Boiler design

A boiler is a device that heats and stores hot water. Structurally, it is a container of one volume or another, equipped with thermal insulation and heating elements. The water supplied to the tank is heated to a predetermined temperature, after which it can be used by consumers. Heating temperature control and maintenance is carried out using a built-in thermostat. The maximum temperature reaches + 70-80 degrees.

Most boilers have a pressure head design. That is, the outlet water flows under the same pressure as it is supplied to the unit tank. If the supply of cold water stops, then it will not work to get water from the storage water heater - it simply will not flow out of it. Thus, the water in the tank is under constant pressure (increasing with heating).

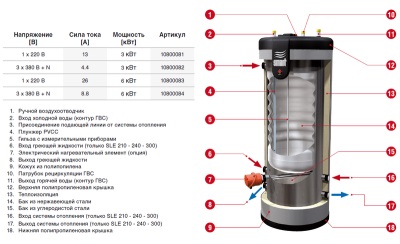

How does the boiler work and what nodes can we find in its interior?

- A tank with a protective coating is the basis of any storage water heater. The tanks are made of metal and coated with enamel or glass ceramics to prevent corrosion. The capacity of the tanks varies from 10 to 300 liters;

- Heating element - inside the boilers we can find one or two heating elements. They are responsible for heating the water (in gas boilers, this function is performed by the burner);

- Thermostat - provides support for the set temperature (mechanical or electronic regulation is used);

- Control panel - hidden or open, it is used to set the temperature;

- Thermometer - provides control of the temperature of the water in the tank. The thermometer can be mechanical or electronic.

The design of the boilers is extremely simple, and the bulk is occupied by massive tanks of various capacities.

Pros and cons of boilers

In the absence of a centralized hot water supply system, it is boilers that are used. Their advantages include the following points:

- The convenience of use.

- Large volumes can be heated.

- One device can be used to supply several rooms.

- The operation of the device does not depend on the force of pressure.

- Possibility of heating to high temperatures.

- Retention of high temperature for a long time due to high-quality thermal insulation of the tank.

Among the disadvantages are the following:

- Long time for initial heating.

- If the water flow is low, maintaining a constant temperature will incur energy costs.

- A large tank requires ample space.

- The cost is higher than that of a flow-through product.

In case of problems with the water supply, you can put a boiler in an apartment building... The device and principle of operation will depend on the type of device, its functionality and additional functions.

Device depending on the type

Direct heating

The energy carrier that enters such devices is spent only on heating the water inside the device. This means that this type of appliance produces heat on its own, which heats up the water. They are gas, when a gas burner is used for heating, as well as electric, that is, with heating from a heating element.

By their design, such boilers are a container (a tank with water), around which there is thermal insulation and an outer casing with a control panel. In addition to the heating element (burner or heating element), such devices have a magnesium anode, a thermostat, a safety group and nozzles (inlet and outlet).

Indirect heating

This type of boilers is installed in houses or apartments with autonomous water heating, providing for a single-circuit boiler.The temperature of the water inside the indirectly heated boiler does not increase as a result of the direct influence of the energy source, but as a result of heat exchange with the heating circuit.

The design of this type of boiler includes a body, inside of which an inner tank is placed, separated from the outer casing by a layer of thermal insulation. Water from the cold water supply pipes enters the tank through the inlet pipe, and is discharged after opening the hot water tap through the pipe located in the upper part of the device.

Separately, the device has a heat exchanger, which in most models is represented by a coil. It can be evenly spaced within the tank or at the bottom of the tank. Both pipes of such a heat exchanger are connected to a heating boiler.

The heat carrier from the boiler moves through the heat exchanger, heating the water in the tank by means of heat transfer, and then it is removed through a separate branch pipe, returning to the boiler. Such a heat exchanger is most often one, but there are models with several heat exchangers that can be connected not only to a gas boiler, but also to another source.

There are also indirect heating boilers without a coil, the design of which is called "tank in tank" due to the presence of another tank inside the tank of such a boiler. Sanitary water in such a device is heated in the inner tank, and the coolant moves between the walls of the inner tank and the outer walls.

In some models of this type of boiler, a recirculation branch pipe may be present. Mandatory elements of all such devices are a magnesium anode and a safety group, as well as a thermal sensor. In large boilers with a capacity of more than 150 liters, an inspection window is often provided.

Combined

These boilers combine the two previous types of heating devices. By their design, they are represented by devices with indirect heating, but they differ in the additional installation of a heating element, which allows the device to be used as a storage electric boiler for direct heating. This is especially useful for the summer period when the single-circuit boiler is off.

Almost like a thermos

In a thermos flask there is a glass flask, double, with a vacuum - a heat insulator. In the boiler, the water tank is made taking into account metal corrosion and work under pressure. The best material is stainless steel. But such a tank turns out to be the most expensive even in comparison with the construction of ordinary steel coated with a super-anti-corrosion compound. The heat insulator is any modern material with the necessary properties, placed between the inner and outer parts. If water flows from the inner tank through its wall with corrosive damage, the outer part will not save from the flood.

Therefore, for storage water heaters, corrosion protection is the most important task. It is solved by placing a special rod with a layer of magnesium inside near the heating element. It is called a magnesium anode and is designed to protect the housing from corrosion. Magnesium is chemically more reactive than the iron in the body material. For this reason, negative ions in the composition of water interact with this anode, and not with the wall, in which there may be a microcrack in the protective layer. The anode is a consumable item that is recommended to be replaced annually.

In a direct heating boiler, the heating element can heat water to a temperature even above 100 degrees Celsius. At the same time, due to the increase in pressure, it will not boil inside the tank. This is, in principle, dangerous for users. The water will boil immediately at the outlet of the tap, and spray of boiling water will scatter in all directions. Therefore, a reliable automatic thermostat with a thermometer and thermostat is required in the boiler.The factory setting of the thermostat operation will eliminate the human factor, ensuring the timely shutdown of the heating element in any case.

Gas heaters

- The storage gas boiler uses a gas burner as a heating element. The power and heating rate of a gas water heater is higher. But for the installation of a gas storage boiler, equipment for the removal of exhaust gases is required.

The design of the gas storage water heater also includes a control device. The photo shows that in appearance only the presence of forced gas removal distinguishes electric and gas storage boilers.

The storage type boiler also requires the installation of special safety fittings, which include a non-return valve, a safety valve and a reducer.

The video below shows the different types of storage boilers, and examples of their installation.

- Gas boilers of flow type are also referred to as gas water heaters. Their principle of operation is the same, the difference is in the design and method of ignition. The geyser in appearance is a metal box, to which two pipes fit, one with water, the other with gas. The main parts of the structure:

- heat exchanger;

- main burner;

- pilot burner.

The gas released during combustion of the main burner is sufficient to heat water in a heat exchanger made in the form of a spiral. Electronic ignition is used in modern models of gas water heaters.

Forced or natural removal of waste gas is also required.

When using gas water heaters, as hot-water equipment, special attention must be paid to good ventilation of the room.

Indirect heater

The indirect water heating boiler uses the heat generated, for example, by the home heating system. The main convenience is the use of water from the heater at several points in the house, since there is a supply of hot water in the tank of the device. Externally, the water heater for indirect water heating is also cylindrical, but rectangular options are also possible.

The design consists of a tank, inside which a heat exchanger is placed with a coolant circulating through it. Inside there is a magnesium anode designed to prevent corrosion of the inner surface of the boiler. The anode is part of the safety system group, which also includes a check valve, an overpressure valve and a temperature sensor.

It is advantageous to purchase an indirect heating water heater together with a single-circuit heating boiler. Although together this unit costs more than a double-circuit boiler and is a more cumbersome structure, it provides an almost uninterrupted supply of hot water to several points, at a uniform temperature of the supplied water.

Models of boilers for vertical and horizontal installation are available, which are installed depending on the area of the room, vertical ones are attached to the wall and take up less space. Models without heat exchangers consist of containers inserted one into the other, with a coolant circulating between them. A variant of a combined boiler is possible, in which water is heated both from an external source and from a heating element.

Modern water heaters are equipped with thermostats to ensure the safe operation of the device. Replenishment of the water used up from the water heater occurs automatically. The reliability and durability of the boiler also depends on inner tank lining, which today are mainly made of glass porcelain and enamel. The time for heating the water in the water heater depends on the power of the heating element. The power of gas boilers is twice that of electric ones.

There are also free-flow open boilers, although they provide hot water to one point, they are applicable in systems with little or no water pressure.

Summarizing all of the above, it should be noted that the principle of operation of all modern boilers is simple, which makes them indispensable for rooms in which there is no centralized hot water supply.

How to save energy?

You can save a little on the electricity consumed by the boiler during operation. For this it is recommended:

- Set the heating temperature not to the maximum (75-85 degrees), but to 55-60. When cold water enters the tank and combines with the liquid that is already there, less energy is needed to warm up the mixed mass. In addition, a temperature regime of 55-60 degrees will help to significantly reduce the process of scale formation on the heater.

- It is necessary to choose the correct location of the boiler so that the pipeline from it to the sink or shower is not too long. Due to this, the heat from the hot water will dissipate less.

- Periodically it is necessary to carry out preventive cleaning of the heating element from scale. Due to this procedure, the efficiency of its work increases - the cost of electricity for heat generation will be less.

Top 5 popular models

| Model name | Volume of the tank | Price | Power | type of instalation | Peculiarities |

| BOSCH Tronic 1000 T ES 050-5 N 0 WIV-B | 50 l | $ 125 e. | 1.5 kW | vertical, wall-mounted | magnesium anode, thermal insulation - 32 mm |

| Ariston ABS VLS PW 80V | 80 l | 270 USD e. | 2.5 kW | vertical, wall-mounted | frost protection, thermal insulation - 32 mm |

| GORENJE GBF 80 | 80 l | 190 USD e. | 2.0 kW | vertical, wall-mounted | magnesium anode,

thermal insulation - 17 mm |

| THERMEX IF 100 V | 100 l | 245 USD e. | 2.0 kW | vertical, wall-mounted | magnesium anode, thermal insulation - 17 mm |

| THERMEX ER 80 V SilverHeat | 80 l | $ 100 e. | 1.5 kW | vertical, wall-mounted | magnesium anode,

thermal insulation - 17 mm |

Connection diagram and installation

The installation of the storage water heater should be carried out in strict accordance with the installation instructions, which you will definitely find in the user manual.

We want to give you some recommendations that will allow you to connect the device to communications as efficiently and safely as possible.

- The boiler should be installed against a wall; at the same time, make sure that the pipes for hot and cold water are strictly parallel to it. There should be a small distance between the water heater and the wall, allowing for routine inspection and maintenance of the nodal connections.

- It is recommended to use a ¾ ”pipe for connection to the water supply. Stand facing the appliance: the pipe for hot water should be located on the left hand, and for cold water on the right hand.

- Using a safety valve for the storage water heater will help to avoid overheating of the device and the associated unpleasant consequences.

- Before you start connecting the boiler to the water pipes, open the cold water tap. Make sure it is clean enough to be free of sand inclusions, rust particles and other small debris. If necessary, cut a special water filter into the pipe (in the section of the network before the water heater).

- It is also recommended to check the pressure in the water pipes before starting the installation. Its level should not be higher than 8 bar. If this figure is exceeded, a pressure reducer must be installed.

- Drops of water falling from the hydraulic valve are a sign of normal operation of the device and the water supply network. But it is necessary to ensure that water from the valve does not get onto the water heater body. To do this, a special drain funnel with outlet to the sewer must be connected to the valve.

- If the boiler is installed in a country house in which there is no constant heating, you need to make sure that no water remains in the tank when the outside temperature drops below zero. Therefore, when leaving the house during the cold season, always drain the remaining liquid from the tank, otherwise the device may fail.

Tips for choosing a boiler

Like any household appliance, the boiler has its positive and negative sides.

The main advantage of this technique is that under any external circumstances there will always be hot water in the house. For small towns and villages where there are problems with hot water supply (or there is no hot water supply at all), this is the only way out.

When making a choice of a water heater, one must take into account the advantages and disadvantages of each of them. For example, by installing a flow-through boiler, you do not have to wait until hot water is warmed up, its amount will not depend on the volume of the tank. But you will need a powerful hotel machine and a power cable to connect the device, and electricity consumption will also significantly increase.

The storage boiler consumes less electricity, but only a certain amount of hot water is produced. And its main drawback is that it takes up a lot of space.

When choosing a boiler, certain criteria must be adhered to.

Installation purpose

The main criterion when buying a water heater is the purpose of its purchase:

- have a margin in case of disconnection of hot water supply;

- instant heating of water for washing dishes or taking a shower;

- constant supply of apartments (houses, dachas) with hot water.

External dimensions and volume

Immediately you need to decide on the place of installation of the water heater. This technique is large-sized, you can't put it anywhere or hang it

When choosing external parameters, one should not forget about such an important criterion as the volume of the boiler. This value depends on the number of people living in the house.

The bathroom equipment also plays a role, that is, what is used for bathing - a shower or a bath. Using a shower is much more economical, with such a bathing about 15-20 liters of water per person is spent. In the bathroom for such a procedure, you will need 50 liters.

Water consumption table

If a boiler is needed only to provide hot water for washing dishes, and nothing else (without bathing), then a device of 15-20 liters will be enough. Such a water heater is usually installed in the kitchen directly under the sink.

Power

An important role in the selection. The more powerful the heating element will be (from 1 to 6 kW), the faster the water heats up, but will the electrical wiring in the house withstand such a load? If it is new and capable of withstanding a load of 6 kW, then the power of the boiler can be easily selected based on the needs and the number of residents. In apartments with old electrical wiring, the maximum that can be counted on is a water heater with a capacity of 2.5 kW.

Internal tank lining

In cheap boilers, the inner lining of the tank is made. In expensive models, titanium spraying or stainless steel is used. When choosing, a person proceeds from his financial capabilities, but a high price, as a rule, guarantees quality and durability. In the case of household appliances, it is not worth saving.

It is recommended to check the quality of the water heater by weight. The heavier it is, the better it will resist corrosion due to the greater wall thickness.

Tank lining (stainless steel)

What else should you pay attention to?

The degree of protection against moisture and dust of the boiler (IP) must be at least 23. If the water heater is to be installed in a bathroom, sauna, bath, a more protected model with IP 44 is required.

It is worth giving preference to models with a dry tubular electric heater (TEN)

The lack of contact with water not only prevents the appearance of scale, but also reduces the risk of electric shock, since the heating element is placed in a sealed glass.

When buying a boiler, be sure to pay attention to the presence of a magnesium anode. Safer and more comfortable in terms of operation will be models with overheating protection, power-on indication, and accelerated heating function.

When choosing a boiler for a summer residence where no one lives in winter, it is worth giving preference to models with a frost prevention mode.

When buying a water heater, be sure to ask about its heat-insulating layer.

The recommended thickness is not less than 35 mm (the thicker, the longer the set temperature will remain).The highest quality material is polyurethane foam (much better than foam).

Purpose and principle of operation of the indirect heating boiler

Connecting an indirect heating boiler to the system avoids limiting the number of DHW consumers. Correctly calculated power of the heat exchanger and its volume, allow you to quickly and evenly heat the water in it to the desired temperature, the same throughout its volume.

For example, a 100 liter tank can provide about 500 liters of hot water per hour. An ordinary electric "apparatus" is not capable of this.

The principle of operation of an indirect heating boiler necessarily assumes a "tandem" with a heat source in the heating circuit of the house. The volume of the heater tank is coordinated with the power of the heating boiler, which provides an increase in the water temperature due to the transfer of heat from the coolant from one circuit (heating) to another (DHW circuit).

There can be several heat transfer "radiators" in the boiler.

For example, a solid fuel boiler, solar collector, heat pump of a geothermal heating system can be used to heat water. Each of these "heat sources" has autonomous coolant flow lines connected by "heat transfer" in the heated medium.

Device and principle of operation

Accumulative water heaters, unlike flowing ones, heat water in advance. Heating takes place in a metal tank, which is the main part of the design of any boiler. The size of the tank depends on how much water it is designed for. Domestic boilers with a capacity of 50 to 300 liters are on sale.

The water in the tank is heated by a heat exchanger. Most often it is a steel or brass coil. It is located at the bottom of the tank or is distributed over almost the entire surface of the device. The coil receives heat from a gas burner, which is located at the base of the water heater in a special combustion chamber equipped with a flame tube.

In addition to all of the above, the design of the gas boiler contains heat-insulating elements, pipes for supplying and removing water, as well as a variety of sensors.

The tank is replenished with water automatically. When a fresh portion of water enters the tank, the gas burner turns on, the heat from which flows out through the flame tube and heats the tank. As soon as the water in the tank heats up to the desired temperature, the sensor is triggered and the gas supply is stopped.

You can get even more information about gas boilers from the following video.

Main characteristics

The main technical characteristics of the boiler are:

- Body material (enamel, stainless steel, plastic).

- Placement type (wall, floor, vertical, horizontal).

- Rated voltage of the electrical network (220 or 380 V).

- Water pressure (especially important for instantaneous water heaters). If the pressure in the water supply is low, the heating element may deteriorate.

Horizontal water heater model

- Volume of the tank.

- The weight.

- Overall dimensions (depth, width, height).

- Maximum power.

- The presence of a water temperature regulator, magnesium anode.

- The thickness and material of the thermal insulation layer (the most efficient is polyurethane foam).

- Heat losses (directly depend on the thermal insulation layer, the thicker it is, the less losses and the more economical the water heater).

- Control type (hydraulic, electronic, LCD display).

Pros and cons of the scheme of work

The main advantages of the indirect heating boiler operation:

- the operation of such a water heater does not overload the electrical wiring during the heating season, since the boiler depends on central heating and does not consume electricity;

- with the correct design, the boiler has very high performance indicators and an optimal cost ratio;

- the inner surface of the heater and the coolant does not interact with running water, which ensures a safe and long service life of the unit;

- due to recirculation, hot water flows immediately after opening the tap;

- the indirect heating boiler can always be switched to an alternative heat source or several can be used.

Unfortunately, each scheme of work, in addition to positive, also has negative sides:

- additional costs will be required to re-equip the system;

- the cost of a boiler with indirect heating is much higher than gas or electric heaters;

- the initial heating of water (with a volume of more than 100 liters) lasts from 1 to 2 hours, this can negatively affect the quality of the heating system of the room;

- for a boiler with a volume of 100 liters or more, a separate room is required due to the impressive size of the device.

What to look for when choosing an indirect heating boiler?

The most important characteristic of a boiler is its volume. You need to roughly estimate how much water is needed for a comfortable existence for your family. Based on average indicators, a person spends 5-15 liters a day on personal hygiene, 15-25 liters / day for washing dishes, 50-100 liters / day for taking a shower, and 150-200 liters / day for taking a bath.

It is believed that 80-100 liters of hot water is needed per resident, of course, this calculation is conditional, it all depends on the preferences and habits of residents. For example, someone likes to take a shower twice a day, while another manages to take a bath once a week. The larger the volume of the boiler, the higher its cost.

Preference should be given to boilers with a brass coil. It will heat water more efficiently than a steel one, besides, it is much easier to clean a brass coil. The water heater must be protected against corrosion. In cheaper models, the tanks are covered with a layer of enamel or glass ceramics. Expensive devices are protected from corrosion by stainless steel. In addition, do not forget about the thermal insulation of the unit, high-quality boilers are insulated with mineral wool or polyurethane foam. Foam insulated models are best avoided.

Device depending on the type of energy

Electrical

Such boilers are the most common and are presented in a wide range. For their work, they use electricity, so the main part of such devices is the heating element. It is this part that heats the water collected in the tank of the apparatus. The heating element can be located directly in water or be placed in a capsule and not in direct contact with water (such heating element is called "dry").

Next to the heating element there is a thermal sensor that controls its operation through an electromechanical or electronic thermostat. These parts ensure that the temperature of the water inside the tank is maintained at the desired level. As soon as the water cools down a little, the temperature sensor transmits a command through the electrical circuit to the thermostat, as a result of which the heating element begins to heat the water.

The tank of an electric boiler is surrounded on the outside by a layer of heat-insulating material, as well as a decorative plastic or steel casing. Cold water enters the inside of the device through a pipe located at the bottom of the boiler. As it heats up, the liquid rises to the top of the device, from where it is taken through the outlet pipe after turning on the hot water tap.

Most electric boilers have a magnesium anode inside. Due to its lower electrical potential, such an anode attracts free ions of those salts that are dissolved in tap water. As a result, scale deposits on the anode instead of attacking the heating element and the tank walls. Over time, the anode collapses, therefore, with regular maintenance of the electric boiler, it is replaced with a new one.

A safety group with a safety valve must be installed at the inlet of the electric boiler.

Its presence is important to protect the boiler from overpressure. If the pressure inside the tank rises, the valve releases it and thus prevents damage to the device.

Gas

This type of storage heaters is not as common as electric boilers, due to the complexities of the installation (approval, chimney, good ventilation, registration is needed).

Such heating devices work on natural gas. In their design, a water tank, an incoming cold water supply pipe and a hot water outlet pipe are distinguished. The body of the device is thick enough and is separated from the water tank by a layer of thermal insulation to maintain the temperature of the heated water for a long time.

Heat exchange in gas boilers occurs through the bottom wall of the water tank, since there is a combustion chamber with a gas burner located under it. Also, heat is transferred to the water inside the tank from the central channel, through which the combustion products from the burner chamber are removed to the chimney.

Such a boiler is controlled by a temperature sensor and a thermostat. These elements record the temperature of the water and, if necessary, turn off the gas supply to the burner or turn it on. Also in gas boilers there is a safety group, the main part of which is an emergency valve for relieving excess pressure.

To prevent scale from depositing on the walls of the apparatus, the design of the gas boiler includes a magnesium anode. Over time, it is "eaten", so it needs to be replaced.

The scheme of the storage water heater

The standard operation scheme for hot water equipment is based on the principle of separating several water layers that differ in different temperature conditions. The selection of hot liquid from the water heater is carried out through the hot water supply pipe.

Such a tube has a strictly defined length, reaching the upper, most heated layer. The laws of physics do not allow parallel arrangement of a vertical design hot water device.

Electric circuit of the storage water heater

When choosing a storage boiler for electric heating, you need to pay attention to its design features, as well as take into account the basic rules for installing a water heating device.