistance to weathering. |

| 439 | As an air outlet from gas boilers and solid fuel plants with a capacity of up to 30 kW. | The composition includes titanium, which increases thermal stability and resistance to aggressive environments. |

| 316 | The best option for any type of gas boilers. | It is formulated with molybdenum and nickel to increase resistance to acids and high temperatures. |

| 304 | For boilers of small and medium power. | They contain a small amount of nickel and molybdenum. Refers to the economy version of the AISI 316 brand. |

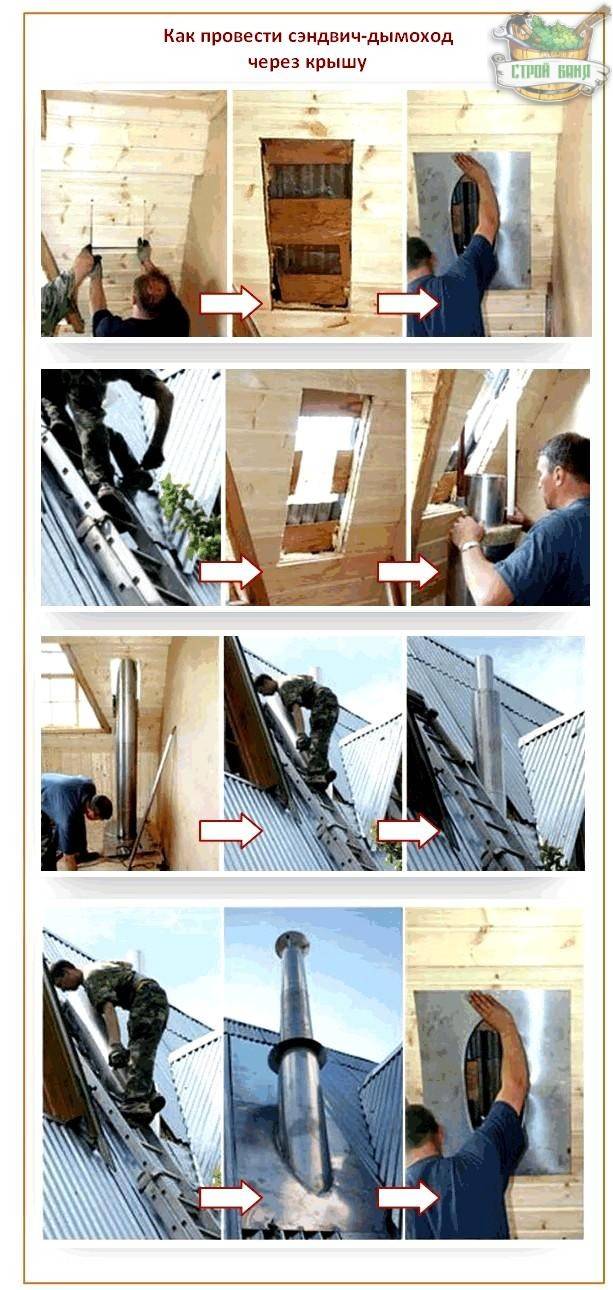

How to lead a chimney through the roof

Before the pipe can pass through the roof, it must be passed through the ceiling of the room. For this, a hole is created in the ceiling. The minimum distance from the wall to the chimney is 25 cm.

There are two options for installing the chimney through a hole in the ceiling:

- In the first case, the thermal protection is made independently. To do this, along the edge of the hole in the ceiling must be covered with a fireproof coating. The space between the coating and the pipe is filled with mineral or basalt wool. The entire structure from the side of the room is covered with a sheet of stainless steel. There must be a layer of thermal protection between the steel and the ceiling, for example mineral wool.

- The second option is simpler. It is enough to purchase a ready-made ceiling block. In this case, the edges of the hole in the ceiling are closed with mineral wool, and then a block is inserted into it, which already has a thermal insulation box and a stainless steel coating. The pipe does not have to be firmly attached to the floor, it is enough just to set it to a vertical position.

Exiting the chimney through the roof is the most difficult part of the installation

It is important to know the location of the roof beams and slabs in order to position the pipes correctly. The chimney must pass between the beams without touching them

The distance between the chimney and flammable building materials must be at least 13 cm. All combustible materials must be additionally insulated with a thermal protective layer, for example, with mineral wool. This will prevent fire if the pipe starts to heat up.

Outside, the pipe is at least 13 cm away from the roofing. A layer of thermal protection is located along the edges of the roof, the space between the chimney and the thermal insulation is free. To isolate it, you need to purchase a master flash. This part is called a rubber "skirt" or "cuff".

In addition to rubber, there are more reliable silicone options. The master flash must be matched to the pipe diameter and roof configuration. It is put on the pipe, pressing it tightly against the roof.

A layer of sealant is applied between the collar and the roof, as well as the collar and the pipe.

After that, the master flash is attached to the roof with roofing screws. The process of installing the chimney is completing the attachment of the head.

Mounting

It is imperative to adhere to the requirements of SPiP 41-01-2003 "Heating, ventilation and air conditioning":

- The cross-sectional area of the flue duct must be at least the cross-sectional area of the boiler pipe. Flue ducts should be carried out vertically, without ledges.

- The inlet vacuum must be at least 5 Pa. The recommended duct height is at least 5 m from the boiler air intake.

- It is obligatory to use polyurethane foam when crossing a roof or wall.

- Lack of horizontal channels for cleaning in attics.

- Connections of parts cannot be installed in interfloor and attic ceilings.

- The smoke channel should not come into contact with any communications.

- Heating of the nearest building elements should not exceed 50 degrees.

How to mount:

- It is not recommended to use a sandwich pipe as the first element installed directly on the outlet of the heat generating apparatus.The first item must be an adapter.

- Installation goes from bottom to top, each subsequent element is included in the previous one.

Calculations and installation rules

Installation rules imply careful thought over all stages of future work:

- Make sure that the pipe itself will not come into contact with any combustible materials that, under the influence of high temperatures, can begin to smolder and give off toxic fumes.

- With direct external installation of the system, it is necessary to remember about the angles of deflection, which will act as active guides for the removal of smoke. The chimney should not be located parallel to the wall of the house, since in this case smoke stasis will occur - it simply will not be removed from the system.

- Special tees should be installed in the lower and lateral parts of the pipe, which will be used as a place for installing mechanisms for removing condensate. If this step is not performed, then moisture when lighting a fireplace or stove will simply enter the firebox and extinguish the flame. All this will significantly complicate the kindling process!

- The top of the chimney should rise above the edge of the roof to ensure that smoke and soot are blown away in the more rarefied air area. Typically, such zones are formed at a distance of 15-25 cm from the roof sheet.

Installation instructions for specific types

Ceramic chimneys are characterized by high resistance to high temperatures, durability and excellent performance. The smooth surface reduces the likelihood of soot or ash build-up.

Divided by material:

- They are found from high-quality varieties of clay (this is a very expensive material in itself), the main feature of which is fine dispersion and uniformity.

- In the production of chamotte, inexpensive grades of clay are used, which have coarse particles.

The service life of such models is also different.

By the type of assembly, ceramic chimneys are:

- ceramic-expanded clay - the pipe is "edged" with expanded clay blocks and looks like a brick;

- ceramic-stainless - the shell is made of mirrored stainless steel 0.8 mm thick (external effect - the pipe looks like metal);

- expanded clay stainless.

Design features and materials for manufacturing

Sandwich in construction is called three-layer building materials and structures. In a flue gas system, a sandwich is understood as a combination of an inner flue duct, an insulating layer and an outer shell. Sometimes it is possible to create a sandwich chimney based on an existing pipe or shaft by adding the missing layers.

For the construction of a sandwich chimney, combinations of materials or ready-to-assemble sections can be used:

| Materials (edit) | Design features | pros | Minuses |

|---|---|---|---|

| steel, backfill brick or roll non-combustible insulation | a single-walled smoke channel from a steel pipe is mounted, an external brick shaft is erected, the space between the layers is filled with insulation | low cost of materials, easy installation | a foundation is required, the shaft can only be vertical, the shaft material is hygroscopic, the tightness of the seams is easily broken, due to which moisture can enter the insulation, which reduces its thermal insulation properties |

| steel, mineral wool (ready-made sandwich sections) | the chimney is assembled from ready-made non-separable sections, consisting of two steel pipes and basalt insulation between them | low cost, ease of transportation and installation, availability of all necessary connecting and additional elements on sale, relatively low weight of the structure, ease of replacement of failed sections, relatively low weight, configuration variability |

short service life - 5-10 years, the outer pipe may heat up |

| heat-resistant ceramics, steel, mineral wool (ready-made sandwich sections) | the chimney is assembled from ready-made non-separable sections: ceramic flue duct, basalt insulation, steel outer shell | service life - 20-25 years, average price range, ease of transportation and installation, availability of fittings on sale, configuration variability | unloading platforms are required every 2 meters in height, the outer pipe may be heated |

| heat-resistant ceramics, foam or expanded clay concrete, mineral wool | the chimney is assembled in sections: a ceramic chimney, basalt wool, an external shaft made of foam or expanded clay concrete | service life - up to 40 years, absolute fire safety | service life - up to 40 years, absolute fire safety |

| heat-resistant ceramics, bricks, mineral wool | the chimney is assembled in sections: ceramic chimney, basalt wool, external brick shaft | average total cost of the chimney, long service life of the chimney - up to 40 years, fire safety, no need for special tools for the construction of the mine | a foundation is required, the shaft can only be vertical, the shaft material is hygroscopic, the tightness of the seams is easily broken, due to which moisture can enter the insulation, which reduces its thermal insulation properties |

Assembling sandwich pipes

The manufacturer's manual recommends the use of two types of assembly, each suitable for specific conditions. When assembling and installing a chimney, you need to proceed from two factors:

- Smoke installation.

- Condensate installation.

The first option is not entirely correct from the point of view of organizing high-quality smoke removal, since the formed condensate will fall into the slots and gaps of the middle layer. This is due to a loose fit. It is very difficult to notice this, especially during installation, but over time the problem will manifest itself. And with the onset of frost, the water that has got into the heat insulator will simply "break" the chimney.

Two installation principles "smoke" and "condensate"

Two installation principles "smoke" and "condensate"

The second type of assembly is more preferable and correct. With this solution, all moisture flows freely through the sealed joint and enters the condensate receiver. The same will be true externally, drops will flow down at the seams without getting into the heat insulator.

Insulation of the external chimney

A more practical option for a chimney is the use of a sandwich pipe, which is not only easier to install, but also does not require additional insulation.

If a single-circuit pipe is used for smoke extraction, it is necessary to mount it in a box, where the distance between the walls of the box and the pipe is filled with a basalt heat insulator.

You can also use foil or other non-combustible material for insulation, but there must be a thick layer of heat-insulating non-combustible material on top of the pipe.

A chimney shaft made of brick, where the chimney is placed, is, of course, beautiful, aesthetically pleasing, but very time consuming and impractical - a brick shaft is non-separable, it is difficult to clean, and besides, the brick is not cheap.

Design features and principle of operation

Removing the chimney pipe through the wall

Removing the chimney pipe through the wall

Chimneys installed from the outside are wall-mounted or root, in the second case they are placed on a separate foundation near the building. The pipe can be made of brick, single layer steel, sandwich pipe, asbestos cement or ordinary cement. The most difficult thing is to build a brick pipe, for this you need to have the skills of a bricklayer. Asbestos-cement options are quite fragile, it is difficult to select components for them, they also require additional insulation, and they can collapse under the influence of the condensate component. The best option is considered to be steel pipes that do not cause problems during installation and do not require the laying of insulation, while they are inexpensive.

The work of the chimney to the stove is based on the reaction of combustion substances, which, when heated, rush upward.The heated gases are able to expand, as a result of which their density decreases, then they pass into the elevated atmospheric layers. After raising the spent components, a rarefied layer is created inside the furnace, to which fresh air is added. For the constant supply of oxygen to the fuel, the thrust is responsible, which is influenced by the height of the chimney, the insulation of the channel and its cross-sectional area, the location of the head section in relation to the top of the roof, as well as the flow of the required amount of air.

How to install a chimney?

The chimney installation process is subdivided into several main stages, which consist of:

- Preparatory work;

- Installation of fasteners;

- The actual installation of the chimney.

General stages of work:

It is required to drill a hole in the wall through which the chimney itself will exit, using a special tool. Modern models have adjustable nozzles and active cooling systems to eliminate the appearance of cracks on the surface of the facade.

- Passage through a concrete / brick wall. Concrete and brick walls are the most convenient material that does not require additional processing. It is recommended to additionally putty the place where the hole was created in order to exclude the possibility of imminent degradation of the room wall.

Walking through a wooden wall

When working with wooden surfaces, carefully protect against overheating. Hot air flows through the pipe, which can cause the materials to inadvertently ignite.

Ceramic mixtures, heat-resistant insulating materials and even glass wool are often used as insulating materials. You should not skimp on thermal insulation, as the consequences can be very sad!

The nuances of installing the place of passage of the chimney through a wooden wall

Advantages and disadvantages of a sandwich pipe for arranging a chimney

This type of pipe has a number of advantages. The main ones are:

- Good traction, which is ensured by an even surface and no temperature fluctuations.

- A smooth inner layer that does not allow soot and soot to settle inside the chimney, which simplifies the operation of the device and preserves its functionality for a long time.

- Minimal formation of condensation, which is also due to the constant temperatures inside the chimney.

- Fire safety, due to the fact that the outer layer of the pipe does not heat up, this is prevented by the layer of thermal insulation, so all objects that come into contact with the pipe (primarily the building materials from which the walls and roof are made) will not change their temperature.

- Convenient comparison of the components, due to the configuration of the pipes themselves, which allows you to insert one part of the pipe into another and fix the joints with a sealant, which is more convenient and simpler than welding pipes using special devices.

- Simple installation, which is due to the sale of ready-made products, the presence of special modules for that part of the chimney where it comes into contact with the roof, as well as additional parts in the form of knees, bends, umbrellas.

- Low weight of the structure, which allows you to place it without additional fasteners and install it yourself.

However, in addition to a large number of advantages, sandwich pipes have a number of disadvantages:

- High cost compared to other types of pipes.

- Loss of tightness that occurs over time due to the fact that the space between the layers is not impermeable to air and water, which contributes to the gradual delamination of the pipe.

- Service life no more than 20 years.

We install a sandwich chimney in the bath in stages

The installation of a sandwich pipe for a chimney itself is not difficult. Since sandwich pipes are as fireproof as possible, even a person who is very far from construction can connect and properly fix them.

The "sandwich" chimney is mounted from the bottom up - from the stove to the roof, and the outer pipe must be "put on" the inner one, as it were. In general, there are several important points for assembling a sandwich. Let's take a closer look.

Stage I. We connect the elements of the chimney

When installing a sandwich chimney, pay attention to the fact that one of the ends of the pipe is always narrowed with a slightly smaller radius. It just needs to be inserted into the previous pipe.

Due to the fact that soot hardly accumulates in such a chimney, it is easy to remove condensate from it - and it is better to additionally install special tees for this.

Stage II. Option 1. We draw the chimney through the wall

If the chimney exits through the wall, it will have to be disassembled and reinforced with the seats under the bracket. Next, we assemble the outer bracket and attach two corners to it like runners - so that you can easily move the tee during the installation of the chimney from the sandwich pipes, and nothing gets stuck.

The wall itself can be closed with one centimeter thick plywood and an asbestos sheet can be fixed with screws throughout its entire area. On top of that - a solid sheet of galvanized metal 2x1.20 cm. In the sheet itself we cut a square hole for the passage and fix it with screws. Finally, we paint the bracket with metal varnish to protect it from corrosion. Next, we drill the required hole in the adapter and put a sandwich in it.

Used in the construction of a chimney and such a concept as a concession is the space that we specifically leave between the chimney and the wall.

Stage II. Option 2. We carry out the chimney through the roof

When passing a sandwich pipe through the roof, you must first take a galvanized steel sheet, attach it from the inside to the hole, and lead the pipe out. Only after that we attach the sheet to the roof. If necessary, it can be additionally brought under the edge of the roof.

If the roof is made of combustible materials, it must be protected from fire. And for this, on the chimney, which rises above the wooden tiles or bitumen, we install a deflector with a spark arrestor mesh with small cells.

Stage III. We fix the chimney

We fasten all tees, elbows and other elements with clamps, and fasten the tee with a support bracket. If the upper part of the chimney remains loose, it is better to insure it. At least with the same 120-degree stretch marks. Here's how to additionally fasten the docking joints: sandwich pipes to each other - with crimp clamps, pipes with other elements, like adapters and tees - with the same clamps, but on both sides.

Stage IV. End of installation

After completing the assembly, be sure to remove the protective film from the pipes

The optimal length of the chimney is 5-6 m from the grate of the stove to the head - pay attention to this. And we seal all seams and gaps

To do this, you will need a heat-resistant chimney sealant that is designed for a temperature of at least 1000˚C. You need to apply it like this:

- For inner pipes - on the outer surface of the upper inner pipe.

- For outer pipes - on the outer surface.

- When changing from a single-walled to a double-walled pipe - outside, in a circle.

- When connecting a single-wall pipe and other modules - as in the last version.

When everything is ready, be sure to check the most dangerous heating zones of the chimney for temperature. And so that later cleaning the chimney is simple and easy, an audit is necessarily provided in it - this is a special removable part or an opening with a door.

Installation of a sandwich chimney is very simple and easy due to its simplicity of design and light weight - if you have already decided on a project and purchased material, feel free to roll up your sleeves!

Advantages and disadvantages of pulling the pipe through the wall

A chimney located in a horizontal plane has many pros and cons.The positive aspects include the following:

- Competent execution of the project of a wooden house allows you to fit the chimney into its overall design.

- Saving space in the room, since the external location of the channel preserves the internal volume of the house.

- Ease of assembly and installation, in contrast to traditional technology of installation through the upper structure of the building. Exiting the pipe through the wall eliminates the violation of the integrity of the floors between the floors of the building and / or its roof.

Among the negative points, the following are noted:

- The need to insulate the outer walls of the chimney.

- The external location of the channel requires the installation of a horizontal section under it.

- According to experts, the external gas exhaust pipe has a low efficiency.

- The emergence of certain difficulties in combining the design of the structure with the exterior of the structure.

v class = 'yarpp-related yarpp-related-none'>