Features of operation

- Install the chimney so that it can be easily removed. It often clogs up.

- Check the jacketed oven at all times due to the high temperature of the structure.

- If you want to paint the stove, then use only heat-resistant paints.

- The firewood should be in the size of the fuel part.

- The use of ignition fluids is not recommended. But if you decide to use them, then first splash quite a bit on the wood, and then load them into the firebox.

- Use protective gloves when loading fuel.

- Items that are flammable should be kept away from the oven.

- Household waste must never be burned in the oven. Including plastic.

- It is recommended to start cooking food on such an oven only 10-15 minutes after it has been kindled.

- If you decide to create this design, then it is better to work in the fresh air.

Calculations of structural elements of the stove

With the seeming simplicity of the bubafony oven, it is necessary to understand that its dimensions play an important role.

Particular attention should be paid to the ratio of its diameter to height. This ratio ranges from 3: 1 to 5: 1

At the same time, it is the diameter of the structure that is strictly selected, it varies in the range of 600-800 mm. Why is it so strict?

- If you choose a case of a smaller diameter, then inside the unit, the air entering the smoldering zone will not have time to heat up to the maximum and mix with pyrolysis gases. It will simply fly out into the chimney, taking away the efficiency position with it. In this case, a combustible mixture that should burn out will not form in the afterburner.

- With a large boiler diameter, the fuel itself will mostly burn in the center, and the edges will burn slowly. That is, a pit is formed inside the smoldering zone. It turns out that the load (pancake) will be located at the edges of the fuel load, and a free space will form under it, which will be filled with incoming air. The fuel will simply start burning, and you will have to forget about pyrolysis as such. Again, a decrease in efficiency. But, as practice shows, in this situation most often the stove simply dies out.

This is how the fuel burns in the smoldering zone under the pancake

We return to the wall thickness. If a bubafony is made with a water jacket, then this indicator should not be less than 4 mm. The thing is that through a thin metal wall, heat immediately passes into water, but the exhaust gases will immediately begin to cool down. At temperatures below 40 ° C, the afterburning process is simply impossible. That is, the gas-combustible mixture will not burn, carbon deposits will form on the walls, condensate will form inside the chimney. And all this is a decrease not only in efficiency, but also in the service life of the bubafon stove.

Oven from a barrel with a thin wall

Pros of the oven

- The main advantage and main purpose of Bubafoni is the duration of its burning. The quality, which, judging by the reviews of the owners, raises the least complaints. According to the owners, the balloon versions are capable of burning from 6 to 20 hours.

- It's amazing how little it takes to create this type of oven. A minimum of components, a drop of cutting work, and a little welding. Even making a simple potbelly stove will take more.

- If we ignore the ecological aspect of the issue, then the omnivorousness and variability of the burnt materials are at their best here. When the chimney, the “heel” of the piston and the oxygen supply are arranged as they should, there are no problems.

Advantages and disadvantages

A simple but effective installation for long burning - the bubafon stove is quite popular.

It has advantages and disadvantages:

- Low costs for heating are the advantage of the system; not only wood can be used as fuel, it also works on sawdust.In places where sawmills or woodworking workshops operate, it is very profitable to use a sawdust stove, since fuel can be purchased very cheaply.

- This stove is a long burning installation, which means that you do not have to constantly add fuel to the firebox.

- The simplicity of the design makes it possible to do it yourself, without resorting to outside help. Moreover, you can make a stove from scrap materials. For example, many recommend making a bubafony stove from a gas cylinder.

- Small dimensions make it possible to place the bubafony stove in almost any room.

- Uncomplicated service.

- The ability to use any pipe as a chimney, no need to make a brick structure.

- You can choose a more functional model. For example, for heating, you can use a bubafony stove with a water jacket. However, this is already a more complex design; it will be more difficult to make a bubafon oven with a water jacket with your own hands.

Good ventilation is necessary for a product of this kind - this is, of course, a disadvantage. The structure is not able to accumulate a sufficient amount of heat that is generated during the combustion process. After the end of the combustion process, the furnace cools down quickly enough.

To increase the heat transfer of the structure, it is recommended to overlay it with bricks and plaster with clay mortar. As a result of such work, the heat capacity of the unit will be increased.

Some points should still be completed to improve the work of the structure:

- Do not assemble the chimney from the unit, but from the roof.

- To ensure safe operation, take into account the high heating of the oven. Do not neglect safety rules. To install the oven, you will need to prepare a solid fire-resistant base.

- Make the chimney collapsible. It should be cleaned periodically, otherwise the exhaust gas draft will constantly decrease. The boiler itself will have to be cleaned, but it will not be easy to do it with your own hands, it will be especially difficult to clean the bottom of the boiler, and it is there that soot collects.

- Carry out several test furnaces with different moisture content of the wood. This will determine the optimal combustion method.

Video: Bubafonya oven from a metal barrel

Building a Bubafoni from a barrel or gas cylinder is a feasible task even for a novice home craftsman. The resulting furnace will show good results in terms of thermal efficiency and will delight you with its omnivorous nature. Nevertheless, one should not forget that the Bubyakin unit, like any other solid fuel heating device, is a source of increased danger. This should be remembered both at the manufacturing stage, achieving maximum tightness of adjacent parts, and during operation, without leaving the operating heat generator unattended. And then the stove with the funny name "Bubafonya" will delight you with warmth and comfort, not allowing you to regret the time spent.

Disadvantages and dangers

There are enough disadvantages of this oven and, most likely, you should start with those that most affect its performance.

Wood moisture

The first is the sensitivity to wood moisture. The combustion of the top layer of wood is already a rather unstable process. The increased moisture content of the wood slows down, so necessary for good traction, the process of heating the piston and the walls of the furnace. Fuel dampness exponentially worsens traction and efficiency. In addition, material with this quality carries a latent threat. Once in an upright position, a raw chock can noticeably lag behind in the process of burning wood and block the lowering of the piston. As a result, combustion can stop altogether and lead to the occurrence of reverse thrust.For combustion, so beloved by all pyrolysis fumes, above the plane of the piston, a number of conditions must be met. The disc should not be thick-walled and, on the contrary, have a high temperature even from smoldering from below. Clean, superheated air should be supplied to the area of possible secondary combustion. The height of the chimney and the diameter of all its sections must be sufficient to ensure reliable draft.

This is interesting: How to choose the best interior doors: we study together

Boiler construction "bubafonya"

The main part of the furnace is the body. Most often it is in the form of a cylinder and can be made from gas cylinders, fire extinguishers, pipe sections

It is important that the walls are thick, do not burn out from the heat. If a pipe is taken as the basis, the bottom must be welded to it.

To remove combustion products, it is necessary to make a chimney

A pipe with a diameter of 11 to 15 centimeters is suitable. There will also be parts of water in working out and therefore it is better to use stainless steel.

Suppressor. A metal circle with welded-on ribs, clinging to the outlet pipe. The ribs are needed in order to create an additional air cushion between the suppressor and the fuel, this increases the burning time.

Gate valve. Movable element that regulates the amount of air supplied.

Cover with air holes. It is necessary for the formation of a secondary combustion chamber, into which gases enter.

Since the bubafon long-burning stove does not have a high efficiency, it is well suited for rooms with a small area. It is safe, there is no risk of explosion and fire, which makes it suitable for garages and utility blocks.

Advantages and disadvantages

- A pyrolysis oven is a versatile piece of equipment with significant advantages. Before making them, you must definitely consider them.

- Consumption. Long burning stoves are characterized by low fuel consumption. On one load, they can work for more than 12 hours. This is convenient for dryers, greenhouses, garages and sheds.

- Manufacturing. The production scheme is simple, does not require skills in working with special equipment.

- Unpretentiousness. It is possible to lay relatively damp sticks, but the water content in them should be no more than 20%. Wood waste, pallets, paper are suitable.

- High operating temperature. Warming up occurs at a temperature of more than 500o Celsius. This performance allows you to quickly warm up damp rooms.

- Environmental friendliness. There are practically no harmful impurities in waste smoke that cause damage to nature.

- Security. The equipment is completely fireproof. There is no possibility of explosion, sudden spread of fire.

- Autonomy. The peculiarity of bubofoni, a long-burning stove, is that it does not require constant monitoring of the fuel. One kindling is enough every few hours and it will burn all the time on its own. The closed housing will prevent flame blowing out.

- Minimum maintenance. When burned, little soot is formed on the walls and chimney. There is no need to constantly maintain the boiler and clean it.

- Durability. Due to its simplicity, physically nothing can break. That is why it can serve for ten years.

But you have to pay for simplicity, since it has a number of significant disadvantages. In many ways, they are associated with the construction of the bubophone.

- Efficiency. A do-it-yourself bubafon oven will not give high performance. It is designed for relatively small premises. The casing of the unit heats up unevenly, which contributes to a decrease in temperature.

- Inconvenience of service. Despite the low formation of soot, it is inconvenient to clean. It forms at the top of the cylinder.

- Unattractiveness. The mediocre appearance is associated with the general artisanal production.Using materials at hand, it is difficult to achieve aesthetic harmony.

Advantages and disadvantages

Let's start with these questions, because before starting the construction of the boiler, it is necessary to decide whether it is worth starting all this.

So, the positive aspects of Bubafoni:

- Simple design that is easy to do by hand

- . Possibility to use different types of fuel from the category of cheap and generally available. And some will get you for free

- For the manufacture of such a long-burning boiler, you will need materials at hand, which can always be found in a suburban area. Even if they are not there, they are inexpensive, so you can buy them.

- .Small dimensions of the heater and its low weight. Hence the high mobility of the device - even one person can manually transfer Bubafon

- .Simplicity and ease of use. He laid, for example, firewood, set them on fire and enjoy life. A single bookmark, when placed correctly, can last half a day.

Unfortunately, there were some drawbacks.

Cons of "Bubafoni"

- First of all, it should be said about the low efficiency. Condensation forms in the boiler itself and inside the pipes for the removal of combustion products, which reduces the efficiency of the heater

- The long-burning boiler Bubafonya itself in the classic version does not accumulate heat very well. Therefore, experts advise to surround it with a water jacket or brickwork, which significantly increases the cost of the unit.

- .The boiler must be installed on a solid, non-flammable base. Most often it is placed on a concrete or brick foundation.

- It is very difficult to clean the boiler, especially its bottom, where soot and ash from the burnt fuel collect.

- A prerequisite is a well-functioning ventilation system in the room where the Bubafonya boiler is installed.

The principle of operation of the Bubafonya oven

Bubafonya is one of the variations on the theme of long burning stoves. It consists of only three welded parts. A loading tank, in which the wood is pressed against as it burns out by a movable piston with a load.

The combustion process takes place in a small vertical area.

Unlike the factory model, where combustion air is supplied through a telescopic pipe with a distributor, in Bubyakin's model the pipe is one-piece and it is much easier to make and maintain it. For its free movement, a hole is made in the removable cover. Micron accuracy of the gaps is not needed - the main thing is that the rod moves freely up and down, and a little air will penetrate into the gap, which will be useful for the afterburning process in the furnace. The lid itself should fit tightly.

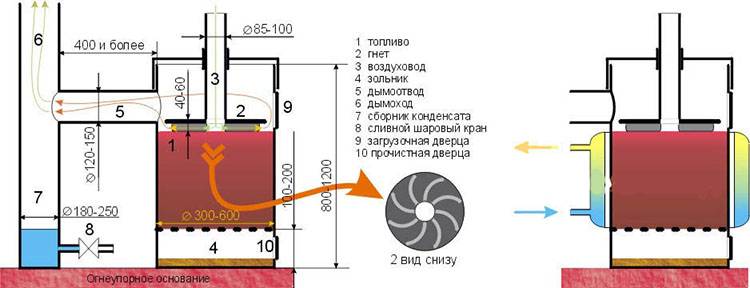

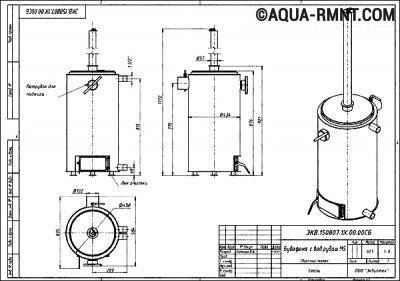

Bubafonya stove drawing with dimensions

Also, factory models have a difficult-to-reproduce heating of the incoming air. If the air does not pick up 400 ° C, the efficiency of the device drops sharply. In a homemade oven, this is achieved using a weighty pancake with ribbing along the bottom surface. The piston, with its weight, compacts the layer in which the combustion is taking place so that the air has time to heat up enough until it overcomes a path of several centimeters. The unit not only kept the efficiency at a high level, but also made it possible to get rid of reverse combustion, and also to reduce the furnace height by almost 2 times.

The outflow of exhaust gases occurs simply into the gap between the heavy piston and the boiler wall, and then into the branch pipe and chimney.

Bubafonya is not a pyrolysis boiler, but the share of pyrolysis is still present here and it is even slightly higher than in factory models.

Preparatory work

The design process does not end with just sizing the furnace components. It is necessary to calculate other parameters that affect the installation of the unit and its connection to the chimney. In this case, you can focus on the above diagram. In addition, before proceeding with the construction of a heating unit, you need to properly prepare.

First of all, determine the place for installing the heating unit, based on the fact that the length of the horizontal part of the chimney should not exceed 400 mm. Otherwise, the thrust will decrease, which will negatively affect the combustion intensity. It is also not worth minimizing this distance too much - part of the heat, instead of heating the room, will simply fly into the pipe. By the way, the chimney must be at least 4 m, otherwise it will be impossible to ensure good draft. In addition, the design of the chimney must provide for a water collector in the form of an elbow installed in its lower part.

Regardless of whether Bubafonya is installed on legs or rests directly on the bottom of the body, the base of the floor must be made of fireclay bricks. Of course, you can do with a simple cement-sand screed, but over time it will begin to crumble and become unusable. If this fact does not bother you, then in this case it is better to protect the improvised foundation with a steel sheet.

The next stage is the preparation of materials. Since most people make the stove from used metal, it must be cleaned of dirt and rust. The fuel barrel is burned out, and the domestic gas cylinder is filled with water. Only then can you start cutting and welding them.

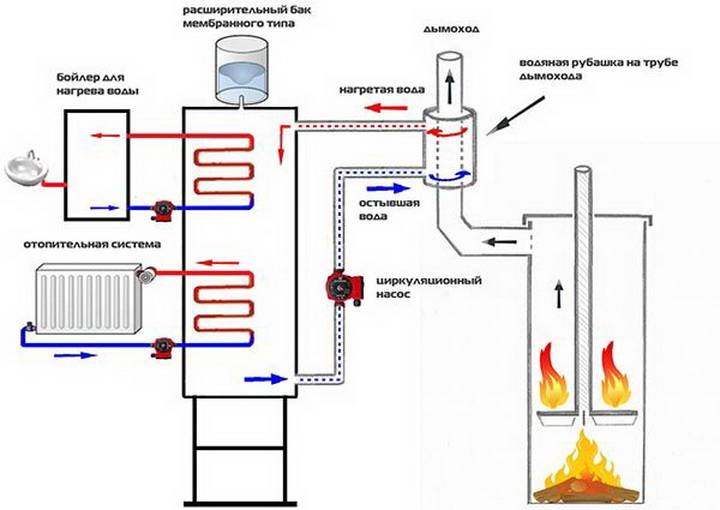

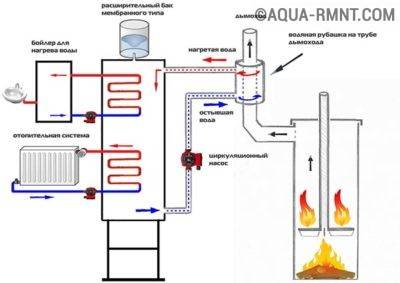

"Shirt" for bubafon

Such a furnace has many advantages: its low cost, ease of creation, and high efficiency. But there is also a minus of this design: it delivers heat unevenly. The way out can be blowing it with a fan. But this is inconvenient. To solve this problem, a water "jacket" was invented. To create it, you will need another cylinder, whose diameter will be larger than the furnace body itself.

The project clearly shows the placement of a water "jacket" on the chimney and the connection of water and battery heating to it

In fact, the water "jacket" is a kind of improvement of the stove, to which heating equipment can be connected. The "shirt" can be installed in two places: directly on the body and on the chimney pipe. Both places heat up well. In order to put on this very "shirt", you need to use a pipe with a larger diameter than the place where you are going to put it on. The open ends of the pipe must be well welded and welded into it the inlet and outlet, where the heating devices will be connected. The principle of operation is simple. Water flows through the jacket, heats up and carries heat into the room.

Uneven heating and other minor imperfections

The next point is the problem of uneven heating of the radiating surfaces. From the moment of ignition, the first hours of the furnace, the flame actively contacts only a limited area of the metal, while the surfaces below the point of contact with the flame remain cold. This problem becomes especially obvious when trying to equip the furnace with a water circuit, which, by the way, cannot effectively cover the entire surface of the furnace (top and bottom). Some inconvenience is the presence of a branch pipe protruding high into the room, which, during modernization, has to be transformed into a telescopic structure.

In the simplest options, cleaning ash from a cylinder is a very unpleasant and dirty task. Condensate flowing down to the bottom, mixed with coals and soot, can form a dense amorphous mass. Not very important, but also a drawback, this is the appearance, which is caused by a specific configuration. Taking into account all the listed problems, it is obvious that you can place such a heater only in a special or technical room.

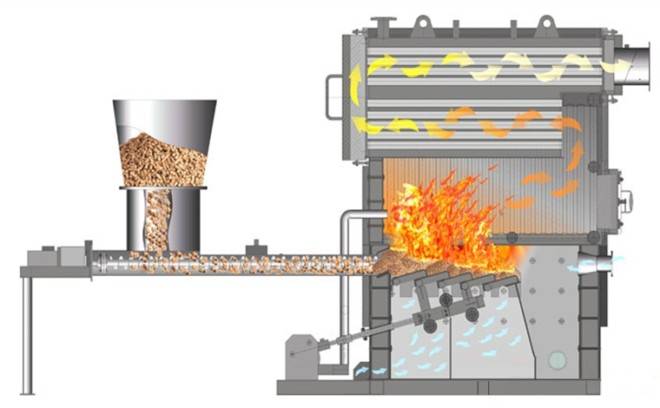

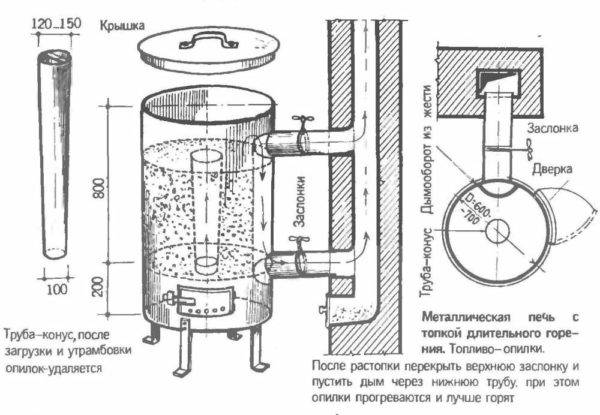

Sawdust boiler for hot water heating

Often, sawdust or wood chips boilers are used as the main heat source in heating systems.

Structurally, a long-burning sawdust boiler consists of the following functional elements:

- In the lower part of the building there is a grate and an ash pan (compartment for collecting ash).Some models of devices in this part are connected to the fuel dispenser.

- In the middle part, there is a combustion chamber in which the combustion of fuel material is carried out. There are also special inlets or an air blower for uniform sawdust burning.

- A heating module is located above the combustion chamber.

> Modern models of boilers are equipped with a reliable automatic control system to control the heat engineering processes inside the equipment.

The main advantages of a long-burning boiler include:

- Possibility of loading various fuels: wood chips, sawdust or pressed shavings.

- Efficiency at the level of 85-90%.

- High efficiency of air heating.

- Wide scope of use - for heating, hot water supply, cooking.

Calculation of basic parameters

A solid fuel long-burning stove can be made from scrap materials, such as: a used gas cylinder, a piece of a large steel pipe or metal barrel. Select material with a wall thickness of at least 5 mm. This is due to the fact that the smaller case thickness will burn out after a while.

A version of the "bubafonya" oven with a water jacket

Furnace size

In the absence of any drawings and diagrams for the manufacture of the furnace, you can make all the necessary calculations yourself.

calculation of the parameters in the "bubafonya" oven

In this case, it would be more accurate to talk about its diameter - D and height - H. These values should be proportional to each other, where the ratio in the range from 1: 3 to 1: 5 is considered optimal. The height of the furnace is usually made at least 100 cm, since this parameter is directly related to the duration of the unit's operation. However, it is not worth making a structure that is too high, since it will be inconvenient to load it with firewood. It can also negatively affect traction. It can decrease so much that the maintained flame inside the combustion chamber goes out.

If the furnace frame is made too wide, then there will be no uniform combustion of fuel near the inner walls of the chamber and in the middle of the hearth. In this case, only the central part of the combustion material will burn out. The metal circle of the piston will sag and clog the hearth, causing the flame to go out. The optimum diameter of this design is from 300 to 900 mm.

Thickness of the used material

This criterion must be taken into account, since the thin walls of the case will burn out after a while. In this regard, it is necessary to select a material with a thickness of at least 5 mm

This is especially important if you plan to equip the frame with a water jacket, turning it into a boiler. In the image, the wall thickness is indicated by the symbol Δ

If you use material with a wall thickness of up to 4–5 mm, then this is fraught with the fact that the furnace will lose its power. Due to the thin walls of the housing, the temperature above the piston plate will drop. As a result, the afterburning of pyrolysis gases will decrease, and, consequently, the heat generated will decrease.

Metal pancake parameters

For the efficient operation of the furnace, not only the diameter of the circular plate on the piston is important, but also its thickness. After all, a metal pancake is a partition and at the same time a heating surface for the ignition of pyrolysis gases.

When making a metal pancake, you should adhere to the optimal size. The distance from its outer edge to the inner wall of the oven should be 5%. In the image, this gap is indicated by the formula C = 5% D.

The diameter of the metal pancake should be slightly less than the inner diameter of the furnace body

Dimensions of the air supply pipe

In the diagram, its diameter is indicated by the letter d. For the construction of such a furnace, a 75 or 80 mm pipe can be used. The pipe must be welded to the metal circle (in its hole in the middle).The result is a part called a piston.

Stages of building a bubafoni from a balloon

Before manufacturing itself, you need to decide on the size of the oven.

Balloon preparation

-

Cut off the top carefully. Save it. In the future, it will play the role of a lid.

- Weld a strip of steel to the stove body. This will be a side that will prevent the lid from sliding off the body.

-

Now you need to make a pressure circle, thanks to which the fuel will be pressed down, and oxygen will enter the furnace, ensuring long-term combustion.

- Take a thick (3-4 millimeters) sheet of steel and cut a circle out of it. Let's make an air distributor out of it. Its diameter should be slightly smaller than the main frame of the oven. The gap between the edge of the air distributor and the walls of the gas cylinder is 1/20 of the pancake diameter. Make a hole in it in the middle. This hole must be at least 10 centimeters for thrust to be effective. Weld the air pipe to it. Its height should be 20 centimeters more than the stove body.

-

At the bottom of the air distributor plate, weld 6 metal blades. They are needed so that the fuel burns evenly in the lower chamber, and the pyrolysis gases in the upper chamber burn completely.

Chimney and fuel insertion point

-

At the bottom of the frame, make a rectangular hole using a grinder. Weld the curtains to it and hang the door. To ensure complete tightness, sheathe the door with asbestos cord around the edges. A little lower, in the same way, you can make another door, but a little smaller. It will be convenient to clean the bubafon through it.

- To make a chimney, it is necessary to make a hole in the lid through which the exhaust gases will exit and the required draft will be created. The pipe diameter for it should be 10-15 centimeters. Smaller sizes are undesirable.

-

Make a chimney elbow out of two pipes. Trim their edges at a 45 degree angle and weld together at a 90 degree angle.

- All parts of the oven are ready. Now you need to collect them together and load with fuel. Sawdust and paper can be poured onto the wood for faster and more convenient ignition.

If the stove is supposed to be heated not only with dry wood, then the pipe should be extended downward and make a place for collecting condensate.

Furnace drawing showing all parts and dimensions

Assembling the structure

-

Load the stove with fuel. Arrange the firewood vertically, sprinkle it with chips and lay the paper.

-

Install the air distributor or "piston".

-

The last step is to install the cover.

Advantages and disadvantages

Bubafonya solid fuel stoves are distinguished by their simplicity and good characteristics. They save users from the hassle of using firewood, providing long-term heat supply to the premises. Let's take a look at their main advantages:

The fuel in Bubafon burns for a long time, warming up the room well, however, as soon as the combustion stops, the stove cools down very quickly.

- Long burning - from 6 to 20-24 hours (and even more). It all depends on the size of the unit used and the quality of the fuel used;

- The simplest design - allows you to easily assemble the Bubafon stove with your own hands, using the tools at hand;

- Minimum adjustments - the only regulator is a small gate damper in the air supply pipe;

- Does not require electricity - the Bubafonya oven can work in buildings without electrification;

- Reliability - if we look at the diagram of this stove, we will find that there is practically nothing to break in it;

- The ability to work on any type of solid fuel - up to anthracite, which is characterized by maximum heat release.

There are also some downsides:

- Rapid loss of temperature when the firewood dies out - there is simply nowhere for heat to accumulate;

- Not the most beautiful design - to the greatest extent this applies to home-made units, which are often assembled from old gas cylinders and barrels;

- Difficulties in maintenance - loading firewood requires removing the pressure pancake and thoroughly cleaning the bottom of the stove from ash and coals;

- Care must be taken to remove soot and condensate - soot is most often formed when burning coal;

- Too intense combustion of the Bubafonya stove can lead to overheating of the air or coolant (when using a water jacket) - therefore, the most minimal control is still necessary;

- The possibility of smoke entering the room - this happens due to the back draft effect, when the smoke exits through the air supply pipe.

Some of the downsides are pretty serious, but you have to put up with them. For example, for easier removal of condensate, it is recommended to work on the chimney, and in order to give the draft in the right direction, a blower fan with speed control should be installed in the system.

The easiest way to collect condensate is to make a chimney with a vertical downward outlet. Smoke will go to the top and condensate will collect at the bottom, equipped with a drain cock.

The nuances of the manufacture and operation of the stove

The chimney will periodically clog up. Therefore, when designing a stove, you need to immediately think about how it can be replaced without damaging the boiler.

To melt a slow-burning boiler, it is filled with fuel, a little flammable liquid is poured into the compartment and a burning rag or match is thrown there.

Finished oven

To melt the stove with coal, you need to fill it 1/3 with coal stones, and put firewood on top of 2/3. After the wood burns well and charcoal remains, you need to open the door and load the stove with coal until it is full. The control flap is then fully opened. The heat from the coal fuel is maximum, therefore, when the stove starts to glow in half an hour, the damper is closed.

The foundation is being equipped, even if the stove is made on metal legs. The bottom of the oven gets very hot!

Long burning stoves "bubafonya"

There are many designs of long burning stoves. The difference between their device is the dosed air supply to firebox. A decrease in its supply leads to a slowdown in oxidation and a more complete use of fuel. The intake is adjusted through the firebox and ash pan with special dampers, that is, from the bottom.

Sawdust furnace design option

In the bubafony oven, air is supplied from above through a hollow rod. In this way, the effect of gradual fuel combustion is achieved without heating the underlying layers. When such a thermal unit warms up to a temperature of 300 degrees or more, the process of wood pyrolysis begins. Combustible furnace gases enter the upper part of the furnace and burn there with the release of a large amount of heat. That is, wood fiber burns at the bottom with the release of combustible gases that ignite on top of the piston.

The principle of operation of the long-burning furnace Bubafonya with a water-heating jacket and an ash pan

Application area

Depending on the capacity of the furnace, the combustion of one fuel load can last from 12 to 24 hours. It is convenient when used in heating systems of a country house, greenhouses, garages and industrial premises.

Advantages and disadvantages of the heating unit

The advantages of such a furnace include the following factors:

-

The simplicity of the design, allowing you to make it yourself.

- A pyrolysis furnace of this design provides ample opportunities in the choice of the type of fuel. It can successfully burn woodworking waste in the form of sawdust, wood chips, small trimmings.Such a heating unit can also operate on peat briquettes, low-grade coal and fuel pellets.

- Long, up to a day, working time. But it depends on the air flow rate and the volume of the combustion chamber.

However, there are also a number of significant disadvantages of this design:

- Bubafonya has a low efficiency. This can be attributed to the uneven heating of the furnace body, which results in a decrease in the degree of heat transfer from the unit. For pyrolysis furnaces with improved designs, the efficiency can reach 90%.

- Bubafonya of classical design is inconvenient for cleaning from fuel combustion residues. They have to be removed from the top. But this drawback can be easily eliminated by the device of the door in the lower part of the fuel tank. The door should close tightly enough to minimize air flow through it.

- Unattractive appearance. The stove looks rough and does not decorate the interior when installed in a residential building.

Furnace ignition

You need to fire up the unit in the following sequence:

- remove the lid from the boiler and remove the piston;

- place the fuel correctly, otherwise combustion, as well as the working process of the furnace, will go wrong;

- additionally lay a layer of chips and sawdust on top;

- moisten a rag in kerosene or other flammable liquid and put it on top of the bookmark;

- install the piston and cover with a lid;

- throw the lighted paper through the air duct, since the match will not give the desired result.

When the fire starts, you need to close the valve somewhat, which will limit the air supply. Otherwise, the fuel will start burning and not smolder. And as you know, the basis of work is precisely the decay of wood, and not its combustion.

The shirt will hang the efficiency of the unit

The shirt will hang the efficiency of the unit