Disadvantages of steam heating and how to fix them

- steam radiators heat up above 100 ° C, which is why they are dangerous, especially for children and animals;

- the steam heating system is noisy;

- temperature control is difficult;

- the impossibility of installing water heated floors.

The first drawback can be eliminated by protecting the radiators and leading pipes with screens. There is a huge selection of these decorative interior elements made of wood and plastic.

Wooden screen protects against accidental contact with hot radiators

The noise effect in the system can be significantly reduced by using anti-noise brackets for radiators during their installation, and the steam generator itself can be arranged in a separate room.

The third point is difficult to eliminate. But for the fourth, there is a solution - water heated floors, if desired, can be replaced with infrared film.

Attention! It is undesirable to plan a brick oven with a steam generator at the same time for heating and cooking, since it will still be impossible to use it in the summer. Or, you will have to come up with an alternative option for the warm period.

For example, make a summer stove in the open air.

Also, plastic pipes cannot be used in the system, they will not withstand the temperature regime.

Features of steam heating

In Soviet times, at many industrial enterprises, whose boiler houses produced steam for technological needs, heating was organized, where it served as a heat carrier. Registers or steel convectors were used as batteries, and the boiler for steam heating provided system pressure 3 bar and higher at a coolant temperature of more than 130 ºС. At the same time, the surface of the registers posed a risk of burns for the employees of the enterprise.

Since then, the overwhelming majority of enterprises have undergone reconstruction and a transition to water or air heating has been carried out. But, as we have already noted, many Internet resources give recommendations for the installation of steam heating in private houses, which in itself is nonsense. This is motivated by the fact that the steam heating system in a private house:

- does not require large radiators, because the temperature of the coolant is much higher;

- provides very fast heating of the premises;

- needs pipelines of a smaller diameter than water;

- will cost less in equipment and installation.

To dispel all myths and save homeowners from irreparable mistakes or a waste of time studying all aspects, we will look at how steam heating works and list all its features. So, at first, the boiler plant produces steam of a certain temperature and pressure, these parameters are directly interconnected. For example, at a temperature of 133 ºC the steam pressure is 3 bar, at 140 ºC it is 3.5 bar, and at 144 ºC it is 4 bar.

Steam under pressure moves through a pipeline, whose diameter must be larger than for the same mass of water. Giving off heat in radiators, it condenses, but only partially, as a result of which a steam-water mixture is obtained. Moving back along the condensate line, it goes through the process of secondary boiling, which is fraught with water hammer. In order for steam heating on wood or other fuel to function normally, the following requirements must be met:

- to get rid of the steam-water mixture, a special separator must be installed on each branch - a condensate drain;

- the system can only be assembled from seamless steel pipes (for example, according to GOST 8732–78). Water and gas pipes, copper, and even more so polymer pipes are unacceptable to use for steam;

- all heating of a private house must be mounted on flanges or welded, ordinary coupling joints will flow in six months;

- shut-off - control valves also need a special one, designed to work with steam.

Work technology

If the house does not initially have a stove, then first you need to partially open the floors under the place of pouring the foundation, lay the foundation, cover it with roofing material.

The first row is laid on waterproofing. The following are laid in compliance with the order, controlling the vertical with a level or plumb line. At the places where the doors are installed, a fire-resistant wire is inserted, tying the door contour.

The firebox is laid out according to the previously described technology.

The chimney is made in two layers. A metal pipe is installed as a base, and the outside is tied with thermal insulation. It remains to lay out around the brick, leaving space for the shutter.

For safety, each connected radiator is equipped with shut-off valves and air discharge valves.

Mayevsky's crane on the radiator

At the beginning of the heating system, a cooling reducer and a pressure reducing valve are installed, and a condensate tank is mounted under a slight slope. The liquid from it will be directed to the heat exchanger. A circulation pump is placed in front of the oven.

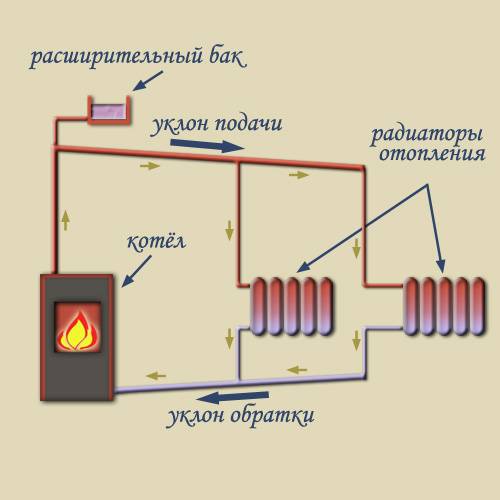

Natural circulation

Conducting steam heating in a one-story house and at the same time maintaining the natural circulation of the coolant is a rather difficult task. After all, the pipeline must be placed at a certain angle. Heating up, the coolant loses its density, becomes lighter and moves up the system on its own. Only the right angle contributes to this.

If we allow even a minimal deviation, which can be done due to inexperience, then we can safely forget about natural circulation.

Radiators, especially those located closer to the heating boiler, will be very hot, but there is little sense from this. This is approximately 10% of the entire system, which means that the remaining 90% of pipes and radiators will have a low temperature.

If we install a pump, then we will already deal with the forced circulation of the coolant in the system.

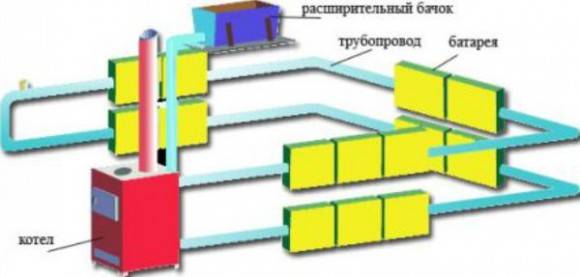

Natural heating circulation system

About steam boilers and their piping

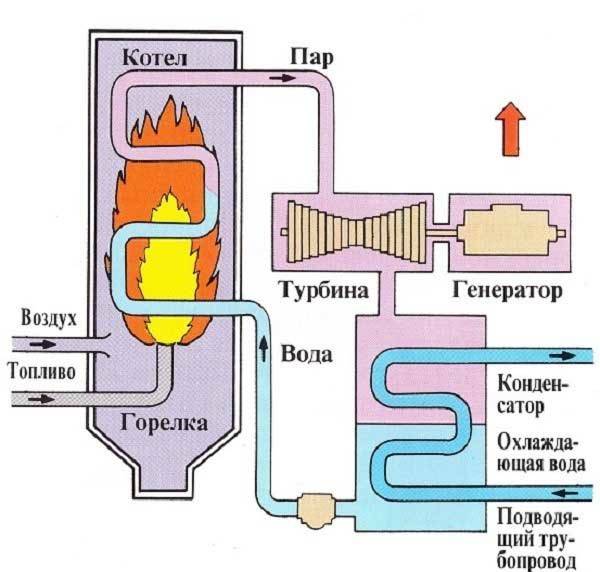

A thermal installation for the production of steam is much more complex than a hot water boiler. She has to work with high pressure and temperature, so the quality of the metal used is higher, and the thickness is greater. In addition, the unit is equipped with expensive automation and safety equipment. The figure below shows a diagram of a steam boiler:

Due to the extreme operating conditions, the installation of the boiler also includes the provision of water treatment. Yes, plain tap water will not work here; it must be demineralized, purified, and dissolved oxygen removed. Otherwise, the coil, where the evaporation of water occurs, will fail very quickly. A separator is installed on the supply pipe of the heat generator, which does not let non-evaporated water into the pipes.

With regard to circulation, the pump for steam heating works differently here. Steam moves through the pipes on its own, like condensate. The latter enters the storage tank installed in the boiler room, from where the make-up pump pumps it into the boiler as needed to repeat the cycle.

Steam heating scheme in a private house

One of the most effective and inexpensive ways to heat a private house is steam heating. The effectiveness of this method consists in the immediate ability to independently equip the heating system (of course, the presence of a specialist will be a desirable moment), along with the maximum functionality of rapid heating of both small and large rooms. However, for this project, you will need a steam heating circuit, which is best ordered from a professional.

To install steam heating in a house, the following basic components are required:

- Boiler;

- Exhaust valve;

- Radiator;

- Pipes (metal);

- Pump (open loop);

- Firebox.

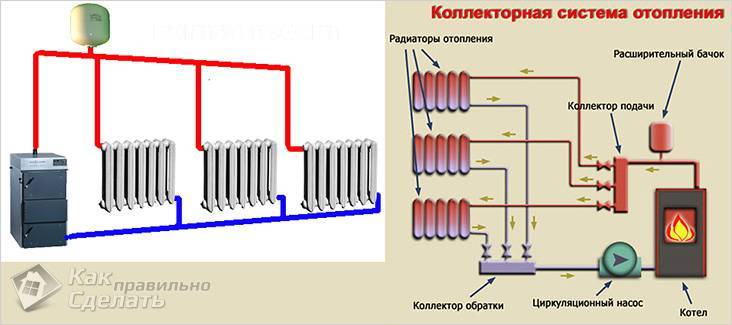

Varieties of systems

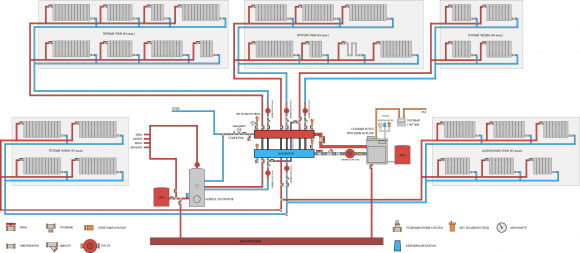

All types of systems are divided into single-circuit and double-circuit. In the first variant, the entire boiler power is used to warm up the medium, which will take part in increasing the air temperature inside the room. In the second version, there is an additional heat exchanger in which running water is heated, which makes it possible to use it for domestic needs. When implementing the second option, it is worth remembering that it will be necessary to supply additional communications to the boiler room and return them back to the living quarters.

Different heating systems

Different heating systems

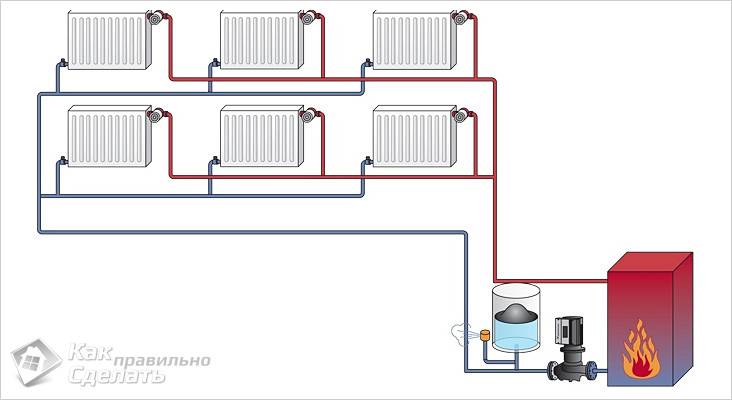

By the way of circulation of the carrier, as in the case of water systems, they are distinguished:

- Natural circulation or closed. In this case, after condensation, the water, under the influence of gravity, by a natural current without a pump, returns to the boiler, where it is again converted into steam and used.

- Forced circulation or open circuit. In this case, water does not immediately flow back into the heater. At first, it is collected in a special tank, from which it is supplied with the help of a pump for further conversion into a gaseous state.

By the level of pressure inside, there are:

- Atmospheric. In them, the pressure value is several times higher than atmospheric pressure, which in case of an accident can cause serious injuries. In addition, in such a system, the emitters are heated to a high temperature, and the deposited dust burns up and an unpleasant odor is emitted.

- Vacuum. To implement this option, the entire line must be sealed. With the help of a special pump, a vacuum is created inside. The result is the conversion of water to a gaseous state at lower temperatures, which increases safety.

According to the method of pipe routing, there are:

One-pipe. Steam flows continuously through one pipe. In the first half of the journey, it gives its energy to the radiators, gradually turning into a liquid state. In this case, the temperature of the radiators that are closer to the boiler will be higher than those that are at the end of the circuit. In this case, large diameter pipes will be needed so that no obstacles arise.

One-pipe heating system

One-pipe heating system

Two-pipe. Steam is supplied through one pipe, and condensate returns through the other. In this case, the carrier reaches all devices, practically without losing temperature. This option will be relevant for large houses with several floors. If the premises are small, there is no point in it, this will only increase the total cost of the project.

Two-pipe heating system

Two-pipe heating system

Water heating. Operating principle. Structural elements.

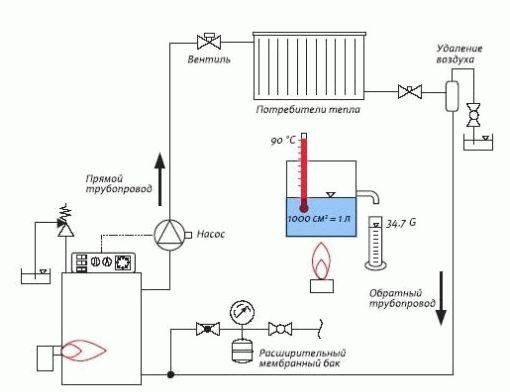

The circuit is a closed loop built around a heater - boiler. Water radiators are used as heat transfer elements. Water, heated in the boiler to about 75 ° C, enters the heating circuit. By giving off heat to the surrounding air with the help of radiators, the cooled water flows back into the boiler for further heating. Further, the cycle is repeated.

Depending on the type of fuel, boilers are divided into:

Depending on the type of fuel, boilers are divided into:

- gas,

- solid fuel,

- on liquid fuel,

- electrical.

Gas boilers are the most popular. This is due to their economy and the relative cheapness of natural gas. The range of models allows you to choose a boiler for every taste, for solving any task. Disadvantages - the installation and installation of the boiler can only be carried out by a specialized organization. The second drawback is that your area must be gasified, it is very expensive to use gas in cylinders. Solid fuel boilers are fired with coal, peat, and pallets. The downside is obvious - the fuel must be constantly loaded and stored somewhere. But if there is no gas, then the choice is reduced. Liquid fuel boilers have a number of serious disadvantages. The main one is the cost of fuel. And the cost is growing every day. In addition, a very noticeable odor is emitted when fuel is burned. A special storage tank is required for storage.

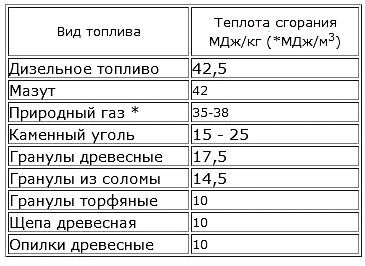

Perhaps, when choosing a boiler, a table of calorific values of different types of fuel will help you.

Perhaps, when choosing a boiler, a table of calorific values of different types of fuel will help you. Electric boilers - connected to a centralized electrical network.The disadvantage is the high fuel cost compared to a gas boiler.

Electric boilers - connected to a centralized electrical network.The disadvantage is the high fuel cost compared to a gas boiler.

A few words about how much boiler power you need. If you do not want to go into cumbersome calculations, then it can be estimated using the table.

House area, sq. m. Boiler power, kW 60-200 up to 25 200-300 25-35 300-600 35-60 600-1200 60-100

There are boiler models that can use several types of fuel. For example, gas and coal. For the device of the line (circuit) through which water will circulate, steel, stainless and polypropylene pipes are used. The latter have become the undisputed leader; they are cheap, with enviable heat resistance and strength sufficient for heating a residential building. It is better to purchase reinforced polypropylene pipes, they are durable and have a lower coefficient of linear expansion when heated, which means they do not deform during service.

Water heating radiators are:

- cast iron,

- steel,

- aluminum,

- bimetallic.

Cast iron - the most deserved type of radiators. They heat up slowly, but keep warm well. Very heavy, brittle and somewhat more expensive than steel, but the service life is up to 50 years and are not afraid of rust. Steel - a budget type of radiators. They have high efficiency and low price. Warm up quickly. Minus - they are afraid of corrosion. Aluminum radiators are lightweight, they are mounted on less durable brackets compared to cast iron and steel. They warm up quickly, and surpass other heating devices in terms of heat transfer. Cheapness and modern design attract a lot of supporters of this type of radiator. The disadvantages include a short service life (up to 15 years), fear of corrosion and water hammer.

Bimetallic - combine the strength of steel radiators and the heat transfer of aluminum. They are a tubular steel structure, sometimes reinforced with a steel frame, on which an aluminum shell is placed. They warm up quickly, give off heat well, hold water hammer, the richness of modern design, ease of installation - this is a list of their advantages. The downside is the high price.

Bimetallic - combine the strength of steel radiators and the heat transfer of aluminum. They are a tubular steel structure, sometimes reinforced with a steel frame, on which an aluminum shell is placed. They warm up quickly, give off heat well, hold water hammer, the richness of modern design, ease of installation - this is a list of their advantages. The downside is the high price.

Positive aspects of choosing this type of heating system:

- High efficiency. Easy to install and, in principle, the operation of the unit has sufficient efficiency for a long time. The steam system, by its very principle of circulating water and condensate, is highly productive;

- Good heat storage characteristics of steam, which allow you to transfer heat through radiators without significant costs;

- Low cost of installation and a wide range of choices, both for your budget and for any type of room in which the installation will be carried out.

- Possibility of sufficiently fast and controlled heating of a private house.

In general, it should be noted that the steam heating system is a rather profitable option for those who want to equip almost independently, cheaply and in accordance with their own budget, a sufficiently reliable and ergonomic system. The range of choice of boilers, types of pipes, radiators and other input elements is quite wide and varied. Summer cottages, large rooms and private houses with safe and correct installation (see steps and general tips) can be sufficiently provided with this type of heating system.

Water heating from the stove

There is such a concept as stove steam heating, introduced into everyday life by our grandfathers. But there is no steam in the pipelines, this is a water system with radiators, powered by a heat exchanger installed in the firebox or flue gas duct of the furnace. Heat exchangers for these purposes are of two types: in the form of a coil or a container with nozzles. The tank is usually welded from stainless steel, and the coil is made from thick-walled steel pipes.

To make steam heating from a stove, you need to perform piping and install radiators. As a rule, the power of the heat exchanger is enough for good heating of 2–4 batteries, and you need to be guided by this amount. The system can be made by gravity, but this will clutter your house with large diameter pipes.If there is no urgent need, then it is better to install a circulation pump and lay the lines above the floor.

As in the case of boilers firing solid fuels, a safety group must be installed in the supply pipe. It is not always possible to control the combustion process in the firebox or to suspend it in time, so the presence of a safety valve with a pressure gauge will not interfere. The best option, in which overheating of the furnace tank is almost impossible, is the presence of a heat accumulator.

Pipe classification

The device of the steam pipeline assumes the presence of 2 parts: the condensate pipeline and the steam pipeline.

Pipes can be made from different materials.

- Steel. Such pipes are highly durable and resistant to mechanical damage. However, they can become rusty if not first coated with an anti-corrosion solution. For their installation, you must use a welding machine.

- Copper. It is a fairly strong, sturdy, durable material that can withstand high temperatures. For the installation of copper pipes, the high-temperature brazing method is used. The disadvantage of this material is its high cost.

- Galvanized and stainless steel. These pipes are also expensive. But at the same time, they have a long service life, are distinguished by high reliability, strength and corrosion resistance.

- Cast iron. This is the classic version of pipes. Cast iron is characterized by its special strength and availability. However, it weighs a lot, which is also worth considering.

Plastic and metal-plastic pipes are not used in the installation of steam heating, since these types of materials are not resistant to high temperatures.

5 Subtleties of installation

When installing steam equipment, you need to pay attention to several working points. Among them:

- 1. The area of the room to be heated.

- 2. The number and angle of arrangement of radiators, filters and other parts of the installation.

The circulation pump and steam fans are selected in such a way that the movement of the coolant through the system is carried out with maximum efficiency. To do this, you need to take into account the location of the equipment. When self-installing such an installation, you need to find the following materials and components:

- 1. Boiler.

- 2. Pipes.

- 3. Radiators.

- 4. Instruments for measuring pressure.

- 5. Shut-off and control valves.

In the corresponding document, you need to indicate the length of the pipes, their number and diameter

It is also important to pay attention to the type of radiators and other heating elements used. Any values must be written down on paper in the form of a diagram, describing in detail all the small details. Upon completion of the project, you can proceed to the installation work

For a successful installation, it is important to follow the diagram exactly and not deviate from the specified parameters.

Upon completion of the project, you can proceed to the installation work

For a successful installation, it is important to follow the diagram exactly and not deviate from the specified parameters.

First of all, you need to prepare the surfaces on which the equipment will be fixed. Fasteners are fixed on the walls, where radiators will then be attached. Further, heating devices are fixed under the windows, which are needed to prevent cold drafts: the air flow that enters from the outside will immediately heat up, preventing the appearance of fogging on the window.

The next stage is the installation of the steam generator on a concrete base. The floor is pre-assembled with fireproof material. It is advisable to install it in the basement, since vapors are able to rise upward, or in a separately equipped room.

Then the installation of the pipeline begins.First of all, wiring from the steam generator should be carried out, leading the pipe from it to the first heating device. If the pipe is too long, it must be cut. After that, all inputs and outputs are connected, and pipes are connected. Each battery is equipped with a special tap.

Steam heating boiler in a private house

The steam boiler is an alternative type of heating for private houses and summer cottages. Water heating of buildings is incorrectly called "steam" - this confusion in names is associated with the principle of heating apartment buildings, where an external coolant under pressure flows from the CHP to individual houses and transfers its heat to the internal medium (water), which circulates in a closed system.

Steam heating in a private house is used much less often than other methods of heating premises. The use of a boiler in a country house or a country house is economically justified, when year-round living is not provided, and the main role in heating is played by the speed of heating the premises and the ease of preparing for the conservation of the system.

The possibility of installing such equipment in addition to the existing one, for example, an oven, is another advantage of using steam as a heat carrier.

As a result of the boiling of water in the boiler unit (steam generator), steam is formed, which is supplied to the system of pipelines and radiators. In the process of condensation, it gives off heat, providing rapid heating of the air in the room, and then in a liquid state it returns in a closed circle to the boiler. In a private house, this type of heating can be implemented in the form of a one- or two-circuit scheme (heating and hot water supply for domestic needs).

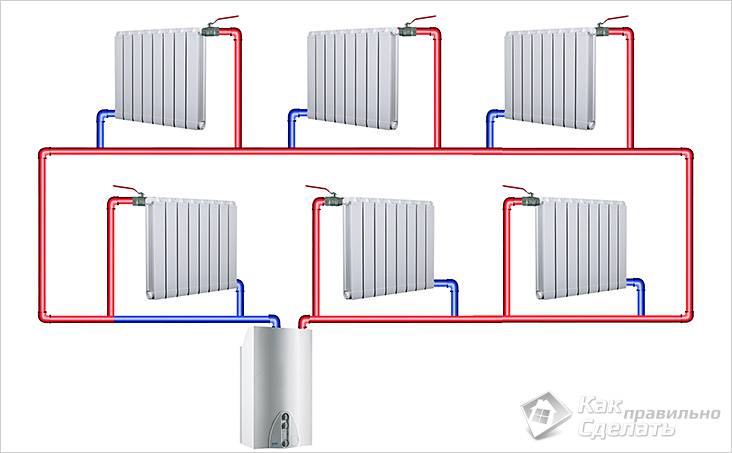

According to the wiring method, the system can be single-pipe (serial connection of all radiators, the pipeline runs horizontally and vertically) or two-pipe (parallel connection of radiators). The return of condensate to the steam generator is possible by gravity (closed circuit) or forcibly using a circulation pump (open circuit).

The steam heating scheme for a house includes:

- boiler;

- boiler (for a two-circuit system);

- radiators;

- pump;

- expansion tank;

- shut-off and safety valves.

Description of steam boiler heating

The key element of space heating is a steam generator, the design of which includes:

- firebox (fuel combustion chamber);

- evaporating tubes;

- economizer (heat exchanger for heating water due to flue gases);

- drum (separator for separating the steam-water mixture).

Boilers can operate on various types of fuel, but it is better for private houses to use a domestic steam boiler with the ability to switch from one type to another (combined).

The efficiency and safety of such space heating depends on a competent approach to the choice of a steam generator. The power of the boiler unit must be commensurate with its tasks. For example, to create an optimal microclimate in a house with an area of 60-200 m2, you need to buy a boiler with a capacity of 25 kW or more. For domestic purposes, it is effective to use water-tube units, which are more modern and reliable.

Self-assembly of equipment

The work is carried out in stages, in a certain order:

1. Drawing up a project taking into account all the details and technical solutions (length and number of pipes, type of steam generator and place of its installation, location of radiators, expansion tank and valves). This document must be necessarily agreed with the state control authorities.

2. Installation of the boiler (performed below the level of the radiators to ensure that the steam moves upwards).

3. Piping and installation of radiators. When laying, a slope of about 5 mm should be set per meter. Installation of radiators is carried out using a threaded connection or welding. In reviews of the steam heating system, experienced users recommend installing taps to eliminate problems with air congestion and facilitate subsequent operation.

4. Installation of the expansion tank is carried out 3 meters above the level of the steam generator.

5.The piping of the boiler unit should be carried out only with metal pipes of the same diameter with the outlets from the boiler (adapters cannot be used). The heating circuit is closed in the unit, while it is advisable to install a filter and a circulation pump. A drainage unit must be installed at the lowest point of the system so that the pipeline can be easily drained for repair work or preservation of the structure. The boiler unit must be equipped with the necessary sensors that control the process and ensure safety.

6. Testing the steam heating system is best carried out in the presence of specialists who can not only perform all procedures in accordance with the current norms and standards, but also eliminate any shortcomings and inaccuracies of the installation scheme with their own hands.

Advantages and Disadvantages of Steam Heating

To make you decide whether you should buy steam heating, let's take a closer look at all the advantages and disadvantages. The information read will be able to give a clear answer to the question posed.

The low cost of all equipment plays a very important role in making a decision.

Low heat loss during the operation of the system - this will reduce the cost of heating the house.

Very high heat dissipation - allows you to completely warm up a large room in a matter of hours and create a comfortable environment for residents of the house.

High noise level from system operation. Knowledgeable people are aware of the noise generated by such systems.

Very high steam temperature, which, on contact, can easily cause burns.

Corrosion is also a significant disadvantage. As a result of this process, pipes often begin to leak, thereby causing inconvenience in operation.

- commissioning of steam generating equipment requires permission from the relevant control authorities;

- equipment for generating steam is a source of increased danger. Its scope is industrial production.

Steam heating circuit

The heart of the steam system is the steam boiler. Its task is to convert water to steam. The equipment consists of a manifold, a drum and a pipeline. A water space is also provided - a container with a coolant. When working around the container, a steam space is formed.

Air separation structures are installed inside the steam space. All boilers are divided into 2 types: fire-tube and water-tube. In the first version, gas moves through the pipes, and in the second - water.

Before equipping steam heating, you should familiarize yourself with its diagram

Before equipping steam heating, you should familiarize yourself with its diagram

The principle of converting water into steam:

- Prepared water is directed to the reservoir, which is located in the upper part of the boiler;

- The liquid is directed to the manifold;

- Then it flows into the upper drum, bypassing the heating zone;

- Steam forms inside the pipe, which rises upward;

- With the help of a separator, condensate is separated and the steam is directed further.

Further it is worth considering the design of pipes and radiators. High steam temperatures exclude the use of plastic and metal-plastic elements. It is best to use steel pipes. They are strong enough to withstand high temperatures. But the material corrodes and won't last long. In addition, when installing such equipment, you will have to use welding, which is rather difficult.

Heating radiators must be strong. Better to choose cast iron options. Finned steel pipes can sometimes be used.

How to correctly calculate the steam system

Having opted for a steam system, you will have to draw up a project for its location in the building and perform preliminary calculations.

There are two options:

- calculate the main components of steam heating on your own;

- seek help from a professional designer.

The second way to resolve this issue is the most preferable. After all, only a specialist, having more than one successfully implemented project for the arrangement of the heating system, is able to take into account all the wishes of the owner, not forgetting about the regulatory requirements.

If there is no possibility and desire to contact the designer, you can proceed to the independent calculation of the steam heating system. You can use standards and useful recommendations from specialized literature, for example, from a designer's handbook.

For the calculation, you have to take the plan of your house and calculate the area that you want to heat. Then designate the location of the heating radiators.

In steam heating, instead of a battery, registers made of galvanized or finned pipes are often used. They can have a design

Radiators are selected depending on the required power

Moreover, it is important to take into account the technical characteristics of the device you like - it must withstand the load when working with steam

It is better not to use cast iron radiators in the steam heating device of a rarely visited summer cottage. After standing cold for a long time, they may not cope with sudden heating and burst

A comparative overview of different heating radiators and recommendations for their selection are given in this article.

It is best to calculate the length of the steam and condensate piping while in the room itself. So it is more convenient to plan the height of their laying and the location of the radiators, if they are needed.

For steam heating, you can use metal pipes made of galvanized steel or copper.

Having calculated the required number of running meters of the pipe, do not forget about the steam fittings - valves, tees, if necessary - condensate drains, a pump.

To determine the power of the steam boiler, it will be necessary to calculate the volume of all heated rooms and multiply this figure by the indicator of the required amount of energy for heating 1 m3. This indicator depends on the region of residence. So, for the European part, the indicator is 40 watts.

You can calculate the boiler output for a 3-room house with a ceiling height of 2.6 m.

First, you need to calculate the area of individual rooms:

- 1st room: 5 * 2.95 = 14.75 m2;

- 2nd room: 3 * 2.45 = 7.35 m2;

- 3rd room: 2 * 5.4 = 10.8 m2.

Then you have to calculate the volume of the whole house: 14.75 * 2.6 + 7.35 * 2.6 + 10.8 * 2.6 = 38.09 + 19.11 + 28.08 = 57.02 m3.

Now the resulting volume must be multiplied by the heat demand: 57.02 * 40 W = 2288 W. To the obtained value, a power reserve of at least 20% must be added: 2288 * 1.2 = 2745.6 W or about 3 kW.

The second option for determining power is by area. It is conventionally assumed that for heating every 10 m2, 1 kW of boiler power + 30% of the reserve is required if the ceiling height does not exceed the permissible level of up to 2.7 m.

Only a certified unit can be used for steam heating. It is very dangerous to take a self-made boiler - you can seriously suffer if it explodes

Choose a steam boiler from a trusted manufacturer. The unit must have a quality certificate and a guarantee from the factory that issued it. The steam boiler must be equipped with a safety valve. Also, temperature and pressure control devices and a pressure reducer will be required to normalize the pressure, if required.