Reducing gas consumption in gas boilers

If there is no need to use double-circuit boilers, it is better to refuse them, since they consume more gas. However, if it is impossible to install economical options for heating devices, it is possible to reduce the consumption of blue fuel. To do this, you must follow these recommendations:

- install plastic double-glazed windows in the rooms, as well as insulate the walls from the outside;

- if there are a large number of large icicles on the roof, the main heat loss is carried out precisely through it, therefore, it must be blocked or isolated;

- when choosing, it is better to give preference to modern models equipped with automation;

- installation of thermostats and regulators on radiators will reduce fuel consumption;

- the presence of special modes or timers on heating equipment allows you to maintain a minimum power on certain days;

- technical inspection of the equipment should be carried out annually to avoid degradation of its performance.

Two-position thermostats - thermostats for gas boiler

Electromechanical two-position room thermostat Protherm Exabasic for a gas boiler is simple, cheap, but temperature fluctuations in the heated room will be significant - about 2-3 ° C.

Electronic two-position room thermostat Protherm Exacontrol provides higher accuracy and stability of maintaining the temperature in the room, has a function of protecting the heating system from freezing. The display shows the current room temperature.

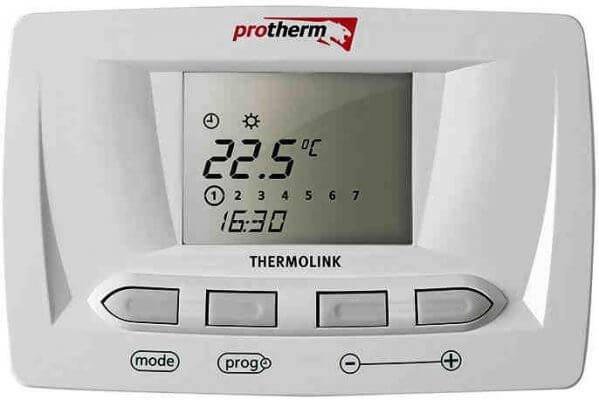

Electronic two-position programmable room thermostat - thermostat Protherm Thermolink S

Thermolink S is an electronic two-position programmable regulator, which differs from previous models in that it allows you to set the temperature according to one weekly program with the possibility of combinations of three different time intervals (morning, afternoon, evening).

Weekly program for regulating the heating temperature in a house, apartment with a room thermostat Protherm Thermolink S

In addition, it is possible to set one of three temperature modes: "Comfort", "Eco" (economy) or "Vacation" mode.

Thermolink S regulator supports the function of frost protection of the heating system when the room temperature drops to 3 ° C.

The display shows the current room temperature, as well as the time and day of the week.

Features of the boiler operation with a two-position thermostat

Two-position thermostats have a relay with contacts at the output. Contacts can be in one of two positions: closed or open. Closed thermostat contacts connected to the boiler switch on the boiler heating mode. When the contacts are opened, the heating mode is switched off. The boiler works in cycles - on / off. There are no changes in the heating mode settings on the boiler itself.

The cyclic operation of the boiler under the control of a two-position room thermostat can hide the boiler timing, which occurs due to a significant discrepancy between the capacities of the boiler and heating devices (for timing, read the beginning of the article).

Many even argue that the boiler clock can be eliminated not by adjusting the gas valve, but by installing a room thermostat.

However, if the power of the boiler significantly exceeds the power of the heating devices, then the frequency of the boiler operation cycles with a two-position thermostat increases. The boiler switches on and off more often. In addition, the range of temperature fluctuations in the room expands.

The correct setting of the power of the gas boiler is also necessary when the boiler is operated under the control of a room thermostat.

The sensitivity of the electronic two-position room thermostat is 0.5 ° C. The thermostat switches contacts when the room temperature changes by half a degree.

Dependence of gas consumption on internal and external factors

Russian gas fuel consumption rates are based on Soviet technical standards. This is an average indicator for the former territory of the Soviet Union, which takes into account:

- ambient temperature;

- wall material and thickness;

- a variety of window structures installed in the house;

- method of ventilation of the room;

- technical level of boilers.

But in a specific case, these norms do not always work. For example:

- during the construction of the building, walls with increased thickness were created, or a material with minimal characteristics of heat loss was used;

- entrance doors and wooden windows were replaced with metal-plastic ones;

- when arranging the building, comprehensive insulation was carried out (for example, the walls, the attic and the basement were improved).

The factors above are external. The impact of each factor from the specified list has a direct impact on gas consumption in relation to the current technical standards.

Therefore, the first step towards additional savings in winter is the purchase and installation of a gas meter.

There are also internal factors that further reduce gas consumption, especially in winter.

There are also internal factors that further reduce gas consumption, especially in winter.

- Dismantling of an old gas boiler made in the Soviet Union. Instead, the owner integrates into the premises a modern heat generating unit, complemented by a circulation pump.

- If a country house was built during the Soviet Union, there are probably steel or cast-iron radiators inside it. Instead, new aluminum or bimetallic counterparts must be installed. Additionally, a floor heating system (water or infrared) is equipped, which supports temperature control by zones.

- Installation of an electric boiler, air conditioner, which will be paired with a forced ventilation system.

- Using alternative heat sources together with gas boilers.

What is the specific result provided? First of all, the overall effectiveness of the measures outlined above varies from 30 to 50 percent, depending on the particular case.

In official Internet sources, figures are often found at the level of 70-80 percent. This figure is probably overstated, so you cannot rely on it.

Underfloor heating thermostats

A thermostat is a device that measures the temperature of something, compares this temperature with a predetermined temperature and, depending on the result of the comparison, instructs the servo to turn on or off the control valve. Thus, by turning on or off the supply of heat, the thermostat maintains the temperature of something with minimal deviations from the set value, usually with an accuracy of + \ - 0.5 ° C.

To measure temperature, the thermostat can have a temperature sensor built into the body of the device. The temperature sensor can also be remote. The remote sensor is connected to the thermostat with wires.

The thermostat always has buttons or wheels, with the help of which the temperature is set, the stability of which it must ensure. All thermostats have an indication of the current state - "heating on" or "heating off".

The thermostat, depending on the method of connection with the executive servo drive, can be wired or wireless.

The smallest budget option is a wired thermostat. The device itself is installed in a room in which it must maintain the temperature. The underfloor heating collector with servo drives can be installed in another place, for example, in a boiler room. These devices are connected to each other by thin wires.

The wireless thermostat transmits the control command to the collector servo drive via radio.For this, there is a radio transmitter in the thermostat housing, and a radio receiving unit is installed near the collector. Installing a wireless thermostat can be beneficial when automation work is carried out in an already built house - there is no need to lay wires and disturb the decoration of the premises.

Thermostat with the function of regulating the room temperature and the temperature of the warm floor. It works with two temperature sensors, one in the device case, the other remote, in a warm floor.

To regulate the air temperature and the temperature of the warm floor in accordance with the algorithm - we adjust the air temperature in the room, but do not let the floor heat up above the set temperature, a thermostat with the appropriate functions is needed.

Underfloor heating thermostat:

- Must work with two temperature sensors: a built-in air temperature sensor and a remote floor temperature sensor.

- The thermostat must be able to set separately the air temperature and the underfloor heating temperature.

- An algorithm for regulating the air temperature with the limitation of the temperature of the underfloor heating surface must be laid down.

Switching module for connecting several underfloor heating circuits to one thermostat

One thermostat can control several servo actuators installed on one manifold. The thermostat with servo drives is connected through a special block - a switching module.

How to reduce gas consumption?

If suddenly gas costs do not suit you, then the following recommendations will help you optimize them:

- Insulate your home. The better you insulate the house, the less heat you will have to go outside.

- Check windows, doors for possible cracks. A lot of heat is lost through such structures.

- If you are using an open heating system with a cistern on the roof, then convert the heating system to a closed one. A significant amount of heat is also lost through the roof.

- If you have a simple floor-standing boiler, then replace it with a wall-mounted one. Costs can also be reduced by 10-30%.

- Service your heating system. Sometimes it can also have a positive effect on gas consumption. This is especially true for the boiler itself.

Calculation of the consumption of liquefied gas

Many boilers can be powered by LPG. How beneficial is it? What will be the consumption of liquefied gas for heating? All this can also be counted. The technique is the same: you need to know either the heat loss or the boiler power. Next, we convert the required amount into liters (units of measurement of liquefied gas), and, if desired, we calculate the number of necessary cylinders.

Let's take a look at the calculation using an example. Let the boiler power is 18 kW, respectively, the average heat demand is 9 kW / h. When burning 1 liter of liquefied gas, we get 12.5 kW of heat. This means that to get 9 kW, you need 0.72 liters (9 kW / 12.5 kW = 0.72 liters).

- per day: 0.72 l * 24 hours = 17.28 l;

- 17.28 liters per month * 30 days = 518.4 liters.

Let's add a correction for the boiler efficiency. It is necessary to look in each specific case, but take 90%, that is, add another 10%, it turns out that the consumption per month will be 570.24 liters.

Liquefied gas is one of the heating options

To calculate the number of cylinders, we divide this figure by 42 liters (this is the average amount of gas in a 50 liter cylinder). In total, this boiler will require 14 cylinders of liquefied gas (13.57). And consider the cost yourself - the prices in the regions differ. But don't forget about shipping costs. By the way, they can be reduced by making a gas holder - a sealed container for storing liquefied gas, which can be refueled once a month or less - depending on the storage volume and needs.

And again, do not forget that this is only an approximate figure. In cold months, the consumption of gas for heating will be higher, in warm months - much less.

Thermostatic valve on the radiator reduces gas consumption

Thermostatic valve - a thermostat for a radiator reduces gas consumption for heating. Installing a thermostat on a radiator is a mandatory requirement of building codes.

Weather regulation changes the temperature of the heating water in the heating system in depending on the temperature outside.

The room thermostat regulates, adjusts the temperature of the heating water depending on the temperature in one room, where it is installed.

A room thermostat is always installed in the largest room of a house or apartment. The temperature in other rooms will differ from that which is required in one direction or another. For example, in order to save gas, it is beneficial to keep the temperature in rarely visited rooms lower.

The temperature in other rooms can be regulated using thermostats installed at the heating water inlet to the radiator. A thermostatic valve or an electronic radiator thermostat is used as radiator thermostats.

The thermostatic valve regulates the heating water flow through the radiator so that the room temperature remains constant, set on the scale of the thermostatic head. The control head of the thermostatic valve contains a bellows filled with liquid or gas. When the temperature in the room changes, the temperature of the liquid (gas) changes. As a result of thermal expansion of the liquid (gas), the bellows changes its position and acts on the valve stem of the valve on the radiator pipe.

On sale you can find thermostatic valves with a remote temperature sensor. Such devices provide a more stable temperature in the room, since the influence of a nearby radiator and window is excluded.

Electronic radiator thermostat

Electronic programmable thermostat for a heating radiator. Powered by AA batteries, 2 pcs. Adjustment temperature from 5 ° C to 35 ° C. Hysteresis ± 0.5 ° C. LCD display.

The electronic radiator thermostat, like the head of the thermostatic valve, is mounted on a control valve on the radiator pipe. Compared to a thermostatic valve, it has many more control functions.

The radiator thermostat consists of a built-in or remote thermosensor and a servo drive that opens and closes the valve on the radiator.

In the programmable radiator thermostat, you can select the temperature mode for daytime and nighttime, for different days of the week. This allows for greater comfort and gas savings. For owners of a country house, a programmable thermostat will maintain an economical heat mode on weekdays, and will switch to warming up mode before arrival.

An electronic programmable radiator thermostat can provide:

- Indoor temperature indication.

- Battery discharge indication.

- System malfunction indication.

- Operating mode indication.

- Installation of an economical and comfortable temperature regime.

- Setting a schedule for alternating between comfort and economy mode for each day of the week.

- Childproof lock function.

- Room ventilation function.

- The function of protecting the valve from acidification.

- System frost protection function.

Nuances of operating liquefied fuel boilers

Before deciding to heat your home with a propane gas boiler, you should talk to experts, find out the opinion of neighbors who also use such heating. Perhaps, it is in your case that this type of fuel will not justify itself.

It should be noted that a special room will be needed for the storage and operation of gas boilers. It is equipped in accordance with all fire safety rules:

- The room must be located outside the residential building and have a separate entrance.

- Adequate air intake must be ensured - 160 m3 / h.

- At least one window is required.

- Flammable materials and agents must not be stored together with cylinders: rags, gasoline, chemicals, etc.

- External and internal walls must be made of non-combustible materials.

Based on the listed requirements, we can conclude that it is impossible to heat the garage with liquefied gas.

Most often, cylinders are placed in large metal containers.

The best option for storing liquefied fuel would be to install a gas tank. It is a gas reservoir that is located underground. If this is not possible, you can install the gas tank on the ground, away from home.

Using a gas tank is much more convenient than constantly changing cylinders. The large volume of the gas holder allows for a long period of time to supply the boiler with gas, it is enough to refuel 2-3 times during the heating period. Also, using a reservoir will quickly dispel the smell of gas in the air.

In addition to the gas tank, it is possible to organize a convenient gas supply from cylinders using a ramp. Up to 10 cylinders are connected to it. The ramp has the form of a dividing two-arm manifold. First, gas is consumed from the main cylinder, and when it runs out, it switches to reserve tanks.

Note! Gas equipment should only be connected by specialists. After all, gas is a very explosive substance and connection errors can be costly to the owner

Today on the market there is a huge range of gas boilers that can operate both on main gas and on liquefied gas. There is an opportunity to purchase a unit for every taste and budget. But before making a purchase, you should find out about the gas consumption of boilers operating on propane.

It is better to opt for the unit of a company that has been working on the market for a long time and has proven itself well. These include BOSCH, Buderus, Vaillant and others.

Gas flow control

In order to control the gas consumption during the operation of the boiler, both on liquefied fuel and on the main one, a pressure gauge should be installed. He will help determine the remaining amount of gas in the cylinder and tell you when to prepare a replacement.

The best option is to install two pressure gauges: one will determine the pressure in the cylinder, and the second in the pipeline. This will allow you to control the gas pressure in the pipeline and regulate its optimal value.

Approximate calculation of gas consumption

So, let's say you have already calculated the heat loss at home. If not, then for most regions, a rough value of heat loss of 100 W per 1 square meter is taken. m. Let's say our house has losses of 10 kW and we need to find out how many cubic meters per hour our boiler will consume. To do this, you need to understand how much heat we can get from one cube of gas.

According to GOST, 9.3 kW of thermal energy can be obtained from one cube of gas. Ideally, at 100% boiler efficiency with a heat loss of 10 kW, we will spend 0.93 cubic meters of gas per hour.

And now why this calculation can be called the most inaccurate. Even if the gas complies with GOST, the boiler performance is different. A traditional wall-mounted boiler has an efficiency of 92-93%. Therefore, another 8% must be subtracted from 9.3 kW. This will be a more accurate figure.

Another thing is that we calculated the maximum flow rate at the lowest temperature. But this temperature is not always the case. It might be warmer today, colder tomorrow. And the losses will be different. Therefore, from here you can take some average value and you will get the most pessimistic gas consumption figure.

It is simply unrealistic to calculate something exactly. (Of course, if you want to conduct a static analysis of temperature measurements in your region over a hundred years, find dependencies and compare everything, then a more accurate calculation will be obtained. But it is better to stop even thinking about it.)

LPG boilers

Modern gas heating on liquefied gas involves the use of a whole complex, consisting of several types of equipment and a heat supply system. But the main unit is still the boiler, which provides heat from fuel.

As in traditional heating structures, a gas-fired liquefied gas boiler for private buildings makes it possible by combustion to provide heating of living quarters and hot water supply, since a combination of these two functions is possible.

Often, heating equipment that runs on liquefied gas is compact in size, productivity and high efficiency rates, sometimes reaching 95%. In addition, a liquefied gas heating boiler (see photo) has a low cost and, together with its economy, can significantly reduce the costs associated with the purchase of fuel.

In addition to all the advantages described earlier in the article, this type of fuel assemblies differs from devices operating on natural gas in that they can function at low pressure of the supplied fuel. In order to fully satisfy the need of residents of a large house for heating and hot water, it is enough to have a pressure in the system equal to only 3-4 mbar, while when working on main gas, this indicator should be much higher. Even in the presence of low pressure in the structure, heating with liquefied gas has insignificant fuel consumption. This saves a considerable amount of money from the family budget. At the same time, liquefied gas for heating will be consumed as efficiently as possible.

Owners of private households should be aware that liquefied gas heating boilers can be easily switched to another mode of operation - using a different type of fuel, or rather main gas. For this purpose, not only the injectors are replaced, but also other equipment elements. Thus, it turns out that the buyer buys two boilers in one and saves a lot of money and time.

Saving gas when heating, the main ways to reduce fuel consumption

You need to start saving energy from the very beginning - with the purchase and installation of a modern heating boiler.

- The required power of the boiler is calculated based on the following rule: per 10 sq.m. of the heated area of 1 kW of thermal energy, while the height of the ceilings for this calculation is taken not higher than 3 meters. So, a house with an area of 200 sq.m. can heat a boiler with a capacity of at least 20 kW. After carrying out the necessary calculations, a heating unit is purchased with a small tolerance upward and piping is done. The most profitable heat carrier distribution system is considered to be a collector one.

- Such a system makes it possible to regulate the temperature in each room, depending on the frequency of its use by the residents. This can be done manually, or you can install thermostats that will regulate the heat of the water in the radiators.

- Heater automation. There are many different types of automation on the market, from the simplest to the very expensive. For example, one of the new products is thermostats with outdoor air temperature sensors. When the air temperature "overboard" rises, the automatics begins to supply a smaller amount of fuel to the burners, and this is already a real savings in gas when heating a private house.

- According to many experts, the "warm floor" system is a more advantageous type of coolant supply. When installed, warm air is more evenly distributed throughout the building. At the same time, water is supplied to pipes in the floor with a temperature of 65 degrees, and to heating radiators - 95 degrees. However, it becomes more difficult to regulate the temperature in different rooms.

- The provision of hot water for household needs is best organized using a gas flowing water heater (column) or a double-circuit boiler. It should be noted that there is one burner in a double-circuit boiler, so when it heats water for the bathroom, the heating does not work at this time.

Russian brands

Floor standing gas boilers are one of the main directions in the work of all Russian manufacturers.

Consider some of them

:

-

Conord.

The head office is located in Rostov-on-Don. Floor standing gas boilers are available in single and double-circuit versions.In total, 4 series with a capacity from 8 to 30 kW are offered, the difference between which is in the number of circuits and the type of automation; -

Signal.

The plant is located in Engels, Saratov region. Currently, two series of floor-standing non-volatile boilers are being manufactured - S-Term and Comfort. The power of the boilers ranges from 7 to 150 kW, which allows you to choose the right model for any premises and conditions. There are one- and two-circuit models; -

Siberia.

Products of the company LLC "Rostovgazoapparat". This is a group of non-volatile floor-standing units presented in three series - Economy, Comfort and Premium. The power range is from 11 to 50 kW. There are single and double-circuit models; -

ZhMZ.

These are gas boilers manufactured by the Zhukovsky Machine-Building Plant. The range includes single and double-circuit models of non-volatile floor-standing units with a capacity of 11 to 68 kW. They are produced in three series - Economy, Universal and Comfort, differing from each other in the type of automation and the shape of the case; -

Lemax.

Manufactured in Taganrog. The plant's products are wall and floor models with one or two circuits. Three series are produced - Premium, Premier and Prime. The power of the units ranges from 10 to 35 kW.

Most of the boilers are non-volatile, which is determined by difficult working conditions, dilapidated power supply networks or a complete lack of connection in remote villages.

This approach is quite justified - in cold weather, a sudden power outage will immediately stop the heating system, and if the energy supply is not restored in a matter of minutes, defrosting of pipelines is inevitable.

.

The only solution will be an emergency drainage of the coolant, but this measure is not always possible.

Therefore, the presence of heating boilers independent of external conditions is a very useful solution for the domestic user.

Automatic temperature control in a house with underfloor heating

In a house with underfloor heating, it is necessary to have three automatic temperature control systems: 1 - underfloor heating according to the air temperature in the room, but with limited floor temperature; 2 - radiators according to the air temperature in the room; 3 - boiler weather control based on the outside air temperature.

As is known,underfloor heating can be either "comfortable" or "heating".

"Comfortable" warm floor slightly warms up the surface and provides a pleasant sensation when a person is on the floor. The main supply of heat to the room is provided by radiators. For a comfortable warm floor, it is necessary to maintain a constant, coolant temperature.

"Heating" warm floor, in addition to comfort, it provides complete heating of the room.

In the conditions of the Russian climate, the relatively low heat output of the warm floor makes it suitable most often only for comfortable heating.

An air temperature sensor in the thermostat housing and a sensor in the floor provide room temperature control and protect the floor from overheating

In a house with a comfortable underfloor heating, three automatic control systems are required to control the temperature.

One system that regulates the operation of underfloor heating must be controlled according to the room temperature until the temperature of the floor surface reaches a comfortable level. That is, in the off-season, the house will be heated with warm floor heating.

If the floor temperature reaches the upper limit and the room temperature drops, the automatic radiator control system is activated. Radiators will warm up the air in the room, add their own heat to the heat that will constantly come from the warm floor.

The mode of heating the coolant by the boiler must be regulated by another automatic weather regulation system that reacts to the outside air temperature.

Considering that the underfloor heating system has a high inertia (heats up slowly and cools slowly), it is recommended to use weather automation to control its operation. Then the temperature of the heating medium supplied to the system will be adapted to the outside temperature. Due to this, together with a change in the outside temperature, the temperature of the heating medium circulating in the floor changes.

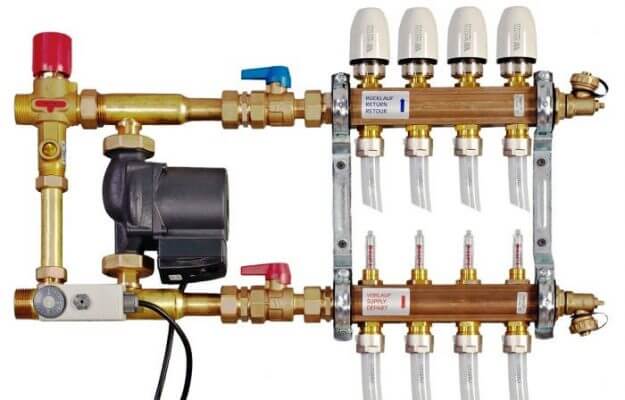

Mixing unit with a circulation pump - on the left. On the right, a collector of underfloor heating pipes is connected to the mixing unit. The manifold is equipped with servo-driven control valves. The valve is controlled by a thermostat through a servo-actuator, which regulates the supply of heat carrier to the underfloor heating circuit, depending on the temperature of the floor surface and the temperature of the air in the room.

Each room with a "warm floor" is at least one circuit (one pipe loop). All these circuits must somehow be combined into one and connected to a boiler or other heat source. Both ends of the pipe of each underfloor heating circuit are connected to a manifold.

To control the temperature of the underfloor heating, it is necessary to select and install a manifold equipped with servo drives on the control valves.

A servo is a device that, when an electric current is supplied to it from a thermostat, acts on a valve, opens or closes it. The servo works like a switch, opening or closing the valve completely. The temperature of the underfloor heating surface will be maintained with an accuracy of +/- 0.5 - 1 ° C.

Method # 2: Reduce hot water consumption

The most difficult thing about energy supply at home is saving on hot water. Water of any temperature is always needed, and in this case it is even more difficult to control oneself than in the consumption of food. And, nevertheless, there are some rules and principles.

- It is believed that a shower is more economical than a full bath. This is not always true, but it is worth considering this opinion.

- A good washing machine uses a lot of electricity but saves water. Most of it goes to the rinsing process, which is automated in the machine. When rinsing by hand, the amount of water is determined by the will of the person and his ideas about the cleanliness of the laundry. So in a duel with a stylish car, both sides can be more economical.

However, if a person sets out to save water, he will do it better than a machine.

The best way to save hot water is the serviceability of pipes and taps, as well as the presence of meters by which you can track costs. A drop from the tap can flow more than the family spends on their real needs.

Why choose a gas boiler?

Installation of heating equipment that consumes gas as fuel has a number of advantages and even advantages over the use of units using other types of fuel:

- high equipment efficiency;

- a wide range of prices for gas boilers;

- no need to create fuel reserves;

- affordability of the price of this natural energy carrier;

- high degree of automation.

By purchasing such an installation, the buyer, naturally, counts on the warmth in the house, safety during the operation of the boiler and the durability of this equipment.

Regardless of the model and manufacturer, the heating temperature of the coolant is approximately the same for all gas boilers. In addition, before being released on the market, the units undergo a mandatory check for compliance with safety standards; top-end models are equipped with self-diagnostics and multi-level protection systems.

After analyzing the service life, the need for repairs and feedback from experts, buyers can be identified up to ten models of gas boilers, characterized by a high degree of efficiency, safety and ease of use.