Do-it-yourself Kuznetsov oven: ordering drawings and description of the oven masonry

IV Kuznetsov has been designing, manufacturing and improving furnaces since 1962. During this time, more than 150 different designs were invented, each of which strove for an absolute indicator of efficiency - 95% efficiency. In this article we will tell you how to make a Kuznetsov oven with your own hands.

Photo 1 Kuznetsov's stove

The principal feature of the development is the system for separating gases into cold and hot streams. Due to the unique bell structure of the furnace, hot air is retained inside, and cold air is discharged through a separate channel into the chimney. Considering that a higher combustion temperature is maintained in the bell, and the heat is evenly distributed over the body, the efficiency reaches its peak. For comparison, the efficiency of conventional furnaces is 30-35%, solid fuel boilers - 80%, pyrolysis - 85%.

The low performance of most solid fuel units is due to the fact that warm air comes out together with the combustion products into the pipe. In addition to the fact that the remaining volume is not always sufficient for full heating, the rapidly escaping flue gases further reduce the thermal threshold. In some designs, they try to solve this problem by increasing (lengthening) the chimney, but then there is a risk of a decrease in draft and, as a result, a decrease in efficiency. The creation of such a unit that would provide full traction and increase heat transfer, and became the main goal of the designer Kuznetsov.

Video 1 Construction of a heating furnace according to the Kuznetsov system

DIY Kuznetsov furnace construction

The sequence of actions is as follows:

First, they study the plan of the room where the installation of the heater is planned. In the event that the house has not been erected, it is necessary to ensure uniform heating of all rooms. It is undesirable to build a heating unit into a finished building, but if necessary, you can

But at the same time, the location of the supporting structures and beams should be taken into account when arranging the chimney.

Then the foundation for the heating device is prepared. It is made of concrete, while the width should be 10 centimeters larger than the size of the device

It is advisable to design the foundation for the oven at the planning stage of the house.

Views

By purpose and design features, "blacksmithing" can be divided into several types:

- Heating. The devices are designed for efficient and safe space heating.

- Cooking. Used to prepare food. These include ovens for baking bread and bakery products.

- Bathrooms. Kuznetsov's stove for a bath is designed for simultaneous heating of the main bath rooms. Such devices have high heat dissipation with minimal fuel consumption.

- Street. A stove complex consisting of a grill or barbecue for outdoor cooking.

- Fireplaces. The equipment is used as a decorative element of the interior or as an additional heating option. Some fireplace stoves are equipped with special loungers for a pleasant pastime.

The most popular are complex devices that are distinguished by their multitasking. A striking example is the Kuznetsov heating and cooking stove, which is intended both for heating living quarters and for cooking food.

Despite their functional features, all stoves work according to the same principle - efficient distribution of heated gases in the bell into separate streams.

It is noteworthy that the stove hoods can be equipped with additional equipment - electric heaters, hot water tanks, steam generators, an oven and a stove.

A well-designed and built Kuznetsov sauna stove will provide reliable heating in all functional rooms: a steam room, a washing room, a dressing room, a rest room. In addition, it will allow you to quickly heat up water, accumulate hot steam and purify the air.

The principle of operation of Kuznetsov bell-type furnaces: ordering

The principle of operation of Kuznetsov's furnaces is not complicated. During the construction of the furnace, it is necessary to carry out all the work according to the drawings, diagrams and, of course, use the orders.

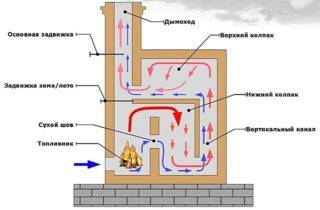

All Kuznetsov bell-type furnaces operate on the principle of separation of combustion products. This principle is that the gas resulting from the combustion of fuel is divided into two streams: cold and hot. The movement of gases inside the furnace structure is very well thought out. Hot air is retained in the oven and keeps heat for a long time. Cold air quickly flies into the chimney, along a specially made recess. A furnace operating on this principle is called a bell-type (dome). Inside such a furnace, the hearth is combined with its lower part and forms something like a bell. He then acts as a gas separator into two streams. The hot air flow rises and is retained in the hood, thus concentrating heat.

Advantages of Kuznetsov stoves:

- Profitability;

- Long-term heat retention;

- Slight soot formation;

- There is no need for frequent cleaning;

- A choice of different shapes and designs is possible.

The high efficiency factor (95%) of Kuznetsov furnaces is the result of a fundamentally new development and design features. For comparison, a traditional Russian stove has an efficiency of 25-40%. If Kuznetsov's stoves have disadvantages, then there are few of them, and they are lost against the background of advantages.

Recommendations for self-construction

Having decided to build a furnace according to one of Kuznetsov's orders with your own hands, get ready for careful and scrupulous work. On the diagrams you will find a graphic representation of each row, however, before starting the laying, you need to get acquainted with the features of the technique, in particular:

- selection and preliminary processing of bricks;

- purchase of metal parts (plates, dampers, doors, latches);

- determining the most suitable place;

- preparation of the base and foundation;

- the possibility of equipping a chimney, etc.

Fireclay refractory bricks (Ш-5, ШБ-8) were recognized as the best material for the internal masonry of "blacksmiths", and ceramics (М-150) for external decoration. To strengthen the brick walls, metal elements (reinforcement, wire) are used. In order for the stove to function with maximum heat transfer, experienced craftsmen hone not only their skills, but also every brick - in the literal sense. They polish every detail, which is why projects made by professionals look flawless.

Fireclay brick masonry

Having the author's order on hand, we recommend not experimenting, but following the indicated order. Departures from the circuit do not guarantee full heat transfer.

What is the difference

The main feature of the group of stoves invented by Kuznetsov is the absence of extended smoke channels with many turns and bends. To make the most of the heat from the combustion of fuel, duct stoves are provided with a system of passages, as hot smoke moves along which heats the bricks. In this case, the oven heats up unevenly at different levels, which can lead to cracking of the masonry. In addition, there is a need for regular cleaning of tight spots and curves.

Kuznetsov's stoves for home and baths are devoid of this drawback. In them, hot gases from the firebox enter the so-called bell - an internal space bounded from above by an overlap, and from below it has an outlet.The heated smoke rises to the very top of the hood, where it lingers until it begins to cool down. As they cool, they gradually descend along the walls of the bell, and a new portion of smoke takes their place.

The cooled smoke goes through the channel into the chimney or into another bell, depending on the design and purpose of the furnace. Gradually, as it passes through the cascades of hoods, the flue gases cool down to a temperature of 120-150 degrees. The temperature of the gases at one level of each bell is the same, which avoids uneven expansion of the brick.

Design and principle of operation

Bell furnace design

Bell furnace design

The stove with a hood was developed by engineer Igor Kuznetsov in the early 60s of the last century. Subsequently, the Russian metallurgist Leonid Kotlyar improved the design so that it retains heat up to 19 hours. The peculiarity of "blacksmithing" is that the heated air does not leave the pipe, but is collected under the hood. It gradually cools down and is displaced by rising hot streams. The advantageous difference between a bell-type stove used for heating a house and a duct stove, where hot air under the influence of draft, freely goes out into the street, lies in saving heat.

A two-meter-high structure with a base of 1m * 1m can reach a heat output of 3.5–4.5 kW. Such a bell-type stove is enough to heat a house of 50 square meters in a temperate climatic zone, if you heat it twice a day.

The inventor has improved the design by adding another hood. In Kuznetsov's two-bell heating furnace, the first covering element is connected to the combustion chamber and separates the cold and heated streams. The second bell is located in the upper part of the stove, trapping hot air, which, before entering the chimney, gives off heat to the bricks for a long time.

A two-bell oven is more economical in fuel consumption and is usually equipped with a hob. This allows you to prepare delicious meals without consuming electricity or gas. The design of the stove already includes an extractor hood - there is no need to install an additional ventilation system.

Double bell oven

The most common option for high-quality heating of a private house is a Kuznetsov device with two hoods.

Its efficiency is significantly higher due to the longer retention of hot air.

The hoods made of heat-resistant bricks are located one above the other with a slight displacement - the air displaced from the first hood immediately enters the second, from which it already goes into the chimney.

The size of such a stove is directly dependent on the area of the house; even a building with an internal volume of up to 5 cubic meters is possible. m. The firebox usually occupies the entire base area, this helps to increase the heating power of the air in the furnace.

Reference. In the design of a two-bell furnace, special valves are often installed to isolate the second bell and reduce the heat transfer of the device. This is necessary in warmer seasons, when a large heating power is no longer required.

When using valves, hot air from the first bell is directed directly into the chimney.

Kuznetsov's fireplace stove: ordering

The Kuznetsov fireplace stove is a large heat accumulator. The brick structure is like a fireplace and as warm as an oven. Due to its mass, the fireplace stove heats the room in a unique way.

The construction of fireplace stoves is a complicated matter, but if you wish, you can do everything on your own. It is imperative to start such a complex process with orders at hand. The Kuznetsov fireplace stove has a lot of advantages.

Advantages of fireplace stoves:

- The beauty and grace of the masonry;

- Brick heater efficiency;

- Low emission of carbon monoxide and soot;

- Long-term maintenance of a comfortable temperature in the house;

- Profitability.

Some fireplace lovers make them look like works of art, decorating them with grates and decorative elements, using the services of a blacksmith. A pleasant sensation of radiant warmth can be felt on yourself if you equip your country house or summer cottage with such a fireplace.

Building the foundation for the furnace: universal instructions

Regardless of the oven model, it needs a solid and solid foundation. This foundation is suitable for both the Swede and the two-bell model.

The sequence of arranging the support is as follows.

We dig a foundation pit about half a meter deep.

Foundation pit

Second step

We tamp the bottom of the pit and fill it with a 15-20 cm layer of sand. Pour water over the sand and tamp it thoroughly.

Fifth step

We prepare a solution from a part of cement, five parts of crushed stone, three parts of sifted river sand and water. We fill with this solution about half of the free horizontal space of the pit. Let the fill dry.

Sixth step

We prepare a solution from a part of cement and three parts of sand. Fill the remaining pit space with the mixture. We carefully level the upper part of the fill using the rule.

Poured foundation for laying a brick stove

Types of designs with an oven

Kuznetsov furnace

It is installed in rooms with minimal possibilities in terms of area, while the design and decoration are selected on an individual basis. A feature of this type of furnace system is a high efficiency rate, which for such devices is more than 80% simultaneously with an insignificant amount of soot formed during operation. The design is suitable for placement in any part of the room, it is possible to place several such furnaces at once. Any solid fuel option is suitable for the firebox.

Bykov's device

The thick-walled structure has a simple bookmarking scheme and a rectangular shape. A similar version of the furnace provides for the placement of the device in 2 rooms at the same time. Nevertheless, Bykov's design in its structure has significant differences from bell designs. The lower area includes 2 gas channels: ascending and descending. The upper part is in the form of a sieve, the hood of which is divided by 5 channels.

Second heat load

Nothing works on bare principles. In order for a theoretically absolutely correct stove to heat, dry and cook well, it must also be performed correctly in the material. With regard to bell-type furnaces (and especially to two-bell ones), this means that the thermal load on the material must be high. To make a massive bell-type stove with thick walls is like making a fire in a cave. To feel the warmth, you need to sit by the fire itself, and there will be soot ...

Take a look at fig. On it - drawings and orders of some Kuznetsov stoves: a bath. heating and cooking. a double-circuit hot water boiler and an improved Russian with a stove bench. Not being an experienced stove-maker, it is clear that the amount of material per unit of released power (500 W * sq. M of the outer surface) in the Kuznetsov furnace is one and a half to two times less than in the traditional ones. In general, any bell-type furnace is "empty" inside a channel furnace of equal power.

The orders of some Kuznetsov furnaces

On the one hand, this is good, a brick with a masonry mortar costs money. But on the other hand, it requires careful development and adherence to construction technology (see below). The heat load, from which the pile of cobblestone does not move, will destroy the thin brick wall already during the accelerating firebox.

For Kuznetsov furnaces, structural mechanics are also important.The strength of the wall on clay mortar decreases with decreasing its thickness much faster than on cement-sand. Therefore, the foundation for these furnaces must be carried out especially carefully in strict accordance with the recommendations of the author. They also need to be strictly followed during construction.

Note: I. V. Kuznetsov allows you to freely copy your materials for yourself, for construction, but objects to reprints. However, the pictures in Fig. small. An amateur can not build anything on them, but a master knows where to get full-fledged drawings. Therefore, we hope that Igor Viktorovich will forgive us for this small borrowing for the good of the cause.

How to make do-it-yourself Kuznetsov brick ovens

IN AND. Kuznetsov developed a large number of furnace designs. Some types of ovens can be made by hand. This will require the ordering of the furnaces and their drawings.

Many, knowing about the positive reviews about Kuznetsov's stoves, as well as in order to save money, start building them on their own. Of course, everything will work out, but for this you need to use the appropriate materials and strictly follow the procedures.

Materials used for the construction of the Kuznetsov furnace:

- Fireclay brick;

- Clay brick of the M150 brand;

- Good quality clay;

- Refined sand;

- Metal fittings.

Fireclay bricks are used for the construction of internal masonry. According to the order, you can calculate its quantity. For the construction of external masonry, clay brick is used, preferably grade M 150. Its quantity is also calculated using the same order. It is recommended to use only good quality clay for mortar. Twice as much clay is used for refined masonry sand. You can use commercially available clay sand mixtures. For 500 bricks, you will need about 0.2 cubic meters. m of clay-sand mixture. In addition, you will need grate bars, two doors (blower and furnace), two steel corners and five meters of wire. Kuznetsov's book "We Build Stoves and Fireplaces: A Practical Guide" will help you build the structure you need. It presents all types and designs of stoves and fireplaces.

Kuznetsov furnaces device and principles of operation, advantages, variations, drawings

Kuznetsov's stoves are well known not only to stove-makers - they heat many houses in Russia and abroad. IV Kuznetsov has been working on improving the furnaces since 1962 and has gathered around him a strong team of like-minded people. The team has more than 150 developments covering almost the entire range of household stoves, see fig.

Some of the stoves of I. V. Kuznetsov

Many would like to fold some of Kuznetsov's stoves with their own hands, and this article is to help them. But we are not going to reveal some hidden secrets of "blacksmiths" - they simply do not exist. On the website of Igor Viktorovich, those who wish for free will find a huge array of stove information: from information on the design and construction of stoves to detailed drawings and recommendations for installing a stove in a house and arranging a blind area around a building with stove heating. We also do not intend to criticize or correct anything in this home-stove encyclopedia: we are far from IV Kuznetsov in the stove business, to put it mildly.

The purpose of this article is to provide a kind of introduction to the body of Kuznetsov's information, which allows one to more freely navigate the source material. Let us explain with an example why this is needed.

Let's say I'm a station wagon mechanic with a lot of experience and I want to pass it on to others interested. A car is a complicated thing. If I start to get distracted along the way, explaining in detail that how the run-in and caster (let's say, readers are not really teapots, now everyone drives) affect the handling and directional stability of the car, and the gas distribution diagram affects fuel consumption depending on the road conditions, and so on, I will eventually get confused to the point that I myself no longer understand how the car I drive works. Willy-nilly, I will have to present the material, albeit “on the fingers,” but in a professional way.

However, it will be difficult to read it even for specialists just like me, and an amateur will be dizzy in general. Therefore, I will need someone to help me, who can be conditionally called a "recipient". In fact, he is not a kettle at all, he can adjust the suspension himself, and set the valve tappets. But in this case, his task is to describe how the entire filling of the car is assembled into a single whole, controlled according to the principle: "Steer the wheel, gas the gas, brake with the brake."

In the automotive industry of the USSR, a similar situation arose in the late 50s - early 60s, when the industry began to produce cars for widespread sale to the population. Then the superbstseller of that time - "How the car works" was published. Edited by none other than the chief designer of the legendary "Victory" A. A. Lipgart.

The information "from the recipient" will not yet allow you to get down to work: it does not provide in-depth knowledge that will allow you to at least intuitively figure out the necessary values of the numerical parameters along the way. But it is fundamentally fundamental: owning it, a professional text is read with understanding and faster. And, if somewhere something in him is still incomprehensible, this no longer causes loss and rushing, but just a mark in the mind: you need to find out more about this.

So far, the government has not adopted any landmark decisions on stoves and stove heating. But their role in household heat power engineering in times of energy shortages is undeniable: a heating stove with an efficiency of 70% with mass use will give fuel economy on a national scale, since in the projects of new heating plants, heat losses in the mains are included in 35%, and it is not yet possible to reduce them. So with the popularization of stove knowledge, you have to get out yourself, without being either Lipgart or Kuznetsov. Well, let's try.

More about plump

In theory, round stoves generally have a lot of advantages, only they are not very convenient in the house. However, there is a considerable demand for compact mobile furnaces, and here the extremely high efficiency of round multi-caps can be a decisive factor, because when the size of the furnace decreases, its efficiency drops sharply due to the square-cube law.

Such ovens, of course, would have to be made of metal. This solves the problem of cleaning, the stove can be made collapsible. But the choice of metals suitable for the ratio of heat capacity and thermal conductivity is extremely limited. Of the inexpensive - only cast iron, but it is heavy and fragile.

However, there is a lighter and stronger metal material with similar properties. These are products of powder metallurgy. When applied to scissor knives, "powder rubbish" is quite justified, but for a furnace in which nothing works for shear, powder parts can be a godsend.

The second problem, which has already been mentioned, is the heat-resistant lining on the roof of the first bell. If we manage to solve it, then, perhaps, the works and efforts of Igor Viktorovich Kuznetsov will bear fruit more extensive and significant than it seems now.

Operating principle of ovens with two bells

The secret of the efficiency of this stove lies in its original design, which allows accumulating and storing heat for a long time. To understand the principle of operation of a two-bell furnace, consider its design diagram.

After firing up in winter, the incandescent flue gases rise under the roof of the lower bell, transferring heat to the surrounding walls and the hob. But new air enters the combustion chamber, the combustion process continues and the release of hot combustion products continues, displacing the cooled gases under the top of the bell. Those, in turn, descend and fall into a vertical channel leading to the upper bell, where the two-bell design of the furnace provides for the repetition of the previous process with the release of gases to the outside through the chimney.

The temperature of the flue gases coming out is lower than any other stove with a stove, as they intensively give off their heat to the walls of the stove. For this reason, the chimneys of heat sources of this design must be protected from the destructive effects of condensation.After the heating is over, the heat remains for a long time at the top of both hoods, even if the main valve remains open. Cold air entering through the blower cannot rise under the dome of the hood and passes into the chimney along the path indicated in the diagram by blue arrows.

The two-bell cooking stove with a stove allows you to cook food in the summer thanks to an additional valve, the opening of which allows gases to pass directly into the chimney. If the valve is not fully opened, then the flow of combustion products is divided into two, going along different paths. In this way, in the autumn-spring period, it is possible to regulate the intensity of warming up the hoods, that is, the heat output of the stove.

Features of the Kuznetsov furnace

Since the main goal of Kuznetsov's developments was efficiency and productivity (he worked to increase the value of efficiency), this required a fundamentally new and perfect approach.

From the above, the conclusion follows: the system of free movement of gases created by this master is more natural, it optimizes the operation of the device and uniform heating. In addition, the formation of soot is minimized.

In addition to these advantages, Kuznetsov furnaces have other positive aspects:

- combustion takes place without soot and smoke;

- heating is more uniform;

- better heat transfer;

- the need for cleaning is dozens of times less;

- profitability;

- there is more room for the steel heating element;

- low level of heat loss;

- resistance to cracking;

- the ability to change the shape and design of the structure.

Kuznetsov furnace device

In most of the models that were invented earlier, the hot gases always moved through the channels. During their movement, the structure heated up, and then cooled down itself. This movement of gases was formed by thrust. At the same time, the body warmed up unevenly, which ultimately led to cracks. The heat exchanger was placed in the firebox, because there was no more room for it. There he was in direct contact with the fire and his life quickly dwindled.

Kuznetsov used a completely different principle of gas movement for his model. The stove has hoods turned upside down. The hoods can be fastened one above the other and connected together with a dry seam, as a result of which gas begins to pass through them from one hood to another. It is because of this principle of operation that the Kuznetsov furnace is also called bell-type furnace.

Improve your designs I.V. Kuznetsov started in 1962, and a large number of like-minded people gathered around him. Many summer residents also want to create a Kuznetsov stove with their own hands. Let's say right away that it is possible to build a Kuznetsov bell-type furnace with your own hands, but many of the hidden secrets of the like-minded master did not disclose, or maybe they simply do not exist.

It is worth noting that, thanks to the principle of operation of the Kuznetsov oven, it is possible not only to create separate heating in the house, but also to receive hot water. For this, the hood on the rear side must be equipped with a steel heat exchange.

Advantages of the Kuznetsov bell-type furnace:

- Flue gases are stratified throughout the structure in the same way after the combustion chamber.

- In one building there may be not one, but several caps. They will help you reach more warmth.

- The hood is located near the firebox and all carbon monoxide gases get into it. Therefore, ash, carbon monoxide and volatile hydrocarbon, which in other furnaces come out through the chimney, in this case burn out under the hood. This will increase heat dissipation and minimize soot production.

- With the help of their convection, all the products formed as a result of combustion cannot get out of the oven, therefore they give up their heat to it.

- The heat exchanger in this building is located in the bell or outside the combustion chamber, so it does not affect the temperature of the fire and cannot reduce the efficiency.

Styling tips

In order to correctly lay bricks during the construction of a bell-type furnace with your own hands, you need to adhere to some tips:

- It is not necessary to make the combustion chamber any part of the bell, because the fuel needs a certain space for combustion in order for the structure to have a high temperature. If the firebox is part of the bell, then you will get an ordinary Russian stove with poor draft.

- Firing should be done at a minimum temperature and gradually increase the intensity of combustion.

- At the maximum temperature, the brick begins to expand, for this reason the fireclay box installed inside begins to "hang", in other words, an empty space appears around it.

- After the masonry is over, you need to apply a refractory compound to the entire brick.

- After every second row of bricks, you need to lay steel wire to strengthen the bond.

- Doors and other metal parts must be installed so that they can expand at high temperatures. To separate the brick from the metal, you need to create a new spacer.

The Kuznetsov bell-type stove, the order of which was created with the maximum accuracy of step-by-step steps, comes not only with one bell, but also a two-bell one, which allows you to warm up a room with a large area.

As you can see, a simple bell structure can be built with your own hands, but if you want a more functional stove in your suburban housing, the laying scheme of which is complicated, then it is best to resort to the help of experienced stove-makers. They will do their job quickly, adhering to the order, and the finished structure will last a long time. After all, there are many subtleties and various nuances in the construction of the Kuznetsov building, and it will take some time.

Despite this, you can build a bell-type furnace with your own hands using the order and diagram. The main thing is desire, and then the stove will bring joy and comfort to the house.