The sequence of laying a fireplace from bricks

Base device

If the floor is made in the room, disassemble its section at the location of the future fireplace. If there is a subfloor, arrange a wooden formwork for pouring concrete in a size 5 cm larger than the size of the base of the fireplace according to the project.

A layer of rubble mixed with sand is poured onto the bottom to compact the soil and ram it. The concrete is poured 10 cm below the existing floor surface. The concrete is covered with a thick layer of sawdust and moistened to prevent cracking. After a week, they are removed and the formwork removed.

The foundation is isolated from the brickwork with two layers of roofing material to prevent moisture transfer from the soil through the concrete to the fireplace body.

Brickwork

The first row of bricks is laid without mortar. The complexity of further work depends on the correctness of its location. Be sure to verify the right angles, horizontal rows and measure the evenness of the diagonals. The first row should raise the brickwork to floor level.

The laying of the next three rows is continuous and forms the base of the fireplace, and from the fourth, the design of the combustion unit begins. All rows are laid according to the drawing of a brick fireplace, the horizontal and verticality of the work is constantly checked in order to prevent distortions. Bricks are laid with bandaging of seams.

The height of the further masonry of the combustion chamber occurs according to the scheme and depends on the accepted volume of the internal space of the fireplace. The walls of the firebox are made of fireclay refractory bricks... The steel sheet is fixed during masonry, it serves as a reflector.

The chamber in which the smoke is collected before sending it out into the chimney is 5–6 bricks high.

Do-it-yourself bricklaying of a brick pipe is carried out to the entire remaining height to the ceiling of the room. When making the front surface of the fireplace, select decorative bricks are used, unless other wall decoration is provided.

The metal furnace frame for the fireplace is fixed with their own hands using embedded metal parts, which are inserted into the seams of the masonry and sealed with mortar. The elements are made of steel strips with a thickness of at least 3-4 mm. You can use annealed wire, the diameter of which is not less than 2–3 mm.

Chimney

- a steel chimney sandwich can be inserted into the decorative brick chimney of a corner fireplace. This is done because the brick does not work well in an aggressive smoke environment and quickly collapses. The combined chimney will last much longer. Cleaning is performed in a more comfortable environment;

- when bringing metal pipes out through a hole in the wall, provide insulation. If the wall is made of stone, brick or concrete, then it is enough to blow out the hole with foam for outdoor use. When passing through wooden walls, the pipe is wrapped in two layers of asbestos, and only then is it isolated;

- when laying a pipe, a mortar with the addition of cement is used. When working, after each new row, be sure to wipe the inner surface of the pipe, removing the protruding solution. Plastering of pipes is not performed;

- the height of the pipe on the roof depends on the ridge, the closer the location is to it, the higher the chimney. In any case, the pipe is made no lower than 50 cm from the roof surface. This rule also applies to flat roofs.

Do-it-yourself fireplace masonry will bring a lot of pleasure to the owner and his assistants, who will be happy to take a photo of the entire masonry process. Dull winter evenings will be diluted with the warmth of a living fireplace and unhurried friendly conversation with crackling firewood.

Cladding

Facing a false fireplace with decorative stone

Facing a false fireplace with decorative stone

Externally, a brick fireplace structure looks inconspicuous. To give the structure a beautiful look, you can:

- Plaster the surface.The plaster mortar is applied after 14 days - it can crack from wet bricks after drying. It is allowed to paint the plaster layer with fire-resistant paints.

- Carry out the cladding. Artificial or natural stone looks beautiful. The ability of the material to withstand temperature fluctuations and accumulate heat will provide a comfortable microclimate. To create a drawing, you should be inspired by a beautiful photo.

- Fasten the gypsum board. Plasterboard sheets are fixed on a metal frame that is welded to the oven. The finish is varnished and easy to clean or dust-free.

- Lay out the tiles. With the help of heat-resistant tiles, it is easy to create a beautiful motif or to opt for a laconic monochromatic cladding.

Corner fireplace models combine the possibilities of an interior item, heating the room and creating a cozy atmosphere. With an understanding of the principle of ordering, knowledge of the technology of work, the structure can be folded up by yourself. In the apartment, stop at fake models or devices with live effect flame.

Calculation of the main parameters of a corner fireplace

Before work, you need to decide on a masonry scheme, pick up drawings of the structure in a section and order, sketches of the design of the fireplace facade. The dimensions of a corner fireplace are determined in accordance with the volume of the room in which it will be installed. The area of the fireplace insert in a 15 m2 room should be 0.25–0.3 m2.

The size of the future structure and its individual elements is determined depending on the area and characteristics of the room.

- First of all, we determine the width and height of the fireplace insert opening. It is also called the firebox portal. It represents a niche, for laying out which refractory fireclay bricks are used. The firebox of the correct size will be able to provide the required amount of heat and the aesthetic appearance of the entire structure, therefore its dimensions depend on the area and configuration of the room. The standard ratio in small fireplaces is 2: 3. In our example (for a room of 15 m2), the width of the firebox portal will be 40 cm, and the height will be 60 cm.

- Then we determine the depth of the firebox. This is a very important parameter on which the efficiency of the structure depends. Depth is related to height in a ratio of 2: 1 or 3: 2. A fireplace with a deeper fuel portal will have less heat transfer or require more fuel. A firebox that is too narrow will produce a lot of smoke. In our example, the optimal depth would be 22–30 cm.

- The dimensions of the smoke extraction hole are determined depending on the size of the furnace slot. The quality of the draft depends on the size of the chimney. The smoke hole should be 9–15 times smaller than the firebox portal. In our example, if the pipe is square, it should have dimensions of 14x14 cm. The diameter of a round pipe should be 10-13 cm.

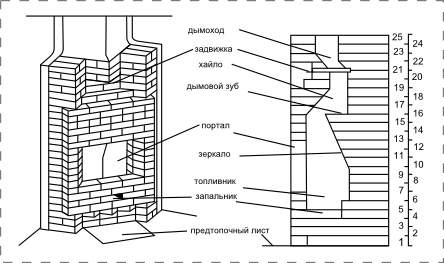

The side walls of the fuel portal must be laid out with an inclination forward, as this will increase the draft in the fireplace, and, accordingly, heat transfer. A chimney is installed in the upper part of the firebox. An additional pass in the form of a cornice is created between it and the inclined wall, which prevents smoke from entering the room and prevents the emission of sparks through the pipe. Above the level of the fuel portal, a special ledge (smoke tooth) is built, which excludes the ingress of combustion products and cold air from the street into the room, and also prevents soot from falling down from the chimney.

The dimensions of the corner fireplace are determined in accordance with the volume of the room

With the correct drawing up of drawings, you can calculate the required number of brick blocks one by one and ensure the highest quality work of all elements of the fireplace. At present, all calculations will help to carry out special computer programs that also draw up drawings and develop the order of the fireplace.

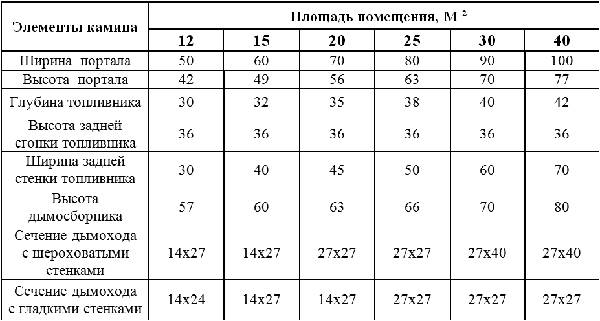

Table: proportions for a corner fireplace

| Premises | Firebox portal | Chimney section, cm | |||||

| Area, m2 | Cubic capacity, m3 | Width, cm | Height, cm | Depth cm | Neck, cm | Back wall width, cm | |

| 12 | 42 | 50 | 45 | 30 | 12 | 30 | 14x14 |

| 16 | 50 | 60 | 50–52 | 32 | 12 | 40 | 14x27 |

| 22 | 60 | 70 | 56–58 | 35 | 12 | 45 | 14x27 |

| 30 | 80 | 80 | 60–65 | 37–38 | 13 | 50 | 27x27 |

| 35 | 100 | 90 | 70 | 40–42 | 13 | 60 | 27x27 |

| 40 | 120 | 100 | 75 | 45 | 14 | 70 | 27x27 |

Materials and tools for work

For a small corner country fireplace you will need:

-

whole solid bricks, based on the order, with the addition of 10% for scrap and battle during unloading;

- coarse sand with a fraction of 0.3–1.5 mm;

- clay;

-

Portland cement grade not lower than M-300 and not higher than M-500;

- crushed stone of fraction 2–6 mm;

- bar reinforcement - 10–12 pieces with a diameter of up to 10 mm and a length of up to 700 mm;

-

steel corners and smoke damper;

- stainless steel pipe - for a metal chimney;

- cast iron door - for a fireplace with a closed firebox;

- spark arrestor - a conical nozzle on a pipe for fire protection;

- deflector - a device for enhancing traction in the pipe and protecting from the wind;

- grate;

-

screen;

- roofing material or other waterproofing material;

- building level, trowel, hammers;

- facing materials.

Before work, the brick must be soaked in water or simply moistened to remove air from the pores. This will make the masonry more reliable, and in addition to everything, the material will not take moisture from the cement solution.

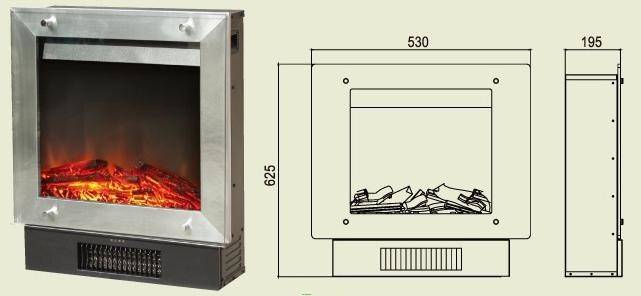

Dimensions of decorative fireplace

Sizes, a corner fireplace for which is determined according to the area of the room for decorative installations, can also be determined based on the following tips and recommendations:

The room chosen for the installation and installation of the structure must be of suitable dimensions. As a rule, the dimensions of the stove should not exceed one twenty-fifth of the living room;

First of all, it is recommended to buy the firebox itself.

Electric hotbeds are versatile

Miniature corner fireplace for home or apartment

- Since a real flame does not burn in the hearth of false fireplaces and the structure does not heat up, it is quite possible to make it not only an addition and decoration to the interior, but also add some functionality. To do this, equip the framing with various shelves, countertops or shelves on which you can place books, accessories and other necessary, useful little things;

- If you want to install a purchased electric or bio heating stove in the decorative portal, all calculations are made according to the existing installation dimensions. If the portal is purchased, you can find its installation dimensions in the instruction manual attached to the purchase. For self-made frames, all measurements are done by hand, choosing a suitable hearth in this case is quite difficult and it is quite possible to make it only on order.

You can also view photos of corner fireplaces in various interiors in this article.

How to calculate the dimensions of the combustion chamber

In order to calculate the size of the corner fireplace and its combustion chamber, adhere to the following rules:

- To calculate such a parameter as width, you will need to fold the width of the firebox itself and its side parts, as well as fold the framing consoles;

- To calculate the height, the height of the firebox, fireplace shelves and other decorative elements is added;

Dimensions of a rectangular metal hearth

The ratio of the firebox to the parameters of the purchased frame

Overall dimensions of the hearth and portal

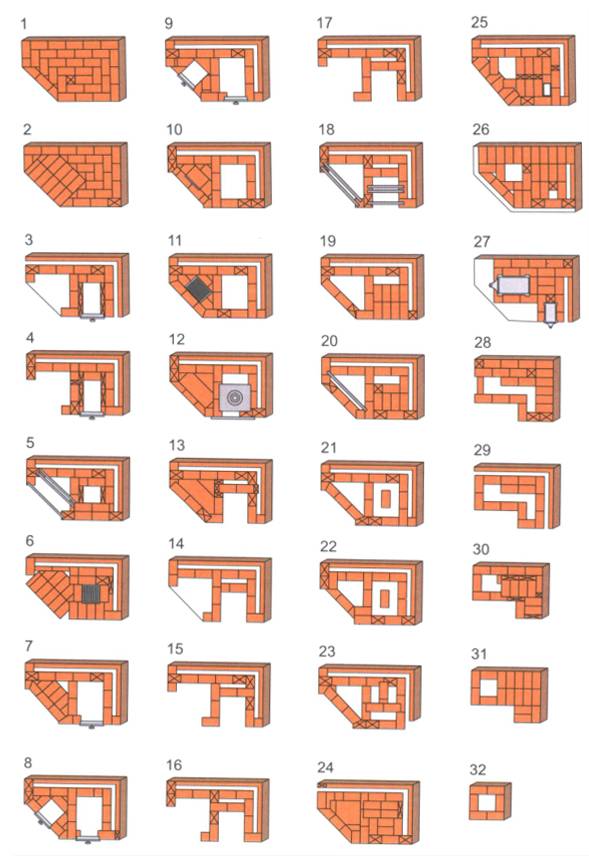

Fireplace construction according to the order

To prevent the brick walls of the future hearth from dampening, absorbing moisture from the foundation, the base area must be covered with roofing material in 2 layers. Without waterproofing, the building will crack pretty soon and start to smoke into the room.

This is how the corner hearth "Annushka" looks like

The brickwork of a corner fireplace is carried out according to the orders in the following sequence:

- Prepare a clay-sand mortar from a dry masonry mixture, following the instructions on the bag. Lay out the first solid row of 1020 x 1020 mm bricks in the shape of a square platform. This design makes it possible not to place a pre-furnace metal sheet in front of the portal.

- Lay the bricks of the second tier, starting from the far corner of the landing, to form a triangular base of the hearth 890 x 890 x 1260 mm. For cutting and shaving off stones, use a grinder equipped with a concrete circle.

- In rows 3-4, a niche is laid out for storing and drying firewood. From above, it is covered with a sheet of metal laid on the lintel from the corner. The next 5th tier is solid, it plays the role of a capital overlap.

- On the 6th row, the hearth part of the firebox is formed, consisting of chamotte stone and framed outside with red brick. Further, up to the 13th tier, the side and rear walls of the fuel chamber are placed. A chimney tooth is formed from the 12th row, for which the refractory stones of the back wall are cut obliquely and moved forward (30 mm on each row).

- On the 13th tier, a horizontal portal lintel is placed from two steel corners, deployed with shelves towards each other. From the 14th to the 16th row, the overlap of the firebox and the chimney tooth are simultaneously formed.

- Rows 17-21 make up the walls of the smoke collector, gradually turning into a rectangular channel, and the 18th tier is made with a protrusion of the bricks of the frontal part. The remaining rows 22-30 form a chimney with curly side walls. Install the valve on the 28th tier.

The order of construction of a corner-type fireplace with the romantic name "Annushka" is displayed in the following video:

The chimney channel crossing the timber floor and the roof structure must be laid with a fire cut (thickening of the pipe in the place of passage). The top of the chimney is removed from the leeward zone and rises to a height that provides normal draft, which is reflected in the diagram.

Facing the finished fireplace

If you wish, it is perfectly acceptable to leave the "front" part of the fireplace without finishing, especially if you used a nice red brick. It is worth thinking about this even during the laying, if no further finishing is envisaged, it is better not to put the mortar end-to-end to the very edge, leaving characteristic slots between the bricks. To make them, then it is problematic and threatens with a violation of the integrity of the masonry. In case you nevertheless decided on cladding, make a choice on one of these materials:

- Stone (any variation, even natural.)

- Tile (better tiled).

- Drywall, do not forget that it must be fire and temperature resistant. In addition, it will require a special frame (only made of metal).

- Classic plaster.

Here are some tips to help you keep your fireplace intact. For example, if you use stones, tiles, it is better to immediately varnish. This will make it easier to treat dust wiping.

By the way, one more thing, if you chose plaster as a finish, remember an important rule, plastering is allowed only after complete shrinkage. Otherwise, huge cracks will go along the entire plane, which will definitely not add grace.

The plaster itself is, at first glance, a simple way of finishing, however, taking into account the variations in different shades and design styles, you can create a prettier and more expressive cladding, even better than that of natural stone. A variety of ornaments and patterns can be applied with plaster, which cannot be done with any other finishing material.

Materials and tools for creating a furnace

Having worked out the scheme, having drawn up the necessary drawing with calculations, proceed to the acquisition of the necessary materials and tools:

- waterproofing in the form of polyethylene film and roofing material.

- medium-sized crushed stone and river sand for mortar preparation. Sand is also relevant as an insulating cushion in the pit.

- boards for formwork, where the concrete solution will be poured. Formwork is of two types - temporary and stationary. With a temporary option, a mixture of crushed stone and river sand is poured between the ground and the foundation.

- metal mesh or steel rods with a diameter of 8-10 mm for reinforcing concrete mortar.

- red fired brick for the construction of walls and a fireplace and chimney.

- fireclay brick for laying out places, in close contact with fire. The calculation of the elements is carried out by the piece. You will need a little material - from 360 to 600 pieces.

- clay, cement and sand in proportions 1: 1: 3. The components are needed to prepare the oven solution. The ready-made mixture can be purchased at specialized stores.

- metal corners with a size of about 50x50 mm, intended for laying furnace niches, an opening for firewood, if one is provided.

- plywood sheet when the combustion chamber is shaped like an arch.

- a metal pipe with a length of at least 5 m for arranging a chimney.

- a metal gate valve with a handle, which can be purchased at an oven supply store.

- asbestos sheets for wall insulation.

- finishing materials for outdoor decoration - plaster, artificial stone, ceramic or facing tiles.

Tools that you will need in the process of building a brick oven with your own hands:

Tools that you will need in the process of building a brick oven with your own hands:

- building level for perfectly smooth masonry joints.

- tape measure for measuring the parameters of parts and general product.

- mortar trowel.

- a rubber hammer, which gently knocks out protruding bricks, achieves the maximum leveling of the masonry.

- grinder for cutting blocks.

- tanks for solution and water.

- shovel for mixing the solution.

Use the above construction materials and tools, following safety precautions.

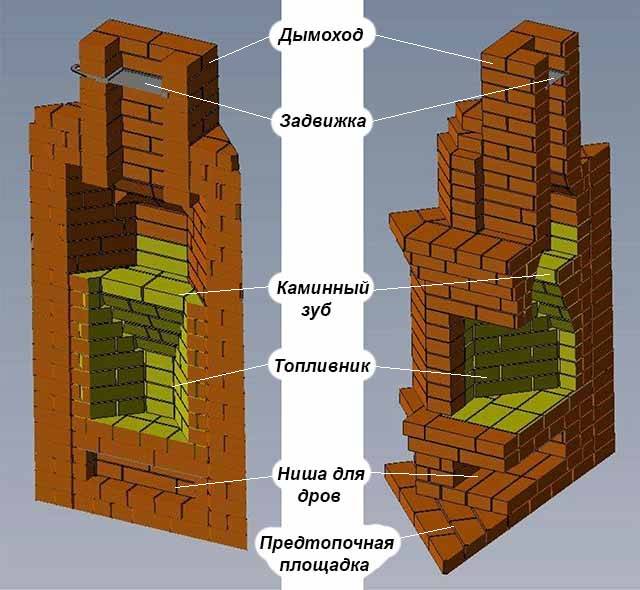

Device and size of the hearth

Structurally similar fireplaces, whose example is shown in the photo, are similar to traditional "brothers" of the wall type. The hearth consists of an open firebox without an ash chamber, a cone-shaped smoke collector with a chimney tooth and a straight chimney. The difference is in the triangular cross-sectional shape, which complicates the construction process.

The principle of operation of a triangular fireplace remains the same: firewood is burned on the bottom of an open firebox, combustion products are removed through the chimney shown in the diagram below. A part of the heat is retained by the chimney tooth (in general, about 20%), the rest goes away with the smoke due to the natural draft arising in the vertical channel.

In order for the hearth to properly serve as a source of heat, it is necessary to select the size of the structure for the volume of the room and take into account a number of points:

The size of the furnace opening is determined as 1/50 of the area of the room (usually the fireplace is located in the living room). The height of the portal is made approximately twice the maximum depth of the fuel chamber.

With low draft, smoke will enter the room, and excess will lead to increased heat loss, especially when the fireplace is not on

Therefore, the optimal cross-section of the chimney is taken as 1/9 of the area of the combustion niche.

For the normal operation of the fireplace stove, it is important to organize the flow of air into the living room, otherwise the draft in the chimney will deteriorate.

Burning wood often "shoot" heat particles through the front opening. To avoid a fire, a pre-furnace sheet of metal is laid on the floor in front of the hearth.

If the structure is adjacent to the walls of a wooden house, then the combustible surfaces must be protected with roofing galvanized.

To simplify your calculations, a table will help, where the dimensions of the portal and the cross-section of the chimney duct of corner fireplaces, depending on the size and volume of the room, are indicated.

We propose to consider the construction of a brick hearth in a private house or in a country house using the example of the classic Annushka fireplace shown in the photo. The project is designed to heat a living room with an area of 18–20 m² with standard ceilings, the section of the furnace opening is 70 x 50 cm (width x height).

Often, a simplified method of building a brick hearth using a cast-iron fireplace insert is implemented in residential buildings. How this is done is described in detail in the video:

Advantages of corner fireplaces

Corner fireplaces have a higher efficiency than wall fireplaces

Corner fireplaces have a higher efficiency than wall fireplaces

Compared to frontal heat sources, fireplace structures have a number of advantages:

- Compact dimensions, due to which a small room is not overloaded with objects.

- High-quality heating of adjacent rooms.

- High efficiency - the corner stove reflects heat flows from the wall.

- Even distribution of heat as it occupies a corner.

- Effectiveness - the fireplace fits into any interior, creates an atmosphere of tranquility and comfort.

- The possibility of organizing a place for a family or romantic getaway, when a live, soothing fire burns in the hearth.

- Saving materials when building a stone model in a corner compared to island or wall models.

- Ease of self-creation of a false model.

- Easy ordering. Masonry in the presence of a scheme is easily performed by a novice master.

- Functionality. The design heats the room, provides the house with hot water, and is equipped with a hob.

Finishing the finished fireplace

The finished fireplace is decorated with facing materials or left as it is: the brick gives the room a special charm and authenticity.

How to make the right jointing

It is performed if the facade of the fireplace is not planned to be faced.

- We use a clay solution: we bring the clay pulp to readiness, and then pour the cleaned and dried sand into the mass, stir the mixture until a homogeneous thick composition is obtained, which is easy to form.

- To make the jointing more convenient, when laying brick blocks, we do not bring the cement mortar to the outer edge of the wall by 5 mm.

- We regularly check the geometric parameters of the structure using a level.

Facing the fireplace with various materials

There are many options for decorative finishing of fireplaces:

-

The finished fireplace structure can be plastered without affecting the inner surface of the firebox and smoke box. This is the easiest method for finishing a heating structure. With the help of special spatulas and special techniques, interesting decorative effects can be created. In addition to plaster of the usual color, you can use colored compounds.

-

Another common method of decorating a fireplace structure is to decorate it with drywall sheets. The material is cut and attached to a steel frame. In this case, it is necessary to strictly check the geometry of the walls and corners using a level.

-

Also, the fireplace can be faced with refractory tiles or elegant tiles, overlaid with synthetic, wild stone or marble. To improve the aesthetic characteristics and facilitate the maintenance of the fireplace, decorative stones should be coated with a special fireproof varnish.

- To make the fireplace even more aesthetically pleasing, it is worth installing a special screen in it. For the manufacture of fireplace screens, a metal mesh and elements of artistic forging are used. In accordance with fire safety regulations, a steel sheet must be laid in front of the fireplace.

Optimal fireplace dimensions

When determining the optimal dimensions of the structure, it is necessary to take into account the indicators of the area, as well as the volume of the room, which will be further heated by the unit being built. Specifically in this example, a fireplace is built with a combustion chamber opening having an area of the order of 0.3 m2. You can change the suggested sizes according to the conditions of your situation.

How to build a corner fireplace

Determine the optimal dimensions of the firebox portal. In the case of the structure under consideration, a portal is called a combustion hole. Its main parameters are width and height.

Stick to the standard ratio of width to height as 3: 2. In this example, the width of the portal will be 560 mm and the height will be 400 mm.

Maintain the height of the fireplace portal and the depth of the fuel compartment as 2: 1; a ratio of 3: 2 is also permissible.

These sizes are the most optimal. If the firebox has a greater depth, the heat transfer of the unit will significantly decrease. If the size of the firebox is reduced, smoke will appear.

Corner fireplace dimensions

In the situation under consideration, the firebox should have a depth of 240-300 mm.

After determining the optimal dimensions of the combustion chamber of the corner fireplace, proceed to calculating the appropriate dimensions of the hole for the chimney. Select the dimensions of this hole taking into account the dimensions of the opening of the combustion chamber. The size of the chimney opening should be approximately 10-15 times smaller than the area of the combustion chamber opening.

The optimal size of a rectangular chimney is 140x140 mm. If the chimney cross-section is round, make a hole with a diameter of 100-120 mm. The optimum chimney height is 350-400 cm. This figure may increase depending on the height of the roof ridge.

In order to improve the heat transfer characteristics of the unit, the rear wall of its firebox is laid out with a slope forward. This slope should be started from about a third of the height of the firebox.

The design includes a smoke collector. He settles himself above the combustion chamber. Between the mentioned elements, the so-called. cornice, also known as the pass. This element will prevent the release of soot, sparks, etc.

If your fireplace is laid out of carved bricks, make sure that all of its dimensions exactly correspond to the standard masonry module. Typical dimensions of the building material under consideration are 25x12x6.5 cm. Keep the masonry joint at a level of about 5 mm.

In accordance with the section of the structure at the level of the combustion compartment, other dimensions of the structure to be built will be determined. Perform their calculation and draw up a drawing-order according to which the brickwork will be carried out.

Also, the creation of an order and the implementation of the necessary calculations can be entrusted to a professional. If desired, all the necessary design documentation can be easily found in open sources. Do the way that suits you best.

Types of corner fireplaces

An electric fireplace can be installed in an apartment

An electric fireplace can be installed in an apartment

The classic corner fireplace consists of a portal (body), a firebox, an ash pan, a grate, and a smoke exhaust system. Today there are several types of heating facilities.

Electric fireplace

Floor-standing and back-to-wall models are installed in apartments without permission. The device looks like a standard heater with simulated flames and embers. A corner electric fireplace is inexpensive and easy to operate.

Fireplace stoves

They support long-term burning, work on solid fuel. The facade is semicircular, which provides an extended view of the fire. At the moment of combustion, heat is reflected from the walls and evenly distributed throughout the room. The following brands are included in the user rating of fireplace stoves:

- Teplodar, wood-fired. The difference between the structure is its compact dimensions, the efficiency is 95%. Suitable for baths, combined with steam generators;

- Bavaria with the upper outlet of the smoke ducts. A slightly elongated device has a power of 9-12 kW and is designed for a room volume of up to 180 cubic meters. A decorative look is created by a heat-resistant tile cladding, and functionality is created by a high-quality hob;

- Eurokom, which maintain a long burning mode. The Polish cast iron apparatus is equipped with a hob;

- Godin with futuristic or classic designs. French products are manufactured in cast iron, steel, with a tile lining. Thanks to the secondary afterburning system, the living room, kitchen or the entire home is heated qualitatively;

- Neva from a Russian manufacturer. Firewood is used as fuel. The cast-iron stove has small dimensions (0.87x0.64 m), but it will warm up the house by 60 m2 with high quality.

Bio fireplaces

Brick fireplace stove can be equipped with an oven, hob, water circuit

Brick fireplace stove can be equipped with an oven, hob, water circuit

They run on alcohol fuel, therefore, they require compliance with the operating rules. The mixture for ignition is poured only into a special compartment, and then ignited. The biofireplace is economical - you only need to refuel once every 3-7 hours. Manufacturers offer a modern way to control the intensity of combustion - from a smartphone or remote control.

Brick models

To consider the device and features of brick modifications is the example of the Annushka model, designed by E. Doktorov. The structure is mounted at the outer or inner wall of the building.

In the classic design, the furnace hole was 0.2 m2, and the width was 2/3 greater than the height. For good heat transfer and no smoke, the depth and height of the firebox are correlated as 1: 2 or 2: 3. The chimney is 8-14 times smaller than the firebox. Other features of the author's fireplace include:

- the presence of a foundation is 15-20 cm more than the fireplace space;

- arrangement of screening made of galvanized iron. Its size is 100x200 cm;

- the protrusion of the upper edge of the screen 35-36 cm from the firebox and 7-8 cm from the walls;

- use of ceramic insulators;

- the presence of a heat-resistant layer near wooden walls - asbestos or fire-resistant drywall is used;

- primary laying of materials dry;

- thermal insulation of the chimney exit point to the attic or second floor

- outlet of the pipe head 50 cm from the roofing.

Gas devices

A gas fireplace requires a permit and a working chimney

A gas fireplace requires a permit and a working chimney

The facilities are connected only after obtaining permission from specialists. Installation takes a long time, but the finished product almost does not emit combustion products, does not require frequent cleaning from soot or soot.

Metallic options

You will need wood-fired fuel for the bookmark. Similarly, brick ones require the construction of a chimney, but the foundation is made in the form of a layer from below. The factory door made of fireproof glass allows you to view the flame.

How to choose a place for construction

It is customary to attach such a fireplace to the load-bearing wall opposite the outer door and away from the windows. This arrangement is considered optimal for efficient heating of the room. At the same time, there are many options for installing the fireplace: build it into the wall, place it in a blind corner, or install the device separately. The choice of location depends on the interior of the room and the availability of free space.

A properly built fireplace will not smoke and scatter sparks, but still it should not be placed near flammable interior items. It is advisable to choose a place in such a way that there are no windows in the immediate vicinity of the fireplace, as well as in front of it: this way the maximum heat will be retained in the room.