At the edges or in the center?

The structure itself is traditionally located either in the center of the canopy, or in the corner, or - playing the role of one of the walls of the structure.

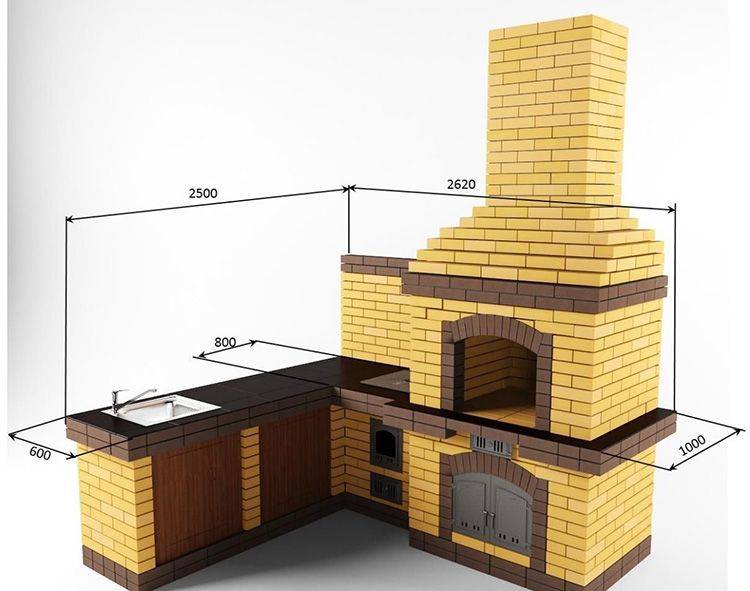

Photo 4. An intricate brick barbecue complex with a hob in the center, a stove, a barbecue and several niches. A good corner position in the gazebo leaves a lot of free space, and makes the cooking process convenient.

Photo 4. An intricate brick barbecue complex with a hob in the center, a stove, a barbecue and several niches. A good corner position in the gazebo leaves a lot of free space, and makes the cooking process convenient.

The location in the center is the most traditional option, reminiscent of those times when not a stove was placed in a house, but a house was built around it. However, in this version, it is quite difficult to place both the table and the cutting surface inside.

A barbecue grill in the corner saves a lot of space, but requires construction according to the drawings, providing for the angular arrangement of the stove.

Therefore, it is most optimal to place it as one of the walls of the gazebo - in this case, the space for the table will remain, and it will be more convenient to cook, and to load the stove with fuel.

Fire safety

The location of the barbecue stove should not only be convenient and fit well into the landscape, but also comply with safety rules. There should be no trees, power lines or other obstacles above the building. The foundation should not be in contact with the foundation of the house - at least half a meter of distance must be left between them. Also, it is impossible for outbuildings, playgrounds, etc. to be in the immediate vicinity.

It is unacceptable to use two types of heating in one design - solid fuel and gas equipment. The distance between the fire door and the gas source must be at least two meters, so the installation of a gas burner in a gazebo with a hearth is a violation that can lead to serious consequences.

Important! The distance from the brazier to the firebox should be at least 30 centimeters, this will help protect yourself from burns during manipulations with the brazier and cauldron

Drawing up an action plan

During construction, you must follow the general guidelines that apply to all types of barbecue:

- the grill should be at least 70-80 cm, taking into account the growth of the owner;

- the stove is traditionally located 10 cm below the grill level;

- a niche for firewood and cabinets, a hook for tongs should be provided.

In this case, it is necessary to take into account all the small details so that later it is convenient to use the structure. When the drawings are ready, you should make a calculation, draw up an action plan and prepare a list of building materials (including for the foundation).

The list of materials for the main work should contain:

- fireclay and facing bricks;

- clay and ordinary mortar;

- metal bar d-30 mm;

- steel sheet 5 mm;

- doors for the firebox and blower;

- grate.

And for arranging the base:

- building mixture;

- reinforcing bars;

- boards for the construction of formwork;

- crushed stone and sand.

The construction of the furnace takes place on a slab base, the frame is erected from fireclay bricks. Then he is faced with a stone. Granite, sandstone, dolomite, rubble stone are suitable. You can show your imagination and give the fireplace any fancy shape.

Coating with stone tiles

When you have finished laying the walls, install a treated natural stone top floor. On the upper surface of the inner and outer walls, lay a layer of mortar, designed for a joint thickness of 1 cm. Lay a tile floor, one edge of which should be flush with the inner surface of the refractory brick. Make sure the tiles are flush. Finish the seams when the mortar starts to set. After a week, seal the joints between the plates with a special compound and set up the grill.

Advantages and disadvantages of a brick barbecue complex

Outdoor brick barbecues have a number of undeniable advantages:

- have an aesthetically pleasing appearance;

- can be used for a comfortable pastime at any time of the year;

- allow you to cook tasty and healthy food;

- the brazier has a fairly large area;

- allows the use of various types of fuels;

- the design features of the brazier contribute to an even distribution of heat, so even a large dish is baked evenly;

- sufficiently functional and versatile. Can be used for cooking fish and barbecue.

Presentability and functionality are the main advantages

Presentability and functionality are the main advantages

The disadvantages of a brick barbecue complex include large dimensions. We have to look for a site that will not only allow the building to be placed, but will also fully comply with fire safety requirements. You will also need a place for a smokehouse, a hob and an exhaust device.

A lot of space is required to install the complex

A lot of space is required to install the complex

Brick BBQ Foundation

slag metal

Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the earth

For the foundation, the mortar is prepared as follows: for 10 kg of cement, you need to take 30 kg of sand, about 40 kg of crushed stone or gravel and about 45 liters of water. The consistency should be such that it can be mixed with a shovel without any extra effort. But it should not drain quickly and easily from the shovel. To mix the solution, it is advisable to use a concrete mixer, then it will turn out to be homogeneous.

It is advisable to pour the foundation in the warm season. When it is cold outside, then it will be necessary to warm up the water to prepare the solution, otherwise it may set earlier. In addition, the mortar will not be strong and will not bond tightly to the reinforcement.

Building materials

To fold a complex do-it-yourself barbecue oven, shown in section in the drawing, you will need to buy the following set of materials:

- clay bricks of standard sizes - 720 pcs. (corpulent is recommended);

- fireclay stone brand ША-8 for firebox masonry - 80 pcs .;

- loading door 25 x 21 cm, ash pan - 25 x 14 cm;

- cleaning doors 13 x 13 cm - 3 pcs.;

- equal flange corners 40 x 4 mm, 4 studs with M12 thread and nuts (length - 70 cm) for assembling the floor frame;

- cast iron panel for 2 burners 71 x 41 cm;

- sheets of basalt cardboard and roofing material;

- reinforcement of a periodic profile Ø 12-16 mm in the foundation tab.

For fireclay masonry, you should purchase a special refractory clay or mortar. The furnace body is laid out on a clay-sand mortar with the addition of M400 cement. Crushed stone, sand and Portland cement will be used for the foundation. How much building materials are needed depends on the stability of the soil and the depth of the laying.

How to choose a brick barbecue design: information relevant when developing a project

Among the many different barbecue options, the most popular are:

Only barbecue is prepared

Only barbecue is prepared

barbecue complexes with wide functionality;

The structure provides ample opportunities

The structure provides ample opportunities

barbecue fireplaces.

Fireplace, near which it is always comfortable

Fireplace, near which it is always comfortable

Complexes are performed with angular and frontal. They can have many elements, the need for which in each specific case is determined individually. Judging by the drawings and photographs, the dimensions of a barbecue made of front-type bricks are usually 3.7 × 1.3 m, corner ones - 2.5 × 3 m.A good design can include not only a brazier, but also a smokehouse, a countertop, an area intended for cooking food, various cabinets and more.

Front-end complex with wide functionality

Preparatory stage

At this stage, we prepare the tool and purchase the material.We assume that our outdoor stove will have a cauldron, a barbecue, a frying surface and a fireplace compartment, in which the classic barbecue is actually being prepared. Plus, this kitchen complex has a coal preparation chamber and a wood log.

Tool:

- Master OK;

- Half-scrubber - wooden and metal;

- Hammer - rubber and regular construction hammer;

- Buckets - at least 2;

- Concrete mixer, in the absence of such, prepare a trough and a couple of shovels;

- Grinder with discs for cutting ceramics;

- Levels - normal building and hydro level;

- Plastering rule.

You won't be able to lay out a high-quality oven without a good tool.

Material

For the construction of the furnace itself you will need:

The supporting structure of the stoves is laid out of solid red brick.

- Red solid brick - forms the basis of the structure;

- Fireclay refractory bricks - for lining fireboxes from the inside;

- Ash pan doors - 2 pcs;

- Firebox doors - 2 pcs;

- A metal box with a door - a chamber for the preparation of charcoal, made of a sheet with a thickness of 5 mm;

- Grates - 2 grates;

- Corner 50 mm - 12 m;

- Cast iron plate for the frying surface of the oven - 1 piece;

- Metal plate with a thickness of 10 mm or more for arranging the base under the cauldron - 1 piece;

- Cement mortar - cement-sand mortar 1: 3 is used for masonry of the main structure;

- Refractory mortar - for laying fireboxes and a fireplace, you can buy a ready-made stove solution or make it from clay (1 part), sand (1 part) and cement (0.1 part) with your own hands.

A professional oven solution is much easier to work with.

The instruction is simple:

- Soak the clay for a week and stir it to a jelly state;

- Add sifted sand;

- Add cement and mix well.

To build a foundation for a barbecue on the site, you will need:

- Cement grade 500, the same cement can be used for masonry mortar;

- Sand;

- Gravel or crushed stone of the middle fraction;

- Reinforcement or ready-made reinforcing mesh with a cell of 50-100 mm;

- Formwork board, preferably planed.

We start construction

If you are serious about building such a structure as a brick barbecue with your own hands, be prepared for several stages of work.

In particular, when building such complexes for preparing food in the open air, you must be able to do the following work:

- prepare a solution;

- perform brickwork;

- fill the foundation;

- carry out the necessary finishing work.

Below is a detailed description of how to complete this or that stage of the work. Carefully read the recommendations, then you will not have any problems with the construction of the oven in the open air.

Features of pouring the foundation

Since a brick barbecue can still be rightfully considered a capital structure, it will require a full-fledged foundation. The best option in this case would be a strip foundation, which is characterized by ease of pouring and relatively low flow costs.

Pouring the foundation for the barbecue

The instructions for pouring the strip foundation provide for the following work:

- marking (the best way to do it is to hammer in the pegs and pull the string);

- prepare a trench, up to thirty centimeters deep, but not less than twenty centimeters;

- fill a layer of gravel on the bottom of the trench, which is well moistened with water and rammed;

- a foundation mesh or any old metal products that you no longer need (crowbars, elements of a steel fence, etc.) are laid on top;

- formwork is being prepared from boards, which should rise above the trench by about ten to twenty centimeters;

- after that, you can pour in a solution, for the preparation of which three parts of sand and one part of M300 cement are used;

- be sure to keep track of the level of the foundation to be poured - it must be the same.

How to choose a brick and prepare a mortar for laying it

You can start laying on the fifth day after pouring the foundation. Many are interested in how many bricks are needed to build a barbecue at their summer cottage. The answer to this question will be given to you by the project according to which the furnace will be erected.

If we talk about what kind of material to select, then it should be noted that ordinary building bricks are not quite suitable for these purposes.

You will need the following type of building material:

- facing;

- refractory.

There will be no problems with the choice of the first one - it all depends on personal preferences, as well as what kind of oven you want to see. To create the base, a 150 m double silicate brick is suitable, with which the lower rows are laid.

Basic preparation for the oven

But regarding the refractory, we note that it can be of several types:

- carbonaceous;

- basic;

- quartz;

- fireclay.

Each of them has its own properties, but fireclay refractory bricks, alumina, are best suited. It contains clay that can withstand temperature changes, as well as withstand the elevated temperature characteristic of the furnace for a long time.

Features of the preparation of the solution

For external masonry, a standard cement mortar is used, but for laying refractory bricks it is customary to use a clay mortar, which has certain preparation characteristics.

To make it, you need the following ingredients:

- cement m200;

- fine, dry sand, preferably pre-sieved;

- clay.

The preparation of such a solution will take a certain amount of time. For example, clay should be soaked in water for about five days. Then it is thoroughly mixed. You may need to add some more water.

In a ratio of one to ten, sand and cement are added to the clay. As a result, the price of such a solution will be minimal.

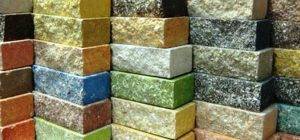

Brick types

Ceramic brick is made of baked clay, it has high strength, thermal conductivity, frost resistance and water resistance. Thanks to these properties, ceramic bricks hold a high position among the variety of masonry materials. Ceramic bricks can be used for laying ducts and chimneys in barbecues. And Vitebsk ceramic bricks can also be used to build a firebox (barbecue).

Hollow brick, it is also slotted and facing, it is a brick with through holes, which can have a round, oval, rectangular or square shape. Oval and round voids significantly reduce cracking during brick making. Also, voids make up a considerable part of the volume and therefore less raw materials are used to make such bricks than to make solid bricks. Well, closed volumes of dry air increase the heat-insulating properties of the material, but only at the same time, the masonry mortar should be thick enough so as not to fill the holes. This brick is not suitable for laying barbecues in places where fire contact occurs.

Solid brick used for laying stoves, barbecues, fireplaces and chimneys. It can be embossed, in which case its use will be necessary in places requiring plastering (walls, partitions), because such a brick provides good adhesion to the plaster. Solid bricks can be produced with technological voids in order to relieve internal stress during firing, which significantly reduces the number of cracks. Well, since mostly solid brick is produced without voids and with low porosity, its water absorption will be low to 8%, and its calorific value will be high. In cases of using such a brick, additional insulation may be required.If we talk about the construction of a barbecue, then it is solid brick that must be used so that the structure is strong and not subject to destruction.

Clinker brick has unique physicochemical properties. This brick has a very low water absorption, which provides it with a high level of operational and decorative properties. The material can be used in an aggressive environment, both for finishing and cladding. Has a rough texture, which has a color from light yellow to dark brown. There are about a hundred shades derived by adding various additives to the composition of raw materials. The main raw material for the manufacture of clinker bricks is a special type of clay (skinny clay), and mineral additives of igneous rocks are used as a charge. Solid clinker brick, well suited for barbecues in places such as ducts and chimneys.

Pressed (silicate) brick is one of the most budgetary options for choosing a brick. Pressed brick has good compatibility with any kind of masonry mortar, and also, pressed brick has high sound insulation. But such qualities as high moisture absorption and low thermal conductivity and fire resistance do not allow using this brick for laying ovens and barbecues.

Main preparatory steps

To build a brick barbecue for a summer residence, it is necessary to carry out certain preparatory work. The quality of the future furnace also depends on how correctly they are carried out.

Photo of a simple barbecue

First - the construction site

First of all, it is necessary to take into account the requirements of fire safety. Since during cooking, non-extinguished sparks can fly out of the chimney and get onto flammable objects. It is also necessary to take into account which direction the wind most often blows.

At the same time, a barbecue for a dacha made of bricks should be located near the main buildings:

- at home;

- gazebos in which you can eat all food cooked on the fire;

- baths, etc.

It is necessary to provide a comfortable approach to the barbecue, and pave an area of solid materials around it.

It is recommended to immediately foresee the possibility of building a roof, which will not only allow cooking in the rain, but also protect the stove and extend its service life. (see also the article Available designs of brick gazebos with barbecues for free - a detailed description of the construction process)

Barbecue in the form of a Russian oven

Variety of projects

Before starting construction, you should decide on the project of the future furnace. Of course, there is nothing difficult about this. First, there are many open source projects. Secondly, if the dimensions of a brick barbecue are small, and the oven itself does not provide for any frills in its design, then the project is easy to do on your own. (see also article Brick BBQs: Projects and Construction Stages)

When creating a drawing, the following indicators must be taken into account:

- the size;

- design features;

- the presence of additional elements (roofs, food stands, dishes, etc.);

- personal preferences.

You don't want to pore over the project on your own, and the options presented on the Internet do not suit you, you can contact a specialized company.

Of course, in this case, you will have to pay for the creation of the project, but all your preferences will be taken into account in it, and the oven itself will be original and exclusive. For example, this could be a brick corner barbecue.

What building materials will be needed

After the project has been selected, proceed with the selection of building materials.

In particular, you will need:

- two types of bricks; cement, sand and clay;

- mesh for strengthening the foundation;

- material for waterproofing (roofing felt or roofing felt).

A little clarification should be made, since a barbecue brick should be not only ordinary, clinker, but also refractory. It is the second type that the oven is lined inside.

Beautiful BBQ Oven Project

You should also choose equipment for arranging the furnace itself, including:

- grill;

- coal pallet;

- chimney valve;

- table top.

It is imperative to provide for where the firewood will be stored, as well as other items and materials used in cooking. For example, why not provide several small shelves from the end?

How to set up a grill

The main element of the garden oven is the grill.

So, barbecue grills are installed as follows:

- at a height of about seventy centimeters from the ground, which corresponds to approximately eight brick rows;

- match the height of the person who will be cooking.

Today, in retail outlets, it is easy to easily purchase everything you need to equip a barbecue inside the oven without any problems.

In particular, these sets include the following constituent elements:

- pallets;

- necessary fasteners;

- reliable, fireproof grating.

Finishing work and decoration of the stove

A brick oven built by your own hands should look beautiful and neat. It is with such a design that it will be pleasant to work and relax nearby. It is better to lay the floor around the stove with beautiful decorative tiles. Stone is usually used to decorate countertops and other horizontal surfaces.

Did you know? On the island of Lanzarote (Canary Islands), a restaurant called El Diablo is open, where visitors are offered to taste dishes cooked over the mouth of an active volcano.

The marble finish looks very nice. When the stove is completely ready, it must be allowed to dry for 4-5 days, and then a test firebox should be carried out with a small consumption of wood (2-3 kg). It is necessary to heat the stove with open windows and doors in the gazebo.

So, if the area and opportunities allow, then at the summer cottage you can build a gazebo with an oven for cooking over an open fire. This is not difficult to do. It is enough to purchase the necessary materials, prepare tools and use the above recommendations and masonry schemes.

Preparation for construction

To begin with, cover the hardened concrete slab with 2 layers of roofing material in order to provide waterproofing of the brick structure. Collect the standard set of stove-top tools shown in the photo: trowels, brushes, measuring devices, and so on.

A solution for a yard oven - a barbecue can be done by hand or you can buy a ready-made building mixture. In the first case, proceed in this order:

- Soak the clay, as cleaned as possible of the earth, in a trough with water for 1-2 days.

- Pass the earthen solution through a sieve, separating pebbles and crushing lumps.

- Sift sand and stir with liquid clay in a ratio of about 1: 1.

- Before laying, add 200-300 grams of cement per bucket.

The finished solution should not stick very much to the trowel, and when squeezed by hand, give a minimum of cracks. For the best properties, experiment with the proportions of sand and clay.

We build a barbecue complex with a hob

To make an outdoor oven in the country - a barbecue is capable of any home craftsman who knows how to work with bricks. The purpose of this article is to help the homeowner build a garden stove correctly with his own hands, using a ready-made project with orders. For convenience, we present some drawings and examples of masonry.

For the construction of an outdoor oven at a summer cottage, we propose to implement the project shown in the photo. Let's list the technical features of the structure:

- 2 workplaces that can function at the same time - brazier and hob;

- overall dimensions in the plan - 1660 x 1020 mm, height - 3220 mm (including the chimney with a head);

- collection of flue gases from both fireboxes is organized in one pipe;

- the design is simplified as much as possible - instead of the arched vault of the firebox used in the Russian stove, there is a direct overlap on a metal frame;

- under the barbecue there is a niche for storing and drying firewood;

- the chimney is equipped with a closed brick head, which excludes the ingress of precipitation into the flue.

At first glance, the design of a universal barbecue stove seems complicated, but in reality it is quite simple to perform. It is better to place the structure under a canopy or inside a gazebo so that the masonry is not washed by rains and stayed longer.

Before starting construction on the veranda, it is necessary to provide a platform measuring 176 x 112 cm (a margin of 50 mm on each side of the furnace body). Take care that the chimney does not line up with the supporting roof beams, otherwise the roof will have to be remodeled.

Reference. There is a simpler solution - to fold the barbecue on the street in the form of a corner fireplace, in which you can grill kebabs

A few words about barbecue oven models

The oven presented above is far from the only option for a barbecue on the site, you can take this instruction as a basis, and develop your own model.

Here are some of the more popular designs:

| Image | General characteristics |

|

Fireplace.

Convenient small design designed exclusively for barbecuing. A small countertop around the base of the fireplace will be a good help. |

|

Complex: cauldron, barbecue and smokehouse.

The central element of this complex is a hot-smoked smokehouse. The cauldron is built into the tabletop, and the fireplace under the barbecue simultaneously acts as a barbecue. |

|

Stove with fireplace and sink.

The brazier is not provided here; instead of it, stands for skewers are made in the fireplace. The countertop with sink and handy cupboards transforms the barbecue into a complete kitchen. But the oven is not very conveniently installed, it is too far from the desktop and the owners will have to make too many unnecessary movements. |

|

Metal oven.

A compact mobile barbecue oven made of metal is very convenient, the quality of cooking in such ovens is quite high, and the main plus is that the structure can be easily removed if necessary. In addition, at cost, such barbecues are several times cheaper than brick ones. |

|

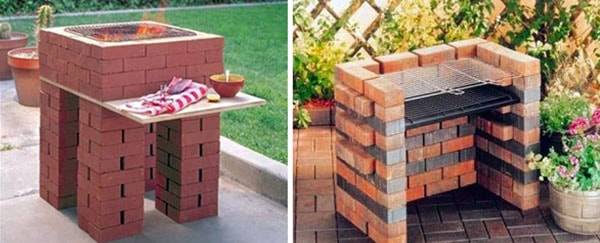

Lightweight brick oven.

The easiest brick oven to make. A powerful foundation slab does not need to be poured under such a structure. You can fold this stove with your own hands right on the asphalt in the yard in one weekend. |

|

Corner oven.

Perhaps the most convenient design in it follows the principle of the golden triangle, when the distance between the key sectors does not exceed 2.5 m. The stove on the frying surface of the oven is also convenient because it has round removable rings, removing which you can insert a cauldron into it. |

Refractory bricks

Refractory (fireclay) brick used in places where high temperatures are present, it can be: fireplaces, stoves, chimneys and other types of heating structures. A simple red or ceramic brick in such conditions will not last long, it does not withstand high temperatures and can begin to melt at temperatures above 1200 degrees Celsius. With respect to the regular heating and cooling cycle, this brick crumbles, which further leads to its complete destruction. In such conditions, where high temperatures and regular cycle changes, refractory brick would be the best choice. It is made from fireclay refractory clay, which is the main component in its production.

By its appearance, refractory brick almost does not differ from simple red brick, but at the same time it can easily withstand temperatures above 1350 degrees. The ability to withstand high temperatures is explained by the fact that the refractory brick consists of 70% fired fireclay clay and 30% graphite or coke powder (these components are binders, they are added so that the brick does not crack during firing.) Weight of refractory fireclay bricks 3 , 4 kg. field of application - furnaces, chimneys, simple home stoves, fireplaces and even combustion chambers for oil and gases in the production of glass, porcelain and steel. Refractory bricks withstands exposure to high temperatures for a long time and has a high heat capacity, due to which it is able to give off heat to the room for a long time after the end of the firebox.

Refractory bricks are subdivided into subtypes: basic, carbon, quartz and alumina. Two of these subspecies - carbonaceous and the main one - are used in steel production.

- Basic - a lime-magnesian base is used for its manufacture, this type of refractory brick is used for the production of Bessemer steel.

- Carbonaceous - is the main material for the construction of blast furnaces.

- Quartz - This brick is mainly composed of quartz and sandstone, it does not involve contact with anything other than metal and fire. In particular, quartz brick has poor contact with various alkalis.

- Alumina - the temperature range of application of this type of brick is 1000 - 1300 degrees Celsius. It tolerates repeated sudden temperature changes well. Convenient for use in household stoves, most household fireboxes are made from this brick.

In conclusion - the simplest options for stoves

We deliberately suggested building a serious garden barbecue complex right away, since the multifunctional oven is of greater interest to users. If you manage to fold a similar brazier out of brick, then the extension of bedside tables, a smokehouse and even the construction of a fireplace will not be a big problem.

Instead of a capital structure, you can make a simple structure shown in the photo. No mortar is required here, and no foundation is needed either: just buy a ready-made barbecue mesh and lay out a brick cabinet according to its size. To prevent the building from collapsing, select a flat, solid area.

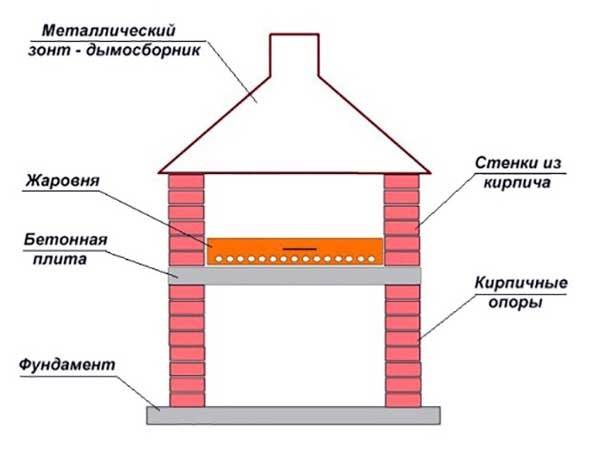

The simplest grill with a smoke collector is built in the form of two retaining walls on a cement-sand mortar. For the installation of the brazier, a reinforced concrete slab is cast (or a ready-made one is used). An alternative option is to tie the brick walls with a frame from the corners. The smoke collection umbrella is made of ordinary roofing steel.