Disadvantages of combined heating units

Against the background of the indisputable advantages of universal installations, it is worth noting that they also have a number of disadvantages. So, in comparison with traditional heating systems, combined boilers have a higher price. But the purchase costs are more than paid off already in the first years due to the interchange of one type of fuel with another.

Universal boilers are made of cast iron, known for its anti-corrosion properties, which are very valuable due to the constant formation of condensation in the system. But due to this, cast-iron installations have a rather high weight and therefore are presented only in floor-standing versions.

The cost of purchasing a boiler will soon pay off

The cost of purchasing a boiler will soon pay off

For the installation of the device, in order to create conditions for the smooth functioning of the system, and the storage of solid fuel, it is necessary to allocate a separate room.

A significant disadvantage of this type of unit is the low power of their electrical part. This limits the number of built-in electric heaters. After all, the total power of the electric heaters should not exceed the power of the wood-burning chamber, the range of which varies within 6-25 kW.

Choosing a combined boiler, you can "kill two birds with one stone", reinsuring yourself and the inhabitants of the house for the future, having two energy resources in stock. The combi boiler can act as both the main source of heat and serve as a backup option for the heating system.

How to choose

The first selection criterion is power. The total is calculated as 1 kW for an area of 10 square meters. Correction factor - 0.7-2 (depending on the geographical area: the farther north, the more). 25% for the second circuit, 10% for the peak voltage in the network. This is a standard calculation.

In your case, the power consists of two numbers: electricity and wood heating. You need to prioritize and calculate approximately how long the boiler will run on wood, and how much on heating elements. It is also not worth choosing a boiler with a power that greatly exceeds the real needs: it will cost more itself and there will be extra costs during operation.

If the heating will be predominantly wood-fired, the size of the combustion chamber is important. It's a matter of your convenience: how often you need to update the bookmark.

Combined electricity-firewood heating boilers can have one or two circuits. The choice depends on your plans: whether you need hot water supply, whether there will be underfloor heating. Boilers with a coil mounted directly into the furnace are considered more economical.

Dimensions and weight. Determine in advance where the boiler will stand. Will it be possible to fill in his own screed for him. The mass, among other things, depends on the material of the heat exchanger - cast iron or steel.

Cast iron models have high inertia - they heat up longer, cool down longer. They are considered more durable due to their corrosion resistance. But they are more fragile, sensitive to sudden changes in temperature. Steel is susceptible to corrosion, but temperature-resistant. And less weight.

The grates are made of ceramic, steel, cast iron, cast iron with ceramic spraying. The heat resistance of cast iron is higher; it is a universal option for all types of solid fuels. Sprayed honeycomb grates are optimal for bulk fuels that require more oxygen for combustion.

A special valve in the design ensures quiet operation. The presence of a built-in fan will increase the efficiency of the boiler and simplify the installation of the hood for the installer. Models with the upper location of the fan are considered more durable: the lower one wears out faster due to dust that gets into the device from the floor.

Automation is electronic and mechanical (with manual control).Since in the presence of heating elements (and a circulation pump), the boiler is in any case volatile, it is hardly worth saving on automation.

It is better to use electronic, it has more functions: almost everything is automated, except for bookmarking firewood. It is even possible to remotely control heating elements (what are Gsm modules for heating boilers).

Choosing the type of heating in a private household

Since the restrictions on installation in an individual house are minimized (you can generally build a stand-alone boiler room next to a residential building), there remains a relatively free choice of energy carrier.

What can be used for heating in the private sector?

- First of all, solid fuel. It can be coal, firewood, or fuel briquettes (in fact, the same firewood). We will leave such exotic products as cow dung for the area where it is "found" in abundance.

- Gas in our country is quite a profitable option. Unless, of course, he is in a particular locality.

- Electricity is valuable because it is almost everywhere. Except perhaps for a territory remote from civilization (there is no gas there).

When choosing a fuel for a boiler, first of all, the cost of a unit of heated area for a specific region is considered. If logging is developed around you, the choice is made in favor of firewood.

Electricity is available almost everywhere (you just need to worry about the technical conditions in advance to ensure the required power).

So, let us assume that the technical possibilities of supplying any fuel are present. Let's make an approximate calculation of monthly heating costs for a 200 m² cottage.

Let's say you have analyzed all possible costs, including shipping costs, and made a decision in favor of one or another type of fuel. We bought a boiler, integrated it into the heating system of your house, and entered into a fuel supply contract.

A year passes, and the forest, in which firewood was procured, was recognized as a specially protected natural area. Firewood must be transported for 100-200 km.

An accident occurred at the nearest coal mine, it was closed. Coal has become more expensive than firewood.

A nuclear power plant was built nearby, the cost of electricity for the surrounding villages has become so profitable that even heating with natural gas is more expensive.

A variety of boilers "wood-electricity"

One purely constructive moment must be put into the basis of the classification of combined boilers "solid fuel-electricity": whether automatic equipment is installed in the boiler or not. There are two groups here:

- With automatic control system.

- With manual.

The manual option is both simpler and cheaper. But recently, consumers have given their preference to boilers that can work in automatic mode, because ease of maintenance is increasingly being put at the top of the choice. In this case, it is possible to adjust the operation of the boiler in such a way as to control the switching from one type of fuel to another. Here's one example.

The firewood burns out to the end, and for some reason the owner did not make a new bookmark (at night, when he sleeps). Immediately, the automation system turns on the heating element, which will maintain the required temperature of the coolant.

Universal boilers

3 Advantages and disadvantages of universal equipment

Combined heating of a private house on wood and electricity has its pros and cons, like any other equipment. In particular, by installing an electric fire boiler, you can get the following advantages:

- 1. Thanks to automatic switching to heating elements in the cold season, such heating will not allow the coolant to cool down during the absence of the owners, accordingly, it will not freeze. Otherwise, it can lead to the failure of the whole system.

- 2.The system is comfortable, since you do not need to get up at night in order to put firewood in the firebox.

- 3. In the case of calculating the price for electricity according to a multi-tariff scheme, you can save on the night operation of heating elements, since the cost of electricity is often lower at night than during the day.

This fact can be considered a disadvantage. But there are also exceptions. When installing the boiler in small rooms (up to 100 square meters), even devices with a low power of heating heaters will heat the room well in relatively warm weather (down to -5 ° C). In this case, heating elements will give off heat at approximately the same level as firewood during combustion.

A combination boiler, like a classic solid fuel boiler, must be connected to water heating through a three-way valve. Such a unit is equipped with a small circulation loop to protect the furnace from condensation. After the firewood burns out, the heating elements turn on, and the firebox cools down.

If the power of the heating heaters is sufficient and they are able to heat the coolant to a temperature of at least + 50 ° C, then the three-way valve becomes unnecessary, since condensation will not form in any case. Then you shouldn't install it at all. A small circuit will still come in handy in certain cases, for example, if there is a power outage. Combined boilers for wood and electricity, in addition to visible advantages, have disadvantages:

- 1. Heating operation always depends on the stability of the power grid.

- 2. Heating elements occupy a certain place in the boiler, respectively, the size of the furnace decreases, a smaller volume of firewood is placed in it in one tab.

- 3. Prices for combi ovens are higher compared to classic solid fuel boilers.

- 4. The efficiency during the operation of thermal electric heaters is reduced by 3-6% due to the fact that the firebox cools down, but a certain amount of heat leaves through the chimney.

The best option to replace natural gas for electricity and firewood will be the installation of individual units and their connection to one heating system at home.

The advantages of combined boilers

As the reviews of consumers who have already installed such installations in their homes show, combined boilers operating on different energy carriers are an excellent way to save money.

Combined boilers - a universal means of heating a private house

Combined boilers - a universal means of heating a private house

In comparison with traditional solid fuel or gas counterparts, combined boilers have a number of undeniable advantages:

- Versatility. The presence of heating elements makes it possible to operate heating installations even in cases where it is not possible to use firewood. And in the event of a power outage, it is always possible to switch to a reserve type of fuel.

- Profitability. Electricity and wood are the most affordable sources of energy these days. And against the background of a regular rise in gas prices, the efficiency of a device running on electricity and solid fuel becomes doubly relevant.

- Availability. The boiler is capable of processing almost any waste from the woodworking industry, the cost of which is minimal.

- Environmental friendliness. In the process of burning wood product, no harmful emissions are emitted into the atmosphere.

Firewood is an environmentally friendly heating medium

Firewood is an environmentally friendly heating medium

- High quality heating. Electricity and solid fuel energy sources in the combustion process emit a lot of heat, under the influence of which the coolant quickly heats up, evenly distributing it throughout all rooms in the house. Thanks to a well-thought-out design, energy losses are minimized.

- Long service life. With properly organized operation, combined systems are capable of regularly serving for more than two decades.

Homemade combined heating units

Let's see how to choose a wood-electricity combined heating boiler for home heating. The main parameter here is the power of the device. Usually 10 sq. m. heated area requires 1 kW of thermal energy. Also, do not forget about 15-20% of the reserve in case of cold winters.

ZOTA Poplar M 20

Electric wood-burning stoves for a home with water heating are in demand among those who are tired of freezing when the fire is extinguished in the firebox. Using the ZOTA Poplar M20 model, you will have at your disposal a powerful heating device from a well-known brand. Its power is 20 kW, efficiency is 75%, control is mechanical. It is possible to work from electricity, but for this you will have to purchase a block of heating elements for it. The boiler is omnivorous, it burns wood, coal and anthracite. The estimated cost in the Russian market is about 36,000 rubles.

GEFEST VLOOKUP KSTGV-25

The GEFEST company produces not only gas and electric ovens known throughout Russia, but also heating boilers for a private house on wood and electricity. The above model is a typical example. It is housed in a simple rectangular case, devoid of any design hint. The sample power is 25 kW, the heated area is up to 250 sq. m. The efficiency is up to 82%, this is a fairly high figure.

Despite the seeming simplicity, the GEFEST VPR KSTGV-25 boiler on wood and electricity is not at all as simple as it seems. The thing is that it is double-circuit - it provides heat and hot water. The DHW circuit capacity is 8.5 l / min with a temperature change of 35 degrees. The primary heat exchanger is made of steel, the secondary one is made of copper. As soon as you get tired of wasting wood and electricity, the device can be switched to gas by purchasing a burner for it.

Sibenergoterm Prometey 12M-5 12 kW

Anyone who knows how to make good boilers that work equally well on wood and electricity are Siberian manufacturers. The presented model has a power of up to 12 kW and can heat an area of up to 100 sq. m, consuming up to 3.2 kg of fuel per hour. As soon as the wood in the firebox comes to an end, the electric heater will turn on - it will maintain the temperature in the heating circuit and will not let it cool down until the next fuel load.

The boiler for wood and electricity Sibenergoterm Prometey 12M-5 12 kW operates not only on wood, but also on other types of fuel - these are coal and coal briquettes. Moreover, coal acts as the fuel recommended for this model. Separately, we are pleased with the high efficiency of the model, which is 84 kW. Also, its design includes an air vent and a safety valve. Heating elements for operation from the mains are purchased separately.

Outbreak KSTGS-16

This boiler, which can work on electricity and wood, is combined, because a gas burner is also connected to it. The power of the device is 16 kW, which is enough to heat houses up to 160 sq. m. Fuel for this model are traditional firewood, coal and wood briquettes, as well as coal. The heating element block is already preinstalled, you do not need to purchase anything additionally. The device is one of the most affordable, its average cost is about 24 thousand rubles. For this money, consumers receive almost omnivorous equipment.

NMK Siberia-Gefest KVO 15 TE

Reviews say that this boiler, powered by electricity and wood, is convenient and efficient. All types of solid fuels are loaded into its firebox, from traditional wood logs to coal. Thermal power is 15 kW, heated area - 150 sq. m. The use of water and antifreeze is allowed as a heat carrier. The boiler water volume is 46 liters. Consumers note the rapid heating of the coolant.

The NMK Sibir-Gefest KVO 15 TE boiler was equipped with an automatic draft regulator. This approach allows you to rely on temperature stability in the heating circuit.A heating element unit is already preinstalled on board, so the equipment is completely ready to operate from electricity. An interesting feature is the possibility of top loading firewood into the firebox.

EVAN WARMOS TT-25

This boiler, which runs on wood, peat, coal and electricity, cannot be called handsome - the word "design" does not apply to it. But he copes with his duties excellently. With a thermal power of up to 25 kW, it heats an area of up to 180 sq. m. In order to extend the operating time from one tab of fuel, the device was endowed with a large firebox with a volume of 50 liters - logs up to 550 mm long are placed in it. The heat exchanger of the boiler is made of durable steel, heating elements for operation from electricity are purchased separately.

Advantages of the model

The advantages of combined heating in such heating systems are obvious. The model completely protects its owner from problems with electricity - you can always use gas or wood. In the absence of gas or wood fuel, the boiler can operate on electricity.

The structure of boilers electricity-firewood

The combi boiler has the following advantages:

- Versatility - heating is possible due to lack of resources;

- The boiler can quickly switch between operating modes;

- Boilers are able to maintain the required temperature regime at any time of the year;

- Easy to use and install;

- Reliability and durability of heating equipment;

- The ability to adjust the temperature in real time, even when gas or wood is used;

Thus, combined boilers are qualitatively different from their closest relatives - heating devices that use only a strictly fixed resource, in particular, gas.

Design features

Combination boiler components

When switching to electricity, the house is heated by heating elements. Practice has shown that with a low-power turnover, a combined boiler is able to maintain a minimum temperature in a house using electricity for several days.

Boiler for home heating combined firewood-electricity

By installing a combined boiler for heating a private house with wood-electricity, you can solve the problem that often arises in houses heated with solid fuels - the coolant in the system cools down between sessions of the furnace. This can happen, for example, at night or during a long absence of the owners.

This problem can also be solved by using boilers with long burning or continuous fuel supply. But such units, as a rule, are quite expensive, cumbersome and often designed for special types of fuel: pellets, shavings, coal of certain fractions.

Most of the simple combined firewood-electricity boilers can be purchased at an affordable price, although the latter largely depends on the model, power and manufacturer.

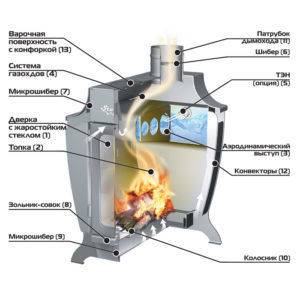

The main structural difference between a combined firewood-electricity boiler from a conventional solid fuel boiler is the presence in its water jacket of an electric heating element (TENA), one or more. In addition, such heating units are equipped with a small control panel, with the help of which the heating element is automatically turned on and off.

Otherwise, the design of such boilers is the same as their counterparts, operating only on solid fuel. Its main elements:

- Body with chimney;

- The combustion chamber;

- Heat exchanger ("water jacket");

- Grate;

- Blower chamber with ash pan - for air supply and ash removal.

The design of the simplest combined heating boiler wood-electricity

This is the simplest version of a combined firewood-electricity boiler. But other more complex designs are also possible. For example, heating elements can be equipped with gas-generating boilers with pyrolysis combustion of firewood. Heat exchangers of such units can also be of different designs, types and shapes. But they all have one thing in common - the presence of an electric heating element in the "water jacket".

How to choose a combined firewood-electricity boiler

Combined heating boiler "wood-electricity"

When choosing a combined electric-wood boiler, you should pay attention to the following points:

- Correctly select its power, which should correspond to the area (volume) of the heated premises of the house, and also take into account the level of their thermal insulation, that is, heat losses. It is best to calculate the heat losses of the heated premises of the house. In extreme cases, you can focus on the average values of 1.0-1.2 kW per 10 m2 of heated area.

- Type and cost of the boiler. This may be the cheapest option - a conventional boiler with a small combustion chamber and short-term burning of wood, or a more expensive unit with pyrolysis fuel combustion. The cost of the boiler also depends on the complexity of the design and the reliability of the manufacturer, as well as the quality of work and materials that were used in its manufacture. Much depends on the availability of funds and everyone makes a choice on their own.

- The power of the heating element should be such that the electrical wiring in your house will "pull" or it will have to be redone.

- Heat exchanger material. The cast iron heat exchanger is more durable, corrosion resistant and has no welding seams. It is a prefabricated unit, the elements of which, if necessary, can be replaced. But he is afraid of sudden changes in temperature and shock. The steel "water jacket" is not afraid of drops and shocks, but rusts and burns out faster.

- Some combined electric-wood-fired boilers have a second heat exchanger (circuit) for hot water supply. This is both a plus and a minus. On the one hand, simultaneously with heating, we also receive hot water into the water supply system. On the other hand, this requires additional boiler power. In addition, such a DHW system will only work during the heating season.

Advantages of a boiler using different types of fuel

We examined economic feasibility in the previous section. Indeed, the cost of heating with different types of fuel can change, and then all your calculations will be reduced to zero. Emergency safety is also important: when you have 300% fuel reserve in stock, life is somehow safer.

But there are other pluses:

- Complete energy independence. There are times when the main energy carrier cannot be purchased. There are many reasons, including illegal ones. You can still provide your home with warmth.

- Any heating system (especially with a liquid heat carrier) is quite inertial. While you melt the wood (coal), until the gas burner comes into operation, a lot of time will pass. If you come into the house after a long absence, you want an instant warm-up. You can start express mode from an electric heater, then switch to economical heating from gas or solid fuel.

- You can dismantle the gas burner for maintenance without disrupting the heating mode.

- The combustion chamber is the same as in a conventional solid fuel boiler. Grates, blower, dampers, chimney. In normal mode, firewood or coal is loaded there. It is necessary to monitor combustion in manual mode (this is a characteristic feature of economy class heating systems).

- A water jacket with a coolant is placed around the combustion chamber. Depending on the "advanced" design, the jacket can have advanced heat exchangers. The illustration shows a cross-section of the cross pipes. The more efficiently heat is transferred from the fire, the higher the boiler efficiency.

- To maintain the intensity of combustion, a fan can be installed in front of the air damper. It works in manual or automatic mode.If there is so-called "bad" weather outside, in terms of combustion, additional traction will be required.

So, you loaded the camera with fuel and went to work. Combustion is slowly maintained according to a given cycle, then the solid fuel ran out ahead of time (for example, the weather improved, the wind rose, the draft improved). You come home and the house is cold. We have to wait for the wood to burn.

Imagine that an electric heater is integrated into the jacket with the heat carrier. With the help of the control panel, it is connected to the mains. You have set the temperature of the heating medium, for example - to 50 ° C. When wood, coal, or pallets burn out, the temperature sensor will work, and the automation will turn on the electric heater. The temperature in the house is returning to normal.

Yes, this heating will cost more than solid fuels. But the home will be warm to your return.

An additional electric heating system can be installed immediately, or purchased additionally. Such sets are standardized for various boiler models, and are offered for free sale.

Of course, this is not a two-way process. If the electrician turns on automatically, then only you can throw firewood into the firebox. Of course, there are systems for automatic pallet feeding, but these are additional costs.

By equipping your boiler with similar technologies, or by immediately buying a multi-fuel system, you will at least add comfort (which is the ability not to get up at 5 am for the morning heating). In addition, such a system will protect your heating system from defrosting at temperatures below zero.

For example, you are going on a winter vacation or a business trip. There will be no one to throw the coal into the firebox. Of course, heating a boiler with clean electricity is ruinous. But you can set the regulator to a minimum, only to maintain a positive temperature in the room. And upon returning, immediately warm up the house, and start traditional heating: solid fuel.

Any wood burning fireplace can be easily turned into a fireplace for the house with wood and electricity. For this, a small-diameter heating element is built into a metal pipe (supply) extending from the device. Here you should make sure that the heating element does not block the pipe lumen and does not interfere with the flow of the coolant.

Technical design features

Combined heating boilers use four types of fuel:

- gas;

- electricity;

- solid energy carriers (coal, firewood);

- liquid fuel (fuel oil, used motor oils).

Contouring

There are the following types of combined heating units: single-circuit and double-circuit.

The first ones have limited functionality - they provide heating for the house, and the double-circuit ones also heat the water.

Since universal boilers are made of cast iron, they are quite massive, therefore, they only have a floor structure. Cast iron has high corrosion resistance, which is important if liquid fuel is burned.

Tank

A hot water tank is included with certain models. Some double-circuit devices are not equipped with a tank, then they are connected to a tank, which is installed near the unit.

Almost all heating units are automatically controlled. This is very convenient because you can freely select the program, adjust the parameters and monitor the operation of the equipment.

To ensure a warm water supply, combined double-circuit boilers include a heat exchange unit, which is characterized by increased productivity - up to 250 liters of water every hour! The possibility of installing a boiler is provided. The double-circuit water heater has several outputs.This will allow you to make warm floors at home and produce heating using radiators.

Fuel combination improves efficiency

Even the most modern wood-fired boilers, with an efficiency of over 90%, can ensure the duration of maintaining the temperature in the room only within the time required for the combustion of a batch of fuel. However, in the absence of an operator who is able to load a new portion of firewood into the furnace for a long time, the process of heating the coolant is interrupted and the temperature of the heating circuit gradually decreases. In winter, this is dangerous due to the threat of freezing of the house and damage to the entire heating system due to freezing of liquid in pipes and radiators.

Therefore, today cast iron and steel household combined boilers have been developed, which can change energy sources in the course of their operation. In open flame heating mode, firewood and other dry combustible materials are used as fuel. And if it is impossible to regularly maintain combustion, such models are switched to operation from the electrical network.

For this, a built-in electric heating element is used in the design of the boiler, which is placed directly in the tank for the coolant. The flame from the wood produces a rapid heating of the coolant, and the heating element maintains its temperature in the future. This option does not require an additional firebox. The electric heating element is simply mounted in the tank and connected to the automatic control panel.

The simplest design of such a boiler is two metal cylinders of different diameters, welded into one another. The inner cavity is a firebox, the outer cavity, bounded by the walls of a small cylinder, is a container for the coolant. An electric heater is also placed in the lumen.

When the wood burns out in the combustion chamber and the temperature in the circuit drops, the electrical appliance automatically turns on and maintains the heating mode according to a given schedule. This option is well suited for houses in which permanent residence is impossible during the winter period of the year, but which must be maintained in a residential condition. After all, even one winter without heating can render a completely high-quality structure unusable.

In these cases, combined boilers become an excellent solution to the problem - leaving for a few days, you don't have to worry that the heating system will freeze. The boiler set to the maintenance mode will ensure the preservation of the coolant in a working liquid state.

Combined boiler TT-electricity

TT boiler with pellet hopper.

- firebox;

- heat exchanger;

- heat exchanger tank;

- insulated body;

- automation system.

The electric heating element is built into the storage tank of the boiler. The heating element is easy to change if it burns out. To do this, it is enough to unscrew the faulty heating element and screw in a new one. The heating element can work independently, or it can simultaneously burn solid fuel. This approach is useful when you need to quickly warm up the system or to extend the periods between bootups.

As you know, in conventional TT boilers, firewood must be thrown every 4 hours, in pyrolysis heaters this time is increased from 6 to 8 hours, but no more. If there is no storage tank in the circuit, but temperature drops are inevitable. The heating element helps to smooth out the drops. You can install a thermostat and connect it to the heating element. This will keep the temperature at the same level.

In addition, the electric heating element can keep the water temperature in the system at the minimum acceptable level when you are away. Naturally, it is simply pointless to fully heat the house when you are not at home for several days.