Calculation of basic parameters

At the design stage, it is necessary to determine the height of the chimney and the dimensions of the cross-section of the flue duct. The task of the calculation is to ensure the optimal traction force. It should be sufficient so that the required amount of air enters the furnace and all combustion products are discharged in full, and at the same time not too large so that the hot gases have time to give off their heat.

Height

The height of the chimney must be selected taking into account the following requirements:

- The minimum height difference between the grate and the top of the canopy is 5 m.

- If the roof is covered with a combustible material, for example, shingles, the chimney head should rise above it by at least 1.5 m.

- For non-combustible roofs, the minimum distance to the top is 0.5 m.

The ridge of a pitched roof or a parapet of a flat in windy weather should not create a support over the chimney. To do this, you need to adhere to the following rules:

- if the pipe is located closer than 1.5 m in relation to the ridge or parapet, then it must rise above this element by at least 0.5 m;

- at a distance of 1.5 to 3 m from the ridge or parapet, the pipe head can be at the same height with this element;

- at a distance of more than 3 m, the top of the head can be placed below the ridge, at a height drawn through it, an inclined line with an angle of 10 degrees with respect to the horizontal.

If there is a higher building near the house, then the chimney should be erected 0.5 m above its roof.

The brick chimney is very neat and fits into any exterior

Section dimensions

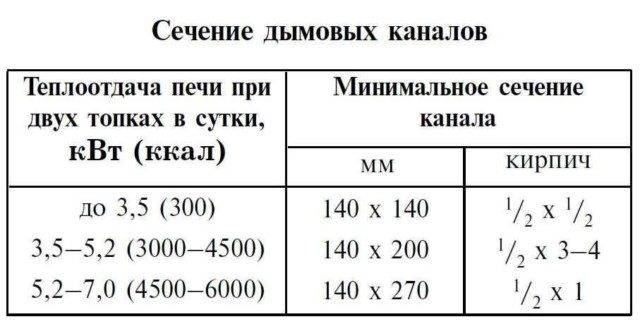

If a stove or boiler is connected to the chimney, then the cross-sectional dimensions should be determined depending on the power of the heat generator:

- up to 3.5 kW: the channel is made in the size of half a brick - 140x140 mm;

- from 3.5 to 5.2 kW: 140x200 mm;

- from 5.2 to 7 kW: 200x270 mm;

- over 7 kW: in two bricks - 270x270 mm.

The power of prefabricated heat generators is indicated in the passport. If the stove or boiler is homemade, this parameter has to be determined independently. The calculation is carried out according to the formula:

W = VT * 0.63 * * 0.8 * E / t,

Where:

- W is the power of the heat generator, kW;

- Vт - volume of the furnace, m3;

- 0.63 - average load factor of the furnace;

- 0.8 - averaged coefficient showing what part of the fuel burns in full;

- E is the calorific value of the fuel, kW * h / m3;

- T is the burning time of one fuel load, h.

The chimney, if desired, can always be decorated

The calorific value E depends on the type of wood and its moisture content. Average values are:

- for poplar: with a moisture content of 12% E - 1856 kW * h / cu. m, with a humidity of 25 and 50% - respectively 1448 and 636 kW * h / m3;

- for spruce: with a moisture content of 12, 25 and 50%, respectively, 2088, 1629 and 715 kW * h / m3;

- for pine: respectively, 2413, 1882 and 826 kW * h / m3;

- for birch: respectively, 3016, 2352 and 1033 kW * h / m3;

- for oak: 3758, 2932 and 1287 kWh / m3, respectively.

For fireplaces, the calculation is somewhat different. Here, the cross-sectional area of the chimney depends on the dimensions of the furnace window: F = k * A.

Where:

- F - cross-sectional area of the flue duct, cm2;

- K - coefficient of proportionality, depending on the height of the chimney and the shape of its cross-section;

- A is the area of the furnace window, cm2.

The coefficient K is equal to the following values:

- with a chimney height of 5 m: for a round section - 0.112, for a square section - 0.124, for a rectangular section - 0.132;

- 6 m: 0.105, 0.116, 0.123;

- 7 m: 0.1, 0.11, 0.117;

- 8 m: 0.095, 0.105, 0.112;

- 9 m: 0.091, 0.101, 0.106;

- 10 m: 0.087, 0.097, 0.102;

- 11 m: 0.089, 0.094, 0.098.

For intermediate values of the height, the coefficient K can be determined according to a special schedule.

This graph allows you to determine the coefficient K at intermediate values of the pipe height

They tend to make the real dimensions of the smoke exhaust channel close to the calculated ones.But they are selected taking into account the standard sizes of bricks, blocks or cylindrical parts.

Brick chimney: pros and cons

The traditional option remains in demand, despite the emergence of more modern models. The indisputable advantages of this design can be considered:

- Long service life. It will last at least 30 years.

- Relatively low cost, especially compared to steel or ceramic counterparts.

In addition, a brick chimney is a traditional architectural element of a house, which is not only functional, but also beautiful. Some types of roofing, such as shingles, go well with it.

Instagram bannie_chertogi

Brick chimney can be a decoration of the building

The system also has disadvantages, and significant ones. Its mass is very large, for this reason it is necessary to build a reliable foundation. It must withstand a significant load. Construction is quite difficult and time-consuming, while steel parts are much easier and faster to install. But this is not all the disadvantages. The inner section of the pipe has the shape of a quadrangle.

This is not good, since a circle is the best option in this case. Swirls form in the corners of the quadrangular chimney, which impede normal draft and impede the movement of gases. In addition, the inside of a brick chimney for a gas boiler, like any other, is always rough, even if it is plastered. On such a surface, soot is easily deposited and accumulates, which leads to a decrease in the passage section and a deterioration in traction.

And one more significant disadvantage. Ceramics are sensitive to acid condensation, and under the influence of it quickly deteriorates. A corrosive substance is formed in flue gases, the temperature of which is below 90 C. For traditional furnaces and boilers, this is irrelevant, because the flow does not have time to cool down so much. But for modern economical models with low-temperature smoke, this is significant. In such cases, it is necessary to sleeve the chimney, otherwise it will quickly become unusable. Sometimes, to simplify the work, the steel pipe is lined with bricks.

Instagram dachazhuk_

A brick flue duct is only good for ovens with high smoke temperatures. For low-temperature models, a chimney sleeve is performed

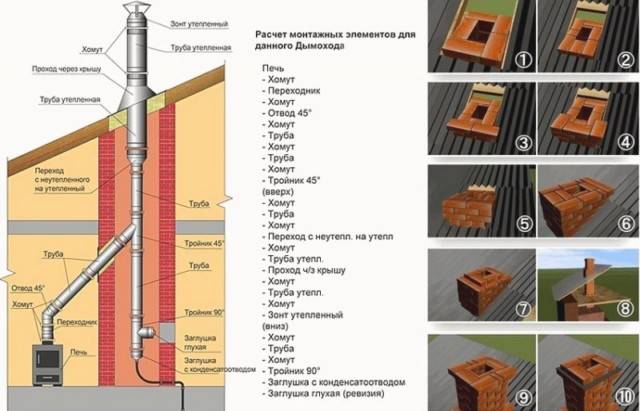

Methods for plugging flue gas ducts

The sleeve is a cylinder of a certain section, made of fire-resistant material, which can be assembled into a pipe of any length.

The sleeving of a brick chimney can be carried out in three ways, which differ from each other in the materials used, cost, and some installation features.

- Casing of flue ducts with polymer inserts. A special pipe made of polymer reinforced with fiberglass is inserted into the chimney, which, when heated, becomes flexible, and fills the smoke exhaust paths, no matter how twisted they would be. After the polymer has hardened, the inside of the chimney is a smooth pipe with a wall thickness of about 2mm. But there are serious temperature restrictions in the use of this material: It can withstand temperatures up to 250C⁰, therefore it can be used to remove combustible gases, only boilers with liquid or gas fuel.

- Chimney sleeve with steel modules. Closing the channel in this way does not require its destruction. This material is durable and relatively inexpensive. One of the greatest benefits of using steel modules is the ease of handling. This material can be used for the reconstruction of smoke exhaust systems, heating and cooking stoves, stoves and fireplaces that run on any type of fuel.But there is also a drawback, in this way it is impossible to sleeve winding smoke ducts.

- Chimney sleeve with corrugated stainless pipe. This material can be used for furnaces with a low temperature of the outlet of combustion products, since this pipe has rather thin walls and will quickly burn out at high temperatures. In addition, soot will surely be deposited on the inner surface. Due to the ribbing, corrugated surface.

Based on the foregoing, it is not recommended to use a corrugated stainless steel pipe for casing the bath chimney.

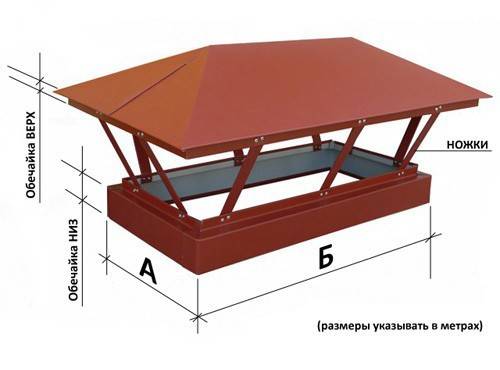

Elements of a brick chimney

The chimney design is very simple.

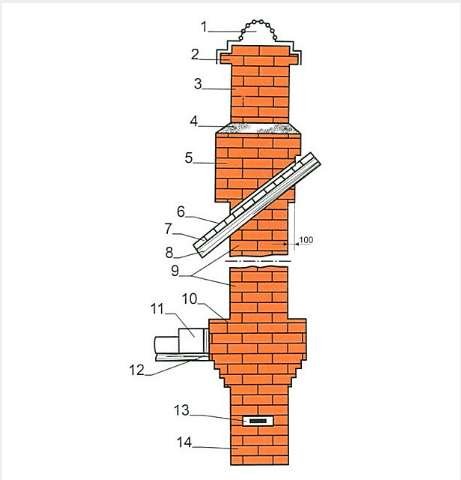

Schematic diagram of a brick pipe, which should be followed

The flue duct is protected from above by a cone-shaped piece - an umbrella or a cap (1), which prevents precipitation, dust and small debris from getting inside. The upper element of the pipe - the head (2) - is wider than its main part. Thanks to this, it is possible to reduce the amount of moisture that gets into the lower area during rain - the neck (3).

There is another widening above the roof - an otter (5). Thanks to it, atmospheric moisture does not enter the gap between the chimney and the roofing (6). A slope (4) is formed on the otter with the help of cement mortar, along which water that has fallen onto the pipe runs. To prevent the rafters (7) and lathing (8) from igniting from contact with the hot surface of the chimney, they are wrapped in heat-insulating material.

The chimney section that crosses the attic is called the riser (9). In its lower part, just at the level of the attic floor, there is another widening - fluff (10).

Brick chimney is more reliable than metal

The thick walls of the fluff protect the wooden floor elements (11) from excessive heat, which could cause them to catch fire.

The chimney can be made without fluff. Then, in the zone of passage of the ceiling around the pipe, a steel box is mounted, which is subsequently filled with a bulk heat insulator - expanded clay, sand or vermiculite. The thickness of this layer should be 100–150 mm. But experienced users do not advise using such a cutting option: the insulating filler is poured through the cracks.

The fluff is additionally lined with an effective non-combustible heat insulator (12). Previously, asbestos was used everywhere in this capacity, but after revealing its carcinogenic properties, they try not to use this material. A harmless but more expensive alternative is basalt cardboard.

The lowest section of the chimney is also called the neck (14). It has a latch (13) by means of which the draft can be adjusted.

Depending on the method of construction, the chimney may be one of the following types:

- Nasadny. The furnace itself acts as the basis for this design. To withstand the impressive weight of the chimney, its walls must be two bricks thick.

- Root. Such a chimney stands on a separate foundation and is not part of any heat generating installation. The flue pipe of the furnace or boiler is connected to it by means of a horizontal tunnel - a crossover sleeve.

- Wall. Chimneys of this type are channels in load-bearing walls. In order to save heat, they usually use internal walls, on both sides of which there are heated rooms.

In a vertical brick chimney, draft is generated naturally, that is, due to convection. A prerequisite for the formation of an upward flow is the temperature difference between the ambient air and the exhaust gases: the larger it is, the stronger the thrust is formed in the pipe.

Therefore, for the normal functioning of the chimney, it is very important to take care of its insulation.

Calculation of the parameters of a brick chimney

For a high-quality installation of a chimney system, a preliminary calculation of the main parameters is required - the height of the pipe and the cross-section of the channel for exhausting gases. This will provide excellent traction and safe operation of the structure.

Pipe height

This parameter is determined based on technical requirements:

- The minimum allowable height difference between the grate and the head is 5 meters.

- If the roof is made of flammable materials, the height of the chimney head will be 150 cm; when roofing with non-combustible material, the height will be 50 cm.

The presence of a parapet or ridge should not interfere with the safe operation of the chimney. For this, the following rules are observed:

- When the pipe is located at a distance of 150 cm from the ridge or parapet, its elevation above them is 50 cm.

- When removing the chimney head from the parapet and ridge at a distance of 150 to 300 cm, no additional elevation is required.

- When the head is removed from the edge of the roof by 300 cm, it can be located below the ridge to a height along an inclined straight line with an angle of 12 degrees.

If there is a tall building on the site, the chimney should be 50 cm above its roof.

3> Channel section

If the chimney is equipped for a metal stove or for a solid fuel boiler, then the calculation of a suitable section is carried out taking into account the operating power of the equipment:

- Power - up to 3.5 kW, cross-section - 14 × 14 cm.

- Power - from 3.6 to 5.1 kW, cross-section - 14 × 20 cm.

- Power - from 5.1 to 6.9 kW, cross-section - 20 × 27 cm.

- Power - from 7.1 kW, section - 27 × 27 cm.

The data on the capacity of the factory heating equipment are indicated in the technical passport. For homemade devices, a similar parameter is calculated by the formula:

W = V × 0.63 × 0.8 × E / t, where

W is the power of heating equipment (kW).

V is the volume of the combustion compartment (cubic meters).

0.63 - coefficient of the average load of the combustion compartment.

0.8 is a coefficient that determines the part of the fuel material that burns completely.

E is the thermal energy of the fuel material (kW × h / m3).

T - duration of combustion of one fuel load (hour).

Thermal energy depends on the type of wood and its moisture content.

Why chimneys collapse

During operation, even without errors, the built chimney is subjected to intense loads. The service life of a brick pipe is 20-30 years. For a steel chimney, the operating warranty is less, and is 10-15 years. The figures given are roughly indicative of the service life without major overhaul, subject to the average load.

In real conditions, the integrity of the flue gas duct depends on many factors, both natural and man-made. Natural causes of pipe failure are aging, wear of the material under the influence of external factors. Subject to the rules for the construction of chimneys, natural factors act gently and prolonged over time. Errors, negligence or ignorance lead to the rapid destruction of the chimney.

The following factors contribute to the destruction of chimneys:

- Errors at the design stage, when the built flue duct initially works with the formation of a large amount of condensate and ash sediment on the inner surface.

- Stove-maker's mistakes when laying a chimney or stove.

- Formation of chemically aggressive condensate on the inner surface of the channel. Occurs when the construction technology is violated or when the stove is rarely used.

- Destruction of brickwork. The reason is poor-quality material, freezing of condensate in the pipe solution, frequent temperature drops with rare use of the furnace.

- Burnout of the steel inner pipe of the sandwich chimney. Occurs when using low-quality steel in the manufacture of a pipe or when installing a chimney on a boiler, which does not comply with the recommendations of the manufacturer of this sandwich pipe.

- Violation of the tightness of the chimney at the joints (for a steel pipe). Air leaks from the outside and brickwork burns out or bricks cracking.

What is a brick chimney and where is it used

Chimneys are used to remove gaseous combustion products in stoves, fireplaces and heating boilers. Smoke, carbon monoxide and soot are carried out of the furnace into the chimney under the action of traction and are discharged outside. As they move, they cool down, giving off heat to the walls of the chimney.

To remove combustion products from a brick oven, you need to build a chimney from the same material, that is, from a brick

Unlike metal pipes, a brick chimney has:

- Higher coefficient of heat capacity. Because of this, the efficiency of such chimneys is higher. Accumulating heat inside itself, the brick gradually gives it to the interior of the dwelling, thereby prolonging the heating time of the air.

- High thermal stability. The temperature of gases as a result of fuel combustion reaches 800 ° C. Metal chimneys, warming up to such a temperature, eventually "burn out", deform, water condensate forms on the walls. Mixing with soot, water turns into a corrosive chemical.

- A variety of architectural forms. The brick pipe organically fits into the style of the building, giving it additional design. The massiveness of the chimney makes the pipe resistant to mechanical damage, little exposed to the effects of natural atmospheric phenomena. Metal pipes, on the other hand, must be carefully secured, in some cases even stretched.

But the brick chimney also has a rather significant disadvantage. In country houses and country cottages, it is not possible to fold cylindrical pipes, which are ideal for the passage of incandescent gases. The internal section of a square or rectangular shape creates obstacles for the outflow of smoke. As a result, a layer of carbon deposits quickly forms on the inner walls, which reduces traction. Accordingly, they have to be cleaned more often than metal ones.

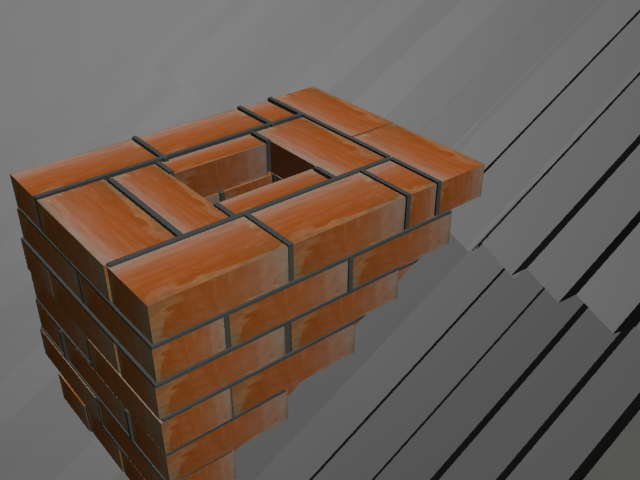

Step-by-step instructions on how to lay out a chimney

The construction of a brick chimney is a technically complex process that requires high-quality masonry in order to obtain an airtight, safe and durable structure.

First, you need to choose the appropriate installation schemes for the chimney system. They can be ordered from design bureaus or found ready-made on specialized resources. The dimensions of the future chimney design are determined at the planning stage and performing the necessary calculations.

Brick chimney masonry is performed as follows:

- Erection of an overhead pipe, the lower part of which is set on a thin layer of clay and sand mortar. If several channels are provided in the chimney, then a three-channel pipe can be used. But the masonry algorithm is preserved for any type of construction. The laying is performed by the dressing method, when each subsequent row has a shift to the side by 0.5 bricks. On the 5th row, before reaching the floor beams, the installation of the pipe is completed.

- The fluff is being laid. The outer perimeter expansion should be 590 x 450 mm, and the inner one 140 x 270 mm. The expansion is carried out by displacing the edge bricks by 5 cm. After the completion of the fluffing, the expansion is necessarily insulated with 10 mm sheets of asbestos or other selected material.

- Placing the otter requires meticulousness and care as the rows are laid out to create a special ledge. The first row is similar to the previous row of fluff expansion, then it is necessary to lay out the second protrusion and subsequent ones.

- Installation of a riser. The masonry is carried out in the attic close to the roofing system of the building. It must be brought out through the roof with an elevation above the ridge of the building to a height of up to 100 cm. The brickwork ends with the organization of a chimney neck, at the end of which a head is erected and a protective cap is installed.

Malfunctions and their causes

All malfunctions that require repair of the stove in the house in the country are related to the temperature regime. Bricks and metal become larger when heated, and when the oven cools down, they return to their original position. If the stove is used every day or vice versa, it is extremely rarely used, the materials do not withstand the stress. It becomes inevitable that there are cracks or a blockage in the chimney.

In addition to the temperature load, there are other reasons for the appearance of problems:

1. Burning conifers. Spruce and pine leave a lot of unburned sawdust. They go up the chimney and clog it.

Conifers for oven use

Conifers for oven use

2. Waste incineration. Since the oven is not designed for this, plastics and other materials tend to crack.

Burning garbage in a kiln

Burning garbage in a kiln

3. Poor termination. If a poor-quality mortar was used, over time it can simply fall off, opening the gaps between the bricks.

Sealing joints with mortar

Sealing joints with mortar

4. A huge amount of fuel. The desire to warm up the stove as quickly as possible often leads to the fact that too much wood is put in it. The result is slots of different sizes.

Loading the stove with wood

Loading the stove with wood

5. Brick in the chimney. Sometimes fragments or even whole bricks fall into the chimney. If this happens, traction is partially or completely lost.

Foreign objects in the chimney

Foreign objects in the chimney

6. Problems in masonry. Perhaps the stove was originally assembled in a hurry. Then a major overhaul is needed.

Brickwork oven

Brickwork oven

Also, malfunctions arise due to external factors. Since the chimney is also outside, it is influenced by weather conditions. Birds occasionally fly into it. It is almost impossible to predict these moments.

Classic chimney

Consider the structural elements of a classic chimney.

Classic chimney device

Bottom part

From the top of the stove to the smoke damper (gate). It accepts very hot gases, fireclay bricks can be used for the channel. It is better to buy a gate ready-made in a store, there is no way - do it yourself. Store structures are more reliable, they are made of ductile iron and do not deform during heating. Steel gates can deform as a result of tempering of the steel. The deformed gate wedges in the grooves, opening / closing is difficult. For laying the lower part of the chimney, it is recommended to use a clay solution without adding cement.

Steel gate in a brick oven

Fluff

It performs two tasks: increases the resistance of the chimney to wind loads - rests on the floor beams. In addition, the increased dimensions of the fluff serve as fire protection for wooden structures.

Pipe flare

Riser

Part of the chimney from fluff to otter. The longest section, during laying, it is necessary to observe the vertical position of all rows.

Chimney riser masonry

Otter

Special thickening above the roof covering. Traditional chimneys are made without the use of modern methods of sealing the exit above the roof, the increased size of the otter excludes the ingress of natural precipitation into the attic of the bath. To improve insulation, galvanized steel sheets can be nailed around the perimeter of the otter.

Otter

Neck and head

The length of the neck depends on the angle of inclination and the type of roof, the specific dimensions take into account all the features of the structure. The neck height influences the thrust stability regardless of the wind strength.

After the neck is formed, you can lay out the head

The head is a decorative element of the chimney.

Chimney head options

Protective cap

Prevents rain and snow from entering the flue duct. There is one more function for the cap. If no one uses the sauna stove for a long time, then the birds can twist a nest in the channel - the chimney will have to be cleaned. To prevent such situations, it is recommended to cover the outlet with a metal mesh.

Chimney visor device

We can give only the approximate dimensions of each element of the chimney, more accurate parameters need to be calculated taking into account the architectural features of the stove and bath.

Choosing materials

For the construction of a chimney, only solid refractory blocks are suitable. Recommended brands from M150 to M200. The material is available in three grades.

- 1st grade. With a normally kept firing time. Smooth, smooth and tight. No crumbling areas. The color is bright red. When tapped, the sound is clear and clear.

- 2nd grade. Unburnt parts of a pale orange color. Porous, loose, with defects. When tapped, they sound dull. They are characterized by weak frost resistance and heat capacity, the density is low.

- 3rd grade. Burnt bricks. They are distinguished by a dark red color. Pores, galls and chips are visible on the surface. An excessively loud sound when tapped. Fragile, not frost-resistant, poorly retaining heat.

The flue pipe should only be assembled from first grade material. It is allowed to use the third one, but only for arranging the foundation. The use of the second grade is excluded.

Instagram brigadir74

Instagram brigadir74

For the construction of the chimney, only high-quality brick of the first grade is used

Chimney cleaning and repair

Both traditional methods and modern ones based on technological advances are used to clean the pipe.

From time immemorial, people were engaged in the maintenance of stoves, whose profession was called a chimney sweep. Today, finding a professional chimney sweep is problematic. They were replaced by chemical agents, which, however, are also often called "Chimney sweep".

It is very difficult to find a professional chimney sweep today, this profession is a thing of the past.

So, a tool called "Log Chimney Sweep" has proven itself well. It contains copper sulfate salts and other active chemical compounds. Burning in the furnace, the vapors of these substances interact with carbon deposits that have settled on the pipe walls. Under the influence of heat, the reaction continues for several weeks and leads to the fact that the solid structure of the soot crumbles and, once again entering the furnace, burns out. According to the manufacturers, the use of "miracle log" twice a year allows you to completely remove soot from the pipe. This results in good draft and a high heat transfer rate of the furnace.

The manufacturers of the Poleno Chimney Sweep product claim that its use twice a year allows you to completely clean the chimney from soot.

From folk remedies, one can note such effective prevention methods as burning salt or soda once every 2 months (about 0.5 kg per one furnace). The powder is poured into the combustion chamber at the moment when the wood is well heated and the temperature is maximum. After that, you need to tightly close all the doors, as the reaction can be quite violent.

Dry aspen firewood helps to clean the chimney well. The fact is that aspen burns with a large release of heat, the tongues of flame are long and penetrate deeply into the passages.

If there is no aspen or soda, you can use potato peelings. To do this, you need to accumulate about half a bucket of potato skins. When burned in a firebox, the released substances bind the soot and force it to burn to the end.

The combustion temperature of aspen wood reaches 800 degrees, so the soot on the walls of the chimney burns out

When carrying out work on the installation of chimneys, especially in the area of installation of the neck, otter and head, safety standards should be carefully observed. If you work carefully and follow the necessary instructions and technologies, you can easily fold the brick chimney with your own hands.