3 Selection rules

Before choosing a wood-burning boiler, you need to calculate the required power. It is quite simple to do this, since a device with a capacity of about 10 kW is required to heat 100 m². This indicator is suitable for housing in the middle lane and for rooms with good insulation.

If the house is located in a harsh climatic zone, then you need to select a device with a capacity of 30-35%. In addition, it must be borne in mind that in the off-season the unit does not work at full strength, which means that it is worth buying a model that has a wide range of action. When choosing a boiler, you should also take a closer look at the material from which it is made:

- steel appliances are lightweight and have a simple furnace design, their smoke channel is quite long, which ensures high-quality heating of the coolant;

- cast iron devices have a relatively short smoke channel, a ribbed surface and a large heat exchange area.

In addition, the structure must be necessarily equipped with an emergency cooling system, in which case there is no need to be afraid that the water will boil and the boiler will overheat. It is also advisable to purchase a device with protection against burns, especially if there are small children in the house. It is best to purchase models that are equipped with heat-insulated firebox handles, protective covers and grates. All heating surfaces must be covered with heat-insulating material.

Why is a wood-fired boiler sometimes the best option?

Of course, gas units are recognized as the best option both in terms of ease of use and the cost of energy carrier. But, unfortunately, not all settlements in the country (and especially in rural areas) are covered by gasification. In addition, supplying gas to the house, even if there is a central highway, is a rather difficult and costly task associated with the execution of numerous documents. Obtaining all permits and approvals, drafting a project, as well as purchasing everything necessary to connect an individual gas supply line will require a lot of time, nerves, and money.

Gas equipment for heating a private house - alas, not everyone has the opportunity to take advantage of its convenience

Electric heating units, it would seem, can be used to heat any building to which electricity is supplied. Such boilers are easy to install, adjust and operate. However, their use also has its pitfalls.

An electric boiler is installed quickly and easily, but the costs of such heating are far from affordable for everyone.

For example, for the installation of high-power devices (above 7 ÷ 9 kW), a three-phase power line is required. And this - again trips to the authorities, drawing up a project, its coordination, approval and other "joys". Another factor that cannot be ignored is the high cost of electricity, and it is growing every year. Therefore, the payment for heating using an electric boiler can be an overwhelming burden on a family's budget.

In addition, it must be remembered that if, in an emergency, a power outage occurs, the house will remain not only without light, but also without heating.

The logical conclusion is that if it is impossible to use gas, a solid fuel boiler is more reliable and profitable when heating a private house. Moreover, heating of homes with wood has been traditional for many decades, since there is no shortage of this fuel. Especially problems do not arise in regions rich in forests, in which there is always enough dead wood. And the purchase of ready-made firewood on the scale of the heating season will be much cheaper than paying for electricity.

That is why, even having installed gas heating equipment, many owners of old houses are in no hurry to get rid of stoves and fireplaces, which are maintained in working order "just in case."

However, a stove is not an option that can heat large areas of the house. Therefore, in order to achieve comfortable temperatures, several ovens had to be installed in the building, which were heated several times a day. Of course, this is not only difficult, but also extremely wasteful.

A solid fuel boiler is a modern powerful unit capable of providing heat to a very large residential building.

This discomfort is eliminated by creating a full-fledged heating system, powered by a long-burning solid fuel boiler, which allows you to supply the whole house with heat from one place. Unlike a conventional furnace, such units are capable of operating from one fuel load up to 12 or even more hours. Thus, such a boiler will require attention twice a day, when the required amount of firewood is put into the furnace.

By the way, there are also models of solid fuel units that are capable of operating on one fuel tab for a day or more.

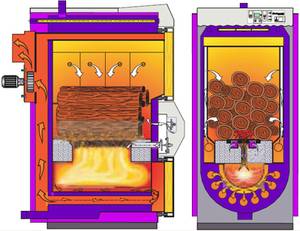

The structure of one of the models of a solid fuel boiler for long burning and the types of fuels used.

The advantage of solid fuel boilers is that almost all models can operate not only on wood, but also on other types of solid fuel. For this purpose, pellets, peat briquettes, as well as the so-called "eurowood" are produced on an industrial scale from wood waste.

Some types of coal are also used as fuel for these units, however, not all models are designed for it. Therefore, if you plan to use coal for heating, then you should choose the appropriate model, having studied its characteristics when purchasing.

4 Best manufacturers

German equipment Buderus and Lopper is distinguished by reliability, efficiency and long service life. A huge disadvantage of such devices is their cost, since they are very expensive. In addition, boilers of these brands are whimsical in terms of fuel quality, so when using simple wood waste, they will work poorly.

Thermal devices of the Czech production Viadrus, ATMOS and OPOP are also popular. They may well be comparable in reliability and quality of automation with German brands, but they are much cheaper.

Polish wood-fired units are presented in large numbers, but mostly they are ordinary heat generators or pyrolysis installations. Russian buyers prefer SAS and Orlan models. Their production characteristics are much lower than those of German and Czech equipment, but they are unpretentious in terms of fuel quality and also have a low cost.

Heating equipment manufacturers produce not only classic models that run on wood, but also multi-fuel installations:

- 1. NMK Sibir-Gefest KVO 15 TE is a universal boiler that runs on wood. Additionally, the design is equipped with an electric heater. The power of the device is 15 kW, it can heat a room with an area of 150 m². In addition, a heating element is additionally built into the device. The model can also operate on coal and eurowood. The efficiency is about 75% and the weight is 115 kilograms.

- 2. Bourgeois-K Modern-12. Pyrolysis boiler with a power of 12 kW with built-in mechanical control. It can heat a room with an area of 120 m². The maximum temperature rating is capable of reaching 95 ° C.

- 3. Protherm Bober 20 DLO has a power of 19 kW.The unit has an additional cast iron heat exchanger that can be heated in the range from 30 to 90 ° C. This heating structure has the highest efficiency factor - 91%. The approximate price of such equipment is 50,000 rubles.

The principle of operation of long-term combustion boilers

Boiler operation begins with smoldering fuel items (coal, wood, peat) in the furnace. Due to the fact that the oxygen supply is limited, the smoldering process is slowed down as much as possible, this allows less frequent bookmarks of new fuel

... This principle of operation allows you to save fuel, since one bookmark lasts 80% or more longer than in a conventional solid fuel boiler. It also allows you to reduce the time required to monitor the operation of the boiler.

Due to the fact that smoldering occurs in a larger volume, a gas with a high calorific value appears in the bunker. It enters the combustion chamber through a refractory nozzle and is ignited by blowing oxygen. The advantage of these boilers is that they burn a large number of various heavy compounds

, including soot. Toxic substances do not enter the chimney, polluting the environment, but burn, giving off heat. During the operation of such a boiler, only non-combustible smoke enters the chimney pipe, which is completely non-toxic

.

The fuel in the boiler is processed according to the principle of upper combustion, it consists in the fact that firewood begins to burn out from the upper layer. The flame gradually descends, which significantly slows down the process of fuel smoldering, but at the same time increases heat supply.

The fuel in the boiler is processed according to the principle of upper combustion, it consists in the fact that firewood begins to burn out from the upper layer. The flame gradually descends, which significantly slows down the process of fuel smoldering, but at the same time increases heat supply.

Depending on the model, the duration of operation of boilers varies from one load of fuel. On average, it is enough for 1-2 days of continuous burning while maintaining a constant temperature. But there are also boilers that able to work for more than 3 days

without outside interference.

Despite the active gasification in many regions and districts of the Russian Federation, they are still relevant for heating a private house. They are appropriate where there is no gas boiler or the cost of gas supply is too high. On the other hand, a wood-fired heating option is much better than a massive brick stove.

To decide whether you need this device in the house at all or not, take a closer look at it. The solution to the issue of heating the house does not require fuss and hasty decisions. You need to understand all the nuances.

Device

-

- The principle on which the wood heating boiler is based is quite simple:

- firewood is loaded into the firebox;

- through a heat exchanger made of steel or cast iron, heat is transferred to the coolant (the boiler is connected to the water circuit for heating the house). As a result, the entire room is heated;

Manufacturers keep inventing new solutions. Follow the market novelties, each modification has its own nuances.

different wood-fired boilers differ primarily in the size of the combustion chamber - the larger it is, the higher the power of the unit.

Heat exchanger

When choosing a heating stove, the question often arises: which heat exchanger to give preference to?

Heat exchangers also differ from each other:

steel heats up quickly

But it also cools faster, although for a stove with a water circuit it is important that the water heats up as soon as possible. Service life on average 10 years;

The main disadvantage of a steel heater is its vulnerability to corrosion. Therefore, sometimes they use a water circuit filled with distilled water, although this implies some waste.

the cast iron element heats up longer and gives off heat for a longer time. It has an impressive service life (it will last at least 20 years).

With frequent and sharp temperature changes, the cast-iron heat exchanger is prone to rather rapid destruction.Be careful when using.

Liquid fuel equipment

It is worth noting that when selecting a boiler by area, liquid fuel equipment is rarely preferred.

The low popularity of such boilers is due to the following factors:

- high fuel prices;

- the need for a place for storing diesel fuel, that is, a large capacity located close to the house;

- the need to ensure heating of the tank so that diesel fuel at low temperatures does not thicken and clog the burner;

- since the operation of the equipment is accompanied by a high level of noise and an unpleasant odor, it must be installed either in a well-ventilated annex or in a separate boiler room.

Wood-burning boilers - device and principle of operation

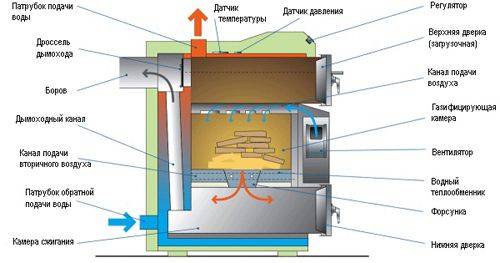

Despite the huge selection of models of wood-burning boilers, their device does not differ so much. Any wood-fired boiler for heating a house necessarily has a fuel combustion chamber, a water heat exchanger, a chimney and an ash pan. The simplest wood-burning boiler resembles a potbelly stove with a water jacket: when firewood is burned in the firebox, the water heats up and enters the heating system. The efficiency of such a boiler is low, and the consumption of firewood is significant, due to incomplete combustion of fuel, part of the money flies into the pipe in the literal sense of the word. The design of modern boilers with a long burning function is, of course, more complicated, the device of such a boiler and its main elements are shown in the figure.

Wood-fired boiler elements

Firewood is loaded into the boiler through the upper loading door at once in a large volume. The initial combustion of the fuel takes place in the gasification chamber. The flow of air, and with it the oxygen necessary for combustion, into this chamber is limited - this is how the intensity of combustion is regulated. In this mode, the wood does not burn, but smolders with the formation of more heat, while the water is heated in the heat exchanger. But the combustion process does not end there: smoldering produces smoke containing combustible gases. These gases enter the second chamber - the combustion chamber, which simultaneously serves as an ash pan. The air supply to this chamber is no longer limited, and with a sufficient amount of oxygen, the gases are afterburned. The combustion temperature of the gas-air mixture is very high, and the heating efficiency of the water heat exchanger in this chamber is also very high. As a result, the smoke is cleared of ash and harmful combustible gases, which makes the new generation wood-burning boilers very environmentally friendly.

Pyrolysis is a long burning process

Video - the principle of operation of a long burning wood boiler

The smoke is evacuated through a chimney duct connected to the chimney and chimney. For supplying cold water and removing hot water from the heat exchanger, the boiler is equipped with branch pipes. They are connected to the heating system according to the selected scheme. Boilers of the new generation are equipped with automation, which makes it possible to simplify boiler maintenance as much as possible:

- a temperature sensor giving a signal to the primary air supply fan;

- a pressure sensor that signals when the normal value is exceeded;

- water pressure sensors in the system.

The efficiency of solid fuel boilers directly depends on the type and quality of fuel. If the boiler is designed to operate on wood, do not load coal and peat briquettes into it! This will reduce the efficiency of the boiler and may damage it. It is also not recommended to use poorly dried firewood and coniferous wood for heating a wood-burning boiler - they burn with the formation of a large amount of steam, resins and soot, and the boiler will have to be cleaned much more often.

Rules for choosing a heating boiler

Before proceeding with the selection of a specific model of a heating boiler, it is necessary to study the criteria that should be guided by. Understanding the features of the work and the main parameters of the equipment, you can choose a device that can satisfy all your needs.

First of all, consider the following nuances:

- boiler type and efficiency;

- camera design;

- the power of the device and the area of the room;

- combustion time and supported fuels;

- heat exchanger material;

- additional functions and protection systems.

Boilers are single-circuit and double-circuit. The first option is connected to an autonomous heating system and is intended exclusively for heating. Some models work in conjunction with a boiler.

The second option replaces the water heater and boiler, providing not only heating, but also hot water supply.

The boiler efficiency indicator, expressed in the efficiency parameter, shows how efficiently the device works. The higher it is, the less fuel will be needed to warm up the room.

One of the main indicators of the equipment is the heat output. This parameter must be selected based on the area to be heated.

It is highly desirable that the model has the ability to adjust the power, which allows you to achieve the optimal comfortable temperature.

Boilers with an open type of chamber design take oxygen from the room and remove the combustion products through the chimney. They should be installed in a location with good ventilation. Units with a closed chamber type can be placed in almost any room

The time of fuel combustion in the boiler depends on the frequency of laying. Pyrolysis boilers and long-term burning devices retain heat for the longest time. The best option would be units that run not only on wood, but also on alternative fuels.

Also, when choosing, it is important to pay special attention to the heat exchanger:

Image gallery

Photo from

Heat exchanger in a heating boiler

Solid fuel boiler with steel heat exchanger

Cast iron model of a heating boiler heat exchanger

Copper heat exchanger boiler

The safety of operation and the efficiency of the equipment are increased by additional built-in mechanisms and functions. It is good if the selected model has protection against overheating, devices for regulating traction, measuring current pressure and temperature indicators.

Solid fuel boilers

Often, during the selection of a heating boiler by area, consumers stop at solid fuel equipment. Although it has a number of disadvantages, it is still the most in demand.

As a rule, coal and firewood are used for kindling solid fuel boilers. The final choice depends on which raw materials are more readily available in a given region. It is worth noting that coal and wood boilers are different from each other. Wood-fired boilers have a large loading chamber that can hold a lot of firewood. Coal chambers have a smaller combustion chamber with thicker walls to withstand high combustion temperatures.

The advantages of solid fuel boilers are:

- savings on heating costs;

- the reliability and the prostate of the structure;

- the ability to work regardless of the availability of electricity.

It is worth mentioning significant disadvantages:

- Due to the cyclical operation of the boilers, the air temperature in the house is unstable, it becomes either cold or hot. To solve this problem, heat accumulators are installed, that is, containers with water that allow you to maintain an optimal microclimate constantly - during the combustion process, heat accumulates, which is then consumed to warm up the house.

- The need for service. Any solid fuel will first have to be loaded, set on fire, control the intensity of its combustion, and upon completion of the process, clean the furnace and re-ignite the boiler.

- The system cannot work offline. As it burns out, it is necessary to periodically add a new portion of fuel so that the system does not freeze.

- Since a lot of dirt is formed in the process of filling fuel and cleaning the boiler, it is advisable to install the boiler as close to the inlet as possible so as not to spread it everywhere.

Varieties of electric boilers

When selecting the power of the heating boiler by the area of the house, it is worth understanding the main types of such devices:

- Heating elements. This is the traditional and most common type of electric boilers. Multistage units are considered more economical, since they are capable of operating in several modes. Among the disadvantages can be called low efficiency due to heat loss for heating the heating elements. But the advantages include low prices for consumables (heating elements) and easy-to-perform repairs.

- Induction. In such equipment, the heating agent is heated at the moment the water passes through the inductive coil. It is believed that induction boilers are more economical in comparison with heating elements, they have no heat loss and practically no inertia. In addition, such boilers are very compact - they look like a piece of pipe from 35 cm to 1 m long. Among the disadvantages is the need for constant circulation of the coolant, otherwise, the boilers overheat and burn out quickly.

- Electrode. Many buyers, when they want to choose a boiler according to the parameters, stop at this type of equipment less often. Although they are considered the most economical, in most cases, consumers are stopped by the need to circulate electrolyte through the pipes as a heat carrier, that is, water with certain additives. This requirement is due to the fact that heating of the coolant occurs due to the passage of current between the electrodes. When operating boilers of this type, it is necessary to monitor the condition of the electrodes and electrolyte. In addition, the entire installation works under voltage - this also frightens consumers a little.

How to choose?

But even such a worthy and proven device must be chosen as carefully as possible. Only under this condition can one expect an optimal result when heating a private house or a bath. Russian and foreign wood-burning boilers operate at approximately the same technical level, so one should focus more on the properties of a particular model, and not on the brand. Of course, in this case, the general popularity of the manufacturer is quite important.

You should also pay attention to the received thermal power, which should not be excessive (and many companies try to supply the most powerful equipment)

The placement of special ribs located on the outer part of the case helps to increase the heating intensity. If you need a "heater", choose a stove with a special container, usually fixed above the body. Sometimes there are options with a grid surrounding the firebox around the perimeter. It is for this that the grid will have to be filled with stones. The correct choice of construction material is very important. The best results are obtained by boilers made of special bricks or natural stone.

The durability of such devices meets the most demanding requirements, and the aesthetic parameters will be optimal. The availability of ready-made kits on sale simplifies installation, but their total cost is very significant.

High-quality structures are often made of cast iron with the addition of chromium, which allows them to withstand sudden temperature spikes without cracking. As a result, the total service life is up to 25 years. The only limitation that prevents the widespread use of cast iron wood-burning boilers is their significant price. You can save money by choosing a product made of heat-resistant steel, but it is not very durable, since the welds are subjected to enormous stress.

At the same time, the absence of a water jacket negatively affects the stability of the material. A fire burning inside heats the structure up to 1000 degrees. And soon enough scale appears, and if it falls off, a kind of "sieve" may appear over time.

Even cast iron is not an absolute guarantee of quality. If there are thin parts in the structure, there is a high risk of their quick breakdown. It is recommended to inspect the working parts of the combustion chambers and cast parts. They should not have the slightest cracks, chipped areas, surface shells

The less curved and intricate the path of the smoke through the internal chimney, the better the boiler will cope with heating the bath; this requirement is especially important for steel products

Wood-fired boilers are sometimes used to heat water in swimming pools. It is no secret that the weather conditions often do not give pleasure to people, but even on the hottest day, the water in the pools is often too cold and unsuitable for bathing. If children or just people with poor health jump there, there is a great risk of hypothermia, and it's just unpleasant.

When choosing a wood-burning boiler for a long burning for a summer residence, you should focus primarily on the number of rooms. Water heating works well in large houses, especially if the entire heating season or most of it will live there. If the dacha will be used only during the vegetative period of plants, it is advisable to choose structures that directly heat the air. They will provide warmth as quickly as possible and exclude the effects of cold weather in early spring or late autumn. But it so happens that the air currents run into an obstacle and cannot heat the entire room; then the choice should be made in favor of the water circuit.

Systems with one circuit are most often more powerful than two-circuit counterparts, and with identical fuel consumption they are able to heat a large room. But double-circuit devices also allow you to get hot water, which is very valuable for summer cottages. The principles for choosing between forced and natural circulation are about the same as in other cases. Summer cottages heated all year round should be heated with plain water, which is undesirable to drain even in summer. When they live in the country in the summer and occasionally visit it in the winter, it is worth choosing antifreeze; but it flows out of any hole much more actively than water, which increases the requirements for the installation of circuits.

Steel or cast iron - which is better?

Solid fuel boilers are made from two types of metal alloys - steel and cast iron, in connection with which there are battles on the forums over which of these options is better.

Cast iron model

Cast iron model

Opinions, as usual, are the most contradictory, and it is simply impossible to make an unambiguous verdict here.

Steel model

Steel model

Let's still try to understand this issue, based on the opinions of experts.

Table 3. Opinion of experts.

Evaluation criterion

Pros and cons

Weight and transportation

A boiler with a steel body is lighter, therefore both its transportation and manual carrying is much easier. Cast iron is generally very heavy, and besides, it is also fragile

You need to move such a boiler very carefully, so after a blow it may not live up to the first furnace.

Maintainability

The most common problem that occurs with cast iron boilers is a burst section that needs to be replaced. And here you can expect difficulties associated with ordering it and waiting for delivery - and with the search for a master who can replace it so that in the future, the boiler, which at the same time needs to be completely disassembled, does not flow

For a steel boiler, the maximum may need to be welded, and any welder can do this.

Price and durability

If we compare two models with a similar design and power, then the cast iron will be twice, or even three times more expensive. Manufacturers and sellers attribute this to a longer service life, with which many experts strongly disagree.

And even if so, then for the amount that needs to be paid for the cast-iron model, you can buy at least two steel ones, which will total the same period. And it is still unknown how many times during the entire life of a cast-iron unit you will need to change its sections.

So here the advantage is definitely behind the steel boiler.

Efficiency

Roughly the same. However, cast iron is more massive and keeps heat longer, when the steel, although it heats up faster, also cools faster.

Complexity of installation

In installation, a cast iron boiler is more complicated, and any connection error can cost it "life". So here, too, he loses to his steel brother.

Video - How to choose a boiler - steel or cast iron

From the above, it becomes clear that a steel boiler is easier to install and repair, has less weight and cost. And all this despite the fact that with the correct piping, it provides the house with warmth and hot water in the same way as a cast iron house. The question suggests itself: "And if there is no difference - why pay more?"