Parapet boiler.

a little late with the construction site. We already have a slight minus at night. To build a heating system with a simple floor-standing boiler is already stupidly not enough time because of the chimney. There is, of course, an option with stainless steel pipes, but the walls made of wood concrete are still damp and it will still be problematic to attach the chimney mounts to them. And then I came across the so-called parapet boilers. There is no chimney (from 250 mm to 530 mm), but they write that there is a problem with blowing.

In general, I have a couple of questions1. I would still like a non-volatile gas double-circuit boiler (with hot water). If anyone has operating experience, share. cons and pros of this boiler. 2. If all the same, parapet boilers are hemorrhoids, then how will they get out with heating in the winter, taking into account the above?

Slava 61 ResearcherTaganrog. South of Russia.10199 2834

Repl. 1 05 Oct 13, 22:12, after 12 min

cons and pros of this boiler. Goodwin, 05 Oct 13, 10:01 pm It's like two in one, always shit. Choose so, the boiler should heat the house, the water column for washing. Two in one is bad. Put asbestos cement pipes, strengthen and mire, as soon as possible, you will overlay them with bricks. Well, they will cry this winter, drill a hole for condensate and substitute a bucket. At the expense of two in one, the water circuit is not working, the boiler is standing still, the boiler is not working, there is no hot water. I hope it's clear.

efim Ph.DL N R687 219

Ans. 2 05 Oct 13, 22:19, after 8 min

Blowing of the parapet is not more common than in the chimney, it is eliminated by picking up all sorts of priblud, well, such as shutting it down from the leeward side or covering the "fungus" with some kind of shield, etc. Often it is possible to cope with the problem by removing or approaching the cap of the fungus on the pipe. And what is a non-volatile double-circuit? If with a coaxial pipe, with its own pump and fan, then any volatile.

Last ed. 05 Oct 13, 22:21 by efim

Ans. 3 05 Oct 13, 22:22, after 3 min

Yes, it is clear, it is understandable, That's just the option with a gas water heater, the same is not ice. This means 2 chimneys are needed. What tempts the option with a double-circuit floor-standing is just the absence of an expensive and long-term chimney. I am ready to endure some inconvenience with hot water for one heating season, since in the next construction season I will weld any chimney and ventilation, and if the parapetnik does not suit, I will replace it with a simple floor + gas water heater. If the boiler works fine, then I'll just buy a gas water heater and that's it.

efim Ph.DL N R687 219

Repl. 4 05 Oct 13, 22:25, after 4 minutes

Parapet, if double-circuit, then the power needs at least 16 kW, for those up to 16, the second circuit is practically sham.

Ans. 5 05 Oct 13, 22:26, after 2 min

Blowing of the parapet is not more common than in the chimney, it is eliminated by picking up all sorts of priblud, well, such as shutting it down from the leeward side or covering the "fungus" with some kind of shield, etc. Often it is possible to cope with the problem by removing or approaching the cap of the fungus on the pipe. And what is a non-volatile double-circuit? If with a coaxial pipe, with its own pump and fan, then any volatile. efim, 05 Oct 13, 22:19 no no. It is non-volatile, that is, without any pumps and other louboutins from 220 volts. well, this one for example

efim Ph.DL N R687 219

Ans. 6 05 Oct 13, 22:30, after 4 minutes

It will push through without an additional pump. Here you need to look at the output diameter, and the diameter of the pipe at the feed is at least an inch.

Last ed. 05 Oct 13, 22:33 by efim

The principle of operation and types of steam heating

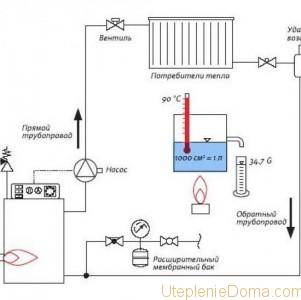

Steam heating works according to the following principle: water, heated in a special boiler (steam generator), turns into steam and in this form is supplied through pipes to radiators, squeezing air out of the system.There the steam gives up its heat and, thus cooling, condenses back into a liquid state. After that, through the return line, the formed water flows back into the boiler and the cycle repeats. At the same time, pipes and radiators of the heating system are heated to a temperature of 100 ° C or more.

Steam heating boiler

Steam heating systems can be of different types and differ:

- method of condensate return;

- the number of contours;

- pipe routing diagram.

According to the method of returning water condensed in radiators, such systems can be open or closed. In open, or as they are also called - open, condensed moisture, before being fed back to the steam generator, is collected in a special container. In closed systems, there is no such capacity, and the condensed water returns to the steam generator immediately, through a pipe of a sufficiently large diameter.

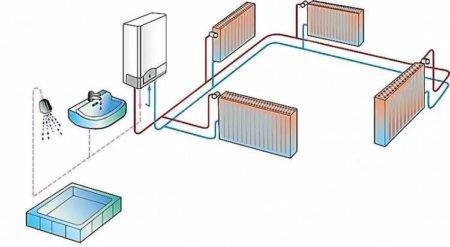

Such heating, like water, can be both single-circuit - used only for heating rooms, and double-circuit, providing water heating for the hot water supply system.

Steam heating scheme at home

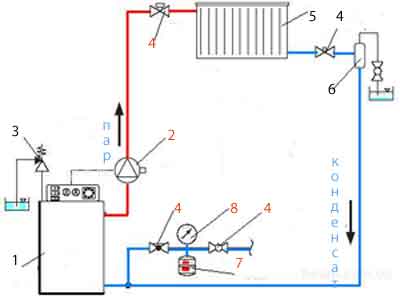

In Fig. 1: 1 - steam generator; 2 - steam fan; 3 - safety valve; 4 - shut-off valves; 5 - radiators; 6 - air valve; 7 - membrane tank; 8 - manometer.

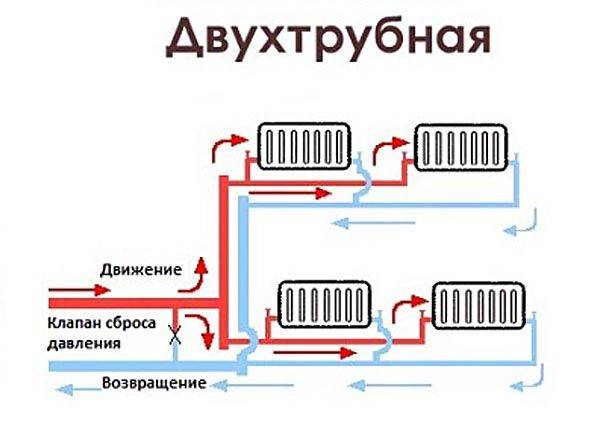

The pipe routing scheme in such systems, as a rule, is two-pipe with an upper or lower location of the main supply pipe. The wiring method, as with water heating, is chosen taking into account the type of pipes used and the characteristics of the rooms in which they are laid.

Advantages and features of parapet units

The main advantage of the equipment is its compactness: a gas-fired parapet boiler can easily fit in the kitchen under the windowsill or in any other room, since it does not consume oxygen from the room during operation and does not pose a danger to residents. A coaxial chimney is a reliable and safe smoke exhaust system, which also offers a choice in favor of such equipment.

The correct choice of a product should be based on the following parameters (except for consumer reviews and catalogs in selling companies):

- Installation technology: the parapet boiler is made for mounting on walls and on the floor, there are also left-side and right-side models;

- The gas parapet boiler can be equipped with one or two circuits. One circuit is for heating only, the second circuit is for DHW;

- Also, parapet boilers can be volatile (with an automatic control system, regulation and control) and non-volatile (with or without manual adjustment).

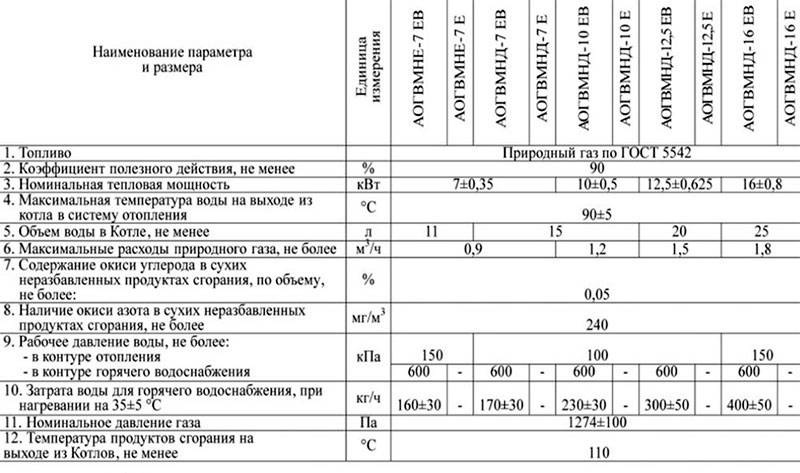

Technical characteristics of universal boilers

Technical characteristics of universal boilers

The thermal power, which the parapet boilers have, varies between 15 kW-40 kW for a unit with one circuit. If the installation of parapet equipment with two water heating circuits is chosen, then the capacity for heating water for domestic needs should be added to the nominal power. For example, parapet boilers with a capacity of 12 kW -15 kW easily heat up the volume of water up to 180 l / h, and this, according to the standards, is four points of water intake (taps, toilets, mixers, showers, etc.).

- The single-circuit unit has a standard heat exchanger (jacket) of a plate design, which speeds up the process of heat exchange between the gas burner and the working fluid of the heating system. Shirt material - thick 3mm steel.

- Double-circuit gas parapet boilers include, in addition to the heat exchanger, a copper or brass coil for hot water supply, in which water is heated only by the flow method. If the DHW capacity is increased by means of an additional hot water tank, then such a boiler will no longer be possible to install in the kitchen.

Also, in addition to wall and floor models, there are products with a difference in installation: with a left-hand connection of a gas pipe, a hot water supply and heating circuit, and with a right-hand one. This convenience should not be overlooked when choosing a boiler for an apartment or a house. The dimensions of the unit are determined by its capacity and the number of water heating circuits.For example, if a boiler has one circuit, then its dimensions will be smaller than that of a double-circuit one.Types of boilers by power

Important features

Boilers are made in a standard rectangular shape. This makes it possible to make their installation easier and more convenient. Also, such boilers are left or right. The boilers, which are made to the left, have an automatic system located on the left side of the device, and the nozzles that are required in order to connect to the heating system and hot water supply are located on the right. The gas boiler Helios in the right version has all the same nuances, but only from the other side. (See also: Gas boilers)

Gas boilers for heating, related to the parapet type, are produced as single-function and dual-function types. Dual-function boilers have a tubular instantaneous water heater, which is mounted in the boiler body, and is required in order to heat water for a variety of household needs. The metal used for the production of such heaters is mainly copper, since it has a fairly high thermal conductivity.

The Italian parapet gas boiler has one significant advantage: due to the fact that it does not need to be connected to the chimney, it can be installed anywhere. Parapet boilers are not energy dependent. In a residential building, parapet boilers are often installed in a window sill. They are also used to supply heat to buildings that have hot water heating system with forced natural circulation system.

Typical variety of equipment

The parapet boiler takes up very little space.

How to choose the right parapet boiler? Consumer reviews indicate the variety of models of this heating equipment. Today, the choice of the device can be carried out according to the following parameters:

- by the method of installation: wall and floor, left-side and right-side;

- by the number of contours: single and double-circuit;

- by the presence of automation: volatile and non-volatile.

In addition, the equipment is classified according to its performance. So, today you can buy a single-circuit parapet gas boiler with a capacity of 15 kW to 40 kW. Choosing a double-circuit parapet gas boiler and reading its instructions, you will notice that water performance is also added to the usual power. So, a device with a capacity of 12 kW-13 kW can heat up to 180 liters of water per hour, which is enough for 4 water intake points.

The number of contours is distinguished single and double circuit boilers. The first option is equipped with a conventional heat exchanger. It has a lamellar structure, which increases the speed of the heat exchange process between the flame of a gas burner and the heat carrier of the heating system. The heat exchanger is made of steel, 3 mm thick. It is this structural material that ensures the durability of the equipment and a sufficiently high rate of heat transfer. Increasing the thickness of the steel reduces the degree of heat exchange between the water in the heating circuit and the gas burner.

Parapet boiler design.

The double-circuit parapet gas boiler is equipped with an additional copper coil. Due to its work, water is prepared for the DHW circuit of an apartment or house. Water heating is carried out only in a flowing manner. The storage tank inside the boiler will significantly increase the size of the equipment. Thus, it will be impossible to use it for installation in an ordinary apartment.

Dimensions and dimensions directly depend on the boiler performance and the number of circuits. So, a single-circuit parapet gas boiler will be smaller and lighter in comparison with a similar device equipped with two circuits. If we compare two single-circuit boilers, then the larger will be the one whose performance is higher. This is due to the dimensions of the gas burner and heat exchanger.

Types of heating devices

To heat a private house or city apartment, boilers can be used, which differ:

- at the place of installation

- by power

- by the method of removal of combustion products

- by functionality

- by cost

- by burner type

- by type of coolant

- depending on electricity

- by the presence of automation and many other parameters

At the installation site, gas heating boilers are floor-standing and wall-mounted. Floor-standing devices are usually more powerful and capable of heating rooms up to several thousand square meters.

Wall-mounted ones are more used in private houses and apartments, since their power does not exceed 30 kW. Naturally, there are wall-mounted boilers with a higher power, but here we are already talking about mini-boiler houses that combine several devices in the form of a cascade.

Chimney type

Aton 7-16 kW

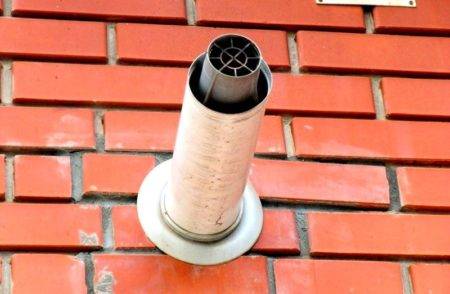

According to the method of discharging combustion products, units with natural draft and forced ones are distinguished. In the first case, gases are discharged through chimneys in the form of a pipe that goes out through the roof. In the second case, the combustion products are removed through special coaxial flues passing through the outer wall.

In some information materials, you can find mention of turbocharged devices. In fact, these are wall-mounted parapet boilers, from which combustion products are removed using built-in fans through a coaxial chimney.

Natural draft boilers use an open burner, and the combustion air is taken directly from the living area. With a coaxial outlet, oxygen is supplied from the street. Such a chimney consists of two pipes of different diameters, located one inside the other. A pipe with a smaller section serves to remove combustion products, and through the space between the walls of the pipes, outside air enters, which is necessary for gas combustion.

It is parapet the gas boiler is equipped with such a chimney, which has a positive effect on the ecological situation in the house. Indeed, in this case, oxygen from living quarters is not consumed, but taken from the street.

Boiler functionality

Boiler functionality

Wall-mounted heating devices, like floor-mounted ones, can have one or two circuits. With one circuit, only the heating of the house occurs, with the presence of the second, it becomes possible to also receive hot water for domestic needs.

In parapet boilers, the built-in instantaneous heater for hot water is made, as a rule, of copper, since this metal has the best heat-conducting properties.

Parapet devices can be connected to the heating system from the right, left or both sides at the same time, which simplifies the installation of heating wiring.

These units are designed to operate on natural gas, but when changing burners, they also function well on liquefied gas.

Heat carrier

Wall hung gas condensing boiler

Many do not know that it is impossible to use hot water from the heating system of the city for domestic needs. And this often happens when the hot or cold water supply is temporarily turned off. Some residents, without hesitation, turn on the tap on the radiator and drain the hot water to use it, for example, for cleaning the floor.

It is categorically impossible to do this, because there are special additives in the water. They prevent the formation of scale and other deposits on the walls of pipes and radiators. The use of such "water" can have the most negative effect on human health precisely because of these additives.

When installing a gas boiler in a city apartment, you need to carefully study this issue, because not all devices are designed for a similar composition of the coolant. Another thing is in a private house, where the water quality is controlled by the homeowner himself, and you can install any heating units without looking at the coolant.

The lineup

Today, parapet boiler models are presented on the market with a wide variety of models from various manufacturers.

In the product line, you can find boilers with various capacities, which are designed to heat houses and apartments.

Also, boilers are classified according to the type of installation, the number of circuits and performance characteristics.  How much a gas boiler costs and how it will recommend itself in the heating system depends on these parameters. Discerning buyers who want to find the best heater option before deciding on a specific model should study products from the main manufacturers operating in the home heating technology market.

How much a gas boiler costs and how it will recommend itself in the heating system depends on these parameters. Discerning buyers who want to find the best heater option before deciding on a specific model should study products from the main manufacturers operating in the home heating technology market.

Boilers from the Termotekhnik brand - reliability and affordable price

Consumers who want to find a reliable and high-quality source of heating should pay attention to parapet boilers from the Termotekhnik brand. These devices are assembled on the territory of Russia and have an affordable cost due to the absence of manufacturer's costs to pay export costs and customs duties.

Despite the availability and simplicity of design, gas boilers Thermotechnik reviews which speak about the stability and durability of devices have all the qualities of a functional and reliable heater.

Specific differences between Thermotekhnik boilers:

- high maintainability;

- availability of spare parts and repair kits;

- inexpensive price;

- adaptability to work in difficult conditions;

- ease of maintenance.

The Taiga gas boiler, whose power range is from 5 to 20 kW, deserves special attention in the line of this brand. The Taiga parapet gas boiler reviews about which can be found on the network is an excellently designed and competently assembled device with an efficiency equal to 90%

The boiler is equipped with Italian automatics, so its use as a basic heating device guarantees the stability and reliability of the circuit.

Boilers "Helios" - an excellent price and a solid guarantee from the manufacturer

The Ukrainian brand "Helios" produces parapet boilers of decent quality. These devices are also characterized by an acceptable cost, ease of installation and ease of use. In addition, the Helios gas boiler, the price of which can vary from 180 to 250 dollars, depending on the capacity, has a number of competitive advantages.

Advantages of the parapet boiler "Helios":

- high efficiency;

- wide range of models;

- possibility of installation in open and closed heating systems;

- availability of reliable Italian automation;

- high level of security.

Boilers from the Luch brand - functionality and reliability

The Ray parapet gas boiler is produced in Taganrog. This boiler differs from analogs in a compact body, a simple installation procedure and an inexpensive price. Various boiler models can be used to heat houses ranging from 80 to 180 squares. When choosing the power of the boiler, it should be borne in mind that the device should not work for wear and tear. Experts recommend to select the power of the device in accordance with the requirements of the heating scheme, developed by competent heating engineers.

The specifics of the work of parapet models from the Luch brand is represented by the following list:

- rational gas consumption;

- complete combustion of the energy carrier in a sealed chamber;

- convenient location of branch pipes for connecting the gas supply line;

- low heat loss;

- the presence of a tubular heat exchanger, which ensures the maximum performance of the boiler.

Features of installing a parapet-type gas boiler

Boilers are purchased only in shops specializing in gas equipment. The seller, upon request, must present a license, all documents for equipment, certificates.

The installation of a parapet boiler begins with obtaining permission from the local authorities for the installation of gas equipment, its connection.

SNiP requirements and standards

Installation of gas equipment is carried out indoors, the walls and floor of which are finished with non-combustible materials. There must be a gap of at least 2 cm between the boiler and the wall.

When installing equipment in a wooden building, it is necessary to cover the walls with refractory materials that prevent smoldering and burning. Used mineral wool cardboard, ceramic tiles, a small layer of asbestos coated with a sheet of metal. Plaster can be applied, but a layer of at least 3 cm is required.

An example of a building according to SNiPs

An example of a building according to SNiPs

The device may only be placed on a special support made of non-combustible material. High temperature resistant tiles or refractory bricks are laid on wooden floors. Projections of at least 10 cm are made along the contour of the entire boiler.

Coordination of work, technical conditions

Installation of a gas water heater is allowed only after agreement. Restrictions, non-observance of which entails refusal:

- The installation of the boiler is allowed only in non-residential premises, which are fenced off from the rest of the rooms by a well-closing door. Restrictions on the installation of equipment in the bathroom or toilet have been removed.

- The boiler room must be at least 4 m², equipped with ventilation.

If these requirements are met, you can proceed with the paperwork.

Design

At the stage of preparing documents for permission, a technical plan for gasification of a house is being prepared.

The project should take into account the brand of the meter, contain detailed information about the boiler used, the system connection diagram, the boiler room equipment with all additional devices.

Project example

Project example

You can order a project only from companies licensed for this type of activity, but it is best to do this in an organization that supplies gas to the population. The equipment installation plan will be carried out in strict compliance with all requirements. This reduces the risk of unforeseen situations in the future when the system is connected to the gas pipeline.

Obtaining permission from Gorgaz

Approval is issued after registration. Technical specifications for connection to the main are drawn up, indicating the expected volume of fuel consumption, a gasification project from an accredited company is attached. It remains to add documents with the permission of Rostekhnadzor and the technical passport of the installed equipment.

Approval takes about 90 days. If errors are detected, a refusal is sent with instructions to eliminate the deficiencies. After the amendment, the documents are resubmitted.

Mounting Location: Hardware Installation Guidelines

The parapet boiler is installed in the kitchen, utility room, bathroom or toilet.

The smoke exhaust pipe must not be taken out onto a balcony, loggia, shed, staircase or other building. It is necessary to put the chimney so that it does not interfere with other people, and the combustion products discharged through it do not fall into the windows of other apartments.

Installation work, connection to the system

Heater installation steps:

- A hole is made in the wall for the chimney. For this, a diamond drill with a diameter of 2.4-2.7 cm is used.

- Parts of the pipe are installed that are not directly connected to the boiler. Place the middle section so that the joints or seams are outside the wall and not inside the cut-out space.

- The chimney is made with a slight downward slope outward so that condensate does not accumulate, but flows down from the pipe walls.

- If the boiler is of a hinged type, then fasteners are fixed under it. Markings are made under the floor model.

- When installing a double-circuit unit, a water supply system is assembled and a pipe is installed to remove exhaust gases.

- An internal pipe from the smoke exhaust pipe is installed, the main boiler is mounted.

- Outlets of gas, water, branch pipes, circulation pump are connected.

Coaxial chimney

Coaxial chimney

The final action is a test run of the system with a check for leaks.

Choosing a gas boiler

Reliability primarily depends on the thickness of the steel used in the design of the heat exchanger.Unfortunately, not all manufacturers indicate this parameter, therefore, when choosing a boiler, it is necessary to clarify this moment with the seller in a separate order, since this can play a key role in the operation of a parapet boiler.

Steel with a thickness of about three millimeters is considered optimal. If the steel is thicker, then the heat transfer process will slow down, which will negatively affect the overall efficiency of heating the room. In addition to the thickness of the steel, its quality also matters. It is possible to determine the quality of the metal and the entire boiler as a whole by the maximum pressure level allowed by the manufacturer. The higher it is, the more reliable and high-quality the selected parapet boiler is made.

The quality of the metal during manufacture can be determined by the maximum pressure level

The efficiency of the parapet boiler is influenced by the design of the heat exchanger and its efficiency. In order to determine how economical the selected boiler will be in operation, you need to find out its efficiency (efficiency), this parameter will most accurately show the efficiency of the heat exchanger and the boiler device as a whole.

By now, almost all manufacturers have achieved an acceptable level of efficiency, which is 90-92%. But just in case, it is worth clarifying the level of efficiency when buying, since in some cases even two or three percent may matter. This indicator is the only one that will objectively reflect the efficiency of the boiler, because different rooms differ from each other in the level of their own thermal insulation, therefore, the reviews of people who have already bought a boiler will always be subjective.

Significant technical parameters include the size, dimensions of the boiler, the location of the connection connectors and the power. The size and dimensions are selected in each case individually and depend on the place and conditions of installation. The location of the connectors is also important for the boiler. The modern model range includes options with both right and left connection of the boiler to the gas and water supply. There are also universal models that can be connected from either side.

Boilers come in various sizes, it all depends on the power

The power of a parapet boiler is no less important characteristic than its efficiency. It is from the choice of the model with the optimal power that the quality of heating the room will depend, as well as the efficiency of using the boiler, because if it is too powerful, then gas and electricity will be wasted

The formula of 1 kW per 10 m2 is often used, but in fact this is not correct, since this indicator is so average that it almost never corresponds to reality. When calculating the power of 1 kW per 10 m2, the difference between the apartment and the house, the number of windows in the room, the material of the walls, the height of the ceiling and other parameters that make up the overall level of thermal insulation are not taken into account.

It is best to double this formula, that is, take 2 kW of power per 10 m2, and not one. In this case, a margin is obtained that takes into account windows, possible drafts, thin walls or high ceilings of the room. But, of course, it is best to consult with experts when buying and determine the optimal boiler power on an individual basis in order to achieve the most optimal ratio of price and quality of heating.

The parapet boiler is economical, easy to operate, has a low cost, can perform the functions of a water heater and does not require an additional heating network, since it is both a furnace and a convector at the same time. Ease of installation allows you to connect the parapet boiler yourself, without the help of specialists.

Summing up, we can say that a parapet boiler is a convenient modern heating device that can be installed in any type of room, in a private house, apartment, garage or any kind of outbuilding.

Features of steam heating

Steam systems have a number of features that should be considered during installation to prevent problems during operation.

• Condensate drainage in steam systems is carried out in two ways.With closed circulation, the cooled steam is converted into condensate, after which it flows back into the boiler by gravity. To do this, take care of the installation level of the outlet pipe, it must be below the level of the radiator. When the circulation is open, the cooled steam is collected in a special tank, from which it is pumped forcibly into the boiler. The pumping process is provided by a circulation pump.

• Heating with steam is characterized by drying the air in the room, so it should be humidified using special devices or by placing a container with water next to the radiator.

• There is a combined type of boilers, which has a number of advantages. Its installation will avoid dependence on one type of fuel.

• Radiators should be placed under the window openings when drawing up the project. This will help to avoid serious heat loss in the room.

How to make steam heating safe?

Circuit Laying Diagram

Like any heating system, steam heating has its own advantages and disadvantages. The indisputable advantages include the low cost of installing the system and its operation at a relatively high efficiency. However, in order to avoid emergency situations, it is necessary to provide for a number of nuances at the design stage:

- the boiler room where the heating equipment will be installed must be located either in a separate room or fenced off to prevent accidental contact with a source of high temperature;

- the expansion tank must be reinforced at least three meters above the heating boiler;

- in the case of using a closed expansion tank, be sure to install a pressure relief valve;

- the use of filters is desirable;

- in the lower part of the pipeline system, several drainage units must be installed;

- use high-quality components and connecting elements;

- regularly carry out control and preventive technological maintenance of the system.

So, as soon as you decide to conduct steam heating, you will certainly want to know the pros and cons of such a heating system compared to others. Let's outline the main features of the steam heating system so that you can decide which of them are priority for you:

- the steam heating system is quite compact;

- the cost of heating devices is not high;

- there is practically no heat loss in the heat exchangers of the system;

- surfaces of pipes and radiators are very hot;

- there is no possibility to smoothly regulate the temperature in the system;

- the service life of pipes is not very long, since hot steam is an aggressive medium.

Having compared all the pros and cons, having calculated the benefits and consequences, do not forget to consult with professionals, especially if you are starting to install a heating system for the first time. Pay attention to all stages of work and then you will be assured of a long and trouble-free use of the heating system.