Painting furnace made of metal

It should be understood that there are several reasons when you can resort to painting a brick stove. So you can approach this issue from the aesthetic side, from the practical and for the sake of safety. As for aesthetics, a stove in a house is needed not only to heat the house and be comfortable in it, but also to maintain the interior and create special coziness. On the practical side, after the fireplace is painted, the heat output increases and the stove surface is leveled.

Note! From a safety point of view, thanks to staining, it is possible to prevent the appearance of microcracks on the brick and, as a result, prevent the fire of the home. There are several options for painting the structure.

You can do this:

There are several options for painting a structure. You can do this:

- enamel;

- oil paint;

- drying oil;

- heat-resistant varnish.

Heat-resistant oil paint for ovens is the best solution, since there is a large selection of colors, the paint can withstand temperatures of 600 degrees Celsius, it is guaranteed to protect the brick from oxidation, has increased resistance and durability. In addition, it is easy to apply and does not need any additional priming on the outside. However, there are disadvantages in the form of unpleasant odor, toxicity and long drying times.

Drying oil is a material that is not able to change the color of the brick, but only slightly make it darker. As for the positive qualities, this coating is reliable and safe. The only drawbacks are the price.

Heat-resistant varnish is a coating that can improve the technical characteristics of a brick surface.

Note! The peculiarity in its use is that it can be diluted with gouache to acquire the desired color with a shade. Cast iron is a sufficiently strong metal that is favorably able to withstand prolonged exposure to high temperatures.

According to some sources, it is possible not to resort to painting the metal, but it is better to do it. An excellent option for a cast iron stove is the use of water-based acrylic or polyurethane paint, which has already proven itself excellent. In addition, the cast iron alloy will be able to withstand even disturbances during painting in a more favorable way.

Cast iron is a sufficiently strong metal that is favorably able to withstand prolonged exposure to high temperatures. According to some sources, it is possible not to resort to painting the metal, but it is better to do it. An excellent option for a cast iron stove is the use of water-based acrylic or polyurethane paint, which has already proven itself excellent. In addition, the cast iron alloy will be able to withstand even disturbances during painting more favorably.

The painting process itself looks like this. First, the surface is pre-cleaned with a metal brush. Next, the oxidation is sanded with sulfuric acid five percent, and the mixture is washed off with a soap solution. Then the metal is degreased with a solvent and covered with paint. This is the whole dyeing technology. In this case, the painting of the metal furnace should be uniform. All seamed corners should be reworked as much as possible.

Note! If you do not want to drip onto the surrounding elements of the oven, you must use cellophane with masking tape

Brick stoves

You can paint a brick stove using enamel, oil paint, drying oil and heat-resistant varnish.

In the first case, the structure will be protected from moisture, will have good strength and durability. In the second case, the plastered and painted surface will be able to withstand high temperatures, and in the latter cases it will be able to give the brick strength.

Before painting begins, you need to clean off all crumbling material from the oven. For this, a construction brush with metal bristles (a brush) is useful, or a narrow spatula will do. If the material is well removed, then it may be more advisable to remove it down to the brick luggage, in this case paint for fireplaces and stoves any can be chosen.

The next step is to remove all debris and clean the surface of dust. Further, with their own hands or with the help of a professional, they repair cracks, holes and seams. Now in specialized stores, ready-made mixtures are presented that are suitable for working with brick ovens.

Surface preparation for processing

No. 5 Recommendations for applying varnish on a brick base

When deciding to use paintwork materials in order to protect and decorate brick walls, it is important to remember that in order to obtain the desired results, one should not only choose the most effective tool, but also observe all the subtleties of the coating. The varnish can be applied to walls in various ways: with a brush, roller or spray gun

Manufacturers insist that the composition should be applied in several layers (at least two). In addition, it is important to follow several important recommendations:

The varnish can be applied to walls in various ways: with a brush, roller or spray gun. Manufacturers insist that the composition should be applied in several layers (at least two)

In addition, it is important to follow several important recommendations:

- The varnish should be applied at a temperature not lower than 10 not higher than 30 degrees.

- Each layer applied takes time to absorb and dry.

- It is possible to cover a brick base with varnish only after preliminary processing of the material.

Sequence of work

- Preparation of a brick base. The wall must be thoroughly cleaned of old paint, dirt, dust. This can be done with a building hair dryer, solvent. Excess cement can be knocked down with a hammer or chisel. Small cracks can be putty, then sand the surface with sandpaper.

- Cleaning from dust and dirt. The base can be cleaned using a household detergent. This is necessary to remove salt stains, dirt and dust. After cleaning, the wall needs to dry.

- Deep penetration primer application. For greater efficiency, it is better to use the primer of the same company as the varnish. It can be applied with a brush or roller.

- Varnishing. Using a roller (bristle length 2 mm), a spray gun or a nylon brush, you can start coating the wall with varnish. The composition should be applied from top to bottom.

- Consumption. As a rule, for application in one layer per 1 m2, 100-200 grams of varnish are required.

The ideal time for varnishing is warm season and low humidity. This will allow the solution to lay down smoother, without streaks. Drying time for each layer is 1-2 hours, for quick-drying compounds - 30 minutes. It will take 1-2 days to dry the finishing layer.

To select the most suitable paintwork materials, it is important to take into account the following factors: the place of its application, protective characteristics, manufacturer, drying speed, decorating effects, cost, service life. Monitoring prices and characteristics can take you some time, but as a result, you can be sure that your walls will stand for many years without losing their aesthetics and functionality.

No. 2. What are the varnishes by composition

Brick varnish - a universal product for protecting brick base

But in order for the varnish to lie flat on the material and fully perform its functions, it is necessary to choose it correctly, paying attention to its composition

Polymer varnishes

This is the most popular type of paintwork materials.The demand for this product is due to its versatility. It can be used on brick and concrete substrates. Polymer varnish can be applied at sub-zero temperatures and in rooms without heating. It is easy to apply, dries quickly and reliably protects the material from scratches, cracks, moisture and dust. The mixture can be used to protect interior and exterior walls. Due to the ease of application of the polymer composition, it can be used by both professional craftsmen and beginners. Polymer varnishes are affordable.

Silicone acrylic varnishes

This type of paintwork is suitable for interior walls. Silicone-acrylic mixture can be used to cover not only bricks, but also concrete, ceramic tiles, drywall, metal. The composition is often used for application to decorative items.

Due to the presence of special polymers in the mixture, the varnish can be of various shades. In addition to the protective layer, the wall treated with this compound can be transformed into any color, depending on your wishes.

Silicone-acrylic varnish protects the base from alkalis, acetone, oils. The only disadvantage of such mixtures is the price, which is much higher than polymer analogues.

Polyurethane varnishes

It is a versatile product that can be used to coat interior and exterior walls. It is the polyurethane varnishes that create the “wet” effect on the brick base. They have excellent moisture-repellent characteristics, which is why they are most often purchased for treating external walls. The popularity of polyurethane varnishes is also explained by the fact that they can be used to process not only brick, but also concrete bases.

Heat-resistant varnishes for fireplaces and stoves

This is a separate category of paintwork materials, which differ in the characteristics of heat resistance, fire resistance. They are designed to prevent condensation from forming on the walls of stoves and fireplaces. Due to their high moisture resistance, such paints and varnishes are also purchased for decorating and protecting building facades.

Solvent varnishes

These formulations are based on silicone resin and solvents. When penetrated into the material, they create a strong protection, preventing cracking and discoloration

But, at the same time, such varnishes are easily flammable, and it is necessary to work with them extremely carefully, observing safety rules

Impregnations

In order to strengthen any paint and varnish, you can use special sealing impregnations. They are made on the basis of silicone and acrylic resins with the addition of aromatic, aliphatic solvents. Due to this composition, maximum protection of the paint and varnish for the brick base is provided. When using impregnation, deep penetration of paintwork materials into the building material is guaranteed.

In addition, sealants provide an extra layer of protection against seasonal rainfall, chemicals and UV rays. Many manufacturers also offer decorated options with a "wet stone" effect. The negative side of such impregnations is their use only for external or internal walls; they cannot be used in work with stove and fireplace installations.

Features of varnish coating

Yes, the process of building a high-quality stone stove in a house is quite complicated. However, the moment of facing the structure should be given no less attention.

It is very important that the heater fits into the interior of the room as much as possible. This will help create additional comfort and coziness.

Someone uses finishing materials for this, but professionals go further and cover the surfaces of the stoves with varnishes.

Given these characteristics, manufacturers offer a special varnish for a brick oven, which differs significantly from the standard material. Those homeowners who have tried to open the surface of the structure with ordinary paint or varnish know firsthand how quickly the material loses its original properties.

Today, various modern technologies are used in the production of topcoats for surfaces that exude high temperatures. Among the constituent components of the material, one can find organosilicon elements that have the ability to dissolve in an oil environment, as well as a special impregnation, which gives the varnish the appropriate properties.

Brick building of a presentable look

The difference between heat resistant varnishes and conventional varnishes is as follows:

- The adhesion level is increased.

- The material dries quickly enough.

- No film is formed that will peel off in the future.

- Increased level of heat resistance.

- Deep penetration into the porous structure of the brick.

Specialists in the construction of stoves also note that the varnish for the fireplace dries very quickly, and the higher the temperature, the less time it will take. The first layer of material at 18 ° C degrees indoors will dry out after 60 minutes. As a result, a sufficient number of layers of material can be applied in one daylight.

Brickwork coated with a protective compound

The presented material is classified as heat resistant. In support of this, it should be pointed out that the temperature that the varnish endures without losing its original qualities can reach 250 ° C degrees.

Preparing the surface for painting

Before painting a metal stove, it is important to properly prepare the surface. In some cases, prior preparation is not required, while in others it is necessary to follow the rules indicated on the label .. Typically, preparation includes:

Typically, preparation includes:

- Cleaning the surface from traces of oils and grease, old coatings, water-soluble salts and others.

- Remove rust down to gray metal using emery, grinder or drill attachment, or sandblasting machine. Sometimes the surface is allowed to be coated with rust converters, but this should be indicated on the paint package. Upon completion of the treatment, the surface must be washed and dried. It is necessary to remove rust completely, up to the elimination of the smallest specks.

- Degrease the surface with xylene or solvent immediately before painting. Further staining should be carried out no later than 6 hours after exposure to air or 24 hours indoors.

In each case, the required number of paint layers and their direction are purely individual. If more than one layer is required, then they are applied in different directions so that the paint lies more evenly.

The temperature and drying conditions of the paint, as well as the gap between coats, are always indicated on the label. Compliance with the manufacturer's recommendations will allow you to get a coating that will last the specified period.

The composition of the do-it-yourself oven plaster solution

You can prepare the oven solution with your own hands. Fortunately, practice has developed many simple compositions of mortar for plastering the oven. Above are already given the main formulations that beginners can knead.

Before mixing the clay solution, the components are prepared:

- The clay is soaked a day (preferably 4-5) before use. After that, it is poured with additional water, the floating debris is removed, the water is drained, or stirred, passed through a sieve, then allowed to settle and the water is drained. The remaining clay is mixed until smooth. Any lumps will cause cracks. The resulting mass of clay is combined with the rest of the components.

- River sifted, washed, dried sand is suitable. It is dry sand that is given in the recipes. Using wet sand will require less water.

- The asbestos is fluffed up.

- Lime is used to prepare milk of lime or dough.

When plastering a stove with your own hands, it is important to maintain the proportions of the components. The clay solution can be different in the ratio of sand and clay, depending on the fat content of the latter

The standard procedure is the first-priority mixing of dry components followed by the addition of liquid components (clay or lime emulsion, water). The standard procedure is the first-priority mixing of dry components followed by the addition of liquid components (clay or lime emulsion, water).

Experienced stove-makers add 200 g of salt to a bucket of solution. The additive prevents the appearance of cracks, slows down the setting of the mixture, thereby achieving uniform drying of the coating.

If you plan to heat the stove with coal or peat briquettes, which give a high temperature, fireclay powder should be included in the compositions.

Which thermo gel polish is better to choose

The cosmetics market offers a huge variety of gel polishes. In order not to get lost in it, consider some of the popular thermo gel polishes, their pros and cons.

Kodi

The Cody brand is rightfully considered one of the high-quality and reliable ones.

The Cody brand is rightfully considered one of the high-quality and reliable ones.

The pluses include:

- a well-known, reliable manufacturer,

- good thermo effect: reacts even to small temperature changes;

- excellent durability;

- wide range of colors.

Minuses:

- very difficult removal, the varnish literally eats into the nail;

- relatively high price.

Here everyone decides for himself: durability or easy removal.

Koto

Pros:

Pros:

- affordable price;

- wide palette of shades;

- good pigmentation,

Minuses:

- liquid consistency, which makes it possible to fill the cuticle;

- small volume of 5 ml.

BlueSky

Pros:

Pros:

- low price;

- large selection of shades;

- high sensitivity to temperatures;

- resistant coating.

Minuses:

- rather thick consistency,

- may conflict with the base and top of another company.

TNL

Pros:

Pros:

- affordable price;

- comfortable brush;

- large volume.

Minuses:

- difficult to remove;

- it is not hypoallergenic, so it is better for allergy sufferers to be careful;

- also, many people note frequent chips at the ends of the nail.

Canni

Pros:

Pros:

- Acceptable price;

- wide palette of shades;

- hold on well;

- removable relatively easily.

Minuses:

- very large volume - 15 ml;

- the color must be applied exclusively to the substrate.

Pros:

Pros:

- price;

- firmness;

- easy removal.

Minuses:

small volume - only 6 ml.

Patrisa nail

Pros:

Pros:

And durability, and application, and price - everything is at a height.

Minuses:

Quite a lot of shades in the palette are contrasting and bright, so it is difficult to choose a “calmer” color.

Lacomchir

Pros:

Pros:

- the most affordable price of all of the above;

- the most beautiful palette of shades.

Minuses:

each color has its own consistency - the shades differ in quality.

Features storage of thermo gel polish

Gel polishes should not be stored near a UV lamp or in direct sunlight, as there is a high risk of polish polymerization. Also, always follow the expiration date - not only the durability and quality, but also the health of the nails depends on it. Expired nail polish can cause an allergic reaction, even if you have never been allergic to gel polish.

How to plaster the stove so that there are no cracks

In addition to the fact that the solutions themselves should not form shrinkage cracks during hardening, the compositions are required to adequately respond to the expansion of the heating walls. Of the wide variety of plaster compositions, this condition is met by types of mixtures on a complex basis, the components of which are clay.

Beginners are interested in whether it is possible to plaster a brick oven with gypsum plaster. Pure gypsum plaster is not suitable for plastering stoves and fireplaces. At elevated temperatures, the gypsum coating cracks. However, gypsum is used in some formulations as an additional binder, for example, in clay-lime-gypsum or lime-gypsum formulations.

Such compositions set quickly, therefore, mixes are made in a small volume, and they are plastered quickly.

In order to make the mixture more plastic and stronger, asbestos fiber is attached to the main components. The asbestos-containing plaster mixture is durable, fireproof, and resistant to moisture.Asbestos prevents cracking. Often, instead of asbestos, chaff straw is added to increase strength, which is cheaper.

Fireclay clay is often included in ready-made heat-resistant compositions. The material is obtained by firing kaolin clay at a temperature of 1500 degrees. Clay burnt to a stone state is ground into small grains. Shelf life is up to 3 years.

Clay-sandy

The clay solution is plastic, non-flammable, waste-free. Clay can be purchased or dug up. In the second case, the clay for the stoves must be clean, not include grass, roots and stones.

The clay mortar, which is popular for plastering a kitchen stove, has no advantages.

Pros:

The disadvantages of clay for the oven are a thick minimum layer (if the thickness is less than 10 mm, the dried mortar will crack and fall off).

It is a simple mixture containing only sand, water and clay. The properties of the mortar and its proportions are determined by the fat content of the clay. The nature of the wall material of the stove can affect the clay to sand ratio. The usual ratio is a part of clay, two parts of sand, a tenth of fluffed asbestos.

Cement-clay-sand

This complex plaster, which forms a durable coating, is used for laying stoves and fireplaces. She fits worse. In addition, the solution sets quickly, so it is prepared little by little. For the mixture, take cement grade 150, mix it with dry sand (from 4 to 9 parts). After mixing the mixture, clay pulp is poured into it in portions, trying not to overdo it, otherwise the mixture may turn out to be liquid.

For facing with tiles, a cement-clay-sand mortar is prepared with the addition of chalk and liquid glass. Clays and Portland cement in 1 part, sand - 3 parts, ground chalk - 1 part. The dry components are mixed, diluted with clay pulp until the required consistency is obtained. Then add 1 part of water glass. The coating is durable and crack-resistant.

For plastering, a mixture with asbestos is also used. One part of clay and cement, 2 parts of sand, 0.1 part of the total volume of the resulting mixture - asbestos.

Lime-clay sand

The addition of lime increases the plasticity, strength, tenacity and biostability of the formulations. For cooking, take part of the clay and lime, two parts of water. It is allowed to add 1-2 tenths of asbestos fibers.

Production products

Modern manufacturers of paints and varnishes have not left the market of materials for fireplaces and stoves without their own attention. That is why everyone can purchase a varnish for stoves and fireplaces with suitable characteristics and parameters. The most popular today can be called KO 85, which is used to treat furnaces not only in private houses, but also in the industrial field.

It contains organosilicon resins mixed with a solvent. Its immense popularity is based on the following qualities:

• increased heat resistance (up to + 300 ° C);

• endurance, the ability to withstand large temperature changes (from - 40 C to + 300 C);

• does not exfoliate after a long period;

• well applied to any surface;

• possibility of application at negative temperatures.

Heat-resistant varnishes for stoves and fireplaces

No varnish can boast of such properties, therefore the 85th always finds application when it is necessary to process a stove or fireplace. But this is not the only representative of this product in this class. If you want to varnish the inner surface of the brick, which lined the firebox of a stove or fireplace, then manufacturers advise using varnish KO 815.

Despite the fact that the temperature limit of this varnish is slightly lower, by as much as 50 degrees compared to the 85th, it perfectly withstands the effects of open fire. This contributes to the high-quality processing of the inner surface of fireplaces and stoves, open to the public.A high-quality decorative coating will delight the eyes of the owners and their guests for a long time, and the combustion section itself will receive bonding qualities that it did not have before processing.

Heat-resistant enamels for painting stoves and fireplaces

It should be noted that both types of varnishes can be tinted with KO 174 paint, which makes the decorative finish of stoves and fireplaces much more diverse. The resulting mixture is suitable for metal and stone, as well as wood. This allows you to get an excellent interior element that is completely fireproof and as durable as possible.

Consumption of varnish KO 85 and KO 815 is absolutely the same. To cover the first layer, it will take up to 250 g / m2. The second will require 100 grams and the third will need 50.

If it is necessary to apply more than three layers, which is very rare, then the consumption will not exceed the third indicator. The fact is that the first layer closes all large and small pores in the material. The second closes the remnants of large depressions, and the third completes the creation of a high-quality and durable film.

Coating features

The principle of working with varnishes is similar to painting. First of all, you need to prepare the surface to be treated. Walls should be cleaned of dirt and dust, cracks should be putty, build-ups should be cut down, and recesses should be filled with plaster or putty. If the facade has been painted before, the paint should be removed completely.

Aligned walls need to be sanded with coarse sandpaper and then washed. A household detergent is suitable for this. After drying, a second inspection is carried out. The identified shortcomings are eliminated. A dry, clean surface is primed. It is advisable to take a primer and varnish from one manufacturer.

Application is done in several ways: by brush, roller or spray. In the latter case, the mixture (if it is not in an aerosol can) must be mixed with a solvent to reduce the density. If this is not done, the spray gun will not cope with heavy varnish.

The varnishing starts from one of the upper corners, gradually going down. On large areas, it is convenient to work with a 20 mm nap roller. Small elements are processed with a brush with natural stiff bristles. Neighboring strokes should be applied with an overlap of a few millimeters. The varnish is applied in two or more layers. Each subsequent layer is applied after complete drying (absorption) of the previous one.

Maintenance of the varnish coating consists in processing with a mild detergent at a frequency of 2 times a year.

See below for more details.

Application technology

No special materials or tools are required. The set for manicure consists of only two elements: a base for manicure and a thermovarnish. In some cases, an additional top is required to fix the gloss.

Before applying the thermal varnish, it is necessary to remove the old coating and then cover the nails with a base. It will significantly prolong the life of a manicure. Since chameleon varnish has a very liquid consistency, it is usually applied in two to three coats. Each of them must be sure to dry well.

To give the varnish a glossy shine, cover it with a top or regular clear varnish. At the same time, the thermovarnish will not lose its properties, this can be checked with a simple test with immersing the marigold under a stream of both hot and cold water. The coating remains glossy, and the varnish, as expected, will change its color.

The longer the nails, the more noticeable the transition will be, and, therefore, the effect of the applied coating. To make the manicure look more profitable, it is advisable to first carefully and symmetrically file the free edge on all fingers.

Folk painting methods

You can make the lining of the stove in different ways. You can plaster it, trim it with tiles, close it with facing bricks, use clinker tiles for this, decorate it with tiles or natural and artificial stone, or you can combine different materials with each other.

There is an option to simply whitewash the plastered walls or cover it with water-based paint, making some interesting pattern of Russian motives.

Homemade varnish

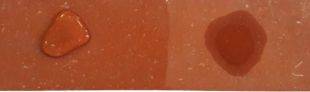

To make homemade paint, you need egg whites.

- Grind the red brick to a powdery state, then sift through a sieve.

- Add egg whites and fresh milk to the powder so that the mass resembles thick sour cream in consistency.

- Mix the ingredients well.

The solution is applied to a warm surface, after which it is recommended to additionally cover the brick with linseed oil or varnish from above. Such a coating will last a long time, because the mortar protects the brick blocks from cracking and abrasion. This option will look great in an interior with natural accents.

If you do not know how to paint the structure, then you can finish the existing hearth in one of the ways presented below:

- Plaster, and then walk with water-based paint.

- Simply paint without pre-coating with anything.

- Coating the oven surface with a varnish resistant to high temperatures.

- Apply a pattern with a relief to brick luggage, and then fix it with a special varnish.

Use of protective decorative varnish

Water based paint - the right choice

Water-based paint deserves special attention, so I would like to draw your attention to it. The application of water-based paint will enable the oven to work efficiently and the surfaces to look like new

Therefore, many homeowners today prefer it. The material, which has a dispersive nature, is becoming more and more popular in painting walls, ceilings and other surfaces.

The advantages of using it for painting the oven:

- The paint dries very quickly, but subject to a constant high temperature.

- The composition is absolutely safe for human and animal health.

- Unlike other products, this paint does not have an unpleasant odor.

- The ability to create your own, individual palette using various pigments, while with other paints this is impossible.

- The painting process does not require much effort and time. You can use a brush, sponges, a special roller, or other convenient attributes, which greatly simplifies the work.