Insulation of asbestos-cement chimneys

The insulation must be wrapped in foil to protect it from moisture.

For asbestos-cement chimney pipes, only fibrous non-combustible materials are used. These include all types of mineral wool:

- glass wool;

- stone wool.

The characteristics of stone wool do not allow it to bend, the thermal insulation is completely inelastic. Therefore, its use is possible only in the form of lamellar mats. The glass wool is soft, easily wrapped around the pipe and secured with wire. The insulation layer should be at least five centimeters.

Foil is wrapped over the thermal insulation. It protects against moisture, ultraviolet radiation, sparks. The foil tape must be wound from the bottom up so that falling raindrops or melted snow do not seep into the mineral wool.

Some people insert asbestos pipes into steel casings, insulate it all, and leave air gaps. Why such difficulties? If you want a normal pipe, then buy a sandwich chimney. If you don't want a tin, then a ceramic pipe would be a great alternative. It is expensive, difficult to install, but safe and will last as long as a house.

Insulation of asbestos-cement pipes for the chimney

Since asbestos is a porous material, soot deposits quickly accumulate on the inner walls of the chimney. Temperature changes lead to the appearance of condensation, which, together with soot, leads to the destruction of the chimney.

Thermal insulation of pipes helps to prevent such consequences. The easiest and most inexpensive way is to use roll materials.

It is important to provide waterproofing. For this purpose, the most suitable would be the use of foamed polyethylene, which is fixed with wire or metal staples.

Heat-resistant heaters are installed outside. Additional brickwork helps to increase the effectiveness of thermal insulation. A metal cover can be installed. It is put on an asbestos-cement pipe, which is insulated with mineral wool. This requires:

- from stainless steel (approx. 2 mm thick) make an outer thermowell with a diameter 10 cm larger than the pipe;

- place an insulating material between the channel and the sleeve;

- ensure good insulation of the joints.

Foil materials are used for thermal insulation of the chimney.

Thermal insulation is also arranged with special cinder blocks. A box is made of them around the channel at a distance of 5-10 cm. The resulting space can be filled with slag, mineral wool or expanded clay.

Advantages and disadvantages

When self-erecting a residential or country house, a gazebo, a shed or a terrace, especially on difficult ground, it is important, saving time, effort and money, to get a reliable and functional structure. Therefore, before deciding on a pile foundation made of asbestos-cement pipes, it is necessary to weigh the pros and cons of this supporting structure.

The advantages of a columnar asbestos foundation are:

- applicability in difficult areas,

- low cost of consumables,

- low consumption of cement,

- speed of construction,

- possibility of installation with a small set of tools,

- reduction of the volume of earthworks,

- resistance to moisture, temperature extremes,

- chemical and biological inertness,

- absence of corrosion of underground and above-ground parts of the foundation,

- protection of the building from flooding.

However, asbestos-cement pipes and supports from them have serious disadvantages:

- low bearing capacity, insufficient for the construction of residential buildings from heavy building materials, houses of a large area and number of storeys;

- the impossibility of equipment under the house of a basement or cellar;

- for a large number of foundation pillars, many wells will be required, the digging of which without a drill is comparable in labor costs to laying a ditch for a strip foundation;

- errors in calculations or installation will lead to the fact that the soil will squeeze out the piles, since the asbestos pipe does not have adhesion to the soil.

What is the peculiarity of the foundation made of asbestos pipes

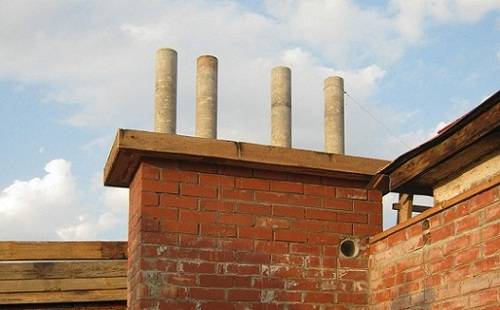

From asbestos-cement pipes, a foundation of a columnar, or pile, type is erected, making original legs for the future structure - pillars, or piles that go deep into the soil.

A feature of such a foundation is the installation of piles under key points of the structure: corners, zones of intersection of walls.

A distinctive feature of the pile asbestos-cement foundation is the filling of hollow asbestos pipes with cement mortar with additional reinforcement. As a result, the pillars of the supports are strong and resistant to soil pressure and able to withstand the weight of the erected structure.

Such a structure of the supporting structure is relevant in cases where it is impossible or impractical to construct a foundation of a slab or tape type:

- When erecting outbuildings, country houses and frame houses that do not have a cellar, baths. Lightweight buildings for various purposes do not need to equip a support tape around the perimeter, especially since it is impractical to pour a monolithic slab under them.

- On difficult ground or in cold regions where excavation is expensive. On unstable ground, prone to crumbling, trenching and foundation installation is impossible without formwork equipment. In cold regions, where the ground does not thaw even in summer, as well as on rocky ground, the risk of crumbling is lower, but the work itself is much more difficult.

- With a high level of groundwater or when the structure is located near bodies of water that are prone to spills. In wet soil, the strip and monolithic foundation will constantly be in contact with water, gradually collapsing and sinking into cavities washed out by underground flows.

Installation of a chimney from asbestos-cement pipes

For chimney installation, asbestos pipes 4-5 meters long are usually used. This allows you to build a chimney, avoiding the difficulties with installation and insulation of joints.

However, this type of installation also causes some problems: in order to install an integral structure of such a length, you will have to resort to the help of neighbors or relatives, since its installation with your own hands is almost impossible.

If you are going to do the installation yourself, it is better to take products with a length of no more than 1 meter and a width of 100-150 mm. You will also need an additional lifting device such as a hydraulic jack.

Chimney installation

The stages of work are as follows:

Chimney for a house made of asbestos-cement pipes

- Before proceeding with the installation of an asbestos chimney, you need to install a structure made of reinforced concrete, silt of another durable material, on which the pipe will be located until it is securely fastened. The height of such a structure should correspond to the lower level of the pipe installation.

- Installing a solid pipe is only possible during the construction of a house. This is a fairly simple task: with the help of a couple of people, we install the future chimney on a support, secure it securely to the ceiling and attic beams, put on a visor, and connect it to the boiler.

- The chimney from the asbestos-cement pipe is connected to the boiler. For this, a stainless steel casing is put on the flue gas outlet from the boiler, which is attached to the asbestos chimney using the same clamp.

- To prevent carbon monoxide from entering the room, all joints of the chimney from the asbestos concrete pipe must be coated with a special refractory solution.

If the house has already been rebuilt, it is better to collect the chimney from separate parts of asbestos. For this:

- we attach the upper part of the pipe to the attic beam, put on the visor;

- we put on a fastening clamp on the upper part of the chimney (as a rule, they are made of metal);

- using a jack, press the next segment of the chimney into it;

- we collect the entire chimney in the same way until we reach the level of connection with the boiler.

Chimney insulation

The rate of passage of gases through the chimney depends on the rate of heating of its walls. To improve the draft, the asbestos chimney must be insulated. To do this, it is enough to make a casing of stainless steel, and fill the space between the pipe and the casing with mineral wool.

How to make a chimney with your own hands? (video)

Andrey, 37 years old. Nizhny Novgorod:

Nikolay, 42 years old. Podolsk district:

Dimensions and construction of asbestos chimney

In the production process, sifted river sand, M600 cement, asbestos fiber, plasticizers and dyes are used. To achieve the density and smoothness of the walls, they can be treated from the inside with synthetic impregnations.

Production technology:

- Pushing asbestos mass into long fibers. Water is added to the container with the runners. The first stage results in a viscous suspension.

- Mixing. Consecutively, cement, dyes and plasticizers are poured into the tank. The mixture is tested for compliance with specifications, filtered and partially dried.

- Forming. It is carried out in a rotary manner on rapidly rotating drums. During this process, excess moisture is removed from the workpieces, they are compacted and take on a given shape.

- Launching. Adjustment of the edges to the standards, external and internal grinding, marking is carried out.

An asbestos chimney can be assembled from fragments of this size:

- length - 390 cm, 450 cm, 500 cm, 600 cm;

- inner diameter - 10 cm, 15 cm, 20 cm, 30 cm, 40 cm, 50 cm.

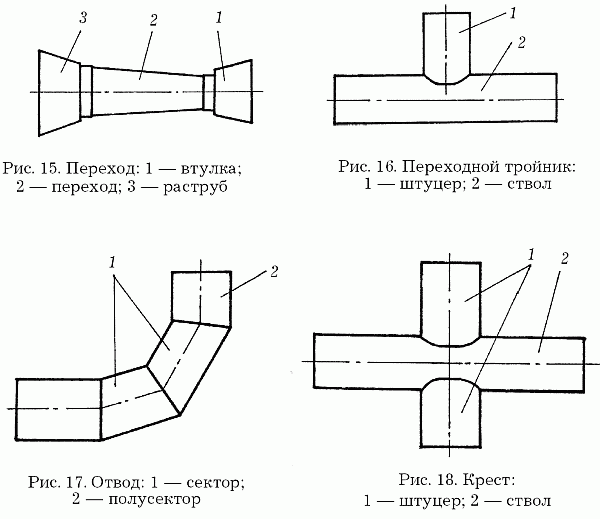

The links are joined using sockets and couplings. Cold material transport connections are insulated with rubber, hemp and bitumen. In systems for the removal of combustion products, an asbestos cord is used.

Dangers of using asbestos cement

While asbestos-cement contained in plumbing is unlikely to be released into the air and cause respiratory illness, serious health effects have been identified for people living in buildings where water still flows through asbestos-cement pipes. Local environmental problems can lead to degradation of this type of pipeline due to leaching of asbestos fibers into the water.

Over time, asbestos-cement pipe undergoes gradual degradation in the form of corrosion, i.e. internal calcium leaching due to transported water or external leaching due to groundwater, which leads to a decrease in the effective cross-section, which causes softening of the pipes and loss of mechanical strength.

Accordingly, as the water distribution system increases, the number of asbestos cement pipe failures increases over time.

Because of these risks, assessing the condition of the pipe is essential to determine the remaining useful life and to develop a suitable active replacement plan for the distribution system. Asbestos cement is a porous material that absorbs moisture as a result of condensation

If the condensate is filled with corrosive substances, the pipeline wall will absorb them, which will lead to the rapid destruction of the structure.

Asbestos cement is a porous material that absorbs moisture as a result of condensation. If the condensate is filled with corrosive substances, the pipeline wall will absorb them, which will lead to the rapid destruction of the structure.

Adjustment of pipes made of asbestos cement is carried out using couplings, which include rubber seals.At certain temperatures, seals tend to deform or even burn. In this respect, it can be caused by the suction of hot air / vapors, sometimes due to this, combustion products penetrate into the room.

When exposed to high temperatures, asbestos cement with a lot of noise, like fire, cracks and scatters in different directions and at a decent distance. Of course, asbestos pipe has thick walls, but high temperatures have a negative effect on the material, even with a destructive effect. At 300 degrees Celsius, the pipeline begins to crack.

Based on this, we can determine the danger of using asbestos pipes:

- Under the influence of high temperatures, the pipeline can break, cause mechanical damage to the building, and become a threat to human life.

- Asbestos cement piping can cause a fire.

- The formation of cracks in the flue pipe can lead to the penetration of combustion products into the room or a decrease in the draft of the sealing element.

Considering all the dangers of using the material, asbestos cement can be used with a reasonable approach during construction. It is not allowed to install asbestos cement in a heating system that works with wood or coal, since under these conditions the temperature of the processed gas is much higher. However, if the pipe is located at a considerable distance from the boiler or furnace, installation is quite possible as an intermediate or end section.

Asbestos-cement pipes are found in the line of the gas water heater, where the combustion product removal system is located. In both the first and second embodiments, the temperature rarely reaches a critical value.

Nuances when installing an asbestos pipe for a chimney

It is possible to smooth out the shortcomings of asbestos-cement pipes if they are installed correctly.

It is necessary to pay attention to many parameters: properties of the coolant, distance from the heater to the pipe, diameter and length, properties of insulating materials

Wood or coal cannot be used as a heat carrier with such a chimney. Sometimes such a chimney is built in baths, but an adapter must be installed. The greater the distance from the heating structure to the pipe, the lower the temperature inside.

Therefore, the more heat the coolant gives off, the longer the adapter is needed. It is recommended to install a chimney made of several materials, with asbestos cement being the farthest from the boiler.

Another parameter is reliable insulation and insulation. They protect the chimney and the surrounding materials from condensation. The fact is that asbestos itself has a good waterproofing ability, but the condensate does not consist of pure water. Such a pipe really does not let water through. Condensate, on the other hand, contains impurities of salts, acids and metals, which easily penetrate into the pores of the pipe and spread to other parts of the chimney.

In addition to internal condensation, it is necessary to protect the pipe from external moisture. For this, in addition to insulation and insulation, special umbrellas are used, which are attached to the head of the pipe.

Chimney insulation

As mentioned earlier, the insulation of an asbestos pipe must be carried out without fail. A feature of such a material is porosity, and soot and condensate can enhance the destruction process. To extend the operating period of the chimney, it must be properly waterproofed. You can insulate an asbestos-cement chimney in different ways, depending on the design features of the heating system and the house as a whole:

- the use of heat-resistant insulation, which is arranged outside. An excellent option is reinforcement with brickwork, which increases the functionality of the waterproofing material several times;

- the use of a metal casing and mineral wool. With this method, the product is wrapped along its entire length with mineral wool, and the casing is fixed on top. The material used for insulation protects the chimney from temperature extremes;

- installation of a metal umbrella that will not allow moisture to penetrate into the pipe. Using a simple structure, the chimney is protected from precipitation;

- installation of a special casing made of cinder blocks, which is mounted at a distance of up to 10 cm. The space between the pipe and the cinder block should be filled with mineral wool, expanded clay or other material.

Service difficulties

The only way out is to constantly clean the chimney (see How to clean the chimney). But unlike brick and metal pipes, chimneys from asbestos-cement pipes are difficult to clean due to the difficulty of installing inspection windows.

The main problem is condensation

Skeptics might argue that this explosion condition only applies to older furnaces and boilers. Modern boilers have an increased efficiency, as a result of which their outlet temperature is much lower, 100 degrees, and an asbestos pipe for the chimney is quite suitable. This statement has its own reason. But again, we will not consider the issue superficially.

Indeed, all modern boilers have good efficiency, which is great. This means that such necessary heat does not fly out into the chimney, but is mostly used to heat your home.

As you know, oxygen supply is required for normal fuel combustion. Oxygen is supplied together with the outside air. Oxygen is supplied together with the outside air. Air is supplied by traction. But what affects the quality of traction?

Of course, the quality of the chimney. Many people believe that the chimney is designed to remove fuel combustion products.

But it is important to know that by removing the combustion products, the chimney ensures the flow of fresh air into the firebox, which ensures normal combustion inside the stove, boiler, fireplace. This is how cravings are formed

The greater the temperature difference in the pipe with the outside temperature, the better the draft.

The greater the temperature difference in the pipe with the outside temperature, the better the draft.

Many have faced this problem. The old boiler worked fine with a regular brick chimney. It's time to change the boiler. They installed an ultra-modern, economical, high-efficiency unit - and the problems began.

Brick pipe

Not only does the boiler not work as stated in the documentation, in addition to everything else, unpleasant-looking spots began to appear on the walls where the chimney pipe passes and such a beautiful brick pipe installed on the roof began to crumble.

Condensation stains

What is the reason? There is only one answer - condensation. Whoever thinks that an asbestos chimney for a chimney in this case would be at a height is deeply mistaken. How so, because asbestos-cement pipes are not afraid of water, they are designed for this. That's right, for water. But the condensate in the pipe is not really water. Or rather, not water at all. Chimney condensate is a very aggressive solution of a mixture of combustion oxides and moisture that destroys the chimney material.

Interesting: Garden drill: general view

Correctly executed chimney from an asbestos pipe

The misconception that installing an asbestos pipe as a chimney is not difficult can lead to many undesirable consequences. Boiler equipment is different, each has its own efficiency.

Therefore, before proceeding with the installation, you need to carefully study all the technical conditions. What a private developer should be ready for by doing a chimney with his own hands is a reliable fastening of the structure, arrangement of pipe insulation, compliance with fire regulations.

Chimney insulation

Fastening the chimney from an asbestos pipe

It is possible to install an asbestos pipe in the general chimney system from the area where the temperature of the combustion products does not exceed 300 degrees Celsius.It is permissible to output both a separate riser (external chimney) and a channel passing through the roof. When arranging, you must adhere to the following rules:

- When the pipe extends over the ridge over 2 meters, it is required to use additional clamps and stretch marks for fixing;

- A separately running chimney is attached to the bearing wall with pipe clamps at intervals of at least half a meter;

- When placing asbestos inside a channel made of brickwork, additional spacers from reinforcement are used;

- The chimney must be fastened at the place of its passage through the roof through an asbestos-cement bracket.

Extension of the chimney with an asbestos channel

Non-pressure pipes made of asbestos, which are used to organize a chimney, as a rule, are built up onto an already finished part of the chimney from another more heat-resistant material. The transition from metal to asbestos can be done through a special stainless steel sleeve.

Connection of an asbestos pipe with a coupling

If there is a build-up of one asbestos pipe with another the same, then the connection is carried out with a coupling of the CAM modification. The coupling has two internal grooves for a heat-resistant seal. When building up a brick chimney, the CAM coupling is fixed inside the masonry. It is propped up with reinforcement mortgages, and the space between the masonry and the coupling is poured with concrete.

Building up brickwork with an asbestos chimney pipe in the absence of a coupling can be done in another way. To do this, a slab of the same asbestos cement or steel with a hole not exceeding the diameter of the asbestos channel is installed on the last row of bricks. The latter is placed on top of the hole and fixed with a solution.

Thermal insulation cushion device

Asbestos cement has a porous structure. It has poor thermal insulation qualities, therefore it heats up a lot, to the temperature of the gases discharged outside. Asbestos-cement pipes for the chimney must be insulated with a material that is resistant to fire for the following reasons:

- To avoid heating and ignition of combustible materials that make up the structure of the house;

- In order to avoid the formation of condensation, which is one of the factors that have a destructive effect on the chimney.

Basalt wool

The classic version of insulation is based on the use of basalt wool, which is wound in several layers on the chimney and secured with special clamps or knitting wire. A layer of foil is arranged on top of the cotton wool. This must be done to waterproof the pipe and provide an additional fire barrier.

You can protect the insulation using a metal frame. For this, sheet thin galvanized metal or with a factory paintwork is suitable. It is advisable to use such a frame for pipes protruding above the roof, where the foil will look unaesthetic.

Tapping a tee into an asbestos-cement pipe

If the chimney is arranged in such a way that it is necessary to bring it through the side wall, add a condensate drain or install an inspection hatch to control and clean the chimney, use tees with a coupling system. After cutting the pipes, putting on the tee, the joint gap should be filled with a compound based on acid-resistant and heat-resistant components.

Chimney sections from an asbestos-cement pipe must not be performed in a strictly horizontal position. When the channel exits to the side, it must go at a slope of at least 3 degrees towards the boiler plant.

How to choose a chimney from an asbestos-cement pipe

Since this building material belongs to the budget, you should not try to save even more and look for the cheapest asbestos-cement pipes. It is better to buy them in a reliable store that provides guarantees for the quality of the products.Otherwise, there is a risk that cheap pipes will not even reach the installation site and will crack on the way.

Rusty deposits and dirt on the surface of asbestos-cement pipes are an indicator of improper storage and unsatisfactory quality

When buying a pipe, it is recommended:

- carefully inspect each product, make sure that there are no cracks and chips, lumps and uncharacteristic inclusions in the material;

- check (at least visually) the evenness of the pipe and the uniformity of the wall thickness;

- pick up an asbestos cord for sealing joints;

- make sure that the cross-section of the pipe exactly matches the diameter of the boiler pipe.

The range of asbestos-cement pipes will not limit your choice

Manufacturers offer asbestos-cement pipes with a diameter of 10 to 50 cm, so choosing the best option for your boiler is not difficult. To minimize the number of joints, it is worth purchasing a 5 m long pipe, but if it cannot be transported, you can take 3 m (this is the minimum permissible chimney length). It is recommended to purchase an adapter or a stainless steel gas outlet pipe directly for connection to the branch pipe, which can be tightly connected to both the metal branch pipe and the asbestos-cement flue duct.

Disadvantages of asbestos pipes

Manufacturers of asbestos-cement products indicate that they can be used for arranging a chimney, ventilation, air duct, and gas duct. At the same time, the long-term use of such chimney ducts revealed their disadvantages:

- high probability of bursting or exploding at temperatures above 300 ° С;

- fire hazard due to the high probability of cracking and gas escape;

- significant reduction in thrust due to the lack of supporting heat capacity;

- accumulation of condensation and moisture absorption;

- the impossibility of arranging inspection hatches;

- installation of pipes only vertically;

- inability to clean the channel from soot.

Thus, asbestos-cement pipes can be used as chimneys only for low-power heating devices and only under certain conditions. For high-performance heating devices that consume solid fuels, it is better to use ducts made of other materials.

How to fix an asbestos chimney

If you did not really listen to our advice and at your own peril and risk decided to make an asbestos chimney, then pay attention to some recommendations for installing this system

- The installation of a chimney from an asbestos product should be carried out on a reinforced concrete slab or masonry.

- Pass through the overlap, fluff. To form it, you need to fix the sides of the required height along the edges of the hole and fill the gaps between the floor material and the pipe with non-combustible material. It is best to use expanded clay, sand, cinder concrete, etc. for filling.

- When passing through the roof, you need to make an otter, which will protect the attic from precipitation inside it. For its reliable fixation, a special coupling is formed from a cement-sand mortar.

- Sections of the asbestos chimney are carefully connected to each other using heat-resistant sealant and special clamps.

Important! Keep track of the quality of the joints, the fire safety of the bath and your health depend on it

Better to spend more money on sandwich pipes, or find a good stove-maker and make a brick chimney. There are many different options and methods for safe and modern smoke removal, and it is about them that we talk about on the pages of our resource.

Scope of application

Asbestos-cement pipes are used in various areas of construction. For example, they are used in the construction of sewage drains, both pressure and non-pressure.Often they also serve to supply water, both drinking and technical. Such pipes can also be used in the construction of a hot water supply system.

In addition, asbestos-cement pipes are used in agriculture. There they are needed when installing a melioration system and drainage facilities. In private houses, they are used to build wells, using them as casing pipes. In apartment buildings, there is another area of application for asbestos-cement pipes, in addition to supplying water and collecting sewage. These are garbage chute pipes. They are designed for both solid and liquid waste.

Due to the fire resistance of both asbestos itself and the structures that include it, such pipes are used for the construction of chimneys. However, there are several limitations in this area of application. In general, asbestos cement is used wherever there is a need for waterproofing, heat resistance, wear resistance and durability.

Characteristics of asbestos cement

Asbestos cement pipes are made from a mixture of asbestos paste and cement compressed by steel rollers to form a high strength laminated material. Their capacity remains almost constant, as in the first installation, regardless of the quality of the water.

Asbestos pipe can be drilled and used for joining, but is not suitable for threading. However, this difficulty can be solved by screwing the lugs through the fixed iron seats at the service point. Asbestos cement is not suitable for use in sulphate soils.

In most cases, good pipe laying and the use of flexible joints is more important to prevent fracture by bending than the strength of the pipe itself. The flexible joint is used at regular intervals to allow for pipe repair if needed.

The pipes are manufactured with nominal diameters from 80 to 600 mm with a test pressure of 5 to 25 kg / cm2, meet the general requirements for water and are classified as class 5,10,15,20 and 25, which has a test pressure of 5,10,15,20 and 25 kg / cm2, respectively.

The working pressure should not exceed 50% of the test pressure for the pumping network and 67% for the gravity systems.

Circumstances of using asbestos pipes

However, the use of this material continues. And this happens due to its low cost and in cases where the flue gas temperature does not exceed 200-250 oC. Such conditions are typical for the operation of gas heating units.

It is also important that when gaseous fuel is burned, the formation of solid non-combustible particles is slower than when burning wood. A similar temperature regime of flue gases is also inherent in pyrolysis solid fuel furnaces, but they are characterized by the formation of a large amount of condensate, which is detrimental to asbestos pipes.

It is allowed to build only vertical sections of the chimney from asbestos pipes, which significantly reduces the possibility of their use even with economical gas boilers

When installing asbestos pipes on the chimney, the following circumstances must be taken into account:

- When arranging an independent smoke exhaust system, asbestos pipes are used only when installed through transition sleeves between the firebox and the chimney.

- When installing a chimney from the outside of the house, special sleeves and adapters from the same material are used for installation.

-

Such products are also used to lengthen the existing chimney with insufficient draft in the furnace.

- An asbestos-cement pipe can be used as a liner for an active brick chimney if the brickwork begins to collapse. The same sleeve can be used in the construction of a brick chimney.

- Installation of asbestos pipes is carried out exclusively on brickwork or reinforced concrete base.

-

Passing the chimney through the ceiling is possible only when using a fluff.

- At the intersection of the chimney, an otter device is required.

- Docking of pipes is carried out only with high-quality couplings with a gasket along the thread of an asbestos cord as a seal.

- Insulation of an asbestos chimney is mandatory. It is made by covering the pipe with basalt wool and a casing made of galvanized metal. It can be pulled together with wire or specially designed strip ties.