Limited options when the stove is running

One of the biggest drawbacks is the impossibility of manipulating a working stove. The upper loading hopper becomes inaccessible and excludes the possibility of refueling, at any time if desired. Put out the hot bubafon, it seems  problematic. If this is achieved with a damper with a gate, there is no guarantee that the already mentioned smoke inflow into the room through a hot air duct will not occur. As a solution, the loading and ash doors were cut into the side walls. However, the problem of the moving element is more difficult to solve.

problematic. If this is achieved with a damper with a gate, there is no guarantee that the already mentioned smoke inflow into the room through a hot air duct will not occur. As a solution, the loading and ash doors were cut into the side walls. However, the problem of the moving element is more difficult to solve.

In addition, the obligatory slit in the top cover does not allow fine control of traction and intensity, which is critical for an economical and safe process. Air passes through it, supposedly designed to cause the afterburning of fumes.

In fact, being drawn by the draft, it escapes into the chimney, and not reaching the right place, it is only necessary to slightly lower the “heel”.

Furnace assembly instructions: the simplest version from a barrel

Here are step-by-step instructions for creating a furnace from a barrel (you must first familiarize yourself with the detailed photo and video materials):

- Remove the top cover of the drum. A grinder is best suited for these purposes: with its help, the weld is cut off.

- The resulting edge of the barrel should be slightly bent inward with a sledgehammer, and on the lid, on the contrary, expand the beading. Ultimately, the lid should wrap tightly around the body.

- In the center of the cover, cut a hole for the air supply pipe. The edges should be straight.

- Make an air distribution device from a blank sheet of metal.

- Weld metal profiles (air ducts) to the bottom of the "pancake".

- The pancake is welded to the air supply pipe.

- An air damper is mounted on top of the pipe.

- Embed and weld the chimney pipe. The seam must be completely sealed.

- It remains only to collect all the other components together and check the tightness of the structure, after which it will be ready for use.

Advice. Carefully calculate and properly mount the horizontal section of the chimney: its length should be no more than 4 m

In addition, it is important to maintain a distance so as not to disturb the thermal equilibrium.

That's all the subtleties that you need to know about creating such a heating unit as a bubafon oven. Good luck!

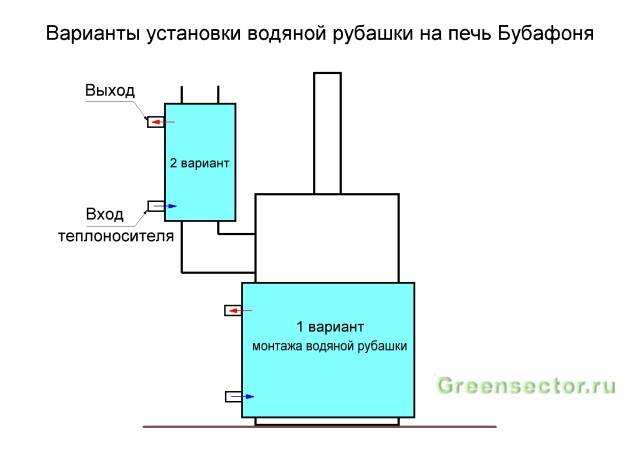

We put on a "shirt" for Bubafonya

Reviews about the operation of the bubafonya oven are mostly positive. The heat output of a boiler made from a gas cylinder is enough to heat a room with an area of up to 60 m2. The only design flaw is uneven heating. The easiest way to fix it is to blow the case with a fan. Note that it is much more profitable to make a Bubafon boiler with a water jacket, which can heat several rooms.

The masters offer two places for installing the water circuit: on the boiler body or on its chimney, which is very hot. The easiest way is to make such a system according to the "pipe in pipe" principle, putting a barrel or pipe of a larger diameter on the boiler body or on the flue channel. The open ends of the "jacket" must be welded tightly and the inlet and outlet pipes must be cut into it for connection to heating devices.

It is possible to make a heat exchanger from a water pipe by installing its coils in an outer steel casing and filling them with sand for a more even heat transfer. In addition, the coil can be placed inside the brickwork around the boiler drum.

(Visited 1,759 times, 1 visits today)

Video: Do-it-yourself Bubafon oven

How to increase the efficiency of the furnace?

Profile sheet around the boiler drum will increase convection flows

One of the disadvantages of a homemade Bubafonya stove is its low efficiency, which can be increased in the following way:

A profile sheet is mounted from the outer part of the body, which fits snugly to the body.Thus, convective currents are formed during combustion. Cold air is drawn in through the lower part of the "waves" of the profile sheet and heats up as it passes along the body, rises up and comes out already warmed up through the upper part of the "waves" of the profile sheet.

Important! To extend the service life of the heater, do not remove all the ash from the bottom of the stove (exactly the same recommendation applies to the Buleryan stove, in which combustion should not occur on convective pipes). Fuel should burn on ash, not metal

This will avoid premature burnout of the bottom.

Self-production

If you wish, you can make a bubafony oven with your own hands. However, since this is not just a stove-stove, but a long-burning installation, the work must be done with all responsibility. Otherwise, the result can be disappointing.

Please note that such a furnace can only be metal, therefore, to make it yourself, you need to have a welding machine and skills in working with it. Alternative fastening options for parts (bolted, etc.) cannot be used

Tools and materials

To make a do-it-yourself bubafon oven, you should prepare the following tools and materials:

- Two pieces of steel pipe.

- The most common barrel with a capacity of 200 liters (another size of the future combustion chamber is also possible).

- Grinder with cutting and grinding wheels.

- Pieces of the channel.

- A hacksaw for metal, a hammer.

- About 50 bricks (you need to put some masonry).

- Sheet metal.

- Welding machine or semiautomatic device.

Preparatory work

Choose a suitable place to do the work with your own hands, the garage space is quite enough, and in good weather you can stay outside. The main thing is that you can connect the power tool.

The difference between such a furnace is the process of fuel combustion, which does not occur from bottom to top, but from top to bottom. This significantly reduces the consumption of combustible materials. This design was borrowed from the Lithuanian boilers "Stropuva". This promotes complete burnout of the combustible material and reduces waste.

Types of long-burning furnaces and their choice for self-production

These kilns are usually made of bricks, metal, or stone. They can be round, cylindrical, square or irregular. Depending on their design and the method of fuel combustion, long-burning furnaces differ in types.

Classic long burning stove

The design, in which the flame spreads from bottom to top, pushing the burning gases through the layers of combustion material, is classic. This type of furnace is equipped with a heat exchanger and an afterburner, into which an additional portion of air is supplied. Prominent representatives of this type are long-burning stoves: buleryan (breneran), Butakov's stove, as well as modified designs with different heat exchangers.

In Buleryan furnaces, the role of a heat exchanger is played by curved pipes located inside the furnace body.

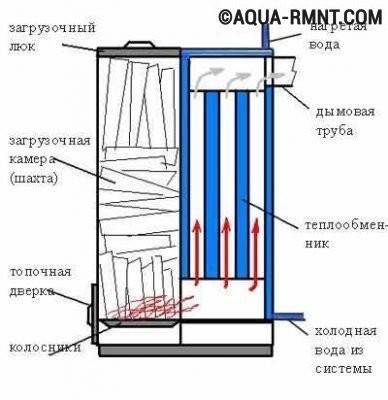

Long burning shaft furnace

Another type of such structures is a shaft furnace. In this design, the combustion zone is shifted to the grate part. The products of fuel combustion are discharged through the adjacent compartment, in which they burn out, creating heat exchange. This type is best built from brick, which has been confirmed for many centuries.

In shaft-type furnaces, the combustion zone is located directly above the grate

Hearth furnace

This is an overhead combustion design in which the top of the combustion material is ignited and the direction of the fire is in the opposite direction.Such a device requires oxygen supply under the burnt layer, therefore the furnace must contain special air delivery channels. The simplicity of design, combined with efficiency and functionality, has resulted in a multitude of DIY options. At the same time, the used cylindrical containers will serve as the material for its manufacture. A striking example of this type of heating unit is a stove called "bubafonya".

An old gas cylinder can be used as a body for a homemade stove.

Gas generating furnaces

Gas generating furnaces or structures with additional combustion of pyrolysis gases. In this design, the combustion material is burned under the influence of two factors: high temperature and a small amount of oxygen. This leads to the release of combustible gases that burn out in the additional chamber. The designs of this type of furnace are the most difficult to manufacture, but their efficiency and ease of use are superior to the previous versions.

Pyrolysis gases burn out in an additional chamber above the firebox

Step-by-step instructions for assembling the Bubafonya oven

It is advised to make a stove not in an enclosed space, but in the fresh air.

It is advised to make a stove not in an enclosed space, but in the fresh air.

In addition to the welding machine, a grinder, a hacksaw for metal and a hammer are useful.

Consider how to make a Bubafonyu stove from a gas cylinder 30 cm in diameter.

Step-by-step instruction:

The upper part of the balloon is cut off.

A round pressure piston with a diameter of 27 cm is cut from the sheet metal.

An 8 cm hole is cut in the center of the piston, into which the air duct pipe is inserted and welded

It is important not to forget to make the protrusion of the pipe to the height of the future edges.

To the underside of the piston are welded 4 pieces of channel, 4 cm high each. These will be the ribs of the piston.

A door is made in the upper part of the furnace

Its width = ¼ of the circumference of the boiler.

At the very bottom, an ash pan door is made. Width = the width of the upper loading door, and the height must be sufficient to allow unburned, sintered charcoal to be removed from the oven if necessary.

A knee is made from a pipe, which will later serve as a chimney. To do this, the pipe is cut at 45 °, then the segments are turned over and welded to each other so that an angle of 90 ° is obtained.

A hole is made in the body of the product according to the size of the pipe. The chimney is inserted and welded.

A device for collecting and removing condensate is made at the bottom of the chimney. This is a prerequisite, since a lot of moisture is generated during the pyrolysis process, even if the stove is heated only with well-dried woods.

To prevent air from sucking in through the doors, there is a technical technique: the neck is made protruding, and the door itself is made double with an asbestos layer.

Advantages and disadvantages of the oven

A simple-looking stove combines many important advantages, among which the following points must be noted:

- Extreme simplicity of design. Almost anyone can handle the assembly of bubafoni.

- Profitability. Depending on the volume of the firebox and the quality of the raw material, the bubafonya can operate on one load for up to several days.

- Unpretentious care and handling. After firing up the fuel, the bubafon can be left unattended for a long time and go about his business (but it is better, nevertheless, to periodically check the condition of the unit), and all the care of the stove comes down to periodic cleaning of the ash pan and chimney.

- No expensive and hard-to-find materials are needed to assemble a bubafoni. A tank, a lid, a few pipes and various simple metal products will be enough.

- The stove perfectly copes with its main task even in very severe frosts.

- Bubafonya can be used to heat a residential building, greenhouse, garage, country house and other objects.

- The unit is characterized by a high rate of fire safety - there are no openings in its design for an open flame.

Despite the obvious advantages, this stove also has disadvantages:

Another important drawback is not the most attractive look.

If the bubafon is used in a technical room - in a garage, a greenhouse, in a country house, then there is nothing to worry about. As it is, so it is.

Well, if you want to use it to heat the house, you will have to hide it somewhere in the boiler room, basement, in an extension.

You can still refine it. For example, brick it. By this, by the way, you will greatly increase the comfort of being near the stove: the brick will extinguish most of the hard radiation, soften it, and become a kind of heat accumulator: the brick will heat up, and then, when the stove goes out, it will gradually cool down and give off the accumulated heat.

Features of a potbelly stove - pros and cons

A good master will calmly make a Bubafonyu oven in one day, this is a significant plus. The maximum that you have to buy is a cylinder and pipes for scrap metal. Other advantages of a potbelly stove:

- burning duration for 1 load 6 ... 10 hours;

- omnivorous - wood waste, garbage, sawdust, freshly cut branches are put into the furnace;

- ease of repair, any burnt-out part can be easily changed.

On the left in the photo - the manufacture of a boiler jacket from a bent steel sheet, on the right - a boiler assembly

The disadvantages of Bubafoni are much more unpleasant:

- The stove is difficult to regulate. When working on high-quality dry wood, the damper helps to choose the optimal mode. If heating with rubbish and raw wood, the duct must be fully open.

- The omnivorous potbelly stove is a double-edged sword. From burning low-quality fuel, the chimney is clogged with soot literally in a day.

- Without good draft, the stove will smoke into the room. Hence the requirement for the height of the chimney - at least 4 m, counting from the grate, 90 ° pipe turns - no more than two.

- Throwing logs "on the go" is impossible, except perhaps pouring a handful of sawdust through an air channel. This means that we are learning to dose the amount of fuel correctly.

- A potbelly stove from an iron barrel of 200 liters is very bulky and inconvenient in terms of operation. The piston is too large and heavy, the thin metal burns out quickly. Fortunately, the case is not difficult to replace.

Why "Bubafonya" is dangerous: a well-heated firebox cannot be extinguished with a damper. Air seeps through the cracks, the wood continues to smolder. The heater must not be left unattended or must not be taken drastically by lifting the lid and pouring out a bucket of water. Smoke screen in the room is provided.

The nuances of the manufacture and operation of the stove

- It is advisable to make the chimney so that it can then be easily replaced without damaging the stove itself. This is necessary for the reason that it can often become clogged and must be replaced periodically.

- In order to find the optimal combustion method, you must first try several times in a row to carry out test furnaces with wood of different moisture content.

- Since the stove generates a lot of heat during operation, constant control over it is needed. It is imperative to follow all safety rules.

- It is advisable to make such a stove not indoors, but in the fresh air or in a garage.

Furnace design, its features and principle of operation

Before you start making your own oven, you must carefully study all the characteristics of the device.

If it is supposed to make a unit for heating a large room, then the stove must have a high heat output.For example, for a house or room with an area of 150 m², you should choose a stove designed for heating up to 200 m². This "reserve" of power is necessary for complete confidence that every corner of the house will be warm.

If it is calculated to heat a room with an area of 30-50 m², then the stove can be made without the specified "stock". In such a small room, heat leakage will be minimal, so a unit with a small capacity is sufficient. Automatic refueling will greatly simplify its maintenance. In the manufacture of such an oven, hobs for cooking can be provided on its body. If the stove is not only a source of heat, but also an interior item, then windows can be made of refractory glass in its body.

Design features of long-burning furnaces

Long burning heaters have design features that distinguish them from other stoves:

- the combustion chamber has a volume for loading a large amount of combustible material;

- the body of long-burning furnaces is equipped with a large door;

- the furnace compartment in the furnace body is divided into two chambers; one chamber is designed for smoldering combustible material, the second is for burning gas;

- the design of such a furnace provides for the presence of a special baffle that prevents flame from entering the chimney;

- this element of the furnace frame is made of a metal plate, which is welded in the upper part of the furnace compartment.

Differences between conventional and pyrolysis oven

To understand the principle of operation of a long burning oven, you need to compare it with the operation of a conventional oven.

The work of a conventional stove is to heat its surface and release heat into the room. The combustion material is ignited from below, which is why the flame spreads along the sides, heading up. This is due to the large amount of air entering the combustion chamber. The fuel in such a furnace burns out quickly, which is why the air temperature in the room is unstable - it either goes down or rises.

The principle of operation of a long-burning furnace is different. The firewood is ignited from above, and the fire spreads downward, while the air is supplied only to the place of combustion. As a result, the material smolders, releasing heat evenly over time. In addition to the flue material, pyrolysis gas is released, which also serves as a fuel, additionally generating heat.

In a conventional furnace, fuel burns quickly, in pyrolysis it smolders slowly

Features of the Bubafonya stove for home heating

The first structure was created from a metal barrel. This way you can put more firewood and save a little. The potbelly stove gradually burns fuel, and does not ignite the entire amount at once. You can also control the supply of oxygen, and hence the intensity of combustion.

The high temperature and complete combustion of the wood increase the efficiency and increase the operating time of the stove. Due to its simple design, the design is widely known among the people. It is used in a greenhouse, sauna, swimming pool, outbuildings, garages and workshops.

Advantages of the Bubafonya stove:

- Ease of installation. Even a beginner will be able to understand the design and build a stove with his own hands in a couple of hours.

- Energy independence. Such a device operates exclusively on wood fuel.

- Any fuel can be used. The oven works on sawdust, wood, branches, straw, cardboard. On all types of solid fuels.

- Compactness. The stove will fit anywhere in the house.

- Simple operation. It is easy enough to understand the mechanism, and firewood is rarely added.

There are also negative sides to the stove. The need for good ventilation is noted, because without an inflow of oxygen, the furnace does not work well. Also, the stove has a low heat capacity. The furnace area is not sufficient for full heat transfer.

If the wood is damp, the stove will not work efficiently. Also, problems are created during the maintenance of the structure. It is rather difficult to clean the device from soot and ash. But all the disadvantages are significantly inferior to the advantages.

Bubafon stove: principle of work, features

She got this name from the consonant English-language network nickname of one Russian master Bubyanik. It is not known for certain whether he was the first to invent such a heating structure or whether he was just the first to make it, but it was his model that became very popular among ordinary people, and a large number of similar and even improved models were created on its basis.

The design has fundamental features that distinguish it from standard furnaces:

The fuel compartment is located not at the bottom, but at the top of the structure. Various types of solid fuels (coal, firewood, etc.) are suitable for the furnace.

The design is equipped with a protective shield on the hearth, which prevents the spread of fire over the entire surface of the cylinder. Thanks to the clearance, the fuel does not burn as quickly as usual.

A damper is arranged in the upper part of the furnace, which helps to regulate the intensity of fuel combustion.

Another feature of the furnace is the possibility of burning fuel for a long period of time.

In general, the bubafonya oven has the following advantages:

- lightweight construction,

- low fuel consumption;

- excellent heat dissipation;

- compactness.

Unfortunately, the bubafony also has some negative aspects that should be taken into account: rapid cooling after heating and the need to thoroughly ventilate the room after using the heating device.

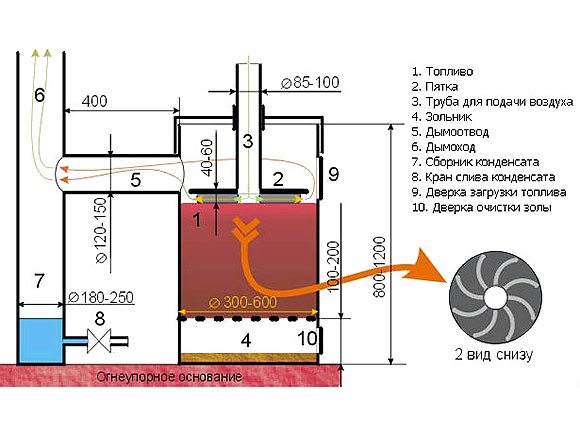

Top combustion furnace device

The design of this type of heater is very different from traditional wood stoves. The Bubafonya vertical stove consists of the following elements (see the drawing):

- a cylindrical firebox with an ash-pan door and a removable top cover;

- disk weight with air distributors welded to the end of the air pipe;

- grate;

- chimney connection pipe.

Drawing of a stove from a standard gas cylinder of 50 l

The cylindrical shape of the walls of the combustion chamber is due to 3 reasons:

- From an aerodynamic point of view, a round tube is always better than a profile tube. Rising along the walls, the combustion products evenly heat the body of the potbelly stove.

- No fillet welds are the weak point of any steel furnace or boiler.

- In the process of burning out, the remaining fuel does not "hang" in the corners, which is observed even in some boilers with prolonged combustion.

The upper end of the air pipe is equipped with a damper for manual regulation of the air supply to the furnace. From below, a disk-shaped load is attached to it (other popular names are pancake, piston). Straight or curved air flow distributors are welded to the bottom of the disc. The pipe itself passes through the firebox cover with a minimum clearance of 2-4 mm.

The furnace is ignited from above (photo on the left), combustion continues under the piston (on the right)

How the Bubafonya long-burning stove works:

- We fill the chamber to the top with solid fuel - wood, coal, sawdust. We ignite the fuel directly from above, as shown in the photo. Then we insert the piston into the firebox, close the lid.

- We open the damper at the end of the duct. When the stove is on fire, close the air supply by about half.

- Combustion takes place in the upper zone of the fuel tab, under the pancake. It is there, under the influence of the natural draft of the chimney, that air comes from the chimney. Distributors contribute to better flow dissipation.

- The hot gases pass through the gap between the disc and the body, give off heat to the walls of the chamber and rush into the chimney.

- As the wood burns out, the load sinks under its own weight until it hits the grate.

An important feature of Bubafoni. Since the fuel is burned from top to bottom, the combustion zone gradually moves after the piston.The walls around the burning layer of firewood are warmed up as much as possible (sometimes red-hot), the temperature of the rest of the body is much lower.

The zone of greatest heating is clearly visible from the outside when the stove is heated red-hot

Ignition of the "bubafonya" furnace

We take out the feed piston with a welded air duct from the inside, after removing the cap from the cylinder.

We put wooden logs inside. They must be placed horizontally end-to-end. Vertical placement of firewood can have rather unpleasant consequences if an unburned log standing with an edge prevents the piston from moving. This will lead to the fact that instead of smoldering in the primary chamber, a full-fledged fire will light up. As a result, the correct operation of the stove will be disrupted, the wood will burn faster and, in addition to everything, it may start to smoke through the air duct. Logs must not be placed higher than the chimney location.

Laying firewood in the pyrolysis oven

Pour chips with sawdust or small branches on top of the wood bookmark. Soak a piece of old cloth in a kindling liquid (kerosene is also fine) and place it on a layer of chips. An alternative to a rag is paper.

Processing the top layer of the bookmark with kerosene

Press the tab with the piston and put the oven cover back on.

Installing a piston with a cover

We set fire to the wood by throwing a piece of lighted rags or paper inside through the duct pipe. A match for striking a bubafoni is not suitable, since it has time to go out before it falls down.

Furnace ignition

After 15-25 minutes, after the bookmark has flared up well, it is necessary to close the valve on the air duct. This will restrict the air supply to the primary combustion chamber and cause the logs to smolder, releasing pyrolysis gases. Thus, "bubafonya" will switch to its main operating mode.