Types of heating stoves

All modern heating and cooking ovens, which have a built-in water circuit, are conditionally divided into systems with and without an additional foundation. The latter design is mobile and the most popular among the modern consumer. It is more compact and successfully copes with all the functions of a similar stationary installation.

The removal of warm water from the stove for domestic needs or to the heating system of a private house is carried out through a block of connecting pipes. Temperature and pressure are monitored visually on a panel with appropriate sensors. All wood-fired combustion installations, where there is a water circuit, have a convection grate for the outlet of warm air and a chimney for removing combustion products.

Heating connection

When choosing the location of the heating device, keep in mind that all the heat will get to this room, you can admire the flame here, but here you will have to heat it, which means that wood debris, fly ash, etc. are inevitable. It should be convenient to approach the fireplace.

A fireproof base and walls around the stove are a must. Many people use ceramics, but you can make a brick casing and metal sheets. It is advised to complete all finishing work before installing the oven.

Before connecting the stove, the heating system must be completely finished: radiators, pipes, security group, expander, etc. Everything must be in place.

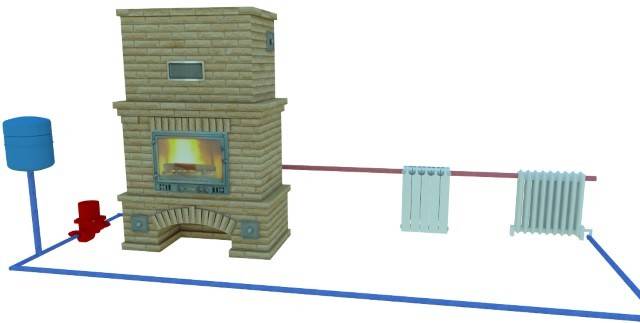

Open fireplace connection system with water jacket

On the back wall there are the outlets of the heat exchanger, and the supply and return are determined (as a rule, there are marks on the case where which branch pipe is).

Using the mounting kit, which can be purchased separately, the connection process can be done quickly and easily. Ball valves are mounted on the heating pipes so that it is possible to perform various work with individual elements without draining the coolant from the entire system. The connection is made with the help of American women. All joints are sealed with FUM tape.

If the house is two-story, it is good to place the heater near the stairs - then the heat will rise up and heat the second floor.

How to choose a fireplace?

The main parameter when choosing a fireplace, which is worth paying attention to, is the power indicator of the fireplace insert. This indicator directly depends on the dimension of the combustion chamber, since the more fuel a cast-iron furnace holds, the higher the power

Photo 3. Water fireplace

Three values are usually indicated in the technical passport of a fireplace insert: maximum, nominal and minimum power parameters. The most acceptable of them is the nominal, which can be determined experimentally after a short period of time.

To heat ten square meters of an ordinary living space with ceilings of two and a half meters, a power of one kW is enough. Keeping this parameter in mind, it will be easy to calculate the required power of the firebox for the home.

However, it must be borne in mind that too intensive use of the fireplace can significantly reduce its service time. For this reason, it is necessary to buy a fireplace that has a power reserve of ten to fifteen percent of the nominal.

If the plans include the installation of a fireplace system in a dwelling, then it is wiser to design fireplaces, water heating systems and boilers even before the start of construction. This will allow for a more rational distribution of hot water and heat in the future, and will provide the most organic interior.

Installing a fireplace

In order for the stove to start heating the room, you need to connect it to the heating system. For this, special tools and materials are used:

- Stand for installing a fireplace.

- Expansion tank.

- Copper pipe to attach the structure.

- Controller to control the heating process.

- Thermal protection - a sensor that protects the oven from boiling. That is, when the water temperature reaches 90 ° C, the water is thrown into the circuit.

- Explosion valve. In other words, it protects the oven from excessive pressure build-up.

- Connecting elements: valves with couplings, sanitary technical connections, which are used during installation.

- Heat exchanger if the form of connection is open.

How the water circuit works

Units operating on the principle of water heating are made of boiler steel with a thickness of 4-5 mm. Sometimes 8 mm thick cast iron is used. The device is decorated with a fire-resistant coating and facing made of heat-resistant tiles.

The thermo fireplace has a cavity where a 40-liter tank is mounted. The "pocket" is located between the walls of the case, and the air supply channels are located near it. The system maintains long-term combustion by supplying oxygen. When heated, air masses penetrate through the holes to warm up the oven installation site. The heating of the water is provided by a heat exchanger, and the distribution of heat throughout the house is provided by the radiator network.

Choosing a fireplace

To increase efficiency and safety during heating, it is necessary to pay attention to the following concepts during the acquisition, installation and use of modern fireplaces:

- Power selection.

- Selection of hull and heat exchange material.

- Security criteria during connection.

- Rules for connecting the oven to the heated system.

- Recommendations and conditions for the construction of a chimney.

- Selection of fuel resources.

- Proper cleaning, maintenance and heating of the stove by yourself.

In addition, you need to take into account the production tips that should be mentioned in the documents. Observing the above rules, the use of the stove will become safe, and it will serve for a very long time.

One important criterion, which you also need to pay attention to before purchasing any model, is the power of heat release during heating. To measure it, use kilowatts.

It has been calculated that with 1 kW of heating power, about 10 m² of the room can be heated.

True, it is necessary to take into account the fact that during production it is tested under almost ideal conditions, and in the room, the power can be reduced by almost 3 times if you use incompletely dried fuel resources (firewood). So in order to use a hearth with a water layer as the only source of heating, it is advisable to purchase a model with an additional supply of power.

Steel or cast iron

Fireplaces with water heating can be made of steel or cast iron. The cost has become much lower. The steel itself is lightweight, however, it is highly susceptible to corrosion. If the stove is completely made of cast iron, then it will be durable and resistant to corrosion. Of the minuses, there is too much mass and intolerance to sudden temperature changes, which may cause cracks.

Combined models are the best option. In them, steel elements are present in the body and in slightly heated parts. And forged cast iron is seen in the composition of doors and grates, which are exposed to excessive heat.

A high temperature level will not affect such a combination, and it can be used all the time without interruption. As a result of intermittent heating, the pipes are filled with condensate, which prevents corrosion.

In order to use a hearth with a water layer as the only source of heating, it is advisable to purchase a model with an additional supply of power.

Advantages and disadvantages of a water heating stove

Water heating stoves have the following advantages:

- Complete non-volatility - for open and combined circuits;

- Increased efficiency compared to traditional furnaces;

- Attractive appearance of factory models, original configuration as a fireplace;

- More even distribution of heat in individual rooms by means of a heat transfer fluid;

- Multifunctionality - the ability to cook food, heat water.

Along with the advantages of water heating furnaces, they have significant disadvantages:

- Manual maintenance of the furnace - loading fuel, cleaning from ash and soot;

- Cyclic operation, while there is practically no temperature regulation;

- High fire hazard;

- The possibility of carbon monoxide entering the premises;

- Large dimensions of brick ovens, the need to build a foundation;

- Hot surfaces in metal ovens.

What does it consist of

The design is extremely simple: body, firebox, heat exchanger. The body can be free-standing. It is sometimes embedded in an array of walls or decorative framing made of bricks, forged or stone sculptural products. The firebox is steel, but the grates are usually cast iron. The heat exchanger is welded from solid-drawn pipes. An air duct is connected at the bottom of the firebox, and a chimney at the top.

Frame

The metal casing of the aquacamine is hollow inside. Water circulates between the outer and inner walls. It is here that its heating begins, and then it enters the upper register of the heat exchanger. Due to this technical solution, the outer shell cannot even theoretically heat up above 100 ° C, therefore it is completely fireproof.

A hob is sometimes placed on the upper plane. This design is relevant for small country houses, where the kitchen, dining room and living room are combined in one room.

The geometry of the case depends only on the imagination of the designer. The main thing that it contains a combustion chamber.

The combustion chamber

Conventional fireplaces had a low efficiency of 20% due to imperfect heat extraction during fuel combustion. The room was heated by the infrared radiation of the flame. There was a large portal in front so that the rays from the fire could warm the maximum area of the room.

Additionally, a small amount of heat heated the air in the house due to convective heat transfer from the incandescent body. The remaining 80% of the heat escaped through the chimney along with the combustion products - hot gases.

The design of aquacamines provides for the possibility of changing the fuel burning rate by regulating the supply of air to the lower part of the furnace. The portal is closed with heat-resistant glass. It blocks the uncontrolled access of air to the fire, which makes the aquacamine fire safe.

To reduce the likelihood of drafts, provide for the flow of air into the furnace through the pipe. Outside, a shallow lattice is installed from rodents and cats. There is an adjustment damper in front of the fireplace.

At the top of the portal there is a "clean glass" system - a longitudinal slot with guides for a small amount of supply air from the room. Cold air flows down the inside of the glass, preventing soot contamination.

Heat exchanger (hot water heating circuit)

In the upper part of the firebox there is a register of pipes for extracting heat from hot gases. A coolant - water - flows inside the pipes. If the capacity of the aquacamine is very high, then additional registers are placed along the side and rear walls of the firebox. To improve heat transfer and increase efficiency, there must be a circulation pump. As a result, the effectiveness of aquacamine is increased by up to 80%.

When heated, the water increases its volume, therefore it is necessary to install an expansion tank. With an open heating system, it is installed at the highest point - usually in the attic. When closed, the membrane-type tank is mounted in any place convenient for service. A pressure gauge is mounted nearby, as well as a safety valve.

Chimney

Ceramic or metal is used to remove gaseous combustion products. Ceramic chimneys are durable, but expensive and laborious to install.

The chimney pipe is glazed during manufacture. This prevents soot from sticking and makes cleaning easier. It is separated from the chimney body by heat-resistant thermal insulation. At the bottom there is a container for collecting condensate.

Main characteristics of ceramic chimneys:

- service life - over 25 years;

- glassy surface prevents soot deposition;

- fireproof;

- do not burn out;

- significant mass must rest on the foundation;

- high cost of components;

- complex installation.

Metal chimneys are much cheaper and easier to assemble. If the operating mode is violated, they may burn out.

Steel pipes are assembled according to the "sandwich" scheme. The inner tube made of technical stainless steel is separated from the outer fiber-basalt thermal insulation. The individual blocks are joined together with a heat-resistant sealant.

Characteristics of metal chimneys:

- the cost of purchase and installation is less than that of ceramics;

- there is the possibility of self-assembly;

- light weight, so no foundation is needed;

- the flame must not be allowed to burst into the chimney.

Installation and connection of a fireplace stove with a water circuit

After purchasing an expansion tank, pipes and radiators, as well as many connecting elements and other accessories, you can start assembling the entire heating system and connecting it to the selected fireplace with a water circuit. Let's take a look at each step of this process:

At the place where the heating unit is supposed to be installed, the floor must be leveled and tiled with fire-resistant materials in order to avoid a fire hazard.

When installing a fireplace with a water circuit, care must be taken to ensure that the device is flat on the floor. The adjustable feet can be used if absolutely necessary.

Depending on the chosen installation scheme - open or closed - it is possible to assemble a hot water heating system with or without a circulation pump. If a forced system is selected, this unit must be placed in a place where the cold return flow enters the heat exchanger. As mentioned earlier, the expansion tank must be installed at the highest point of the house, for example, in the attic. The most acceptable option is a closed-type tank with a membrane. The rationality of this choice is explained by the fact that in this case contact of the air with the coolant is excluded, respectively, the entire heating system will serve longer.

Choosing one or another connection scheme, you need to connect the heat exchanger with the already installed heating system. Such fireplace stoves can work both independently and be connected to the boiler.

After pouring liquid into the expansion tank, check the entire water circuit of the house for leaks at the joints of pipes and radiators

It is also important to test the capabilities of the circulation pump.

When installing the chimney to the fireplace stove, all joints with the channel should be treated with a heat-resistant hermetic substance. In the place where the chimney passes through the ceiling, insulation should be done with non-combustible materials.

At this stage, you can already light up the fireplace to check its operation.

There is no need to worry about the unpleasant smell coming from this device at first. Its source can be vapors that are emitted by the heat-resistant paint covering the body of the thermo fireplace when exposed to high temperatures. Over time, the material will adapt and the smell will disappear.

The final stage of installation is checking the heating of water in pipes and radiators, adjusting the speed of its circulation, balancing the system using valves installed on the batteries.

Scrupulous implementation of the above steps will ensure the normal operation of the fireplace stove, which in turn will ensure sufficient heating of the entire house. Do not forget to systematically check the fill level of the expansion tank. If the owner has to stay outside the house for a long time, care should be taken to drain the water from the heating system in order to prevent pipes from bursting and damage to radiators during severe frosts.

System design

By external signs, it is practically impossible to distinguish whether a given fireplace is with a water circuit, and only the pipes through which the coolant circulates give out its presence. There is a similarity in the internal structure. The process of fuel combustion takes place in the furnace, therefore it is equipped with a grate and an ash pan.

If the power of the stove is selected with a certain margin, and the heating system has automatic recharge, then the stove, fireplace with a water circuit can be used as a source of hot water. When the "hot" water tap is opened, heated water comes out of the system. During this time, the system is fed with cold water. The power of the fireplace should be sufficient so that during a short use of hot water, its temperature does not noticeably decrease.

Fireplaces with a water circuit are suitable for both open and closed heating systems. The open-type system implies the presence of an expander at the top. The fluid pressure is equal to atmospheric. The circulation is carried out by convection. In a closed system, the expander is sealed and pressurized. As a result, the liquid can be heated above its boiling point under normal conditions. The circulation is carried out by a pump.

Visual device of the heating system

The body of the stove itself is made of stainless steel, and the firebox can be made of bricks or heat-resistant tiles. In modern models, the metal door of the firebox is replaced with a glass one. Moreover, special heat-resistant glass is used. It provides an overview of the hearth, so you can observe the combustion. This means that a fireplace with a contour also performs a decorative function.

The brick design of the fireplace implies some arbitrary shape of the body. But the idea remains the same and lies in the fact that the coil is located above the firebox itself and heats up from the flame or the walls of the firebox. Often there are heat exchangers in the form of a boiler and a register. They not only differ in performance, but also in cost. The easiest to manufacture, and, therefore, the cheapest is a metal box in which water is located. Its advantage lies in the fact that it is not susceptible to clogging of channels by scale, and it is easy to clean it from carbon deposits.

Heat exchangers differ not only in appearance, but also in the way they are installed. Distinguish between the top and rear location of the coil. Design thoughts do not end with what is provided by the manufacturer. Optimization work is still underway, which includes issues of increasing the area in the core. The closest approach of the heat exchanger to the fire is fraught with the fact that its resource is sharply reduced.

Detailed description of the heating system operation

The "house" form of the heat exchanger is popular. It is inserted into the firebox and the fire heats up most of the area. There is another type of heat exchange that can be distinguished from a separate line. Pipes, through which cold water flows, cut into the brick of the furnace. The bricks need to be prepared in a certain way, and then the pipe can be laid in them.

An innovative solution is a register that looks like a radiator. It is formed from vertical pipes that are interconnected. One part of the register is immersed in the firebox, while the other can heat the room due to the large area.

DIY making

The construction of a fireplace without appropriate experience is possible if there are detailed drawings indicating the orderly laying of bricks. First, a concrete foundation is poured or laid out of blocks to the level of the subfloor. Above they arrange waterproofing from roofing material.

It is advisable to use fireclay products for the firebox. The heat exchanger is desirable from cast iron, but a welded register of pipes with a wall thickness of at least 4 mm is suitable. The connections between the heat exchanger and the heating pipes must be located outside the furnace.

The rest is erected from refractory bricks on clay mortar. After the formation of the vault, a chimney is mounted on top. It can be built without pipes from bricks on the back of the fireplace on its own foundation.

Before firing up after completion of construction, you must wait two weeks. Then fill the system with water. Conduct the first furnace in a gentle mode, gradually increasing the flame.

The principle of operation of the stove with water circuits

The coolant is heated in the heat exchanger and disperses through the radiators using a circulation pump

The coolant is heated in the heat exchanger and disperses through the radiators using a circulation pump

The principle of operation of a stove for a house with water heating is to heat the coolant during the combustion of fuel. After that, it spreads through the pipeline, from which heat is transferred to the surrounding space.

The heat exchanger is located inside the stove. The device can be used as a main source of heat or an additional one. Moreover, the device provides not only heating, but also hot water supply. Such an oven uses and distributes heat more efficiently.

Furnace device with a water circuit

The classic design of the stove consists of a firebox, divided by grate bars into a firebox and an ash pan, surrounded by brick or metal walls. When fuel is burned, heat is transferred to the premises by means of radiant heat transfer from the enclosing surfaces of the furnace. The use of ovens is usually caused by objective reasons:

- Lack of other types of fuel, except for firewood and coal, namely natural gas and electricity of the required power;

- The relative cheapness of firewood in many regions of our country;

The main disadvantage of the heat engineering scheme is the uneven distribution of heat in the heated rooms, as well as the cyclic mode of operation of the heating unit. In addition, the ovens are manually operated.

The introduction of a water circuit into the design of the furnace greatly improves the performance of heating. A metal heat exchanger allows you to take away part of the heat during fuel combustion and ensure its transportation by means of a liquid heat carrier - water or antifreeze.

Furnaces with a water circuit are divided into 2 types:

- Brick;

- Metallic.

Brick ovens are built independently or with the assistance of specialists. Metal furnaces are made of steel or cast iron, they can be built independently, but this requires the professional skills of an electric welder. Moreover, models of industrial production have better characteristics compared to home-made ones - they are made of heat-resistant steels, carefully calculated by designers.

Brick kilns take longer to heat up, but they also give off heat over a longer period of time. In essence, brickwork partially functions as a heat accumulator.

Metal ovens heat up and cool down at a faster rate. Cast iron furnaces are more profitable than their steel counterparts in this regard - cast iron accumulates a significant amount of heat.

Heat exchangers for furnace water circuits are usually made of steel. Heat exchangers have a wide variety of shapes and sizes, differ by location.In shape, these can be rectangular containers connected by round or shaped pipes, coils, registers, and so on. The thickness of steel for their manufacture is at least 3 - 5 mm.

In brick ovens, heat exchangers are most often placed in furnaces. At the same time, it is not recommended to place the devices in areas directly streamlined by the flame, especially in furnaces using coal as fuel. The temperature in these zones reaches high values and the service life of the metal will be significantly reduced. Heat exchangers are placed in the edge zones of the flame and along the path of the hot combustion products.

In metal furnaces, heat exchangers are often made in the form of water "jackets" surrounding the combustion chamber. In essence, furnaces with a water circuit are analogous to a solid fuel boiler.

Heat exchangers are equipped with threaded connections for connecting the heating system pipelines. Smoke removal is carried out using natural draft, that is, the construction of a chimney is required. The amount of air supplied for combustion is controlled by a chimney gate and a damper on the air intake.

In addition to water heating circuits, furnaces can be equipped with additional elements:

- Fire-resistant glass door - a fireplace stove is being created;

- Hot water preparation tank;

- Cooking stove;

- Oven.

With an increase in the number of options, the dimensions and weight of the furnace increase, and the cost increases. Some models of prefabricated furnaces are equipped with heating elements built into the heat exchanger (with the possibility of removal and replacement). Usually they cannot fully cover the entire heat output of the furnace and serve as an additional or backup heat source.

Materials and functionality

The main materials for fireplaces are cast iron and heat-resistant steel.

It is important to remember that cast iron has the advantage of durability, but it has a very large mass, therefore, structures made of this material can be installed only after special work to strengthen the floor in the room.

Also, cast iron fireplace inserts, due to the lower mechanical strength, must be massive. Russia produces structures of various sizes.

Steel options are less durable, but they can be installed in any room without additional floor reinforcement. The volume of the structure is smaller than that of cast iron fireboxes - this allows you to experiment with the design of the fireplace.

The functionality of the water circuit is not limited to the supply of heat. Many models have:

- self-cleaning system;

- combustion control system;

- shutting off the fuel supply in case of breakdowns.

Many of the commercially available combustion chamber models have additional insulation in the combustion chamber. It is a double glass or cladding with heat-resistant (fireclay) bricks. Insulation makes it possible to increase the service life of steel structures, since it reduces their contact with an open flame, therefore, burnout is slower.

Operation of a fireplace insert with a hot water circuit

Efficiency of a water-heated fireplace

For 7-9 o'clock at night, energy with a capacity of 63-65 kW is spent so that the room can be heated.

Here the boiler plays an important role, without which it is impossible to accumulate heat energy and optimize its use at times of the day. In addition, the boiler is able to prevent possible overheating in a stove with such a shell. To activate this function, you need to fill no less than the calculated amount of water.

During heating, the boiler begins to take water heated to 80 -85 ° C from the boiler. It flows through a coil that is built into the boiler.In this case, the heat of the water is given off, the water gives off heat and heats the water located there. The heat carrier is cooled to 60 ° C, and it goes back to the heating heat exchanger.

Water with a temperature of 85 ° C is drawn to radiators and floors. The cooled resource goes back to the storage tank of the boiler.

To accumulate those 65 kW of thermal energy, the boiler must hold no less than 500 - 700 liters.

To determine the volume of a given drive, use the following formula:

M = 65,000 W / h / (90-30) deg × 1.638 W / deg kg = 633 kg

Where:

1,638 W / deg. Kg - the amount of heat generated or absorbed to change the temperature of 1 kg of water per 1 deg.

Given the fact that the mass of water is almost always equal to the volume of water, then these 633 kg must be equated to the volume, and you get 633 liters.

The storage boiler with a volume of 750 l has the following dimensions:

- Height - from 1.6 to 1.9 m.

- Diameter - no more than one meter.

- The mass of this storage device with a heat carrier is 1.2 tons.

To place this structure, you need to have a sufficiently strong foundation and a site in the building.

It is allowed to use boilers with a lower capacity, and maintain the desired temperature level at night using built-in electric heaters. True, if you do this on the coldest and frosty days, then overheating is possible. And to prevent emergency cooling during heating, you have to periodically pour some of the hot water outside.

Product selection criteria

When planning to buy a stove or fireplace equipped with a water-saving heating circuit, consider its main characteristics. The device must meet not only the requirements of strength and beauty

It is important to pay attention to other indicators

Heat exchanger variations

The design of the coil affects the power of the device:

- a boiler coil made of a steel pipe contributes to the rapid heating of water, the continuity of its circulation through the radiators;

- the register box is easier to clean, but it can heat up the fuel unevenly. The advantage of the element is its low cost.

- the heat exchanger made of welded pipes is compact and can be mounted on the back of the fireplace. The room with the stove will be warmer than the rest.

- cast iron radiators are a good option for a coil, but if they are not located near the combustion zone. The cheap design has a low fire safety and causes emergencies.

- the combined system is made of two steel tanks. Pipes are used for connection. The combination of the boiler and register contributes to good heating.

Thermal power

For installations with a water circuit, the power index has two meanings - the total and the resource of the heat exchanger:

- the total heat output is the degree of heat that can be generated by the firebox, convection ducts, heating system;

- the heat exchanger power is the amount of heat energy entering the radiator network.

Manufacturers produce equipment that uses 1 kW of energy to heat 10 sq. m. dwelling. The declared power can be enough for wood fuel at night and during the day.

Dimensional Features

The dimensions of the fireplace stove modification are determined according to the area of the house. The load on the floor covering is important in buildings with wooden floors; for monolithic or reinforced concrete, this indicator is not taken into account. As an alternative, property owners are advised to build a stove podium or buy small devices.

Nominal volume of the heating medium

To calculate the limit value, you need to take into account the volume of the pipeline, the radiator, the length of the communications and the number of battery sections. The data can be viewed in the radiator's passport, and the rest of the data can be calculated using special tables. Increase the resulting value by 10% - you will get the value of the register volume of the home heating system.

Chimney parameters

Only specialists can calculate the diameter of the smoke exhaust duct, provided that they purchase components. All system details are selected according to the needs of the home. When searching on your own, the task becomes more difficult.

System speed

The efficiency of the device is determined by the speed of water circulation. Keep track of its amount - exceeding it reduces the degree of heating of the pipes and the heat transfer of the radiators. Large bodies of water cool more slowly. If you reduce the water supply, the pipes heat up slowly. The optimal volume of the coolant is 50 liters.

The need to install the product

The unit is connected to other heating systems, which makes it possible to save expensive gas, diesel fuel, and electricity. The product is suitable for integration with an electric boiler. It is heated with wood in the daytime, and the electric boiler is turned on at night.

Additional optional

The comfortable installation is equipped with a set of useful functions:

- hob for cooking, heating them;

- a system for removing carbon deposits from the glass;

- cold handle;

- water heating regulators.

It should be borne in mind that additional options increase the cost of the unit, but ensure its functionality.

Economic benefit from purchase

Water fireplaces are only beneficial under certain conditions.

Having installed the stove in the country, it is advisable to use additional convectors to speed up the heating. The purchase of a device with water circuits is justified for houses where the owners live all year round.

Choosing the right device

The task has been set, and the decision has been made, but the worries do not end there. It is necessary to choose exactly the version of the furnace that can effectively cope with the main task of heating a house of this type and the entire living area. Do not forget about efficiency, so you will have to stock up on knowledge about how systems with water heating are arranged.

When analyzing the technical data, you will have to take into account some of the conditions for the installation and operation of the fireplace. Wall-mounted fireplace system

Wall-mounted fireplace system

The area of the room that will have to be heated. Any owner should know this indicator by heart. Otherwise, you will have to apply the knowledge of the school geometry course and calculate the area of living space. At least approximately.

It is known that the choice of boiler power depends on the area, therefore, at the next stage, you need to decide on this value. If you do not trust the advice of the seller, then choose the power according to the following statement: 1 kW can heat up to 10 m2 of area without problems. Perform the rest of the accompanying calculations yourself. The rated power is a parameter that is indicated by the manufacturer. Russian-made furnaces correspond to the declared characteristics, as they are undergoing experimental tests.

Be sure to consider the place and method of installing the fireplace. An external factor affects the design itself and even the principle of its operation. The corner fireplace cannot be installed along the wall in any way. It is made in such a way that it fits perfectly into the corner of the room. Wall-mounted fireplaces are usually rectangular parallelepiped and limit the choice only to the design of the chimney. There are wall-mounted versions, but here it is worth carefully considering the possibility of mounting, due to the large mass of the device. If the walls in the room are finished with drywall sheets, then this option is not for you.

Functional. This is also an important question, because it is known that a fireplace can simultaneously perform two functions: heating and external decor.

If you are pursuing the goal of profitably and effectively heating a country house, then focus on the technical parameters, and not on the appearance of the device.

Here are a few more tips that will prove useful when choosing a fireplace. The size of the firebox plays a big role in the amount of heat generated. Wood burning fireplaces have the largest firebox in size. This is due to the dimensions of the logs themselves. Therefore, do not confuse or compare the sizes of furnaces of furnaces with different types of fuel with each other.

Modern appliance for heating the whole house

A heat exchanger is a unit where heat is transferred from the metal to the coolant. Naturally, the exchange rate depends on the thermal conductivity and heat capacity of the material. Cast iron has excellent qualities, it is quite durable and, due to its heat capacity, accumulates energy, but a large mass sharply reduces consumer demand. However, the cast iron heat exchange system still finds its buyer. The steel heat exchanger has opposite qualities to those described.

Fireplace connection diagrams

- Open. In this case, a special expansion vessel must be present, which must be located above the furnace and work as communicating containers. Then the water that is heated in the furnace is thrown from the heating system, passing through the heat exchanger.

- Closed. The hearth is connected immediately to the heating system, without going through the expansion tank and heat exchanger.

The scheme is selected depending on certain situations. Experts believe that the open form of the system has increased security, but it is not always possible to connect it technically.

Autonomous fireplace heating scheme