Recommendations from the pros!

Bath accessories

Alcove do it yourself

Concrete fence

Diy potbelly stove

Do-it-yourself veranda

Screw foundation

Country toilet do it yourself

Decorative brick

Stone fence

Pouring the foundation

How to make a fence

Wicket from corrugated board

DIY fireplace

Brick fence

DIY flower beds

Forged gates

Do-it-yourself porch

Bath tub

DIY chicken coop

DIY ladder

Metal gates

Installation of lining

Installation of polycarbonate

Pump for giving

Garage arrangement

Fences for flower beds

Do-it-yourself blind area

Steam room in the bath

Railing for stairs

DIY cellar

Painting the walls

DIY press

Lattices on windows

Rolling gates

Do-it-yourself shed

Alarm for summer cottages

Benches for giving

Fence posts

Floor screed

Solid fuel boilers

DIY greenhouse

Fence installation

House insulation

Attic insulation

Insulation of the foundation

Boiler room

Gas equipment is connected directly to the boiler room. Furnaces can be located relative to the house:

- inside - built-in;

- next to them on a separate foundation - attached;

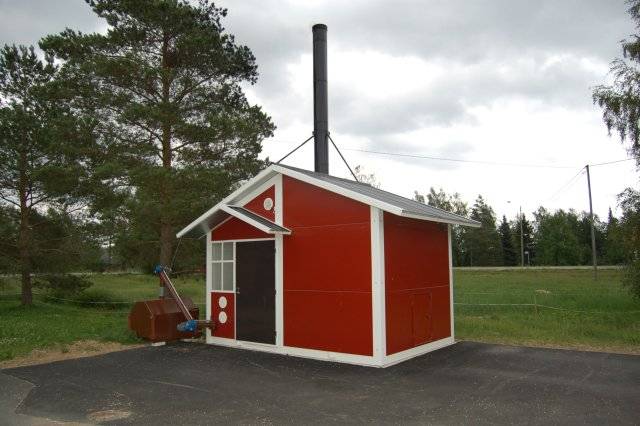

- at some distance - freestanding.

In accordance with the location, certain requirements are imposed on the premises, aimed at ensuring safety during operation.

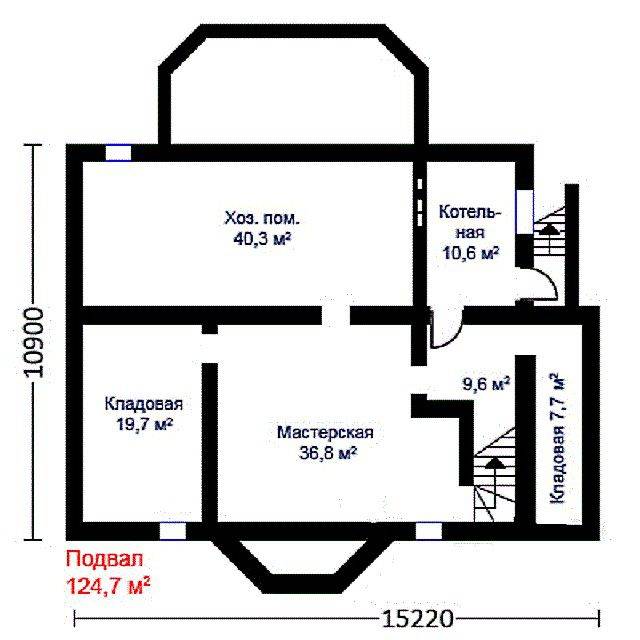

Built-in

Inside the house, according to SNiP, it is allowed to install gas equipment with a capacity of up to 350 kW. Boilers up to 60 kW can be placed in any room. As a rule, this is a kitchen or household premises. More powerful heat generators are located on the first or basement floors, in the basement.

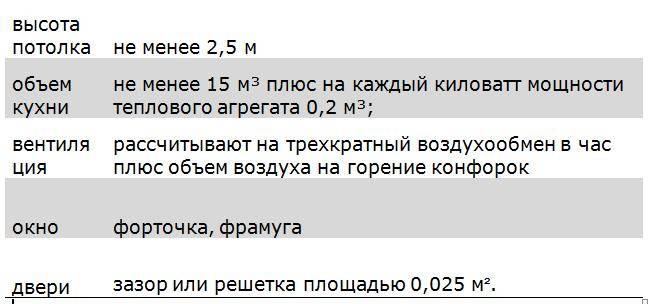

The ceiling in the room should not be below 2.5 meters. Ventilation is expected to change the air three times within an hour, that is, the cross-section of the ventilation ducts should ensure the rate of natural circulation of the amount of air equal to the threefold volume of the room.

The size of the window opening, minus the bindings, must comply with the explosion safety requirement. In accordance with it, the area of easily resettable structures, in this case glazing, is calculated from the condition of 0.03 m² per 1 cubic meter of the room.

When the power of the heating unit is over 150 kW, the room is equipped with a separate exit. Regardless of the characteristics of the boiler, a passage along the front of at least 1 m is left.

Attached premises

An attached boiler room with heating units with a capacity of up to 350 kW is placed along the blank wall of the house. At least 1 meter retreat from the nearest door or window opening. The furnace structure should not rigidly adjoin the foundation, walls and roof of a residential building.

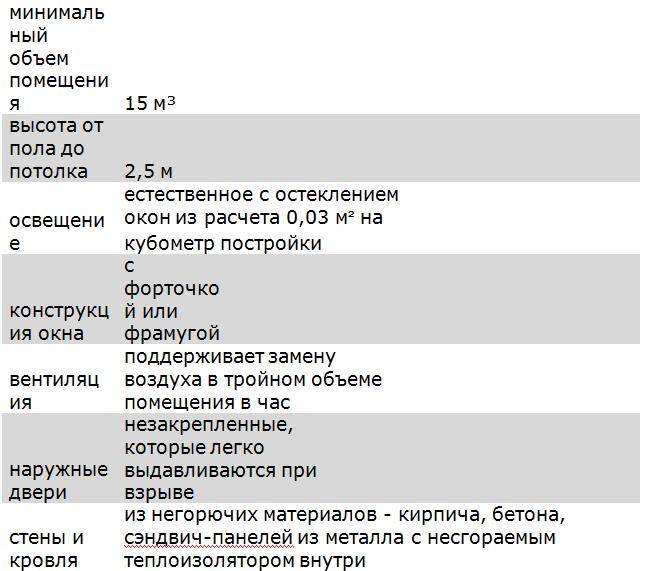

The material for the walls of the boiler room is selected taking into account the minimum fire resistance limit - 0.75 hours. The structures should not burn or sustain combustion.

The height of the boiler room inside is not less than 2.5 m. The equipment is placed so that it is convenient to maintain it. The size of the free platform in front of the boiler is 1x1 meter.

Attached rooms are equipped with a separate exit to the outside. The door must open to the outside.

Natural light is a must. Glazing area - not less than 0.03 m³ per 1 m³. The hood must maintain an hourly air exchange three times.

The door leading to the residential building is made of non-combustible materials. It must comply with the third type of fire safety.

Installing a gas boiler in the kitchen

When installing a gas stove, a water heater and a boiler with a capacity of up to 60 kW in the kitchen, the following requirements are imposed on the room:

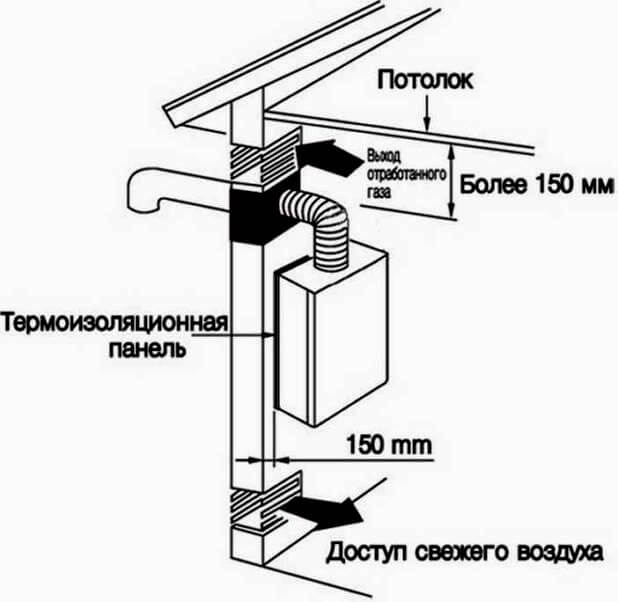

When installing gas-using equipment, they are guided by the manufacturer's passport. The walls must be made of non-combustible materials, and the distance to the unit must be at least 20 mm.

It is allowed to install boilers near walls made of combustible materials, provided that the surface is protected by 3 mm thick asbestos sheet and roofing steel or plaster. In this case, at least 30 mm retreat from the enclosing structures. The insulation is taken out of the dimensions of the equipment in height and width by 10 and 70 cm.

The floor under the boiler also protects against fire. Sheets of asbestos and metal are laid on them in such a way that their boundaries exceed the dimensions of the body and protrude 10 cm from all sides.

Can I install the boiler myself?

Considering all the dangers that gas equipment carries in the event of a violation of the installation technology, the answer to this question is obvious - it is impossible.

Before installing a gas boiler, it is imperative to obtain technical specifications. Otherwise, the installation will be considered illegal and fraught with penalties. In addition, self-installation is very dangerous, especially if it is carried out in a high-rise building. There are many sad examples of this, and the gas services are closely monitoring this.

On any of the other fuels, the user has the right to do whatever he wants, but not on natural gas.

You can independently install a wall-mounted gas boiler, provided that the user has an idea about this equipment and the nuances of installation, strictly complies with the requirements regulated by SNiP. But the first start-up of the unit, tie-in into the gas main and adjustment of the equipment should be carried out by specialized gas services.

Extraction requirements by law

The ventilation rules are enshrined in SNiP. The basic requirement relates to the volume of air exchange - it must provide 3 times air circulation within an hour.

Ventilation of the boiler room in a private house is carried out only according to a preliminary design. In which are presented the executive ventilation schemes of the room, the type and quantity of the necessary equipment, a list of materials and spare parts for the installation of the chimney.

Basic requirements for air exchange

Basic requirements for air exchange

When buying ventilation and smoke exhaust equipment for a gas boiler in a private house, as determined by the design documentation, it is necessary to check them for compliance with the quality regulated by the legislation on the territory of the Russian Federation.

Basic legal requirements for the arrangement of ventilation systems for a gas boiler in a private house:

- Installation of a separate air duct in the ventilation structure.

- Tightness of ventilation ducts, all seams must be treated with heat-resistant sealants.

- Arrangement of a separate air duct in the ceiling of the combustion room.

- Arrangement of sleeves in wall structures for the outlet of the gas duct from the premises to the street.

- Connection to one chimney for no more than 2 gas installations.

- A distance of more than 300 mm must be maintained between the outer wall and the end point of the flue.

- Air supply can be organized both outside and inside the furnace. However, in this case, the living room cannot be used as an adjacent room.

Selection and arrangement errors

When building a house, errors of the selected heating system and gas equipment occur at different stages:

- the design did not take into account the type of boiler - after the end of construction, it may be necessary to rebuild the entire ventilation system;

- unsuccessful form - an abundance of turns reduces traction, in some cases it provokes the movement of air from the pipe into the room;

- the possibility of cleaning is not provided, which can be hindered by sharp turns and the absence of technological holes;

- purchase of materials from different manufacturers - components for composite pipes may differ in geometric dimensions, which leads to air leaks or combustion products leaking into the room;

- non-observance of the height of the chimney on the roof, leading to reverse draft;

- the wrong choice of materials for the pipe;

- insufficient insulation.

The governing documents permit the independent construction of chimneys for gas boilers. The gas supply organization will not accept improperly equipped chimneys into operation, and hidden defects can lead to accidents.It is necessary to study in detail the rules provided for by the governing documents; in case of doubts in their abilities, it is better to entrust construction to professionals.

Boilers for boilers for solid and liquid fuels

The following types of liquid and solid fuels are used to heat residential buildings:

- coal;

- fuel oil;

- gas oil, gasoline;

- diesel fuel;

- working off;

- kerosene;

- wood waste, pellets, firewood;

- oil shale;

- peat;

- petrol;

- vegetable or machine oil.

As a rule, floor-standing units are designed to use solid or liquid fuels. For loading, rather large chambers are needed, and after incineration, waste is generated. Therefore, such boilers are less compact than gas boilers.

When building a boiler room in a private house with your own hands, you must comply with the same requirements as for gas boilers, but with some additions:

- solid fuel and liquid boilers cannot be installed in residential premises due to strong odor or dust, for this they equip an extension or a separate furnace;

- for the installation of a floor-standing boiler, a concrete foundation with a thickness of at least 50 mm is arranged.

- for loading, cleaning the boiler, repairing and replacing parts, there must be convenient access;

- from the place where the fuel was placed to the nearest wall should be at least 2 m;

- it is advisable to place the chimney closer to the ridge to create good draft;

- smoke exhaust is arranged through a chimney in a main wall or a pipe outside the house, while it should not coincide with window openings;

- the chimney is made of a sandwich pipe with insulation and an inner heat-resistant layer of steel or brick;

- an attic or living room cannot be arranged above the boiler room;

- in the room where the gas equipment is installed, do not store flammable materials and chemicals that emit flammable vapors.

So that dust does not accumulate in the boiler room, which adversely affects the operation of the equipment, an inlet opening is arranged at a height of 30 cm from the floor, and an exhaust outlet under the ceiling. Ventilation of the room should be natural.

You can quickly build a boiler room in a private house with your own hands if you use ready-made modular structures. In their manufacture, all standards and requirements are taken into account.

A mini-boiler room can operate on any type of fuel and heat a residential building or summer cottage. The structure is installed on a monolithic or prefabricated foundation, connected to the heating system of the building. When using gas, the project must be agreed with the gas distribution organization.

Requirements for the room for the installation of a gas boiler:

- the room for installing a gas boiler must be at least 4 m2;

- the height of the ceilings in it is not less than 2.5 m;

- the width of the outer door is at least 80 cm;

- you need a window for natural light and an opening for outside air.

- the room in which the boiler is installed must have a separate exit to the street.

It is also necessary that the door to the room open freely or have a cut; an inflow of oxygen is required for the combustion of the wick and the burner.

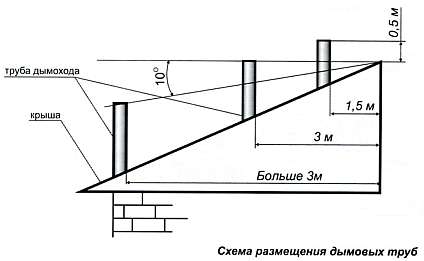

When building chimneys, to ensure traction and to exclude blowing out leading to the extinction of the flame, it is necessary to bring the upper cut of the chimney above the wind support zone. The height of the chimney above the roof of the house is set depending on the distance:

- not less than 0.5 m above the ridge, if the pipe is at a distance of up to 1.5 m from the ridge;

- not below the line, the level of the ridge, if the pipe is at a distance of 1.5 m to 3 m;

- not lower than a straight line drawn from the ridge down at an angle of 10 ″ to the horizon, when placing pipes at a distance of more than 3m from the ridge of the roof.

The chimney must have a cross-section, in accordance with the passport for the installed equipment, but not less - for a boiler with an open combustion chamber and a capacity of up to 30 kW with a diameter of 130 mm, for a 40 kW boiler - 170 mm.

The chimney must have a minimum of bends and bends, and its inner diameter must not be less than the diameter of the boiler neck.

It is also necessary to have a natural ventilation channel in the upper part of the room.

If the gas boiler is volatile, then, in accordance with the requirements, it must have a separate circuit breaker for the network.You can also install a differential automatic device (RCD), which protects a person from a short circuit to the body, while the boiler must be grounded.

When installing the boiler in a separate room without the constant presence of people in it, for example, a built-in or attached furnace, according to the current building codes, a gas analyzer must be installed in the room, which will warn of a leak and automatically cut off the gas supply using an emergency electric valve. An unconditional requirement is also the mandatory presence at the gas pipeline inlet in the room of a temperature shut-off valve for emergency shutdown of the gas supply in the event of a fire. All equipment is subject to annual service by specialists.

Choosing a gas boiler.

The power of a gas boiler is calculated at the stage of building a house, since the diameter of the chimney and a number of parameters of various engineering systems depend on it.

Gas boilers can be steel or cast iron.

- A steel boiler is about two times lighter than a cast iron boiler of the same power and volume.

- The service life of a steel boiler is 10-15 years, and a cast iron boiler is up to 50 years.

- A cast iron boiler is afraid of sudden temperature changes and therefore almost always fails if it is turned on without water, or without warming up in a very cold room after a long stop.

- A steel boiler will rust if left without water after shutdown.

Gas boilers are available in floor-standing and wall-mounted versions.

The wall-mounted boiler housing contains a gas burner, a heat exchanger, a circulation pump, an expansion tank, a pressure gauge, a thermometer and a boiler safety system. Wall-hung boilers are always volatile, that is, they cannot work during a power outage. In this regard, for stable and long-term operation, it is recommended to use a voltage stabilizer or a surge protector. In this case, you need to remember 2 basic requirements. Read more…

Rules for the installation and connection of gas boiler equipment

Before proceeding with the installation of gas equipment of the type in question in a private house, you will need to prepare certain documents, and then perform the required actions, which are rules.

Installation rules for gas boilers:

- A contract with a supplier will be required regarding the supply of natural combustible material;

- The installation of gas equipment must be carried out by an installation organization specializing in the provision of this type of service;

- The technical conditions, as well as the project for the installation of equipment, must be agreed with the representative of the gas service at the place of arrangement of the system. Design documentation, as a rule, is developed by specialized institutes with an appropriate license for this type of activity;

- The heating system is compulsorily pressurized up to P = 1.8 atm.;

- The engineer of the regional or district gas service comes to the facility, after which he checks the correctness of the connection of natural gas in the furnace and kitchen. Also, the engineer checks the compliance with the requirements put forward by the equipment of this type;

- The valve opens only if the engineer has not identified any irregularities;

- There must be no air in the system;

- All connections are checked for tightness;

- A voltage stabilizer is installed, as well as an uninterruptible power supply;

- It is not allowed to add antifreeze to the heating water, as this can damage the gaskets, and then lead to leaks in the heating system of the house.

The following are the features of installing a wall-mounted gas boiler.

The main requirements for the chimney of a gas boiler

Gas boiler device diagram.

- It is recommended to place pipes in the inner wall of the building, which is the main one. If the chimney is located outside the building, insulation is required to prevent freezing. When making a channel inside the outer wall, the thickness of the brickwork should be at least 1.5 bricks, and in severe winters - 2.5 bricks.

- The chimney of a gas boiler must be positioned vertically with a possible slight slope of no more than 30 °. Extensions and contractions are not allowed.

- The cross-sectional area of the duct must be larger than the cross-sectional area of the gas equipment to which it is connected.

- The gas boiler must be connected to the chimney through a special corrugation or using steel pipes with a heat-resistant enamel coating.

- The chimney pipe, through which the gas boiler is connected to the chimney, must have a vertical section at least 0.5 m long. Requirements do not allow more than three turns of the chimney pipes.

- The junction of the gas boiler branch pipe with the chimney must be sealed.

- All components must fit snugly together, be sealed and airtight. For this, heat-resistant sealants are used. The possibility of bending of pipes at their joints must be excluded.

- In rooms with a height of about 3 m, the length of the horizontal pipe sections that make up the chimney should not exceed 3 m.

- The slope of the pipe towards the gas boiler is allowed at least 0.1 °

- A container for collecting condensate must be provided with a window for cleaning. It is usually located below the point where the chimney enters the duct.

- The distance that is permissible between the surfaces made of heat-resistant materials and the connecting pipes is 5 cm or more, and in the case of flammable surfaces - at least 25 cm.

- The chimney above the roof should rise at least 50 cm if the chimney is located from the edge of the roof ridge at a distance of no more than 1.5 m. When the chimney is removed up to 3 m, it is set flush with the roof ridge.

- If there is a flat roof, then the height of the chimney above its level must be at least 1 m.

Requirements for freestanding furnaces

Separate boiler houses are being built for powerful heat generators, the operation of which provides for an enhanced safety regime.

Requirements for furnaces built separately from a residential building:

In the premises, they arrange concrete floors or cover them with a fireproof finish. For equipment weighing over 200 kg, a reinforced base with a height of 15 cm is prepared.

The heated water enters the house through an insulated pipeline with low heat loss. A detached furnace does not occupy the usable area of the house, is safe to use and does not violate the architectural appearance of the building. It can be used to heat a group of buildings, for example, houses, saunas and greenhouses.

Door requirements

In furnaces, two types of doors are used:

- outdoor without amplification for going outside;

- internal fireproof for communication with living quarters.

Exterior doors in the event of an explosion should easily break off their hinges. Then the energy will be directed outward and cause less damage than with a rigidly and firmly fixed canvas. But in any case, you need to protect the room from outsiders who can enter and damage expensive equipment.

Internal doors are designed to hold back flames in case of fire for 15 minutes. The standard corresponds to type 3 canvases with a fire resistance rating of EI 15. They retain their integrity and thermal insulation properties for a period of time sufficient for the evacuation of people from the house and the arrival of the rescue service.

Boiler room ventilation

The requirements for a boiler room in a private house are very strict in terms of ventilation. Combustion products resulting from fuel combustion are hazardous to humans. Inhalation of carbon monoxide leads to severe poisoning. High concentration causes paralysis and even death.

Gas leaks in the network create an explosion hazard. Methane, propane and butane are heavier than air. They accumulate in the lower level of the room. That is why it is recommended to arrange gaps near the floor or exhaust holes in the wall under the outer door to remove hazardous substances. For every 10 kW of unit power, 0.01 m² of the cross-sectional area of the supply duct is required.

Natural ventilation, recommended by the standard, includes supply and exhaust ducts to replace the air in the room. Their area is calculated based on the triple volume of the room and is selected according to special tables, diagrams or using online calculators.

For every 10 kW of power, 0.01 m² of the cross-sectional area of the supply channel is required.

Combustion products are discharged through a chimney or a coaxial pipe built into the wall. In the first case, the channel cross-section must correspond to the diameter of the boiler pipe. The optimal shape is a circle or oval.

The chimney walls protect against condensation. Warm air, moving through the pipe, cools, which leads to the loss of water vapor in the form of dew. In winter, moisture freezes, the channel narrows. This contributes to the deterioration of the removal of combustion products.

Condensation protection is carried out by a chimney lining or a stainless steel pipe is installed inside. The corners and turns must be smooth, the joints of the channel elements must be sealed.

In other cases, the ventilation duct may be lower. Separate smoke evacuation systems are arranged for the two units.

Types of boilers and flue ducts

Gas boiler with coaxial chimney

Gas boiler with coaxial chimney

The industry produces various models of gas heating boilers, but all types are built in two possible schemes: with an open or closed chamber for gas combustion.

It is better to decide which boiler to buy at the design stage of the house. The chosen scheme determines how and where to build a boiler house, as well as how the combustion products will be discharged.

The project must be coordinated with the gas supplying organization - if the construction technology is violated, the use of unacceptable materials, the gas equipment cannot be put into operation, and alteration of the gas disposal system may require significant financial costs.

Open chamber boilers

By design, devices with an open chamber are simpler than devices with a closed type.

By design, devices with an open chamber are simpler than devices with a closed type.

Oxygen for fuel combustion is supplied from the surrounding space. This feature imposes additional requirements on the organization of room ventilation.

Installation of equipment is carried out only in a separate room. To ensure functioning, two channels are built for supplying air and removing products from the burnt gas.

Among the advantages is the relative simplicity of the design without additional fans, which means without "extra" mechanical parts that are most susceptible to wear and tear. The disadvantages should be considered a lower efficiency and the need to build a vertical chimney at a level above the roof ridge.

Features of equipment with a closed chamber

In a coaxial chimney, air is sucked in through one pipe, and out through the other - internal

In a coaxial chimney, air is sucked in through one pipe, and out through the other - internal

Air is forced into gas boilers with a closed chamber. The chamber does not communicate with the room air, and the exhaust gases are removed by the blower.

Boilers with a closed chamber are economical, do not require the arrangement of vertical channels, one coaxial pipe is used.The combustion products are discharged through the inner insert, and outside clean air enters through the cavity between the pipe walls.

It is not necessary to build vertical structures to remove gases, which reduces the cost of the estimate. On the other hand, this type of boilers and pipes requires more frequent maintenance. Turbines periodically fail, which entails additional operating costs.

What else you should know about chimneys of gas boilers

It is allowed to connect to one chimney no more than two connection points for gas appliances, which can be located both on the same or on different floors, but the combustion products must be introduced into the channel at different levels and no closer than half a meter from each other. It is also allowed to enter at the same level, but if there is a cut inside the channel to a height of 50 cm. In this case, the channel cross-section must be determined, providing for the mode of simultaneous operation of all gas appliances that use this chimney.

The optimal shape for the chimney is a cylinder, in addition, oval and square shapes are allowed. But it should be remembered that square pipes have low thrust rates. This is because eddies in the corners trap smoke and cause soot to form. This can negatively affect the operation of heating devices.

Modern gas boilers have fairly high efficiency values, reaching 95%. Therefore, the temperature of the gases formed is quite low, which contributes to the formation of condensate in large quantities. Its aggressive effect contributes to destruction. Therefore, it is recommended not just to line the pipes with brickwork, but to make a sleeve or lining of the channel.

- When making a sleeve, a single-wall pipe made of stainless acid-resistant steel is placed in a brick shaft, which protects the brick from destruction.

- A flexible hose installation is used for channel lining. This method is used for chimneys with non-standard sizes or shapes.

Requirements allow the execution of chimneys in the walls together with ventilation ducts. However, in this case, they should be separated by airtight partitions along the entire height. Partitions must be made of wall material and have a thickness of at least 1.2 cm.

Chimney arrangement for wall-mounted gas boilers

To remove combustion products from a wall-mounted boiler, it is allowed to install a wall-mounted (coaxial) chimney. It consists of two pipes inserted into one another without a layer of insulation. This method of the device ensures the removal of combustion products and, at the same time, the inflow of fresh air. The distance from the ground to the outlet of the pipe must be at least 2 m.

There are modern models of gas heating boilers with a sealed fuel combustion chamber. Their work is arranged in such a way that the installation of traditional chimneys is not required.

What affects the efficiency of the chimney?

Perhaps the question is posed somewhat incorrectly from the point of view of a professional. Since the health, and sometimes the life of people, depends on the effective operation of the combustion product removal system, it is more expedient to consider the requirements for the chimney of a gas boiler.

A chimney of any design must be made in accordance with the requirements of SNiP 2.04.05-91, as well as DBN V.2.5-20-2001. Otherwise, there will be an incorrect design of the chimney and the connection of heating equipment to it. And this, in turn, calls into question the safety of operation of the entire heating system. The specified documents clearly regulate the arrangement of boiler chimneys. These documents are subject to careful study, since a violation of the norms set out in them will certainly lead to problems with the gas industry.

If you briefly voice the requirements for the chimneys of gas boilers, then first of all you need to pay attention to the following points:

- Good traction is a guarantee of efficient use of thermal energy from gas combustion.

- Correct design of the condensate trap - excess moisture should not accumulate on the walls of the chimney.

- It is forbidden to install deflectors, fungi, etc. on the chimney head. These elements reduce the efficiency of removing combustion products, and there is a risk of carbon monoxide entering the room.

- The requirements for the chimneys of gas boilers require maximum attention to the installation work. Particular emphasis should be placed on the tight fit of structural parts at the joints, that is, maximum tightness should be achieved. This will prevent hot gases from entering the outside of the chimney.

- It is allowed to use common connecting flue pipes for several units.

Outwardly, it seems that the chimney is brick. In fact, it is just a finish, and it is inside the pipe.

Room standards for a boiler with a closed firebox

The regulatory requirements for the installation of a gas unit with a closed firebox are not so demanding. This is due to the reliable flue exhaust system of these modifications.

Closed firebox scheme

Closed firebox scheme

In them, exhaust boiler gases are removed from a closed combustion chamber into a coaxial pipe. Through it, right from the street, a forced supply of fresh air is performed to ensure complete combustion of the fuel.

In this regard, modifications of boilers with a capacity of up to 60 kW are allowed to be installed in any non-residential premises that meet the following requirements:

- The height of the room is not lower than 2.2 m;

- full volume - over 7.5 m3;

- reliable supply ventilation;

- walls and floors made of durable fire-hazardous materials.