Fireplace insert

Starting preparation for laborious work, many pay more attention to the appearance of the structure, not paying due attention to one of the most important elements - the firebox. For many, it appears as a metal box or brick niche, intended only for storing firewood. But apparent simplicity can only be misleading.

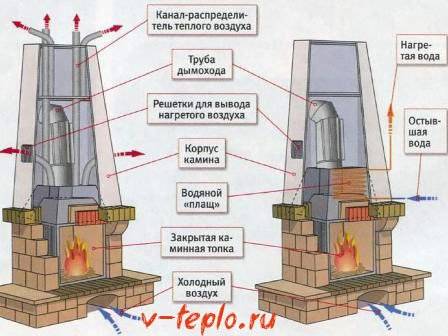

Structurally, the firebox consists of the following elements:

- Base

- Walls

- Smoke collector

- Grate

- Door

- Gate damper

- Ash pan

It is customary to make the base of the firebox made of stone or brick, but in metal models it is usually cast iron. Unlike steel, these materials do not deform under the influence of gravity and high temperature.

The walls can be made of steel, cast iron, fireclay bricks, or absent altogether (for example, in open models). Each of the materials has its own pros and cons; a decision must be made based on preferences or after the advice of a specialist.

In a brick firebox, the back wall must be tilted, the side ones must be expanded. Sometimes they give a more complex rounded shape to surfaces in order to increase heat transfer.

We have already described many aspects of masonry in the article on how to fold a brick stove. go and find out more

Designed to remove carbon monoxide and fumes outside. It can be a separate element or be a direct part of the firebox. The material he has is similar to her. In this case, the vault must be located above the furnace window.

Through it, the hall enters the ash pan, oxygen is supplied to the coal or wood for combustion. In gas or liquid fireplaces, a grate separates the firebox and the burner. It is made from refractory ceramics or cast iron and must withstand temperatures up to 1000 degrees.

The door can be one of two types: open or closed. The greatest preference is given to glass models that allow you to visually observe the combustion process.

The gate damper closes the chimney. Reducing the draft, the wood smolders slowly inside the firebox, continuing to emit heat.

The ash pan is designed to collect combustion products and in traditional models serves as a blower. Sometimes it is made in the form of a drawer, which is freely removed and shaken off. The blower hole must be equipped with a draft control damper.

Corner fireplace construction

Dimensions of the corner fireplace (in centimeters)

The laying of a corner fireplace is no different from the usual construction process. The exception is the fineness of the seams - the thinner they are, the better the structure retains heat. Provided that the project and the necessary drawings have already been prepared, and the order has been developed, construction work should be started.

The following is a step-by-step guide to this process. A pit is pulled out, after which it will be necessary to fold the timbering, the shields of which are coated with bitumen mastic. Also, roll waterproofing is laid. The bottom of the pit is compacted, a layer of gravel is filled up, after which it is watered and compacted again.

Next, you need to install the formwork and lay large stones on top. It is recommended to fill the resulting gaps between the stones with gravel. A cement-sand mortar is poured into the formwork, with a layer of about 10 cm, and left to dry for at least one day.

After the foundation has dried, the formwork is dismantled. The foundation is closed with 2 layers of roofing material and then bricks are laid in accordance with how the order was developed.

No matter how simple a corner fireplace project may seem, it requires exceptional attention, as well as skills and experience in working with materials.In this case, it is preferable to entrust the entire construction process to professionals, since it is they who will be able to competently plan the work process, complete all the required drawings, and also make the heating structure as functional and reliable as possible.

Fireplace technical requirements

- The foundation is made so that it can withstand the load from a brick fireplace. Small foci weigh about 0.5 tons, and large ones give a load commensurate with a ton or more.

- The base is arranged with a concrete strip type or made of bricks on a construction cement mortar. In any case, it plays the role of an independent structure, which is not tied to the supporting base of the house itself.

- The average height of the foundation for the fireplace is taken at 30-40 cm and does not reach the level of the finished floor to a height of 10 cm.

- The volume of the furnace space in the fireplace depends on the volume of the room and makes up its fiftieth part. Its depth depends on the accepted height and is calculated as a third or half of this size. The smaller the fireplace, the more heat it will give into the room. But the volumetric indicators must be respected.

- In order for the heat rays to be better reflected and enter the room, the side walls of the furnace are turned at a small angle outward, and the back wall is tilted starting from one third of the height.

- Fire safety requirements regulate the height of the base of the firebox, which should not be lower than 30 cm from the floor. The same requirements provide for fixing a stainless steel sheet in front of the fireplace on the floor. Its width is 15 cm larger than the front dimension of the combustion chamber.

- In the smoke chamber, a ledge called a pass must be laid out, which prevents soot and sparks from entering the chimney cavity and returning smoke to the room.

The combustion chamber includes the following elements

- Base for laying firewood.

- Two side and one back walls.

- Smoke collection chamber.

- The grate of the grate.

- Door according to the project.

- Gate damper.

- Ash pan at the bottom of the furnace.

Chimney requirements

- To improve traction, the pipe is made of round cross-section. The area of its opening depends on the area of the lower base of the furnace and is 1 / 10–1 / 15 of this size.

- When leading to an external wall, the duct should not have more than three changes in direction.

- The pipe installed above the combustion chamber is made strictly vertical, without bends, its height is set from 5 m and above. The verticality is checked along the entire length, the violation of which may lead to smoke pollution of the living space in the future.

How the fireplace works

Basically, a fireplace is an open hearth stove. Firewood logs burn and generate heat, which is the source of heating. To prevent smoke from entering the room, a curved chimney is provided. It also prevents rain and snow from entering the center from outside.

Do not count on a fireplace as the main heating device in your home. Its design is such that, unfortunately, the efficiency is very low, no more than 25% of all generated heat enters the house, the remaining 75% is drawn out through the chimney. The fireplace does not provide an even distribution of heat, the bulk of the warm air comes out through the open hearth, the side walls do not warm up at all. A fireplace in a modern house most likely performs a decorative function; with its help, it is well to equip a relaxation zone.

Scheme, ordering and drawing of a brick fireplace

Before work, you must definitely acquire sketches and drawings. You can borrow ready-made ones or draw yourself, indicating the dimensions and features of the structure being erected.

If we talk about the order, it is necessary to decide on the type and location of the fireplace:

- Round arch corner fireplace

- Corner fireplace with rectangular arch

- Fireplace with a podium near the wall

- Classic fireplace stove

Fireplace stove

A classic brick fireplace with your own hands should serve not only as an element of decor, but also as a source of heat, be convenient and safe to use. The simplest diagram of such a model is as follows:

- The heart of the fireplace is a spacious firebox with a fireproof glass door

- An ash pan is arranged under it to collect and remove combustion products.

- On top, a smoke channel is arranged from a material with a high heat capacity

The order of a brick fireplace-stove is as follows (with visual images):

- The first two rows will serve as the basis and are laid out completely, starting from the third you need to provide openings for blowing and cleaning doors, a smoke channel

The bottom of the furnace begins to be laid from the sixth row, fireclay bricks (yellow) are used for it, the same continues in rows 7-9. After it is mounted between the ash pan and the firebox, the grate

In rows 10-12, they continue the same thing, but providing a furnace hole on the front side. Before laying the 13th row, you need to mount the door, the 14th row will have a vertical upper arch

Row 15 should line up the vault, 16 should form the mantel. The overlap of the furnace is done on the 17th row and is completely completed at 18, leaving a small hole under the smoke channel

A damper of a suitable size is mounted in rows 19 or 20. The next 7 next to it will make up the walls of the chimney and the stove, and in row 27 a metal strip is placed to support the stove overlap

Rows 28-30 are laid out of red brick and represent an oven ceiling. Then a chimney well is equipped (the height is determined in each case). In this case, a dressing of the seams should be formed so that each subsequent row overlaps the joints of the previous

A second shutter must be installed between the second and third row of the well.

You may also be interested in instructions on how to make a barbecue oven.

Other ordering options

Step-by-step video masonry guide:

Order of a corner fireplace with a semicircular arch:

Arrangement of the fireplace with an arch in the form of a rectangle:

Podium fireplaces:

When choosing the location of the fireplace in any particular room, you need to take into account the presence and path of drafts. The optimal solution is to place the structure away from window openings and doors, as well as from the intersection of air flows between them.

Refractory mortar is used for laying fireclay bricks, ceramic bricks are placed on an ordinary sand-clay mixture. It is prepared according to the instructions on the package. Preparation of the solution is a long process. It is necessary to use clean and well-softened clay, soaked in water for up to 2-3 days.

If the adhesive solution is prepared incorrectly, soon the brickwork will begin to collapse and crack under the influence of high temperatures. Whether external surface finishing is necessary or not - everyone decides for himself. Many people prefer to leave everything as it is, carefully processing the seams.

Video instruction

If you approach the work with all responsibility and thoroughly prepare, everyone can lay out a brick fireplace with their own hands. But even small mistakes can negatively affect the final result. As a result, you can get a short-lived design that does not live up to expectations.

Doubting your abilities, you need to contact a specialist. Having visually assessed the situation, he will help with the most difficult stages and give some valuable advice.

Building a fireplace with your own hands from bricks

First, determine the place in the room for the location of the fireplace. It is recommended that the selection be made taking into account the windows and possible movements of the air currents. It is not recommended to build a fireplace opposite the openings that come off.

The fireplace is not used in most cases, as the only source of heat in the room, since this type of stove gives the room only a fifth of the heat, the rest of the hot air "flies out into the chimney." But fireplaces are made for aesthetic pleasure, they give the decoration of the room an original addition.If, at the same time, the fireplace works without smoke and does not cause trouble for the owners, then all household members will strive to while away the cold winter evenings at this crackling source of spiritual and thermal energy.

To select the location of the fireplace, they are initially determined with the location of the future chimney. It should not, when passing through the roof structure, require the transfer of load-bearing beams or rafters. The distance from the duct to the nearest wooden component of the roof should be no closer than 0.7 m.

Also pay attention to the location of the floor beams and the lag of the lower floor. They also try, if possible, not to reconstruct.

The wall behind the fireplace heats up from the constantly rising hot air, the more it is recommended to make reliable thermal insulation using layers of asbestos and a foil reflector or sheet of steel

Special attention is paid to the insulation of wooden walls

The functional check of the newly folded fireplace is checked a couple of weeks after the end of the work. During this time, all components and materials will dry out and acquire a fortress.

Brick fireplace drawings.

Then it is necessary to carry out the execution of drawings for laying fireplaces, for which, as an example, a room of 15 sq. The rear wall is laid out in half a brick, which will be 12 cm, and the side walls must be laid out in one whole brick, i.e. 25 cm.After calculating these dimensions, a layer-by-layer drawing of the entire fireplace masonry is carried out, i.e. the so-called orders are being drawn up.

To carry out the orders, you need to have checkered paper available, since not only a whole brick will be used, but also half a brick and ¾ of a brick.

It is necessary to start from the base, and, for originality, the layout of this row can be carried out with an edge, or flat. When laying out the 2nd row, the bricks are laid flat. There is usually a gap of 25-30 cm between the bottom of the firebox and the floor, which is equal to 2-3 brick rows.

Requirements for laying brick fireplaces.

When planning the laying of a fireplace, there must be some requirements for it. First of all, the fireplace should not create smoke. Thanks to the work of the fireplace, the air should warm up well. Also, the fireplace should have aesthetic beauty and fit the interior.

The dimensions of the brick fireplace, depending on the area of the room.

Before starting the construction of the fireplace, the parameters of the area of the building in which the fireplace is planned must be determined. As an example, we can consider the calculation of the parameters of a veranda or a room of a country house, the area of which is 10, 15 and 20 m, and the height of the room is from 3.3 to 3.5 m.In volume, the room occupies 35, 50, 70 cubic meters. Then the opening of the furnace will be equated with respect to these volumes in the ratio 1: 50-1: 70, thus, this will be about 0.2; 0.3; 0.4 m². Considering these dimensions, the size of the firebox portal will be:

- 0.2 sq. m - 36x45cm,

- 0.3 sq. m - 44x67cm,

- 0.4 sq. m - 52x77cm.

The depth of the fireplace firebox and the height of the portal must be correlated as 1: 2-2: 3, moreover, during the construction process, these dimensions must be taken into account, since their importance is very high. Indeed, if the depth of the firebox is greater than it should be, a significant decrease in heat transfer will occur, and if the depth is less, this will contribute to smoke

Thus, in this example, the depth will be:

- for 0.2 sq. m. 18-24 cm.,

- for 0.3 sq. m. 22-30 cm.,

- for 0.4 sq. m. 26–35 cm.

The dimensions of the chimney openings are determined by the combustion area, therefore the dimensions of the chimney opening should be 8-15 times smaller, and this will amount to:

- 0.02 sq. m;

- 0.03 sq. m;

- 0.04 sq. m.

In the case of the construction of a brick chimney, its size will be determined: 14x14 and 14x27.

In order to ensure a greater ability of the fireplace to reflect heat, it is necessary to carry out the interior design of its walls at an angle. Thus, it is necessary to make a turn out of both side walls, while the back wall should be tilted forward.

In the area above the fireplace insert, a smoke chamber is being arranged, and between the fire chamber and the smoke chamber, a cornice is produced, called a "pass". The pass is an important part of the fireplace, as it is responsible for preventing the soot from flying out with sparks, as well as providing protection against smoke entering the room.

In order to carry out the bricklaying of a brick fireplace with your own hands, it is necessary to determine the dimensions that are brought to the brickwork module. With a brick size of 6.5x12x25 cm, the seam during laying should be about 0.5 cm in thickness.

In order to calculate the overall dimensions of the fireplace, it is necessary to know exactly its location in terms of the specific room in which it will be installed. The most optimal location for the fireplace is one in which the end walls will be inside in the corner. Erecting a fireplace near a wall looking at a wall with windows is undesirable, since with insufficiently sealed windows, a fireplace built in front of them will contribute to the creation of drafts.

When the fireplace is heated for a long time, the rear walls of the chimney are heated strongly, as a result of which a fire can start in a house built of wood. Under such conditions, there must be provision for fire-prevention measures.

Correct selection and calculation of materials

Kiln brick is divided into types

- Fireclay bricks are made of clay, which are able to withstand a persistent rise in temperature to critical states, do not crack during heat drops, and do not undergo chemical reactions.

- Quartz brick is made from quartz sintering, has high strength, but is exposed to active acids.

- Ordinary clay brick is used for laying sections of the fireplace that are not exposed to very strong heating during operation.

- Hollow ceramic bricks are used to insulate the fireplace from the walls of the house. It can be cement-sandy, poorly heat transferring, or made of foamed dolomite.

For the device of the vault, a special wedge-shaped brick is used. but it can be cut into shape from ordinary ceramic bricks.

Burnt and unburned bricks of dark brown and pale yellow colors are not used when laying fireplaces. Due to its increased moisture saturation, silicate brick is not used when laying fireplaces.

The calculation of bricks for the construction of a fireplace is carried out in strict accordance with the order drawings. Those elements that are indicated in the orders of halves or incomplete bricks are considered as whole. To account for various marriage and battle, a coefficient of 1.15 is used, by which the number of bricks obtained when calculating according to the ordering schemes is multiplied.

If you adhere to the experience of the stove-makers and make masonry seams of 3 mm, then to calculate the finished mortar, you need to count a bucket of mortar for every hundred bricks.

Type and preparation of sand

For the device of the base, masonry of the side walls and the upper part of the chimney, any type of sand is used in the solution. The preparation of the same clay solution for areas of high temperatures is carried out only with quarry or ravine sand.

In river and marine species, grains of sand are smooth due to the constant action of water and have poor adhesion to natural clay.

Before using any kind of sand, it must be sifted from large debris through a mesh and washed with a stream of water through a sieve made of burlap until clean water flows.

The furnace heat-resistant part, the smoke collection chamber and the lower part of the pipe are laid out on a clay solution. It is mixed with quarry sand to reduce the fat content.

To prepare the solution, the clay is pre-soaked for a time equal to 7-10 days.During this time, it must be thoroughly mixed every day, after which sand is added in the right amount.

If there is no time for such a long preparation of the solution, then dry refractory mixtures are bought on the construction market. They are packed in airtight bags, have a balanced composition and only require mixing with water with a construction whisk.

For other parts of the fireplace that are not exposed to strong heat, use a solution of clay, sand and cement.

Classic ordering

Such masonry is used for a simple brick hearth. It is designed for a built-in oven with a hob. The classic ordering is good because it can be re-planned with your own hands quickly enough.

Ordering a classic fireplace

Step-by-step instructions for classic ordering:

- The basement row is laid out on the edge. This technique allows you to get an unusual appearance of the fireplace. When forming a basement row, it is strongly recommended to use drawings. The diagram will help you put all the steps together correctly. The erection of the basement row should be stopped at around 26-28 cm;

- Then the laying is done flat. The first, second and third rows are completely filled with building material;

- The fourth row is the hearth hearth. It must be folded as indicated in the classic diagram;

- Next, we proceed to the formation of the blower (ash pan). A wood-burning stove must necessarily have a place where combustion products will collect. At this stage, a metal lattice is also made by hand from scrap materials. The lattice is placed on the fifth row of bricks;

- The lattice is pressed with the next layer;

- Then you can start laying the portal. In this case, the hoard begins with the lower salary;

- The erection of the portal continues up to the 13th row. It should be noted that at the 11th position it is necessary to start forming the slope - "mirror";

-

On the 16th row, the formation of the mirror ends. The masonry is brought to the 17th position, from which the formation of the facade begins;

Fireplace in the house. Recommendations

- From the 19th row, they begin to lay out the chimney with their own hands. Standard dimensions of the chimney: 27x14 cm. A valve is installed at 22 positions, which will close the stove;

- In the last position, the desired chimney shape is created;

At this stage, the classic fireplace masonry ends. A brick fireplace, built according to the considered scheme, has good efficiency and good heat transfer. It does a good job of heating even large rooms.

Building a fireplace - step by step instructions

Do-it-yourself fireplace stoves are made using drawings. For the most part, preference is given to do-it-yourself wood-burning fireplaces.

To begin with, remember the general rules for fireplace work.

- Each next row is first laid out dry. All bricks are trimmed and fitted to each other, and only then the row is assembled for mortar.

- In each row, the corner bricks are laid first, then along the perimeter and only then the central ones. Each stage is checked by the level.

- Do not lay dry bricks. Each one needs to be dipped in water.

- The joint should be completely filled with mortar and as thin as possible.

Fireplace elements and dimensions depending on the area of the room

Do-it-yourself fireplace ordering. The model of the fireplace is selected and its order is printed. This will be an instruction that must be followed carefully. For convenience, you can trace each completed row with a pencil.

Waterproofing. Roofing or roofing felt is spread on the foundation.

If the fireplace is large, the control cord is pulled and the main work begins.

An example of ordering a fireplace with an arch

The first two rows are made deaf. The first row can be laid on the edge.

An ash pan is built into the second row.

All metal structures (doors, grilles) are installed with the expectation of thermal expansion. The gap should be 5-10 mm and filled with asbestos.

3rd row. The bottom of the fuel chamber made of refractory bricks is laid on the edge. Hereinafter, refractory bricks are not tied with red. The grate is being installed.

4-7th row. The beginning of the formation of the camera. If, as here, several bricks need to be shaped, it will be convenient to number the bricks while they are laid out on dry. The walls inside the firebox cannot be plastered, therefore, having laid out several rows, each time the bricks are wiped with a damp cloth.

Ordering a fireplace with an arch

8th row. The slope of the rear wall is necessary for the free exit of smoke.

9-14th row. Arch formation. The steeper the vault, the stronger it will be and withstand a lot of stress. In order to lay out the arch, you need to make a special formwork from chipboard - it was circling. 2 identical blanks are knocked together at a distance of about 10 cm. They are installed in the right place and an arch is laid out on them, symmetrically from both sides to the middle.

15th. Tooth device. It is a ledge inside the fuel chamber, designed so that ash and sediment do not fall into the fireplace, and the draft is good.

19-20th row - narrowing of the chimney. Curved surfaces are brought out by overlap of bricks of approximately 6 cm.

21-22 chimney.

23rd. Fitted valve.

At the place where the pipe passes through the ceiling, a fluff is arranged.

Further, not clay, but a cement mortar for masonry is used (sand: cement 3: 1).

To protect against precipitation, a deflector is installed on the top of the pipe.

Ordering for a corner fireplace

A brick corner fireplace is a simplified version of a small classic hearth. The order of the fireplace is almost the same as in the classic project. It is necessary to take into account only some of the features of the corner foci, namely - the foundation should rise 10 cm above the floor; the base for the stove requires high-quality waterproofing.

It is also not recommended to forget about the safety of the walls against which the stove is leaning. A reflective screen made of steel or galvanized iron is mounted on the back of the heating system.

Step-by-step instruction:

-

The base of the firebox is laid on clay mortar. The first rows of bricks are placed only on clay mortar. It must be used up to position 4, where the fireplace is divided into two blocks, which are overlapped by a stove.

- The first block is designed as a niche for firewood, and the second under the front facade;

- On the fifth row we use fireclay bricks. In this position, the base for the furnace is formed;

-

The field of overlapping the fireplace with a steel plate, its construction continues according to the worked out scheme up to the 12th row. So that the heating system does not malfunction and works well, it is better to use fireclay bricks to decorate its internal walls;

- Up to 27 rows, laying follows the same pattern as at first. To give additional rigidity, metal corners are placed between the bricks, which you can make with your own hands from steel plates;

-

On top of the building, valves are made. If you do not know which side to put it on, then look at the drawings. The valve, installed in the right place, improves traction control.

At this stage, the construction of a corner fireplace with your own hands is considered complete. The diagram shows that the masonry of the corner extension is fundamentally different from the classic one. Its characteristic features are simplicity and undemandingness to the owner's construction skills.

How to correctly calculate the main dimensions of the fireplace

Be sure to record all calculations and measurements on paper, and it is best to sketch it schematically. 1. On paper we sketch on a scale the room where the fireplace will be located. 2. We calculate the parameters of the firebox. Its dimensions should not be less than fifty of the total area of the room. 3. The depth of the portal is determined as the ratio of the parameters of length and width. So the depth can be 2: 3 or 1: 2. 4. Determine the parameters of the chimney. Average indicators are: length - 6 meters, and pipe diameter - 100 mm.

Corner and ordinary brick fireplace

Required materials for laying a fireplace 1. Fire-resistant bricks. Calculate the quantity according to predetermined dimensions, taking into account 10-15% for fitting and breaking the material. 2. River sand (fraction from 0.2 to 1.5 mm). 3. Construction cement. 4. Crushed stone. 5. Fittings.

How to pour a foundation for a fireplace

A fireplace, like a house, has its own foundation. To equip it, you need to carry out a number of activities: - Preparing the foundation for the foundation. To do this, in a pit, the dimensions of which slightly exceed the dimensions of the future fireplace, we fill in the rubble and tamp it;

- We mount the formwork. Its height should correspond to the height of the future foundation; - Fill in the cement-sand mixture; - After pouring, the base is carefully leveled, covered with polyethylene and left in complete rest until dry.

Step-by-step instructions for masonry fireplace

Before starting work on laying bricks with your own hands, it must be sorted out, selected perfectly flat and whole, soaked before starting work in water for several days. The work of laying a fireplace is not so much technically difficult as it requires accuracy and patience.

Each layer is laid on a roofing material substrate. The quality of work is checked by the level. After the first three rows of the fireplace have been completed, fittings are laid, which in the future will become the basis for the fireplace grate. Laying out row by row, check with the previously drawn diagram.

Photo of a brick fireplace

After the work is completed, the seams between the bricks are treated with special colored compounds, which give the work a finished look and add a decorative effect to the brickwork.

Interesting article: Imitation of a fireplace with your own hands in an apartment. Photo

Watch the video: Laying and ordering the fireplace

Fireplace stove in a private house will become not just a decoration, but also an additional source of heat. A wood burning stove is environmentally friendly and more budgetary, so after a fireplace appears in your house, you can significantly save money.

Counting the required materials.

After the registration of orders, taking into account the pipe, is completed, you can proceed to calculating the amount of required materials. To do this, you need to count the bricks by the piece, and all incomplete products should be considered whole bricks. By the way, for fireplace masonry, the use of solid, stove bricks is optimal.

The sand should not contain dust or debris, it should be large, 0.2-1.5 mm. If there is dust and debris in the sand, they must be removed. To this end, the sand is placed in water and infused; at the same time, it is necessary to change the water until it brightens.

When laying out fireplaces, blue (Cambrian) clay is used. In the absence of this type of clay, you can turn to the use of kiln clays.

Regarding cement, you can use regular Portland cement, 300-400 grades.

The diameter of the crushed stone fractions in the manufacture of concrete and laying the foundation for the fireplace should be 2-6 cm. It is also necessary to have reinforcing rods in an amount of about 20 pieces and a diameter in the range of 8-10 and a length of about 700 mm.