Manufacturer, CHINA - DO NOT CHINA

What can I say now there are a lot of Chinese pipes, and often I chose it! There were no problems in 5 years of service, so we take it - we are not afraid. Moreover, they are the cheapest of all manufacturers.

Turkey is in second place, the quality is already better, the walls are thicker, although these are all millimeters. Also, they have proven themselves only from the best side. However, their price is higher.

Europe and Russia - if we talk about European manufacturers, then they are the most expensive of all. A meter can reach up to 300 rubles! So the question is spinning - do you need it?

Russia is the best choice, you have to take it! It stands at the level of Turkey, but the quality is European, watch the video there in detail!

Steel

Metal pipes have been used in heating systems for a very long time. There are two types of such pipes - seamless, which are more reliable, and seam, made by bending and welding a sheet metal blank. Which pipes for heating an apartment building are better is an important issue that requires detailed consideration.

Among the main advantages of such products, it is worth noting high mechanical strength, the ability to withstand high pressure and significant temperatures. This is where the list of advantages ends, and the list of disadvantages begins, of which there are many more.

The main operational disadvantage of metal pipes is poor corrosion resistance. It is possible to protect pipes from this factor only from the outside by covering it with a layer of paint (of course, the paint will have to be regularly renewed in order to extend the service life of the product). It is impossible to protect the inner surface of the pipe - and if air has entered the system, or the coolant has been drained from the circuit, the process of destruction of the pipeline will accelerate many times over.

In addition to the already mentioned disadvantage, black steel pipes are distinguished by their heavy weight, which complicates transportation and installation, as well as the need for welding during the installation process. In addition, the inner surface of such products is not smooth, so the hydraulic resistance in the system will be higher.

All metal products have the following positive qualities:

- Excellent resistance to mechanical stress, including pinpoint;

- Ability to work at high pressure, up to water hammer;

- Ability to work at high temperatures;

- Small coefficient of thermal expansion, which allows the use of such pipes without various expansion joints.

Steel pipes are most often used in natural circulation systems. Fine tuning of the temperature regime in such systems is usually difficult, and the movement of water becomes possible only if a constant slope of the entire pipeline is observed.

Often, such systems use solid fuel boilers or stoves with a heat exchanger as heating equipment. In such conditions, overheating of the coolant may well occur - and steel pipes can withstand any possible temperature drops without problems.

Advantages of polypropylene pipes

- low weight (compared to "traditional" steel);

- resistance to the formation of salt deposits, biological fouling, the absence of build-up and rust inside the pipes;

- low cost;

- guaranteed service life up to 50 years;

- pipe walls are thicker than metal-plastic ones, and therefore the pipe is less susceptible to mechanical damage;

- low hydraulic losses in the pipeline due to low roughness;

- resistance to hydraulic shocks;

- low electrical conductivity, electrical tightness;

- polypropylene pipe is able to withstand repeated freezing;

- in a water supply system made of polypropylene pipes, water does not change taste, smell and color;

- the ability to install taps and valves between pipes by soldering, without threaded connections, and, as a result ...;

- ... the ability to seal up the entire structure (pipeline) under plaster or drywall;

- there are clips for attaching to walls, and they (clips) are cheap and available (they are sold almost "at every step" - in many (and maybe in all stores selling goods for construction and repair);

- simplicity and speed of installation, moreover, you can master the installation of a polypropylene pipe in just a few minutes;

- welding of a polypropylene pipe does not require the use of harmful materials (glue, flux, solder, electrodes), so that work can be carried out even in an unventilated room;

- labor costs for installation are less than for steel pipes.

Polypropylene by type

You know, when I myself switched to polypropylene, I ran "on the rake". In the beginning, I didn't know which one to choose and a couple of times ran into trouble in the form of breakouts. However, now I will tell you the whole point - so as not to repeat my mistakes.

Polypropylene is divided into three types: - conventional, reinforced with aluminum and fiberglass.

Normal

It was he who appeared the very first and began to spread widely in the vastness of our homeland. It was with him that I got the first trouble!

pros

The structure here is simple - in fact, the pipe is a hollow cylinder made entirely of durable plastic.

It costs a penny, now you can find options for 50 rubles per meter.

Withstands temperatures up to 95 degrees.

Not susceptible to - rotting, oxidation, etc., can stand for a very long time on the water supply.

It seems like beauty, and only, but not everything is so simple with ordinary polypropylene, it has significant disadvantages.

Minuses:

- It has a very high thermal deformation. So, for example, for 10 meters of pipe, it can be up to 150 mm, the pipe simply sags under the influence of temperature.

- Already at 50 - 60 degrees Celsius, it begins to deform, and at higher temperatures, its deformation can reach maximum values.

These are very big disadvantages. It is because of them that many "legends" appeared about the unreliability of these pipes specifically for heating. However, this is not entirely true.

In my practice, there was such a case - during the heating season, the hot water pipe "sagged", the owner decided to straighten it, pull it up with force, and simply broke it. Often, such breakdowns were precisely because of such owners who tried to achieve the aesthetic "straightness" of the pipes.

This remained a problem for manufacturers as well. You need to do something, and you know - they came up with it.

Reinforced with aluminum

The point is also simple here. If you exaggerate, then a layer of aluminum is inserted into the middle of the pipe, the so-called "foil" or "sheet", whoever calls it what. It was this layer that was designed to combat thermal deformation of pipes for heating and hot water.

Pros:

At first, everything was fine. This option has proven itself only from the best side, its deformation has decreased several times. So the maximum that was noticed is about 3 - 5 cm. This is very good. However, these pipes are also far from ideal, and therefore are now disappearing from store shelves.

Minuses

This variant had another problem, which began to appear after 2-4 years. It's all about the aluminum in the middle. This is a metal and like any other it oxidizes and decomposes (no matter how well it resists these processes), this is precisely its weak point. If the connection is poorly sealed and cleaned, then water begins to flow into this layer and slowly destroys it, the strongest effect from hot water supply.

Thus, the pipe begins to "halve" the lower and upper parts diverge, and the aluminum remains, as it were, in the middle. Individually, these layers are not designed to hold water and often break down causing leaks. Also, the disadvantages include the complexity of working with this type of pipes - it is recommended to clean the aluminum at the joints. Its price is the highest of all types of pipes - now the price can reach up to 300 rubles per meter, the running price is about 150 rubles.

I do not advise taking these pipes for either cold or hot water supply! We look at the third view, the most optimal.

Fiberglass reinforced

Here in the building instead of aluminum, there is a layer of fiberglass, which is very firmly intertwined with both the upper and lower layers. Such a structure is very durable and can withstand all loads - temperature, pressure, oxidation.

pros

Fiberglass does not allow the pipe to "sag", the deformation is only 1.5 cm by 10 meters.

It does not deteriorate under the influence of water and remains durable throughout its service life.

It is also a pleasure to work with it, it does not require any preparatory cleanings, as, say, the version with aluminum.

The cost is slightly more expensive than conventional polypropylene, but cheaper than reinforced with aluminum. The optimal price on the market is 100 - 120 rubles.

It is he who needs to be taken for heating and hot water supply.

Minuses

Practically devoid.

Types of pipes for heating

Reinforced polypropylene pipe, regardless of the type of additional material, can be used to supply hot water through the system. Fiberglass and basalt thread are melted with polymer during the production process. Aluminum is fixed on the polypropylene wall with a special glue. The metal is perforated. This allows the bond between the inner and outer polymer layers to be maintained.

Reinforced polypropylene pipes, regardless of the material chosen to strengthen the structure, have a certain structure. The inner and outer layers are made of polymer. In the center between them is a certain material for reinforcement.

When heated, all-polymer pipes elongate and sag. The reinforced polypropylene pipe is distinguished by its special design and increased rigidity. The most effective in this case are aluminum and basalt fiber. They reduce the coefficient of deformation of the product by 3 times. Their price will be higher than that of fiberglass pipes.

PEX - cross-linked polyethylene

A well-known product that surrounds us from all sides. One of its popular uses is plumbing pipes for hot water supply and heating systems. For their manufacture, the so-called cross-linked polyethylene is used.

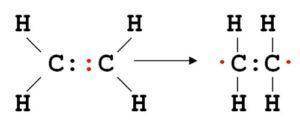

Let's consider how the ethylene gas polymerization process takes place.

Let's consider how the ethylene gas polymerization process takes place.

When heated under pressure, one of the bonds, which is initially weaker, breaks between the carbon atoms. The released one combines with the same from the neighboring molecule. Thus, long chains of molecules are obtained, which impart different physical properties to the new material.

As the temperature and pressure continue to rise, the chains of molecules begin to interconnect, forming more complex structures. In this way, a more durable material is obtained - cross-linked polyethylene.

As the temperature and pressure continue to rise, the chains of molecules begin to interconnect, forming more complex structures. In this way, a more durable material is obtained - cross-linked polyethylene.

The production of pipes from this material is also carried out by extrusion (pressing). The properties of the material make it possible to form a product of infinite length during the production process. Therefore, XLPE pipes are usually produced in coils up to 600 meters long, depending on the size.

What is it for? It is very simple, if you need to mount a warm floor, a continuous pipe of the required length is taken and laid on the exposed floor. The question of which pipes are better for heating under a screed disappears by itself in the understanding that the presence of joints and joints under a layer of concrete is not the best option.

Consider some of the technical characteristics of pipes made of this material:

Consider some of the technical characteristics of pipes made of this material:

- specific gravity - 941 kg / m3;

- melting at a temperature of + 200 ° C;

- combustion occurs at a temperature of 400 degrees, while decomposition into water and carbon dioxide occurs;

- tensile strength in tensile tests is 250 to 800%;

- high flexibility;

- preservation of strength upon impact to a temperature of -50 degrees;

- time of safe operation in heating systems up to 30 years.

With such quality indicators, XLPE pipes have a number of positive features:

- They do not react with acids and alkalis, and are also resistant to most organic solvents.

- Tensile and tear resistant.

- Does not crack when exposed to temperature.

- Biologically stable.

Tests on the number of freeze / thaw cycles show a higher stability of the material, by almost 30%.

The size range of cross-linked polyethylene pipes meets the requirements of GOST 52134-2003 and corresponds to steel products. The peculiarity of the designation of sizes is that they indicate the outer diameter of the product.

The size range of cross-linked polyethylene pipes meets the requirements of GOST 52134-2003 and corresponds to steel products. The peculiarity of the designation of sizes is that they indicate the outer diameter of the product.

In this case, the size by DN corresponds to the previous value. For example, a 40x4 mm pipe corresponds to Du32. This feature should be taken into account when purchasing.

Types of polypropylene pipes

In recent years, the range of PP-R products has significantly expanded due to the introduction of new materials in the design that increase the strength and resistance of plastic products to high temperatures and pressures. Polypropylene pipes offered on the modern market are solid polymer and reinforced. Since in our case we are talking exclusively about the heating system of a private house, we will consider in more detail the reinforced products, whose characteristics allow them to be used for this purpose. All-polymer pipes are suitable only for water supply; they cannot be taken for heating.

Reinforced products are distinguished by the fact that another material is introduced into the middle of the plastic wall, which improves the mechanical properties of the plastic. In order to choose the right polypropylene pipes, let's figure out what types of them exist according to the material of the inner reinforcing layer:

- fiberglass;

- aluminium foil;

- basalt fiber.

A layer of fiberglass or basalt is fused with plastic during the manufacturing process, while aluminum foil is fixed with a special adhesive. The perforation provides a bond between the inner and outer plastic layers. Information about the type of reinforcement, diameter and working pressure is always reflected in the marking of polypropylene pipes.

The reinforcing layer prevents thermal elongation of the pipe due to its heating by the coolant. Aluminum foil and basalt fiber cope with this task best of all, reducing the elongation coefficient of the pipe by three times, but their price is higher than that of products with fiberglass. As practice shows, the latter lengthen a little more when heated.

From the above, a simple conclusion can be drawn: all three types of PP-R pipes are designed to work in heating systems, but the most reliable products are products with an aluminum insert (STABI marking). The further choice depends on your budget. Now that we know which polypropylene pipes are better to choose for installing a heating system, we will analyze their pros and cons.

Reinforcement types

Propylene tubular products are reinforced with several materials: aluminum, fiberglass or basalt fibers. Each species has its own characteristics and structural features

Reinforcement with aluminum

Aluminum foil with a thickness of 0.5 mm to 2.0 mm is used as a reinforcing layer.

Reinforcement is made at the factory in the following sequence;

- A dense foil made of thin sheet aluminum is placed on the polypropylene layer.

- From above, the foil layer is covered with a mass of molten polypropylene. Thus, a reinforcing foil pad is formed inside.

- In the manufacturing process, the resulting multilayer sheet is transformed into a finished product by welding the connecting seams.

The reinforcing layer of aluminum increases the strength to mechanical deformation and prevents the linear expansion of polypropylene when the heat carrier is heated to a maximum temperature of 95 degrees. In this case, the characteristic properties of polypropylene of plasticity and strength are transferred to tubular products.

Glass fiber reinforcement

Increasing the stability of the geometric parameters of PPR pipes is carried out by reinforcing with glass fiber according to the following technology: glass fiber is evenly applied to the molten polypropylene layer, which is mixed with polypropylene granules. During the production process, the polymer and fiberglass are welded, which leads to the creation of monolithic and sealed fiberglass polypropylene pipes, surpassing aluminum reinforcement in terms of reliability.

Fiberglass-reinforced polypropylene pipes are used to create hot water supply systems, which are designed for periodic passage of a coolant with a high temperature.

Basalt reinforcement

Reinforcement of propylene pipes using this method is made by mixing polypropylene with basalt fibers by thermal welding. Basalt interlayer is located in the center between two layers of polypropylene. The unique combination of materials increases the heat resistance of products, resistance to temperature and pressure drops. It should be noted that polypropylene of an improved formula with higher properties of strength, durability and reliability is suitable for basalt reinforcement.

Pipes with a basalt layer are used in cold and hot water supply systems, heating circuits.

Pipes from Turkey. Qualitative characteristics

TEBO manufactures 20-160 mm polypropylene base products. Such products are able to withstand the effects of almost any corrosive environment.

There is a special series with aluminum and fiberglass reinforcement, they are mounted in heating systems.

Pilsa designs are also widely used in practice. Largely due to the combination of such excellent qualities as wear resistance and strength, elasticity.

Video: polyethylene pipe rolls

Any manufacturer requires buyers to strictly follow the rules set out in the instructions for use. Pilsa, for example, does not allow its pipelines to be bricked into the wall, which is an undoubted drawback.

It is better to install a controlled boiler on the system in order to achieve the best results. It will allow you to maintain a temperature inside the temperature not exceeding 95 degrees.

Novaplast manufactures an assortment characterized by a fairly low cost, a small selection of external fasteners. But the quality remains high.

VALTEC also boasts reliability and durability. This applies not only to pipes, but also to fittings. PP-R 100 is a polypropylene brand that has become the main one for production processes.

Firat adheres to all standards when it puts its products on the market. Therefore, its products are able to withstand even strong rust. True, there is also a drawback in the form of a high coefficient of thermal expansion.

Polypropylene of Czech origin

WAWIN Ecoplastic is a Czech company that has become practically the leader in this area of production. Quality products are not the only indicator of a manufacturer's superiority. The products are fully compliant with world-wide standards. Where can Czech products be used?

- Underfloor heating and cold water supply.

- Cold water supply with high pressure, hot water supply.

- For distributions that go to hot water supply, central heating.

- With central and underground heating.

- In order to transport hot water from cold, air distribution systems.

In specialized stores, buyers can easily find:

- Fittings, all-plastic with combined varieties.

- Fiber is a series of polypropylene products.

- Stabi is a multi-layer pipe brand.

- Pp-r is a brand of all-plastic pipe products.

Fibera are plastic pipes that are reinforced with fiberglass. Linear expansion due to heat is minimal. With a low weight, the strength is quite high. The surface does not require additional treatment before welding begins.

Video

FV-Plast

The manufacturer produces tubes with a rigid structure, which are protected from temperature changes by an aluminum insert. They can be installed in systems with any level of complexity.

German quality

German companies have also firmly established themselves as leaders in this market. For example, this applies to products under the Wefatherm brand. This includes not only the pipe rolls themselves, but also various fittings to create high-quality connections.

The systems presented by Wefatherm have the following advantages, differing from their competitors:

- A permissible combination of pipes of several types within one system. This is facilitated by a wide selection of fittings.

- The surface inside keeps the ideal smoothness. Due to this, constant pressure is maintained, there are no sharp drops.

Video

Akwatherm

Faser is also worth paying attention to those who are interested in purchasing quality products. They are used to supply hot water, even if the pressure reaches 20 bar and above.

Their diameter is in the range of 16-250 millimeters. The advantages and disadvantages of polypropylene pipes are also determined by the manufacturer, but in part.

What are the types of reinforcement

Obviously, when choosing materials for reinforcement, researchers could not pass by such an option as metal. The bottom line is that, in addition to enhancing the strength characteristics, it was necessary to protect water from the effects of atmospheric oxygen.

Obviously, when choosing materials for reinforcement, researchers could not pass by such an option as metal. The bottom line is that, in addition to enhancing the strength characteristics, it was necessary to protect water from the effects of atmospheric oxygen.

The structure of the material allows it to penetrate inside, and this happens at the molecular level. The corpuscles of this strongest oxidizing agent are able to penetrate into the channel and dissolve in the circulating fluid. As a result, oxidation of the surfaces of metal products occurs, which include:

- Heated towel rails.

- Surface of parts of shut-off valves, circular pumps, the inner surface of the boiler.

- Heating radiators.

- Metal fittings.

The most reliable alloy for this purpose is aluminum. It is not exposed to oxygen, forming a thin and very strong oxide film on its surface. It can only be destroyed by mercury salts, and these substances are not used in domestic conditions.

Various methods are used in the production of aluminum-reinforced PCBs, including:

- applying a protective layer to the pipe surface using adhesives;

- arrangement of a protective layer in the form of aluminum foil inside the product, in which glue is also applied before laying the sheet and on top of it, after which an outer protective plastic layer is installed;

- use of perforated sheet for reinforcement, which is done mainly to improve mechanical properties;

- welding of an aluminum tape with a laser along the joint, which makes it possible to obtain an airtight oxygen protection of the inner space.

Along with fiberglass reinforcement, all of the above methods significantly expand the range of use of polypropylene pipes.

The end cut of aluminum-reinforced products is distinguished by the presence of a thin shiny strip in the form of a concentric circle. This is a trace of the inner layer, the thickness of which is 0.1-0.5 millimeters.

Heating design and installation rules

One of the parameters that allows you to decide which pipes to choose for heating a private house is the heat source. In the presence of a gas main connected to the house, the optimal and obvious option for such equipment would be a gas boiler equipped with protective elements, automation and a forced circulation system. An alternative to gas equipment are boilers that run on electricity or solid fuels.

In any case, when designing and installing a heating system, the following rules must be taken into account:

- Heating systems allow you to use several types of pipes at the same time, but in this case, you need to figure out in advance which pipes to use for heating the house so that they do not conflict with each other.

- The best option for two-pipe systems, regardless of the method of circulation of the coolant, are metal-plastic heating pipes.

- If the area of the house is 100 m2, the length of the piping between the boiler and the radiators should not exceed 25 m.

- To connect a large number of radiators to heating, only two-pipe wiring is suitable, equipped with a main pipe with an increased diameter.

- Gas heat sources (and some other types of boilers) must be equipped with a system for removing combustion products into the atmosphere.

- In the section of the system located between the safety group and the heat source, there should not be a single element of shut-off valves.

- When installing the elements of the heating system, you need to monitor compliance with a certain gap between the communication lines.

In systems with forced circulation of the coolant, it is recommended to install a filter in the area in front of the pump. The heating pipes themselves can be laid hidden, but in this case, you need to take into account the rules of such an installation and think in advance which pipe goes for hidden heating.

Advantages and disadvantages

PP-R pipes have firmly taken the leading position in the use in domestic engineering networks that provide space heating and water supply. The main advantages of polypropylene in heating are the low total cost of materials and installation work compared to other types of pipes. Not only is the cost of 1 m of steel or metal-plastic products higher than PP-R pipes, but their connection is also more difficult.

The most common question that homeowners have is which pipes are better: polypropylene or metal-plastic pipes? There is no unambiguous answer, because if we compare the pipelines themselves, then metal-plastic ones will definitely win. They are reliable in operation, easy to bend by hand and can withstand external mechanical stress.

If we compare the heating system of a private house as a whole, where there are many different fittings and fittings, then the primacy is for polypropylene. The fact is that fittings for metal-plastic pipes are made of brass, often of dubious quality. They inherit all the shortcomings of metal pipelines and are a weak point of the system, therefore it is strictly not recommended to brick such pipes and fittings for heating into walls. At the same time, in PP-R systems, all parts are made of the same material - polypropylene, and there are no contraindications for laying them in the grooves, you just need to make high-quality soldering of the joints.

The list of other advantages of PP-R pipes is quite impressive:

- corrosion resistance;

- smooth plastic surface provides low frictional pressure losses and low system resistance;

- relatively simple installation and, as a consequence, the speed of assembly of the circuit.

Along with the numerous advantages, there are also significant disadvantages of polypropylene pipes. One of them is significant elongation from heating; we discussed the solution to this problem with the help of reinforcement above.

The second drawback is poor resistance to high temperatures and flammability. If the size of the pipe increases significantly due to the effect of the heat carrier 90 ºС, then at the ignition temperature the material simply "floats", and in case of fire it burns. This limits its scope of application to residential and office buildings; polypropylene is rarely used at enterprises.

When choosing PP-R pipes, it should be remembered that they are not particularly flexible and cannot be bent during installation. All turns will have to be performed using the appropriate fittings - bends or tees. In addition, over the years, the fragility of plastic increases, so sharp blows to pipelines and other mechanical influences must be avoided.

Characteristics of reinforced-plastic pipes

When deciding which types are better, polypropylene or metal-plastic, you need to thoroughly understand their technical characteristics. So, the first in the foreshortening of consideration is pipe-rolling made of metal-plastic.

When examining the MP of the workpiece in the section, you can see a composition consisting of five layers. These are: XLPE, glue, aluminum foil, a second layer of glue, and another layer of XLPE.

Any metal-plastic product is durable and reliable in use, and their service life will last for more than a dozen years. In this indicator, they are much better than other analogues. This rolled pipe does not overgrow inside, and does not become clogged.

It does not corrode and does not deposit salts. The material used for the manufacture of these products is absolutely oxygen-proof, anti-toxic and resistant to the aggressive effects of the chemical environment.

Describing the characteristics of this pipe rolling, one cannot ignore the fact that the polyethylene used in its production does not include harmful impurities. For this reason, it is quite suitable for organizing the supply of drinking water.

Experts are unambiguous in the opinion that MP water supply networks are in many ways better than their "counterparts" made of other materials, including analogues made of polypropylene.