KN boiler selection

The choice of such a unit as an indirect heating boiler must be approached with all responsibility and, first of all, ask yourself the question: "Will it be convenient to use such a device?" The pros and cons of the unit are described above. In this section, we will note a few aspects that you need to know in order to understand whether you need to buy it. They will also help you choose the most suitable version of the KH boiler.

To what extent will the purchase of such equipment be justified? The fact is that it makes sense to buy such a device if the water consumption in the house or room is large enough and is at least 1.5 l / min. For comparison, just such a water consumption is noted in large families of 4 or more people.

The presence of such a boiler will certainly increase energy costs if it is connected to an electric boiler.

The volume of the boiler is also an important aspect. So, you need to calculate and take into account the needs for hot water for the family. It should be selected taking into account the parameter of the room where it will be installed.

The materials from which the boiler is made also matter. So, those made of stainless steel will heat the water up to 90 degrees. In enamel, the temperature should be lower. But highly heated water can always be diluted with cold water, which means that the efficiency of even a small tank in a boiler that heats up the water will be higher

It is also important to take a boiler that will not rust.

The power of the heating boiler itself should also be taken into account. It should be enough to heat not only the unit, but also the heating system.

The pump for loading equipment must also be optimal.

The instruction manual for the equipment will help you choose which one is right - it usually contains all the numbers that you need to focus on.

Water heating time for many will play a decisive role, so this point should also be taken into account. So, on average, it takes about 2 hours to heat 100 liters of water. But some models of tanks heat water even faster - for example, a stainless steel tank will heat up the same amount of water in 20-30 minutes.

The material for thermal insulation inside the unit can be represented by both foam rubber and mineral wool or polyurethane foam. Foam rubber is found in cheaper models.

It is possible to organize a constant uninterrupted supply of hot sanitary water in a private house using an indirect heating boiler

It is also better to take boilers that have some protection elements - safety valves, thermostats, etc. Do not be lazy and refuse to fill out the warranty card in the store when buying. The boiler is expensive, and it will be a shame, having purchased it, to make sure of the inadequate quality of the goods. And it is difficult to change such equipment without a warranty.

Types of strapping

The piping of the indirect heating boiler means the connection of the pipelines of the boiler itself with the water supply. The operation of the system as a whole depends on how the installation is carried out.

Piping with servo and 3-way directional valve

This is the easiest strapping method. It is used when a large amount of water is consumed.

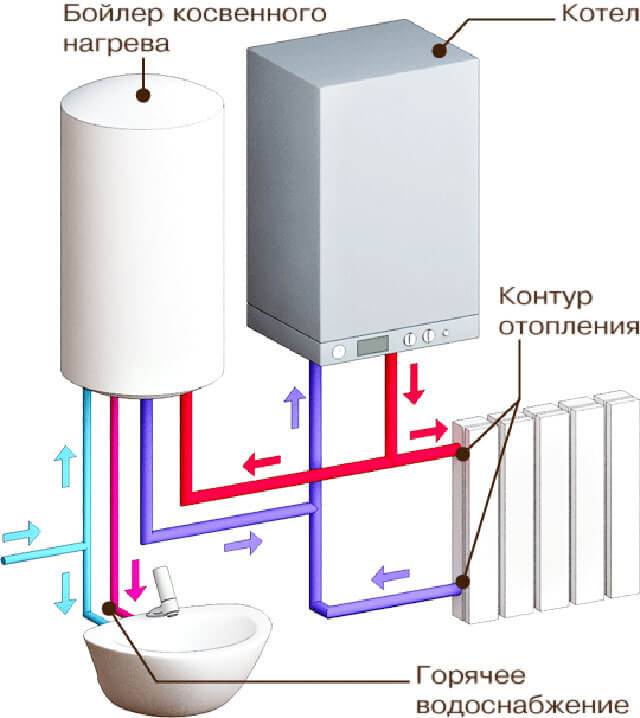

The boiler is connected to the main circuit and an additional one. The first one is used to distribute heat to the batteries, the second circuit heats the water in the boiler itself. For proper flow separation, a three-way control valve is connected.

The thermostat monitors the temperature of the water in the tank, and when it reaches the set value, a signal is sent to the servo.And he already sends a stream of heated water to the main circuit for heating. If the water temperature drops again, a switch in the opposite direction will occur and the coolant will return to the coil.

Piping with two pumps

Another piping option is with the parallel use of two pumps. One is mounted on the heating circuit, the other on hot water supply. The control of the pumps, as in the first case, is entrusted to the thermostat. It is he who switches the operating mode.

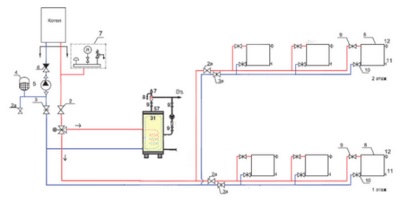

Strapping with hydraulic boom

If the heating system has many branches, such as a multi-circuit battery system or a separate branch to a warm floor, then it makes sense to use this type of piping. To avoid difficulties with a system in which each of the circuits is equipped with its own recirculation pump, a hydraulic distributor is used.

Heat carrier recirculation

In the event that hot water is needed as quickly as possible, then it would be more correct to use a recirculation system. Due to the fact that an annular coolant line is formed in the system. The constant movement of water through it leads to heating. That is why the waiting time for hot water is minimized.

To ensure the continuous movement of water, a recirculation pump is installed in such a system. Such a flow of hot water must be installed so that it passes through installations that constantly need heating. A semi-heated dryer is an example of such a device.

Connecting a boiler to a non-volatile boiler

When used with non-volatile heating equipment, the boiler must be provided with a priority supply of the heating agent. The easiest way to achieve this goal is to install the tank above the level of the radiators - which is why wall-mounted models are usually used in such situations. The optimal location of the wall-mounted boiler assumes that its lower part is located at least slightly above the level of the boiler and heating devices.

Of course, such a piping of a water heater can also work with floor-standing devices, but the heating of the water will be slow and defective. At the bottom of the tank, the water will not be able to warm up to the end (its temperature will be at the same level with the temperature of the liquid in the return pipe), so the total volume of hot water will be reduced.

The circulation of the coolant in non-volatile systems is carried out in a natural way. To increase the efficiency of the system, you can embed a circulation pump into it, and in the presence of electricity, the water will be constantly heated. If desired, you can do without a pump - for the normal supply of the coolant to the water heater, the pipes of the supply lines to it must have an increased diameter in comparison with the pipes of the heating circuit.

Connection of a solid fuel boiler with an indirect heating boiler

Connecting a water heater with a solid fuel boiler solves two problems at once:

- receiving hot water supply;

- obtaining a method for discharging the coolant in the event of an accident.

Thanks to the fact that such a system has a thermostatic valve on the battery, the comfort is increased. But there is a danger of the boiler overheating. The same threat arises during power outages. If a larger capacity boiler is installed, this process poses no danger. Because the excess heat is spent on heating the water in the water heater. Accordingly, for the normal operation of this system, a boiler with natural ventilation is needed.

One of the options for piping a solid fuel boiler with a boiler, see the following video.

General principles

The boiler piping procedure means its connection to the heating system and the water supply main. The productivity of the water heating system directly depends on the quality of the work.

That is why the installation of the boiler should not be carried out according to an arbitrary technology, but in compliance with the following mandatory principles:

- Water supply - through a branch pipe in the lower zone of the boiler.

- The hot water intake must be carried out through the connection at the top of the equipment.

- The recirculation point must be in the middle of the boiler.

- The coolant enters the boiler tank from top to bottom - through the pipe in the upper zone. And to leave, that is, to return to the system, is through the lower zone.

Boiler device

Boiler device

If you follow all four principles, the dispensing water in the upper zone of the boiler will always be hot, which will allow you to achieve the maximum efficiency of the equipment.

Consider the specifics of different strapping methods.

Preparing the tank for assembling the water heater

For the manufacture of an indirect type boiler, you can use a new or old gas cylinder... This container is made of 3–4 mm thick stainless steel and is ideal for hot water applications.

Before assembling the heating structure, you will need to carefully prepare the cylinder. To do this, the product is cut in half with a grinder. The inner surface of the container is cleaned using an angle grinder with a suitable attachment.

Before assembling the boiler, the cylinder must be opened and the inner surface must be cleaned.

After that, the inside of the container is washed, dried and covered with nitro-primer paint. These works should be carried out without fail, otherwise, after the boiler is put into operation, the heated water will smell like gas.

When using a tank from other metal containers, the preparation is carried out in a similar way.

Connection of several boilers into one system

In regions where there is an unstable supply of gas or electricity, they resort to installing two boilers, for example, solid fuel and gas. The two units can operate in different ways:

- Serial connection - a thermal accumulator is installed between the units, into which the heated coolant is supplied from the solid fuel boiler. Then it is sent to the system with a gas device, and then diverges to consumers.

- Parallel connection - in this case, the operation of the solid fuel unit is monitored by safety sensors. A three-way valve is also installed, with which you can turn off any of the units.

Methods of installation and shape of boilers

Boilers are wall and floor executions, horizontal or vertical models. The volume of the product, which is mounted on the wall, is naturally lower: it does not exceed 200 liters. Floor-standing devices can also hold one and a half thousand liters. Boilers are fixed to the wall using standard brackets and suitable dowels. The most common boilers are cylindrical.

For convenience and aesthetic purposes, the working branch pipes for connecting the system are brought out at the rear of the unit. The front panel has a temperature sensor and a thermal relay. There are models with the possibility of additional connection of heating elements, if the power of the main heat source is insufficient.

Frequent installation mistakes

During installation or during the setup process, you need to try to avoid a number of mistakes:

- Boiler and boiler are installed far from each other. Their installation should be made not only as close to each other as possible. But, and to simplify installation, the pipes are correctly exposed.

- Incorrect connection of the pipeline with the heating medium.

- Illiterate installation of the circulation pump.

Competent installation, commissioning and adjustment guarantee a stable hot water supply and allow all systems and devices to work in normal mode. This will prevent wear of parts and save on premature repairs.

General requirements

In order for the piping system of a single-circuit boiler with a boiler to work normally, without interruptions and emergencies, the following requirements must be met:

- At the outlet of the boiler, an expansion tank is installed with a volume of at least 10 percent of the boiler. (not to be confused with an expansion tank for heating). It acts as a neutralizer for thermal expansion of water.

- Be sure to cut ball valves on all pipes that lead to the tank. They will be needed for repair or preventive maintenance of circulation pumps, a three-way valve or other elements of the system.

- A boiler is considered safer to operate if it is equipped with a thermostat to prevent excessive overheating. In the basic configuration, such water heaters are equipped with safety valves that release steam from hot water and prevent rupture of the tank body.

Manufacturing of an indirect heating boiler

The process of assembling a water heater may differ depending on the type of construction, but in most cases, equipment for gas and electric boilers is manufactured in the following sequence:

- In a previously prepared cylinder, two holes are drilled using an electric drill with a crown nozzle. One hole will be located at the bottom and used for supplying cold water, the other at the top for removing hot water.

-

The resulting holes are cleaned, fittings and ball valves are mounted in them. Then another hole is drilled in the lower part, into which a tap is installed to drain the stagnant water.

-

To make a coil, a copper pipe with a diameter of 10 mm is required. A spiral bend is best done with a pipe bender. If there is no such tool, then you can take any round workpiece - a large-diameter pipe, a log, a barrel, etc.

-

The coil is being manufactured according to the calculations carried out earlier. The ends of the heat exchanger are bent in one direction at a distance of 20–30 cm. To mount the coil, two holes are drilled in the bottom of the cylinder. Threaded unions are installed and welded into them.

- Before installation, the coil is lowered into a bucket or large container of water and blown out. If the structure is sealed, then the coil is lowered into the cylinder, positioned relative to the inlet and outlet, and welded.

- If the balloon has been cut in the middle, then an anode is mounted in the upper part. For this, a hole is drilled into which a threaded nozzle is screwed in, and a magnesium anode is already mounted in it. If the container is assembled from three separate parts - the bottom, the lid and the central part, then the anode can be installed at the last stage.

-

Insulating material is mounted on the outside of the boiler. It is best to use sprayed polyurethane. Before application, all pipes are protected with dense polyethylene and a cloth. If funds are limited, you can use conventional polyurethane foam, which, after curing, is wrapped in reflective insulation.

- Attachments for suspension on brackets are welded to the back of the boiler. For floor-standing boilers, support legs from a steel angle or reinforcement are welded to the bottom of the equipment.

At the final stage, fittings are screwed on, taps and the top cover is mounted. If possible, the lid may not be welded, but the clamping fasteners can be made of steel wire with a cross section of 3 mm.

In the manufacture of a boiler for joint use with solid fuel boilers, instead of a copper coil, a U-shaped steel pipe is used, which is mounted at the bottom of the device. From the side of the furnace or boiler, the pipe is connected to the outlet pipe. The pipe is removed from the boiler and connected directly to the chimney.

What are boilers

Indirect heating boilers are of two types:

- with built-in hot water heating control system;

- without automation.

With built-in control, the connection of an indirect heating boiler to the boiler looks simple: hot water is supplied (output) to the coil from the boiler, cold water is supplied to the tank, and a heated water outlet is provided at the top for distribution. It remains only to fill the boiler with water and "civilization" can be used. Such devices have their own temperature sensors, and autonomous control, which opens or closes the flow of water from the boiler into the heat exchanger. Basically, heating with a boiler pays off from a financial point of view.

There are options when the boiler is paired with an automated boiler. A temperature sensor is installed in a certain place, which is connected to the heating unit. Then, the boiler is piped with an indirect heating boiler according to the scheme. In this case, the piping of the indirect heating boiler should be carried out by an experienced specialist. It is possible to connect water heaters to non-volatile boilers.

There are boilers on the market made of various materials: stainless steel, steel with a special enamel coating. Among the latest models of water heaters, aluminum tanks have proven themselves well. They have no seams and can resist corrosion.

This slight inconvenience can be circumvented by installing a combined water heater with a built-in heating element. In this case, the main heating of the water will be due to the coil from the boiler, and the electric heater will correct the temperature. Such a system has shown itself well if a solid fuel boiler is used as the main source of heat: the water will remain warm when the fuel is burned out. A boiler for a solid fuel boiler is an ideal option for conveniently obtaining hot water.