Requirements to be observed during installation

When installing a coaxial chimney, a number of installation requirements must be observed.

- Strict adherence to the rules for installing a coaxial chimney will ensure the safety of your home;

- It is necessary to follow the recommendations of SNiP 2.04.08 - 87; 2.04.05 - 91.3. You need to know that these rules are not prohibited from installing vertical chimneys in private houses;

- The distance to neighboring buildings should be at least 2 m, provided that there are no other holes on it within 3 m to remove smoke. If there are such holes within 3 m, the distance to the structure must be at least 3 m;

The most common vertical chimneys in private households. However, there is another area of their application - this is a coaxial chimney in an apartment building. The use of a collective chimney ensures high safety in the use of gas appliances.

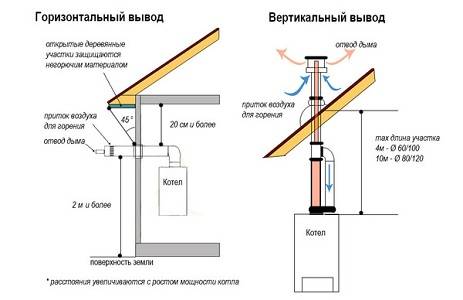

The rules for installing a coaxial chimney regulate the maximum length of the installed chimney no more than 4 m.

The following rules for installing a coaxial flue must be observed.

- A maximum of 2 folds can be used;

- The slope of the outward-facing section for horizontal installation should correspond to approximately 3 º;

- Parts of the chimney must be accessible for routine inspection;

- The chimney cannot be removed below the surface of the soil;

- The distance to neighboring buildings should not be less than 8 m. If there is a deflector, it can be reduced to 2-3 m, depending on the presence of holes on the wall;

- If the chimney is installed in such a way that its outlet is below 1.8 m above the ground, it must be equipped with a special grate;

- If there are winds in the area where the chimney is installed, directed in the opposite direction from the smoke outlet, it is necessary to install a special barrier at a distance of at least 40 cm;

- If the house is located in an area with very severe frosts, it is better to use a coaxial outlet with an extended duct;

- No need to install additional ventilation sources

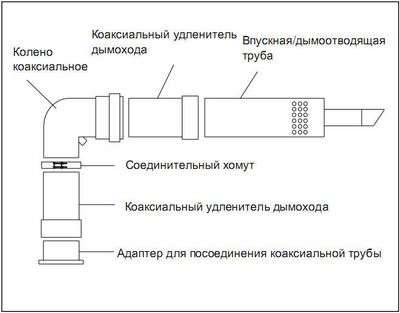

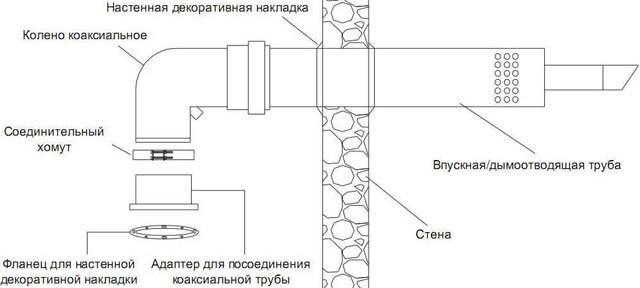

Installation diagram of a coaxial chimney

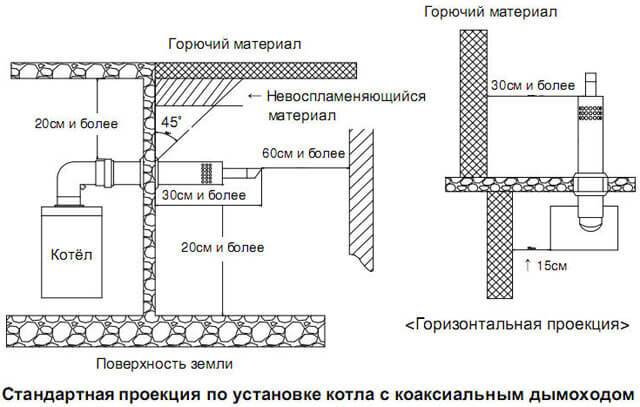

In addition to the above rules, the following requirements must also be observed. The distance from the coaxial chimney to the window must be at least 60 cm. The distance to the gas pipes is not less than the radius of the outer pipe. A very tight fit of the pipe parts is mandatory

It is important to pay special attention to fire safety at the point where the pipe comes out on the roof. Special covers must be used to protect against contact of the chimney with all kinds of objects.

If the gas boiler is located too far from the wall facing the street, the question may arise how to lengthen the coaxial chimney. For these purposes, special coaxial chimney extensions are used. These devices are sold at many building supplies stores. The coaxial chimney extension will help to install it without violating the established requirements.

How to protect a coaxial chimney from icing and wind

The main problem associated with the operation of coaxial systems is the possibility of freezing of the pipe during severe frosts. Icing of the air supply channel leads to a decrease in the flow area and, as a result, a lack of oxygen in the combustion chamber. This leads to a sharp increase in gas consumption and a significant drop in the efficiency of the heat generator.

The appearance of icicles at the end of the chimney clearly indicates violations committed during the design and installation of the coaxial flue system. With the correct calculation of the chimney parameters and quality installation, the likelihood of icing is minimized.

In order to prevent and eliminate the resulting icing, it is recommended to use the following methods:

- Installation of a special tip that allows you to eliminate icing even if the coaxial device is incorrectly installed;

- Installation of a chimney with a slope towards the boiler. This allows the condensate not to stagnate in the pipe, but to drain into a special collector located inside the unit. If there is a condensate drain, the pipe head should be extended 55 - 65 cm from the outer wall;

- Thermal insulation of the outer pipe with mineral wool or other heat insulator also helps to reduce the intensity of condensation and freezing.

Another problem that can arise during the operation of a coaxial chimney is the possibility of back draft. In order to avoid this phenomenon, it is necessary to take measures to ensure protection from wind and draft. The installation of a special diaphragm will help prevent the burner from damping and the ingress of carbon monoxide into the living space.

In addition, when installing the chimney, SNiP should be strictly observed, which specifies the distance from the outlet pipe to window and door openings. The minimum distance allowed is 1 - 1.2 m. For efficient and safe operation of the coaxial installation, first of all follow the instructions of the equipment manufacturer.

Views

Depending on the installation method, chimneys are vertical, led out through the roof, and horizontal, laid through a wall or window. Durability and performance are determined by the properties of the material from which they are made.

Aluminum

Differs in light weight, without damage tolerates temperature fluctuations and all kinds of corrosive effects. But due to the low operating temperature, it is extremely rarely used for the production of coaxial chimneys. Usually used in combination with plastic.

Stainless steel

For the manufacture of chimneys, acid-resistant stainless steel is used, which painlessly withstands sudden temperature changes and is capable of operating when heated to 550 ⁰C. The guaranteed service life is at least 30 years. Manufacturers produce two types:

- Pipes without insulation - used in heating systems at industrial and domestic facilities. The disadvantage is the formation of a large volume of condensate during operation. To reduce it, the installation of a layer of thermal insulation is required.

- Insulated - most often used as vertical collective chimneys in multi-storey buildings. They have improved aerodynamic properties. The rules do not prohibit the connection of heating systems with both forced and natural draft. Installation is carried out during the construction of a house according to a project developed by a specialized organization.

Two-channel plastic chimneys

They are made of heat-resistant material with an operating temperature of up to 205 ⁰C. Plastic is inexpensive, lightweight, easy to install. Coaxial designs of this type are designed to work with gas condensing boilers with a low-temperature chimney mode. The disadvantages include a short service life and restrictions imposed on the use in conventional gas boilers.

When choosing coaxial pipes, it should be borne in mind that some manufacturers produce boilers with non-standard pipes. Therefore, for installation, you need to use the accessories of the same manufacturer.

Special Benefits

When considering the main positive qualities of coaxial chimneys, it should be noted once again that such a structure cannot be connected to all types of heating boilers.For the highest quality operation of such a chimney, it should be borne in mind that it must be installed with heating boilers with a closed combustion chamber on forced draft. It is the built-in fan that allows the entire smoke exhaust system to work extremely efficiently. Such boilers can be both floor-standing and wall-mounted.

The most important advantage in favor of a coaxial chimney is the simplicity of the system design and the installation of the heater in any required place.

Let's consider in detail all the undeniable advantages:

- The horizontal arrangement of the chimney. There is no need to pierce the roof to remove the combustion products. The pipe is led out through the wall or window closest to the boiler.

- The coaxial flue system is not connected to the indoor air. During the operation of the boiler, oxygen is not burned out in the room, and carbon monoxide gases do not enter the inner space of the rooms, as is the case with the operation of conventional gas boilers.

- The air taken from the street enters the combustion chamber heated. This is possible due to the fact that it runs between the outer pipe and the inner one, through which hot, exhaust smoke is discharged to the outside. This makes it possible to increase the efficiency of the heating boiler.

- The coaxial chimney is easy to install, the work does not require special knowledge and serious redevelopment for arranging the chimney. Thanks to this smoke exhaust, it is possible to install a heating boiler even in an apartment.

- The coaxial chimney has an excellent degree of protection against possible fire. This is achieved by cooling the entire system with cool outside air, which flows through the channel between the pipes.

- For such a chimney, there is no need to arrange a separate equipped boiler room. Any of the boilers - wall-mounted or floor-standing, can be installed in a convenient place of your choice: in the kitchen, in the basement, in the annex, in the pantry.

Basic requirements for the placement of a coaxial horizontal chimney

In order for the gas service to have no complaints, it is necessary to correctly determine the point of exit of the pipe through the wall in accordance with the norms specified in SP 60.13330.2012. First of all, it is necessary that the internal section of the product is not less than that of the outlet of the boiler. Installation is carried out in accordance with the basic requirements:

- The length of the coaxial pipe should not exceed 3 m. When installing an exhaust fan, an increase of up to 5 m is allowed. Installation of only two branches for changing direction is allowed.

- The chimney is laid at an angle of 3⁰ towards the boiler. If a condensate trap is installed, from it.

- The boiler is installed in such a way that its outlet is at a distance of 0.5-1 m from the opening in the wall through which the structure is led out.

- If the pipe comes out next to the window, the gap between them should be at least 0.5 m. Placing below the window sill is not encouraged. But when there are no other options, laying under the window at a distance of 1 m is allowed.

- If there is a gas pipeline nearby, the chimney is mounted at a distance of at least 20 cm from it.

- The hole in the wall made of brick or concrete is made so that a gap of 1 cm remains. After laying the pipe, it is not necessary to fill it with heat-insulating material, it is enough to close it with a flange.

- In wooden walls, the size of the gap increases to 5 cm. The gap is laid with basalt wool or filled with heat-resistant foam.

- The height of the passage of the coaxial pipe to the outside must be at least 2 m from the surface of the earth. This is enough to reliably protect the surrounding space from the negative effects of flue gases.

- When removing the structure under the balcony and canopy, the length of the protruding part is determined based on their size. A circle is mentally outlined in the horizontal plane. The center line is the connection between the balcony and the wall, and the radius is equal to the width of the canopy. The end of the pipe must be outside the circumference.

Why is the coaxial design unique?

The concept of "coaxial" implies the presence of two objects inserted into one another.Thus, a coaxial chimney is a two-circuit structure made of pipes of various diameters, located one inside the other. There are jumpers inside the device that prevent parts from touching. The equipment is installed in heat generators equipped with closed combustion chambers. These include, for example, gas boilers.

The coaxial chimney is designed in such a way that the inner pipe is designed to discharge combustion products into the atmosphere. The larger outer diameter is used to supply fresh air for combustion

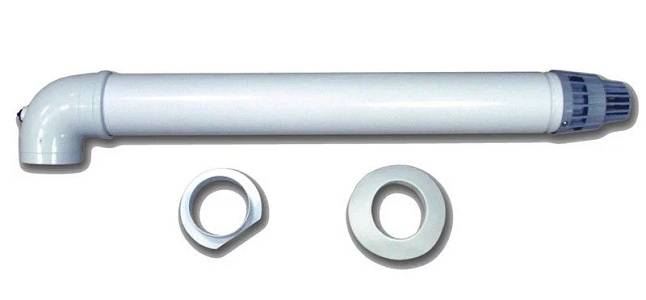

Thanks to the special design of a standard coaxial chimney, it performs two functions at once: it creates an uninterrupted supply of air necessary to ensure the combustion process, and removes the combustion products outside. The length of the device usually does not exceed two meters. Basically, it is intended for horizontal placement and is displayed on the street through the wall. Less commonly, you can find a structure brought out through the ceiling and roof.

The special design of the coaxial chimney allows it to function according to a completely different principle from a conventional device. The oxygen required for combustion enters the boiler from the outside. Thus, there is no need to provide a constant flow of fresh air into the room by ventilation, which is inevitable for traditional flue ducts. In addition, a number of problems typical for standard chimneys are successfully solved:

- Reduction of heat losses due to heating of the air entering from the outside from the internal exhaust pipe of hot smoke, which results in a higher efficiency of the system.

- Reducing the risk of fire in the areas of contact between flammable surfaces and the flue duct, since the inner pipe, giving off heat to the outside, is cooled to safe temperatures.

- The high efficiency of the system allows for complete combustion of fuel, thus unburned particles are not emitted into the atmosphere and do not pollute it. A boiler equipped with a coaxial chimney is environmentally friendly.

- The combustion process, including the supply of oxygen and the removal of gases, takes place in a closed chamber. It is safer for people, since hazardous combustion products do not enter the room. Therefore, additional ventilation is not required.

- Saving space due to the compact size of the device.

- A wide range of chimneys designed for systems of various capacities.

Coaxial chimneys of the best manufacturers - a guarantee of reliability and quality ↑

Coaxial chimney Ariston

Coaxial chimney Ariston

Italian-made Ariston chimneys are suitable for most modern boilers. They also come with gaskets and wall coverings.

Coaxial chimney Baxi

The chimney in its structure must have a length of up to 5 m. If it is directed towards the street, it is given a slope at the rate of 1 cm for each meter of its length. For the conditions of the Russian climate, insulated options are more suitable with the following changes made to the design:

- lengthened head,

- the design of the air intake duct is especially protected,

- made of composite material.

Such a system makes it possible to prevent icing of the chimney and cause the boiler to stop in emergency mode if the outside temperature drops to -50 C.

Coaxial chimney Proterm

These products are very easy to install and help to increase the efficiency of the respective Protherm boilers. In addition to them, the company also offers chimney extensions, adapters for separate smoke exhaust and more.

Coaxial chimney Vaillant

This company is considered one of the leaders in the European market. Its products have been in high demand in recent years.

When choosing a chimney, it is especially important to match its cross section to the section of the Vaillant boiler pipe. During installation, it is necessary to ensure the distance between the chimney and flammable structural elements of at least 100 mm

Coaxial chimney Viessmann

In addition to the coaxial outlet (diameter 60/100, 90 °), the kit usually includes: a coaxial pipe equipped with a ferrule (diameter 60/100, length 0.75 m) and wall plates. Its special design prevents the pipe from freezing in winter.

Regulations and Installation Rules

-

SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated edition) (733.0 KiB, 6 365 hits)

-

SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated edition): pdf file (5.3 MiB, 2 664 hits)

-

Installation rules for De Dietrich coaxial chimneys: classification, norms (8.0 MiB, 6 592 hits)

2020 .

- Security

-

Roof types

- Attic

- Flat

- Pitched

- Glass

-

Roofing materials

- Keramoplast

- Natural

- Ondulin

- Polycarbonate

- Slate

- Roofing

- Soft roof

- Metal

-

Repair and maintenance

- Types of jobs

- Sealants

- Leakage

-

Rafter system

- Mauerlat

- Lathing

-

Shingles

- Flexible

- Metal tile

- Roofing device

-

Warming and insulation

- Hydro and vapor barrier

- Heat insulating materials

- Warming

- I-beams and channels

-

Roof elements

- Ventilation

- Gutters

- Chimneys

- Ridge

- Stairs

- Low tide

- Snow holders

- Gable

New publications

- Why is Tyvek vapor barrier a good choice?

- Specificity of foil vapor barrier: characteristics, conditions of use, installation

- Mansard roof rafter system: diagrams, device

- How to fix the rafters: fastening to the beams, Mauerlat and other roof elements

- Snow load on the roof: subtleties of calculation during design

2020 Stylish Roof Roof

The images published on our site are taken from open sources. If you are the author of the image, then contact us through the contact form, and we will try to quickly resolve this issue.

Advantages and disadvantages of coaxial chimneys

Such systems for supplying air and removing combustion products have now gained widespread popularity. This is easily explained by the many advantages of such a scheme:

First of all, the advantage is that the air required for the combustion of "blue fuel" is taken not from the premises, but from the street. This circumstance greatly simplifies the organization of general ventilation - no calculations are required for an additional inflow, there is no need to resort to frequent ventilation or the organization of other ways of air intake from the street

This is especially important for those cases when the boiler is installed in the "living area" of a house or apartment, for example, in the kitchen. In frosty weather, there will be no unnecessary influx of cold into the premises.

Combustion products, in principle, cannot enter the room - they are immediately discharged from the closed chamber to the street.

The air taken from the street receives a very noticeable heating from the inner pipe, through which the waste products flow in a counterflow

And this is important for uniform and complete combustion of gas, for maximum efficiency of the boiler. In addition, the complete combustion of the gas ensures the minimum emission of the atmosphere that can cause its pollution. Combustion products, on the other hand, are effectively cooled, which significantly increases the fire safety of the system. The likelihood of ignition of soot particles, which can accumulate in the pipe over time, is sharply reduced. And the gases at the outlet no longer have a dangerous temperature.

The outer surface of the coaxial pipe does not get too hot. And this is a big "plus" in the sense that the requirements for the organization of safe penetration through walls (ceilings, roofs) are significantly reduced. No other type of chimney, including a pipe sandwich, allows such "liberties".

Even through a wooden wall, you can lay a coaxial chimney without cutting out a huge window for this fireproof passage.

- Installation of a coaxial flue gas exhaust system will not involve large-scale construction and installation work, as is usually the case with the installation of "classic" vertical chimneys.

- The installation itself is quite simple and intuitive. Any kit is always accompanied by detailed instructions. So in many cases it is quite possible to carry out installation work on your own.

- A wide range of coaxial chimney kits is on sale, and therefore it is possible to choose the right system for the boiler of a certain model. As a rule, it is purchased immediately along with heating equipment. And for any system in the assortment, the necessary additional parts are offered - tees, bends at 90 or 45 degrees, condensate collectors, inspection chambers, cuffs, clamps, fasteners, etc. That is, there are no problems with picking.

The main disadvantage of coaxial chimneys is the abundant formation of condensate, which is inevitable at the border of pronounced hot and cold gas flows. And as a result - ice freezing at the head in severe frosts. And this, in turn, is fraught with failure not only of the combustion product removal system itself, but even of the heating unit.

In severe frosts, despite the very hot exhaust, ice build-up can form on the coaxial chimney. It is necessary to fight this phenomenon so as not to "ruin" the entire system.

Often such a disadvantage is attributed to the fact that initially coaxial chimneys were developed for European countries with much more benign climatic conditions than in Russia. In an effort to increase the efficiency of boilers, the designers tried to reduce to a minimum the possible diameter of the inner pipe for exhausting gases, which led to a shift of the dew point inside the air duct and abundant freezing of the condensed water.

Additional insulation of the outer section of the outer pipe of a coaxial chimney is a simple and effective means of combating its icing.

The second, but very conditional, drawback is the high cost of high-quality coaxial chimneys. But there is something to argue with. Firstly, the price does not look scary against the background of the total costs of the heating system. And secondly, if you add considerable savings on construction and installation work, then it becomes ridiculous to talk about cost in general. And this is without taking into account the other advantages of the coaxial system.

Chimney freezing

Quite often, owners of boiler equipment wonder why the coaxial pipe freezes. In this case, the boiler room may even stop functioning.

In order to avoid such a nuisance, it is important to try not to ignore the manufacturer's advice when connecting the boiler. It is necessary to observe the length of the pipe, its location and slope

The presence of a fan will free the chamber from combustion products, it will provide the rarefaction, which is necessary for the suction of new air.

Coaxial kits also differ in the material of manufacture, as well as structurally, so some of them can freeze through, while others function normally. If the vertical coaxial pipe is frozen, then the problem can be partially solved by removing the plugs that are located in the upper part of the boiler. In this case, flue gases will go outside, and air will flow from the room.

The plug should be reinstalled as soon as the ice melts. After all, the boiler will not be able to work in this mode all the time. Unit breakdown is inevitable if airborne particles such as kitchen dust and soot enter the equipment.When icing does not happen so often, this method can be used, but with regular freezing, you should purchase an anti-ice kit.

Installation specifics

Correct design and installation of a standard coaxial chimney system implies taking into account the dimensions of the structure. Vertical structures are installed where it is impossible to equip an outlet channel through the wall. For example, a chimney can go directly to a small busy street or be located near a window. Naturally, this is unacceptable, although in some cases it is possible to mount pipes at a certain angle.

It is worth choosing a coaxial chimney, focusing on the data from the technical passport. The chimney to the boiler must be connected with a tee or elbow. Each structural element must be fastened so that there is no obstruction to the discharge of exhaust gases.

Based on where the outlet pipe will be located, certain components are selected. If the pipe is at the top, then there should be no problems with the arrangement of the chimney. If it is located on the side, then the structure is brought to a vertical position by means of special brackets.

Important installation requirements

To install a boiler with a closed combustion chamber, an autonomous heating system must be installed. Such a system can be used in individual construction, in city apartments or industrial premises.

If a decision is made to use a coaxial chimney, certain rules and regulations of safety and installation should be followed. They will allow you to perform the flue gas discharge as correctly and reliably as possible and protect the room from exhaust gases.

Coaxial chimney installation rules:

- The maximum length of the vertical outlet of the coaxial flue must be around 3 meters. Longer chimneys are sometimes found. For example, it is possible to connect coaxial chimneys with a length of 4 - 5 meters to Ferolli boilers (floor-standing).

- The outlet of the pipe to the street is carried out horizontally through the wall, near which the boiler is located in the room. The length of the horizontal section is no more than 1 meter.

- If forced draft is installed using fans, there is no need for a vertical section of the system.

- The chimney outlet is located at a height of two or more meters above the ground and at least 1.5 m relative to the location of the boiler (above it).

- The chimney outlet should be located at a distance of half a meter from any window (side or top), door or ventilation grill.

- The place for the outlet of the coaxial flue pipe under the window is not recommended. But if necessary, the location of the window above the chimney should be more than 1 meter.

- To drain condensate, when installing a coaxial chimney, it is necessary to provide some inclination of the pipe.

It should be noted here that disputes about the necessity and correctness of setting the slope of the pipe is a topic that is rather controversially interpreted and vigorously discussed on many construction forums and sites. At first glance, such a simple matter, it requires an intelligent approach and careful clarification of all the nuances. The main dispute arises over the side of the chimney slope. You should understand this issue in detail and note some of the nuances of installing a horizontal coaxial chimney.

Mounting

When installing coaxial devices, there are a number of rules that must be followed, and for collective systems, these rules look like this:

- The chimney can only be mounted vertically, and its edge must be at least 1.5 m above the level of the roof;

- All combustion products enter the common pipe through a separate outlet from each boiler;

- Flue ducts must not be routed through living quarters;

- The basement chimney can be positioned at least 2 m above ground level;

- The edge of the chimney must be installed at least 1 m from windows, doors or balconies;

- It is forbidden to bring the chimney into the window pits of the basement rooms.

Other requirements are imposed on individual chimneys:

- The chimney brought out to the roof should be located at a distance of at least 0.5 m from the ridge;

- The outlet can not be located closer than 1.5 m relative to the combustion chamber;

- The diameter of the flue duct cannot be less than the diameter of the boiler outlet;

- The chimney can be located at a distance of at least 0.5 m from windows and doors (if the chimney is under them, then the minimum distance increases to 1 m);

- The horizontal chimney outlet must be located at a height of more than 2 m above ground level;

- There must be at least 2 m distance between the edge of the chimney with a deflector and a blank wall (if there are windows and doors in the wall, the distance increases to 5 m, and if there is no deflector - up to 8 m);

- To protect the chimney from air turbulence, a thin metal sheet diaphragm can be used, which is located at a distance of 0.4 m from the head;

- The minimum distance from the chimney to the gas pipe is 0.2 m.

It is quite simple to comply with these requirements, so all installation work can be done independently. First of all, you need to find a suitable place for installing heating equipment.

Next, you need to perform calculations and draw up a project, which should take into account the following points:

- The distance between the branch pipe of the floor gas boiler and the hole in the wall should be more than 1 m, and in the case of wall-mounted equipment, this distance can be reduced to 0.5 m;

- A coaxial chimney for a gas boiler cannot have more than two bends;

- The maximum length of the horizontal sections of the chimney is 1 m, and of the vertical sections - 5 m;

- For forced draft systems passing through a wall, a vertical chimney section is not required;

- The horizontal pipe must be installed at an angle of 3 degrees to the boiler (condensation slope) or from the boiler;

- The total length of the chimney cannot exceed 3 m (vertical sections can be extended up to 5 m);

- When preparing a passage in the wall, leave a 10 mm gap (if the wall or ceiling is made of combustible materials, the gap should be increased to 50 mm);

- It is impossible to dock chimney elements in walls and ceilings.

When all aspects of the design are thought out, you can begin to implement them. After installing the boiler, it is necessary to drill a hole in the wall at the place where it should be located. A coaxial pipe is attached to the boiler using a clamp. Each section of the chimney is connected to the rest by means of clamps, and the structure is attached to the walls by means of brackets. The horizontal part of the pipe is inserted into the hole, and the free space between them is filled with non-combustible material. The joints of the parts are equipped with heat-resistant seals.

If the chimney passes through combustible materials, then at the points of contact it is necessary to insulate the coaxial chimney from the gas boiler. Outside piece of pipe in this case it is desirable to increase it to 0.6 m so that the wooden walls do not come into contact with heated smoke - despite the fire safety of coaxial chimneys, minimal fire safety measures must still be taken.

In any case, the outside of the structure is filled with polyurethane foam and covered with decorative elements. When the chimney assembly is complete, it must be checked for tightness and draft efficiency.