What is required for work

To make a fireplace for the home, two types of bricks are used: solid and fireproof. The latter is laid out from the inside, because it is able to withstand high temperatures. In addition, this type of brick is able to store heat for a long time, and heats up slowly. For the solution, use a mixture that is sold in special stores or is made independently using clay and sand. In consistency, it should be like thick sour cream.

If a wood-burning fireplace for a summer residence is built from a closed firebox, then doors made of metal and fire-resistant glass will be needed. You also need to buy a damper, a blow-through door and a cleaning one. A steel pipe is required for the chimney.

Of the tools, they are stocked with a spatula, a building level, a grinder, a tape measure, a container where the solution is kneaded, a trowel, and fittings.

For beginners, when testing and splitting bricks, it is better to use a grinder with a circle along the concrete thread. Then there will be less waste and translation of material.

As soon as everything is assembled for work, they begin to install a wood-burning fireplace for a summer residence with their own hands.

Varieties of brick structures

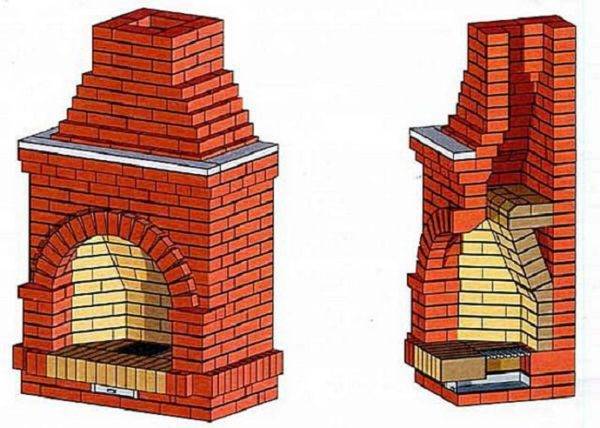

Before you build a fireplace in the country with your own hands, you need to choose its type. There are several types of contraction, which depend on the installation method:

- Built-in.

- Wall mounted.

- Corner.

- Island.

The style and appearance of the hearth depends on the desires of the owner of the house and on the area of the room in which the structure will be erected.

Built-in type

A fireplace for a summer residence of this type is built immediately upon the construction of a wall or column. If you make a built-in structure already in a built house, then the costs will be higher. Since you will have to make a hole in the wall for the chimney and portal.

Of all types, it takes up the smallest space. The portal or firebox is chosen in accordance with the area of the room. This is a size of 70x60 or 80x70 cm. The portal itself is framed with masonry or brick. If the area of the room is small, up to 20, then the size is 60x50 cm.

Wall-mounted type

It is installed against the wall, where the chimney can be built into the wall or partially protrude. You can build it in a house with a ready-made renovation, since it does not require a wall to collapse. It is considered one of the popular types. It takes up a lot of space, so it won't work in a small room. The cladding is made of stone, tile, brick or other similar materials.

Corner type

They are popular because they are conveniently located, do not take up much space, and there is a lot of free space in front of the fireplace. The chimney of the structure is built into one of the adjacent walls. The part that remains open is made of concrete or metal. The very front part is plastered or covered with decorative brick or stone. This type of fireplace creates additional comfort in the house, since you can place chairs near it in a semicircle.

What to consider when designing a house from a profiled bar

Island type

In this case, the structure is erected separately from the walls, in the center of the room. Then the heat spreads evenly throughout the room. Its feature is an open firebox. True, sometimes an open space is covered with glass. Island fireplaces look impressive, but take up a lot of space. Therefore, they are installed exclusively in large rooms. Then they do not block the light and look appropriate and neat.

Determining the size of the structure

The initial stage of building a fireplace in a private house is the definition of project parameters.The calculation is done separately with the help of a specialist, or they take an already free ready-made drawing of a beautiful fireplace.

Note! If the structure is built with the expectation of high-quality heating, then choose the correct size of the firebox. Its dimensions are 1/50 of the total area of the room.

Drawing your own drawing is not such a long task. First, they measure the room where they plan to build the stove masonry. Secondly, they draw the structure itself, taking into account the scale. Thirdly, the firebox, portal and chimney with a chimney are calculated.

When calculating the parameters of the portal, take into account the possible smoke of the room. To avoid this, the proportions of depth and height are adhered to. For proper heat dissipation, a ratio of 1: 2 or 2: 3 is suitable. The chimney opening is eight times smaller than the firebox area. In the chimney, the diameter is chosen up to 10 cm, and the length is 5 cm.

Detailed instructions and order

It is easier to build a fireplace with your own hands if there is a detailed description and photo of each stage of installation. There are several stages that are followed during construction. Carrying out the work step by step, you can fold the summer cottage fireplace with your own hands.

Drawing creation

Regardless of the shape and configuration of the structure, the first thing they do is create a sketch and drawing of the future fireplace. Adhering to the scale on a piece of paper, draw a structure, indicating all the elements of the device

It is important at this stage to choose the facing. For example, if they plan to embroider the outer part, then you will need a ceramic red brick

And if the facing will be carried out with tiles, then they choose a more economical option.

What are frame houses and what are they built from?

Preparatory work

When installing a fireplace in a living room, all furniture and the floor are covered in advance with plastic wrap. If the premises are not residential, then they do not do this, and after construction work, they just thoroughly wash and clean everything.

The next step is the construction of the foundation, on which the reliability of the structure depends. The foundation is made separate for the fireplace, and not shared with the house. If the construction is done in a residential building, then carefully remove the floor in the place where they plan to build the fireplace. It is made 6 cm larger than the structure itself.

They dig a hole 60 cm deep, cover it with 15 cm rubble, fill it in and form a base. The foundation is given 7 days to dry. Before erecting a fireplace, first the bricks are laid out without using mortar, in a dry form.

Note! In the process of laying out bricks "dry", each stone is numbered. This will build the fireplace faster.

Laying out the fireplace

As soon as the foundation has dried, roofing material is laid out in two layers. For the first row of masonry, cement is added to the solution in a ratio of 20% of the total volume of the solution. The first brick row is laid with an edge. The equality of the diagonals is determined using a tape measure.

Solid rows are built using a trowel. The chimney and firebox are built by hand. The mortar is applied to the middle of the brick. With an excess solution, it is removed with a damp cloth immediately, before it dries.

After the foundation, a firebox is made. A grate is laid on the bottom, then rows of the firebox are erected and the door of the fuel chamber is fixed. To securely fix it, the door is placed on a metal mustache and laid between the rows. The blower is built on the fifth row.

The next step is the arch. Regardless of the design of the fireplace, steel corners are used in the construction of the arch. Bricks are attached to them, and when facing, they hide. When erecting an arch, bricks are placed in a wedge.

Chimney construction

It depends on a well-built chimney whether smoke will enter the room or not. If the chimney is round, then the draft is better, and if it is square, it is worse. The walls are made smooth so that soot does not form and smoke easily passes through the pipe. The chimney itself is made vertical, less often at an angle. In this case, the angle of inclination is not more than 30 ° С.The size of the pipe depends on the size of the structure and the outlet. The minimum section is 14x27 cm. A cap is installed on the top of the chimney, which protects it from precipitation and other details.

Facing works

If they are building a regular or mini-fireplace with their own hands, then they complete it with cladding. They decorate the outer part of the structure in several ways:

- Plaster. First, the mesh is pulled, the U-shaped brackets are installed. Linseed oil is applied to protect against corrosion. The first layer of 5 mm plaster is applied to a warm wall. The second layer is applied after the first has dried. The thickness of the layer is made thicker than the previous one. The third layer is made with a thickness of up to 15 mm.

- Coloring. Use a chalk or glue solution.

- Drywall. It gives the fireplace a rectangular shape. First, a frame is made of metal, and drywall is sewn onto it.

- Decoration.

Note! When painting the outside of the fireplace in white, it is recommended to add blue to the paint. Then the paint will be more snow-white.

With the help of cladding, flaws that have arisen during the masonry process are hidden. With high-quality work, the cladding may not be done.

Construction work

Since the masonry of the structure is made with wet bricks, it must be dried before heating the fireplace. This is done for 6-7 days. The furnace door and ash chamber are opened. Then the fireplace is heated to dry, but the temperature is not brought to the maximum. During the second week, the structure is warmed up every day, while not raising the temperature to the maximum.

Firebox selection rules

The metal firebox is equipped with a special pipe, therefore, when choosing this option, the chimney is selected in accordance with the diameter of the pipe.

Specialized stores offer a huge selection of fireplaces with a fireplace insert of any configuration. It can be open, closed, pass-through, or one-way. In addition, the firebox can have a built-in heat exchanger that allows the fireplace to be connected to a hot water heating circuit.

The traditional option is a brick firebox. When deciding how to make a simple fireplace, it is recommended to use white fireclay brick, which is characterized by resistance to strong heating.

The brickwork must be flat, so work should be done with extreme care and accuracy. Arranging a brick firebox requires a lot of time and effort, requiring special skills, patience and endurance from the master.

Adjoining the wall with one of the ends

These models are recommended for fairly large or medium-sized rooms. Having made a similar fireplace in the house with your own hands, you can perform zoning of the room or reduce the size of the passage between individual rooms.

A feature of this option is the ability to install a through metal firebox with two-sided or three-sided heat-resistant glass finishing. In addition, you can make a firebox on one side, and decorate the back with natural stone.

In rooms of a small area, you can also build a fireplace with your own hands, adjacent to the wall with the end part. In this case, it allows one room to be divided into two functional zones, making living more comfortable.

Description of other popular types of fireplaces

Wood-burning fireplaces can be called a classic option, but there are other heating devices. They run on different fuels, their installation is simpler and takes little time.

In the store you can buy ready-made fireplaces of the following types:

- Gas devices. It is very easy to install them, but to connect you need to invite a gas service specialist with a special permit. In addition, you will need written permission to install such a fireplace.

- An electric fireplace can be installed not only in a private house, but also in a city apartment. You can choose a stationary type model or a mobile device.Most stationary electric fireplaces are designed as a firebox with a beautifully designed portal. Fireplaces of this type are powered by a power supply and do not need a chimney. Modern fireplaces are equipped with electronic panels, so to heat them up, switch or turn them off, just press the corresponding button on the remote control.

- Eco-fireplaces are gaining popularity, for the work of which ethyl alcohol is used. However, such fireplaces are not suitable for heating a room; they are purchased as a decorative element of the interior. They are designed to create coziness and a special atmosphere that can “warm the soul”.

- A decorative home fireplace with your own hands can be made from plasterboard sheets and a metal profile. There will be no fire and heat in such a fireplace, but a decoration or a shelf for various accessories in this case can be obtained.

You can install or build a fireplace in the house with your own hands, the main thing is to choose the right model, find out how fireplaces are made, and also take care of fire and environmental safety.

Basic construction principles

- The first row is laid with an edge, and the next row is laid flat.

- The base is made of at least two rows.

- The brick is taken in one piece, without chips and cracks.

- Before laying, the brick is soaked in water so that in the future it does not take moisture from the solution.

- The minimum joint thickness is 5 mm.

- The excess mixture is removed immediately, before it has time to dry.

- The solution is made without lumps and should not be coated on the inside of the fireplace.

- Installation is done during a warm period (spring or summer).

- Construction starts from the corners.

For work, they take high quality materials, a refractory solution and the desired scheme. Cladding also plays an important role in creating extra comfort in the room.

Chimney arrangement - step by step guide

The dimensions of the chimney depend on the type of fireplace insert: in metal furnaces, it is selected in accordance with the size of the branch pipe; for a brick furnace, the section of the chimney hole is calculated.

Correct chimney parameters provide good draft and do not allow heat to escape outside. The chimney channel corresponds to the size of the hearth, in particular, for a 60 * 75 cm furnace, a chimney with a section of 20 * 25 cm or 25 * 25 cm is required.

The continuation of the firebox is a metal pipe, which is put on the firebox branch pipe. For fire safety reasons, a heat-resistant gasket must be installed between the pipe and the combustible wood walls.

At one of the stages of solving the question of how to make brick fireplaces, the chimney can be masked with a decorative screen. For its manufacture, fire-resistant gypsum plasterboard sheets are used, which are fixed on a frame made of metal profiles.

Special requirements are imposed on the place where the chimney will pass through the ceiling. Therefore, it is necessary to make a box that will protect the wooden elements from strong heating and prevent fire. The distance from the pipe to the walls of the box should be at least 20 cm, this space is filled with any non-combustible material, for example, mineral wool or expanded clay. From the outside, the box is closed with a special device, a metal passage. Specialty stores offer a wide range of pre-made aisles. Also, with the help of the passage, you can protect the chimney head located above the roof surface from the negative effects of atmospheric moisture.

For the production of passages, a flexible material is used, which, during installation, is able to repeat the shape of the roof with a shallow relief. The most popular passages are made of rust-resistant materials.

A special umbrella is installed on the chimney as a protective element. This device prevents dirt and sediment from entering the pipe.

The laying of a brick chimney is carried out according to a certain scheme; metal passages are also used for decoration. Their installation is carried out by analogy with the process of how to make a fireplace in a house with a metal pipe.

A brick fireplace can be equipped with a metal pipe, in most cases it is also covered with brickwork.