Fire requirements

According to SNIP, the chimney and ventilation ducts must be checked and cleaned:

- Before the start of the heating season - chimneys in which boilers and heating devices operate seasonally.

- Combined and brick chimneys at least once a quarter.

- At least once a year - asbestos-cement chimneys and channels, pottery, made of heat-resistant concrete.

The initial check of the chimneys of gas boilers should touch on the following points:

- the correct use of materials is carried out in accordance with the requirements of DBN V.2.5–20;

- the presence of blockages in the channels;

- checking partitions that protect combustible structures;

- how much ventilation and smoke ducts are separated;

- how serviceable and correctly positioned the head is;

- checking the presence of normal traction, this parameter depends on the correctness of the construction, in particular, the height and cross-section of the pipe have an effect (see How to improve traction).

The ventilation and chimneys are checked again for blockages, their separation and density, the draft is checked:

- Checking for the first time and after the repair of ventilation and chimneys is carried out by specialist specialists. organizations with the participation of the operating organization. The results obtained fit into the act.

- If the ventilation ducts and chimneys of gas boilers are found unsuitable and unserviceable, the inspector is obliged to warn the owner in writing about the dangers of using gas appliances.

- The SNIP chimney in private houses allows owners to clean ventilation ducts and chimneys with a document confirming the passage of the briefing.

- Before starting the repair of ventilation ducts and chimneys of gas boilers, the operating organization, which is the owner of an apartment building, is obliged to warn residents about the start of work. After completing the repair, all chimneys and ventilation ducts should be checked.

Requirements for premises when placing gas appliances in them

The chimney must comply with the established standards!

SNiP 31-01-2003 - on apartment buildings;

SNiP 41-01-2003 - set out everything about air conditioning, ventilation and heating;

SNiP 42-01-2002 - instructions on gas distribution systems;

SP 31-106-2002 - will tell about the creation of a project and the construction of single-family houses used for living;

SP 42-101-2003 - on the construction and design of gas distribution systems from pipes of various inputs.

What does the letter of the law say:

The room in which the gas water heater will be located and the gas boiler chimney for the removal of combustible products is provided must meet certain requirements, not only the area is regulated, but also the height of the ceilings. So, the height of the ceilings must be at least 2 meters. The volume of areas is not less than 7.5 m³ for the installation of one device, and not less than 13.5 m³ for two units.

The room must also be equipped with a ventilation duct.

A grate or passage between the floor and the door should be provided at the bottom of the door or wall, where the free area should be at least 0.02 m².

Attention: It is unacceptable to remove smoke into the ventilation duct. It is prohibited to install ventilation grilles on the smoke ducts.

In rooms with a standard hood, it is required to compensate for the extracted air by penetrating it from the outside of the room, as well as by replacing it from the rest of the area of this apartment.

Attention: When the windows are sealed in the room, the column may turn off due to the intermittent air supply.

This is due to the automation of the column itself.

In the bathroom and utility rooms, doors should open outward.

The installation of sockets and switches in the bathroom is strictly prohibited.

Classification of galvanized chimneys

The products described in this article are produced in two types - one- and two-circuit (with a layer of insulation). Let's get acquainted with each of them in more detail.

Option number 1. Single-circuit products

They consist of such basic components as pipes and other fittings (these include tees, adapters, various kinds of revisions, and so on). The most popular uses are as follows:

- use as an intra-house chimney;

- use inside a brick chimney.

Such designs are not without drawbacks, the main of which are large volumes of condensate, especially when the heating system is connected to modern equipment with a low temperature of the exhaust gas and excellent efficiency. In order to eliminate this problem, the chimney is insulated or, as an option, the rate of condensation formation is reduced and heat loss is minimized.

As we have just said, such a galvanized chimney pipe is often used for efficient and prompt repair of brick chimney ducts. The purpose of this is extremely simple: instead of repairing half-destroyed masonry, a modular structure of the required size is mounted in the channel. A special mineral heat insulator is installed between the new element and the brickwork, which significantly increases the efficiency of the structure.

Note! The use of galvanized pipes from the outside is undesirable. But if there are no alternative options, then the pipe should be properly insulated.

Option number 2. Double-circuit products

For obvious reasons, such designs are also called sandwiches. Of course, predominantly stainless steel is used for their manufacture, but galvanized pipes are also quite common, often due to their lower cost. There are several sandwich chimneys made of galvanized steel, consider them.

- Only the outer contour of the structure is galvanized, while the inside is a stainless steel pipe.

- Two pipes are galvanized at once.

And due to the fact that the bulk of the loads falls on the inner pipes, the material from which they are made should be at least 0.6 millimeters thick. If we talk about the outer pipe, then 0.5 mm is quite enough for it.

Note! The outer surface of the structure is covered with special heat-resistant enamel and powder coatings, which give them a more aesthetic appearance. The described double-circuit chimneys increase the efficiency of heating devices, and also increase the efficiency of their functioning.

Of course, metal pipes are not very aesthetic, which is why they are often not combined with the overall design of the house. But this kind of drawback can be easily eliminated by brick laying along the contour of the structure (although any other material can be used for this)

The described double-circuit chimneys increase the efficiency of heating devices, and also increase the efficiency of their functioning. Of course, metal pipes are not very aesthetic, which is why they are often not combined with the overall design of the house. But this kind of drawback is quite easily eliminated by brick laying along the contour of the structure (although any other material can be used for this).

Why is the coaxial design unique?

The concept of "coaxial" implies the presence of two objects inserted into one another. Thus, a coaxial chimney is a two-circuit structure made of pipes of various diameters, located one inside the other. There are jumpers inside the device that prevent parts from touching.The equipment is installed in heat generators equipped with closed combustion chambers. These include, for example, gas boilers.

The coaxial chimney is designed in such a way that the inner pipe is designed to discharge combustion products into the atmosphere. The larger outer diameter is used to supply fresh air for combustion

Thanks to the special design of a standard coaxial chimney, it performs two functions at once: it creates an uninterrupted supply of air necessary to ensure the combustion process, and removes the combustion products outside. The length of the device usually does not exceed two meters. Basically, it is intended for horizontal placement and is displayed on the street through the wall. Less commonly, you can find a structure brought out through the ceiling and roof.

The special design of the coaxial chimney allows it to function according to a completely different principle from a conventional device. The oxygen required for combustion enters the boiler from the outside. Thus, there is no need to provide a constant flow of fresh air into the room by ventilation, which is inevitable for traditional flue ducts. In addition, a number of problems typical for standard chimneys are successfully solved:

- Reduction of heat losses due to heating of the air entering from the outside from the internal exhaust pipe of hot smoke, which results in a higher efficiency of the system.

- Reducing the risk of fire in the areas of contact between flammable surfaces and the flue duct, since the inner pipe, giving off heat to the outside, is cooled to safe temperatures.

- The high efficiency of the system allows for complete combustion of fuel, thus unburned particles are not emitted into the atmosphere and do not pollute it. A boiler equipped with a coaxial chimney is environmentally friendly.

- The combustion process, including the supply of oxygen and the removal of gases, takes place in a closed chamber. It is safer for people, since hazardous combustion products do not enter the room. Therefore, additional ventilation is not required.

- Saving space due to the compact size of the device.

- A wide range of chimneys designed for systems of various capacities.

Installation features

The construction of a chimney from galvanized steel pipes is simple and quick, you just need to take into account some of the installation features:

- The assembly starts from the bottom, from the connection to the pipe of the heating unit. In this case, for the first section of the chimney, a single-wall pipe without insulation is always used. Otherwise, the insulation will gradually smolder, since smoke of the highest temperature passes through this area.

- The elements are connected in a bell-shaped manner so that there are no obstacles for the removal of smoke and condensate drainage. In the house, each subsequent pipe is put on the previous one, on the street, on the contrary, the upper pipe is inserted into the lower one.

- To conduct a steel chimney through the wall, ceilings and roof, an opening in the obstacle is cut with a margin to prevent fire. A hole in a non-combustible roof is cut with a gap of at least 13 cm, in walls and ceilings - at least 20 cm for a double-circuit pipe and at least 100 cm for a single-circuit pipe. The hole is filled with thermal insulation and covered with sheet steel, and on the roof - with a special roofing element.

- When connecting one- and two-circuit pipes, the remaining open insulation is closed with a plug.

- The joints for additional sealing are coated with heat-resistant glue and tightened with clamps.

- The number of corners and the length of horizontal sections should be kept to a minimum.

- If it is necessary to rotate at right angles, two shaped pieces with an angle of 45 degrees are used.

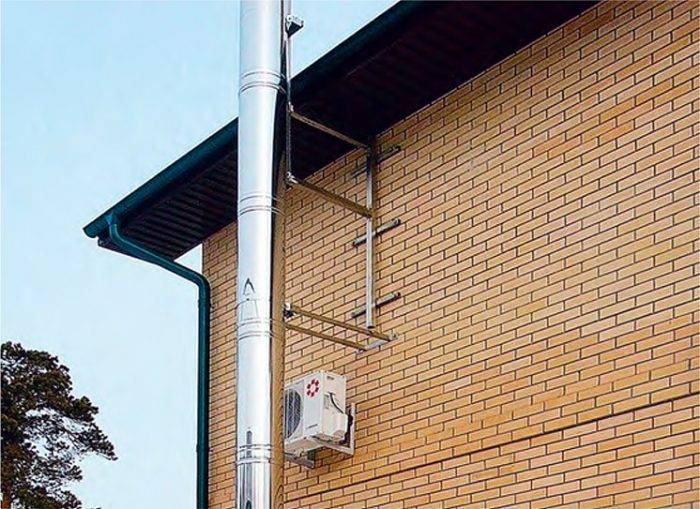

- Every one and a half to two meters of the chimney length, it is fixed to the wall, ceiling or rafter system using brackets.

- The corners of the structure are equipped with tees with a drip bowl and an inspection window for cleaning the pipe and removing condensate.

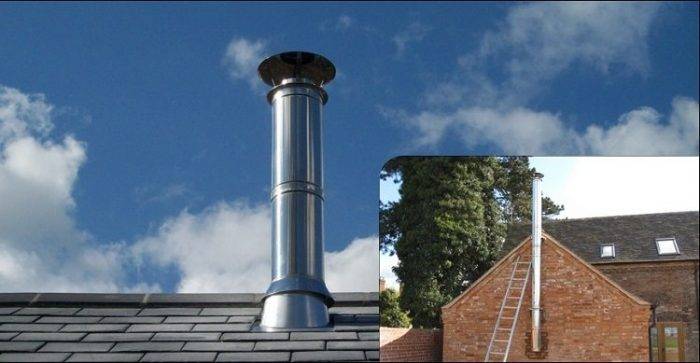

- The total height of the pipe must be at least 5 meters to ensure traction. The upper point of the chimney should rise above the roof and adjacent buildings. Height above a flat roof - from 2 m, above a pitched roof - depends on the distance to the ridge horizontally: near the ridge - from 0.5 m, at a distance from 1.5 to 3 m - not below the ridge, at a greater distance - the upper point on 10 degrees below the ridge.

- The top of the pipe is equipped with an umbrella, a deflector or a smoke exhauster to protect against debris and precipitation and improve traction.

- To extend the service life of a galvanized flue gas vent, its outer surface can be painted with roofing iron paint.

Pros and cons of stainless chimneys

The list of advantages of these alloys is headed by resistance to acid condensation, which appears when the hot air passing through the cold part of the chimney is cooled. This negative impact gradually destroys the metal, however, a stainless steel chimney is able to withstand the threat much better than all other metal structures. Often this property becomes the main criterion when choosing a material.

Advantages of a stainless steel chimney

The list of advantages is not limited to this, it includes:

- Versatility of design, comparative ease of installation of a stainless steel chimney. These pipes can be combined with any heating equipment. Self-installation is possible in any season, and special skills are not needed for such work.

- Safety for people. The stainless steel channels heat up quickly, therefore they guarantee a sufficiently effective draft, which will not allow any force majeure circumstance to happen.

- Long service life of the chimney. It is not as outstanding as that of brick or stone structures, however, if the installation of the chimney was carried out according to all the rules, then the pipes promise more than one decade of trouble-free work.

- Excellent cross-country ability. Plus - the complete absence of angles that can cause swirls of combustion products. The rounded shape avoids the accumulation of a large amount of soot, because there are no obstacles to the escape of smoke.

- Low weight of the flue duct, maintainability. The lightness of the design allows you to avoid arranging a serious foundation for the furnace. Replacing any module is simple; it does not require dismantling the entire system.

- High level of heat resistance. Such a chimney will be able to withstand temperatures up to 600 ° or more, but in this case the exact figure depends on the grade of stainless steel.

- Frost resistance, anti-corrosion properties, no fear of aggressive environments.

- Aesthetic appearance and a wide range of models.

- Reasonable price of the kit.

The list of advantages is quite impressive, but chimneys also have disadvantages. But are they serious?

Possible reasons for dissatisfaction

In a large number of pluses, the only significant minus was "worn out". This is the need to take care of insulation. However, this disadvantage is often absent. Thermal insulation measures are needed only if the chimney is located outside the room, and when a model with single-layer modules is selected.

Advantages of using galvanized pipes

The main advantage lies in the presence of the protective layer described above. We found out that when exposed to condensate, any metal begins to rust, and therefore the tightness of the chimney and the efficiency of its functioning is disrupted. But if the product is well protected from moisture, then it will serve much longer. Because of this, galvanized chimneys have become increasingly popular lately.

Note! High-quality sheet steel is used in the manufacture.Before shaping, it is immersed in a zinc solution, where a chemical reaction occurs under the influence of reagents

The protective layer created in this way is quite sufficient for a significant extension of the service life.

And chimneys made from this material have the following advantages.

- High heating rate and, as a result, almost instantaneous generation of traction. This allows heating appliances to work as efficiently as possible.

- Such chimneys include several modules, which, if necessary, are easy enough to assemble.

- Installation of products can be done on any heating devices. Simply put, their versatility can be considered another advantage.

- All galvanized pipes are fire resistant, which means they are fireproof. And this is especially true for wooden houses.

- Minimum free space required for installation.

- A wide variety of variations.

- High resistance to condensation (especially against the background of brick analogs). Only chimneys made of "stainless steel" are more effective in this regard.

- Finally, thanks to the smooth surface, soot does not collect on the walls, making cleaning faster and easier.

Note! In the light of all of the above, we come to the conclusion that galvanized products are much better than brick products, and are inferior in quality only to stainless steel pipes. Consequently, their main advantage is considered savings (both on the purchase and on installation work)

But remember that often saving on the quality of the purchased material is fraught with significant costs for maintenance and repair work.

Chimney system

The ventilation pipe for the gas water heater is mounted in the same way as the chimney for the boiler

The ventilation pipe for the gas water heater is mounted in the same way as the chimney for the boiler

In a multi-storey building, a sealed channel connects the combustion chamber of the furnace and the ventilation pipe. In a private house mine or pipe goes directly to the street. In the same way, the hood for the gas water heater is displayed when installing an autonomous heating with a gas boiler.

Chimney components:

- intake branch pipe connected to the combustion chamber;

- a line for the outlet of gases of a certain length and configuration;

- rotary fittings of the outlet channel;

- container for collecting condensate (glass);

- pass-through elements;

- ventilation fungus.

Highways are made with and without insulation, depending on the needs and characteristics of the building. Warm combustion products naturally rise upward and are removed from the room. The specific gravity of hot carbon monoxide is higher than that of air. The higher the outlet point of the outlet pipe, the greater the thrust. If possible, the hood is raised as high as possible with a minimum number of turns of the gas outlet duct.

Rules for installing chimneys from corrugated pipes

It is important to install corrugated chimneys in compliance with the established technical requirements, which ensure the successful operation of the channel in the future. Basic installation rules:

Basic installation rules:

- When bringing the corrugated pipe to the branch pipe, you need to choose the right pipe so that it matches the diameter of the outlet from the heating device.

- The diameters of the pipes are selected based on the power of the boilers. With equipment with a capacity of up to 19 kW, the sleeve is 110 millimeters, and more than 130 millimeters.

- For efficient operation of the chimney at the point of connection with the boiler, it is necessary to provide a vertical section with a length of at least half a meter. For connection, the upper part of the chimney is inserted into the lower one, and from above the mount is fixed with a clamp and tape.

- To maintain the thrust level, the length of the horizontal pipe sections should not exceed three meters in new buildings, and six meters in old buildings. In addition, it is undesirable for the chimney to have more than three turns.

- In places where corrugations pass through ceilings, walls or roofs, adapters made of refractory material are installed. The pipe is wrapped with mineral wool or other heat-resistant material.

- Chimneys must not be laid in rooms where people live.It is also not recommended to take them out to the entrance, to the loggias and through the walls that face the street.

- If a flexible chimney is installed for a gas column, the pipe is not brought out straight up, but installed with a bend. In addition, a condensate collector can be provided in front of the column.

Corrugation is often used for sleeveing an existing chimney made of bricks, since over time it loses its tightness properties.

This solution will be especially useful in case of smoke exhaust with axis curvature. But it is best to use a corrugated steel chimney, since the temperature of the gases can reach 600 degrees or more.

Features and benefits of galvanized pipes

For most iron-based alloys, moisture is destructive in itself - it oxidizes the metal, forming rust. Along with condensate, the combustion products of the fuel, containing many chemically active substances, which, when reacted with water, cause even greater damage to the inner surface of the chimney, are constantly moving through the flue channel, along with condensate.

To protect the metal from the aggressive effects of water, iron pipes are protected with a zinc coating. To do this, high-quality sheet steel is immersed in a zinc solution, where a chemical reaction takes place and an additional protective layer is formed on the metal surface. After that, the sheets are cut and sewn into pipes.

Galvanized pipes are popular:

- Due to the lightness of the material.

- The cost of pipes is much lower than that of ceramic and copper products.

- Smooth inner walls prevent the settling of combustion products and the accumulation of condensate.

- Durable metal, protected by a zinc layer, withstands thermal, chemical and mechanical stress.

- The metal walls of galvanized pipes quickly warm up, accelerating the appearance of traction.

- The convenient shape of the pipes allows you to personally mount chimneys of various configurations.

- The material is suitable for arranging a combined chimney.

Installation of stainless steel chimneys

The elements are installed from the bottom of the heat-generating apparatus upwards. If there is a mismatch in diameters, the joint is sealed with a heat-resistant sealant. During installation, the inner pipe enters into the previous one, and the outer pipe is put on the previous one. For better pipe sealing, it is imperative to use a sealant with an operating temperature of at least 1000 ° C.

The joints of pipes and other elements (bends, tees, etc.) are fastened with clamps. They should be located outside the ceiling. Wall brackets are installed for every two meters of the chimney, and the tee must have a support element. Fastening of parts to building structures should also be carried out using consoles and support platforms at least five meters apart. The fastening of the connecting pipes must exclude the possibility of bending.

Installation must be done on brackets through the wall or straight through the roof.

When deciding on the installation method, the following points must be taken into account:

- the dimensions of the building - if small, then it is logical to make an outrigger structure;

- the premises are old or are being built from scratch.

Disadvantages of coaxial chimneys

The two-channel flue gas evacuation system also has a number of disadvantages, which include:

- The need for coordination with the Sanitary and Epidemiological Supervision, since the condensate must be disposed of in specially designated places, which must be reported to the supervisory authorities. First of all, this concerns the installation of common coaxial chimneys in apartment buildings. The owners of private houses are simply warned by representatives of the gas service about the danger of toxic condensate and about the inadmissibility of draining it into the sewer or spilling it onto the ground.

- Sensitivity to correct installation.Even small errors in installation can lead to a decrease in thrust, the formation of an increased amount of condensate, and icing of the pipe.

About the main enemy - rust

Corrosion is dangerous for all metal products. In particular, this applies to iron, because it is more susceptible to the negative effects of moisture and atmospheric phenomena. For this reason, designers are constantly developing new ways to protect against rust.

Note! Different steel alloys only partially solve the problem, but a zinc layer applied to the surface of metal products is an excellent barrier to rust. They do it like this: steel is immersed in a molten mass, after which, by the action of special substances, iron combines with zinc and, as a result, a new protective ball is formed

The thickness of this layer is different, but not more than 60 microns. This technology both protects metal products and increases their service life.

They do it like this: steel is immersed in a molten mass, after which, by the action of special substances, iron combines with zinc and, as a result, a new protective ball is formed. The thickness of this layer is different, but not more than 60 microns. This technology both protects metal products and increases their service life.

Kunstkamera

- The boiler went into operating mode, that is, hot gases were flowing through the pipe at a calculated flow rate, then the burner went out abruptly - the fan stopped, the gas continued to move by inertia, and accordingly left behind a vacuum zone. The boiler was started in violation of the regime map, without preliminary warming up ... more

- Photo 1. Thermal insulation in the form of soft mineral wool mats with a density of 25 kg / m3 instead of 120 kg / m3 according to the project.

Photo 2. Absence of a condensate drain in the lower part of the vertical flue gas shaft of the boiler.

Photo 3. Foreign objects on the diaphragm of the explosive to ... more - Project Notes

The shape of the load-bearing lattice tower does not meet the requirements of SP 43.13330.2012 “Constructions of industrial enterprises. Updated edition of SNiP 2.09.03-85 ". The use of this constructive solution (rigid struts in the form of a system of volumetric trusses) is ... more

- 1. The adopted design solutions of the “KM” section do not meet the requirements of SP 43.13330.2012 “Constructions of industrial enterprises. Updated edition of SNiP 2.09.03-85 ":

- the shape of the supporting exhaust lattice tower does not meet the requirements of Sec. 9.4.8, 9.4.11; … More - The only reason that can cause tensile stresses in a wall located along the generating cylindrical surface is water. When water turns into ice, its volume increases by 9.05%. The breaks of seamless pipes, as they look in the photo, are typical for damages at m ... more

- This chimney calculation cannot be considered sufficient and reliable, since:

- collection of loads in accordance with the requirements of clause 7-14 of SP 20.13330.2011 “Loads and impacts. Updated edition of SNiP 2.01.07-85 * "; - combinations are not shown ... more

Service rules

The chimney, like any other appliance, requires periodic maintenance. In our case, it includes the elimination of minor cracks and damage from the outside that arise due to high temperatures; soot cleaning is also included. And here a problem arises: is it possible to clean such a chimney with your own hands without resorting to the help of specialists?

In principle, you can. To do this, before starting cleaning, the upper part of the chimney is checked - various third-party objects that are blown by the wind often fall under its visor. And if there are such objects, they are pushed down, using a special pole with an iron wire ruff attached to it. A similar procedure is carried out in the lower part through the revision hole.

3 ways to clean the chimney

We advise you to read in more detail the instructions on how to clean the chimney pipe on your own Learn more

Further, the remains of soot and other foreign things are removed from the pipe using a scoop. At the end of cleaning, the inner surfaces of the structure are treated with a special agent that prevents the accumulation of soot, after which the furnace is heated at maximum draft.

Note! Regardless of the material, when installing the chimney and its further operation, all relevant rules must be observed. Then the house will be not only warm, but also cozy.

As a conclusion

As you can see, the galvanized chimney pipe is extremely simple not only in terms of construction, but also in terms of installation. It has a number of technical advantages, but at this time it meets the necessary standards. The design will serve for a long time, if, of course, you do not forget about leaving.

That's all. Warm winters to you!

Manufacturing

For more than 15 years (since 1998) Trankol has been successfully practicing a unique production process. It allows chimneys to successfully cope with their functions for many years. The warranty for this type of product is 10 years. Agree, this is a lot for a piece of steel. The whole process of working with a client when installing chimneys looks like this:

The necessary measurements are made. Experienced engineers, often using a special computer program AutoCAD, if necessary, design a layout of the future chimney and make an estimate. To clarify the parameters, a visit to the site of the proposed installation can be made. When technicians are satisfied with the accuracy of their measurements, they move on to the next step.

The required sizes and shapes of elements are selected. The chimneys themselves are often welded in a special way by argon-arc welding. All processes are automated. A base is taken - stainless steel, for example, grade aisi 304 (it is the most common in the manufacture of chimneys), it is immersed in an argon atmosphere, then welded to other elements with a non-consumable tungsten electrode.

A team of installers goes to the site and installs the chimney or its elements.

The most difficult case is described above. In standard operations, simple product design, some processes are skipped. This does not mean that their quality or service life is falling.

Advantages

Single-walled and double-walled chimneys Trankol have a number of advantages, in addition to the democratic price, which favorably distinguish them from competitors:

- low weight of each of the elements, ease of installation;

- high thermal resistance of the materials used in the manufacture;

- resistance to corrosive processes;

- fire resistance;

- when properly installed, there is excellent traction;

- ease of use, similar to a children's designer: the abundance of elements of various configurations allows you to cope with the most capricious installation conditions.

Views

The diameter of the chimneys can be very different, from 130 to 500 mm. It is possible to manufacture a pipe with a larger diameter, but only on special order. For each case, for each boiler, its own chimney is selected. It depends on the characteristics of the boiler itself, stove or fireplace. Reading the reviews, you understand that most often chimneys need thermal insulation.

For this, two pipes are made: an external and an internal one. This design is called double-walled. In this case, mineral wool of the Finnish brand Paroc serves as a heater. It can be 30 mm thick. or 50 mm. It is a robust and inexpensive thermal insulation material that ensures minimal condensation (if carefully installed).

Separately, it must be said about the steel itself. The austenitic chromium-nickel steel grade AISI 304 is the most popular in the manufacture of chimneys. Its thickness can be 0.5 mm, 0.8 mm. and 1.0 mm. It includes, according to the manufacturing technology, at least 8% nickel and at least 17% chromium.

Also, in some cases, AISI 316L is used (nickel - not less than 12%, chromium - not less than 16%, molybdenum - not less than 2%. Molybdenum provides material resistance to phosphoric, acetic, hydrochloric and other acids.), AISI 304L (nickel not less than 8%, chromium - not less than 17%, reduced carbon content - 0.03%.

This guarantees the absence of corrosion at operating temperatures up to 800 degrees.), And AISI 310S (nickel - not less than 27%, chromium - not less than 22%, molybdenum - not less than 2%, copper - not less than 2%. Chromium makes steel oxide. This property persists up to a temperature of 1050 C. Nickel provides increased heat resistance.Molybdenum in this alloy is responsible for ductility.Copper helps the components of the alloy interact and enhance the characteristics of each other.

All of this steel is of high quality. It is acid resistant and manufactured with a long service life in mind. It also has first-class welding properties and can withstand short-term heating up to 750 degrees. At the same time, constant heating is up to 450 degrees.

In short, all Trankol pipes are high quality products that are worth your consideration.

Installing the node

Having prepared the window in the ceiling, you can proceed with the installation of the ceiling-walk-through unit.

A metal or minerite box is installed in the cut-out opening. The structure is fixed using purchased or standard fasteners (bolts, self-tapping screws), which are screwed directly to the ceiling.

- After the ceiling duct is installed, it is necessary to install the chimney pipe, first putting it on the stove, then leading it through the box to the attic, and from there through the outer layer of the roofing cake (a hole is also cut out in it beforehand). After the chimney is withdrawn, it is insulated with a selected non-combustible material (you can pour a layer of expanded clay on top of the box).

- Another important final stage of work is protecting the structure from moisture. Since when the pipe passes through the roofing pie, a gap remains between it and the materials, water will flow through it into the attic. For waterproofing the joint, it is recommended to use various finished products - the so-called. ties and aprons, which are matched to the diameter and geometry of the chimney and are installed using simple fasteners. For a round chimney, you can purchase special ready-made passages with a flexible sleeve, choosing a product to match the color of the roof and other parameters. They can be installed using self-tapping screws or glued using special adhesives. It is also recommended to use additional liquid and paste sealants, with which the edges of the protective elements are processed. With proper waterproofing, the chimney passage through the roofing cake will always be protected from rain and snow.