How to make a biofireplace with your own hands

First of all, we would like to remind you that even such an uncomplicated finished structure does not require small financial costs. But it is more profitable to make it with your own hands. Materials for this are sold in any building supermarket. No special skills are required.

To proceed with the installation of the structure, the following materials must be prepared:

- medium thickness, heat resistant glass;

- silicone sealant for sealing joints;

- a container made of metal or tin;

- medium-sized metal mesh with fine meshes;

- decorative elements (artificial stones or rounded pebbles);

- wick;

- fuel (special biofuel!).

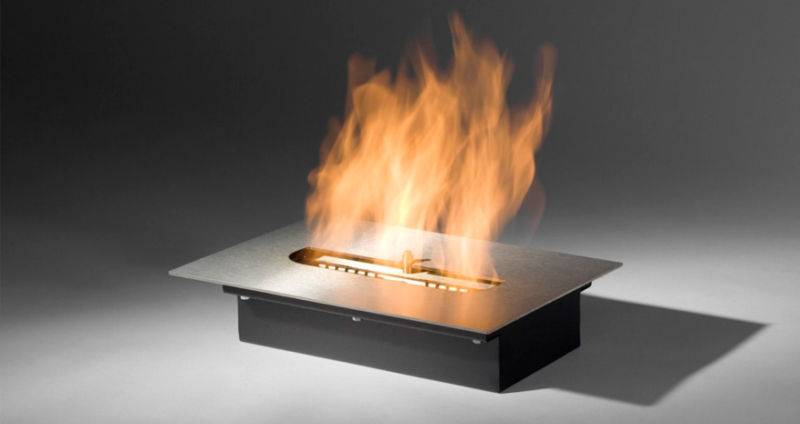

Biofireplace device

Before you sketch the idea of a fireplace for an apartment, you need to know what details are included in the bio fireplace. The structure consists of a biofuel tank, a burner with a plug and cladding materials, which are a decorative part of the hearth.

Before you sketch the idea of a fireplace for an apartment, you need to know what details are included in the bio fireplace. The structure consists of a biofuel tank, a burner with a plug and cladding materials, which are a decorative part of the hearth.

Ethanol alcohol acts as a fuel made on substances of plant origin, therefore such a device is also called an alcohol fireplace. The liquid is poured into a small block under the burner. When the lid is pushed back, it is set on fire with a lighter. A burning flame is turned off by closing the burner. It must be remembered that you should add liquid to the fuel compartment only after the device has completely cooled down. During the operation of the fireplace in the room, doors and windows should be open to improve air exchange.

Some people love wall mounted fireplaces that can decorate empty walls. Some people equate the floor version with a standard fireplace, since it is large in size, but at the same time it is possible to move it, and if the structure is on wheels, then it will not require special efforts in transportation. Compact table biofireplaces can be carried by hand due to their light weight. In addition, they can be placed on a table, shelf, built into small niches and specially equipped portals to create a more realistic image of a real fireplace.

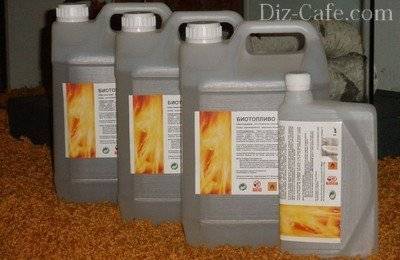

What fuel is used for refueling biofireplaces

Bioethanol is required for the operation of the bio-fireplace. In fact, it is industrial alcohol made with an environmentally friendly biological method. You can purchase it at hardware stores. When burning, such fuel does not emit harmful substances and odors, since it burns out almost completely. You can, of course, independently produce alcohol by the method of fermentation and distillation, but it does not have sufficient purity, therefore, when burned, it smokes and exudes odors. There are other ways to make biofuels on your own, but you still have to buy the ingredients for its production, so it is easier to buy bioethanol.

Biofuels

If you get such a miracle as a biofireplace for your apartment, you can dream, sitting near the playing tongues of flame. It creates a comfortable and warm atmosphere in any home, fills it with coziness and romance. There is no need to be afraid of difficulties if you are not satisfied with the price of finished products. You can pick up a tool and do everything yourself. Moreover, the above methods of constructing biofireplaces are unlikely to cause difficulties for someone.

Device and principle of operation

In the traditional version, the bio fireplace consists of the following elements:

- The burner is made of heat-resistant metal and natural or artificial stones. To control the intensity of combustion, a special adjustable damper can be provided in the design.

- Fuel block - looks like a container for filling fuel.

- Protective shield - placed on the sides or on all sides of the device in order to ensure safety and prevent the possibility of sparks flying out.

- Case - in some devices it is absent. In miniature models, its function can be performed by the fuel sector.

Wall mounted biofireplace

This type almost completely coincides with a floor fireplace, with the exception of its placement. Since it will be permanently placed on the wall, additional wall mountings must be provided.

The frame itself is attached to the wall at key points along the perimeter and center, if possible. But most of the weight of the structure will be carried on the base. Therefore, it is additionally strengthened and connected to the wall using special assembly tools.

The back wall is sheathed with steel sheet, and a layer of stone wool is placed between it and the wall. The front part is covered with a heat-resistant glass protective screen.

Finishing instructions

It remains to attach the legs. They can be plastic or metal. When choosing a material, it is better to give preference to one that can withstand the weight of the resulting fireplace for a long time. Put rubber pads on the bottom. When the structure is ready, a metal container is installed in it under the firebox and the fuel block.

When all the work is done, the seams are carefully rubbed, the surface is wiped with a rag. After that, start decorating. Add a burner, lay out decorative items. The first launch is carried out according to the rules. First remove the decoration mesh. You will have to do this every time you fill the tank with fuel. The latter should be 2/3 of the capacity.

The finished equipment is covered with a grate and set on fire. If the technique is performed correctly, a blue flame will appear. Refueling of the burner is carried out after complete burnout of the fuel.

How to make a biofireplace

Recommended sequence of actions for beginner masters:

- Project development.

- Making the base.

- Buying or building a screen protector.

- Assembling the structure.

Project development

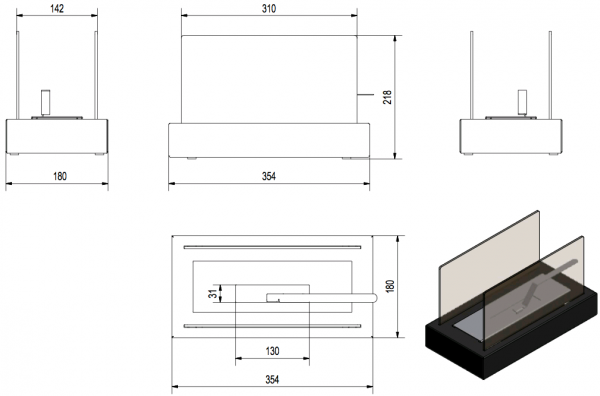

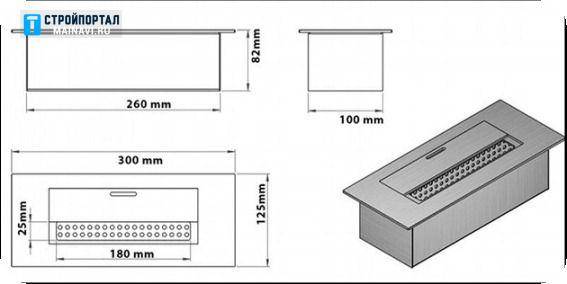

Decide on the look and size of your fireplace. To do this, make a drawing of the future structure.

Planned product dimensions will help you calculate material consumption

Planned product dimensions will help you calculate material consumption

Making the base of the fireplace

The base of the fireplace can be made of a ready-made metal box or steel sheets 2-3 mm thick. Metal is needed:

- Cut to your size.

- Bend.

- Assemble according to the project.

- If necessary, paint or decorate with decorative panels.

- Cut out a metal mesh that will cover the base to distribute heat evenly.

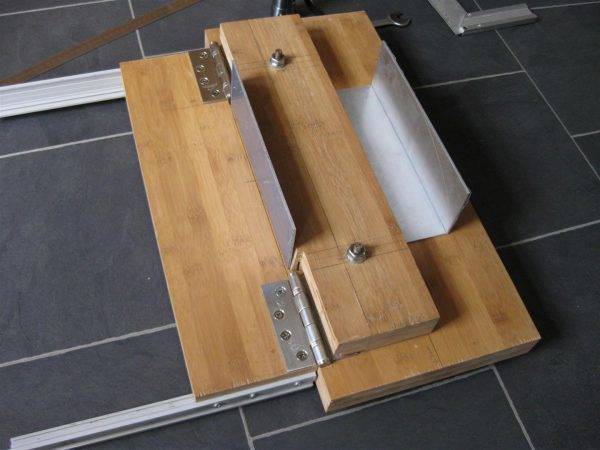

This metal bending device can be made at home

This metal bending device can be made at home

Buying or building a glass screen

You can buy an aquarium from the pet store that is the same size as your base. But if you want to make the design more original, use a heat-resistant glass sheet. How to prepare and cut it:

- Wash thoroughly.

- Dry.

- Degrease.

- Dry again.

- Place on a firm surface.

- Mark up according to your drawing.

- Make a neat cut with a ruler and glass cutter.

- Knock on the line and break off the glass.

- Glue the blanks with silicone sealant (it must also be heat-resistant).

- Place on a hard surface to dry for 24 hours, securing with stops.

- Remove drips of sealant with a razor blade.

For a neat cut of the glass, attach the meter to the surface with plaster or tape

For a neat cut of the glass, attach the meter to the surface with plaster or tape

Assembling the finished structure

To assemble a structure from finished parts, you must perform the following steps:

- Place the metal can (fuel tank) on the finished base.

- Place the protective glass case on the base. The distance from the glass to the burner must be at least 15 cm.

- Attach the mesh over the fuel tank.

- Dip the lace filter into the jar. Instead of twine, you can use fiberglass, which must be pre-filled in the tank.

- Disguise the mesh with decorative stones.

Assembling a fireplace based on a ready-made box is very simple and labor-intensive.

Assembling a fireplace based on a ready-made box is very simple and labor-intensive.

Such a fireplace, made by yourself, will decorate your interior.

Such a fireplace, made by yourself, will decorate your interior.

A properly made bio fireplace is easy to maintain. Add fuel in a timely manner, and also make sure that the structure is installed securely and does not turn over. Enjoy a bright, pleasant and completely safe flame for many years.

How to make a floor structure

The floor construction fits into any interior, as it imitates wood-burning fireplaces

Required materials and tools

- heating block;

- non-combustible drywall (1 sheet);

- metal profile with guides and rack elements (8 - 9 m);

- dowel-nails, self-tapping screws for metal and countersunk head;

- heat-resistant tile adhesive, putty;

- scissors for metal, a screwdriver, a knife for cutting drywall;

- insulating materials (2 sq.m.);

- ceramic tile;

- grout (about 2 kg);

- building level, tape measure;

- wood or other material for the mantel;

- decor for decorating the finished biofireplace.

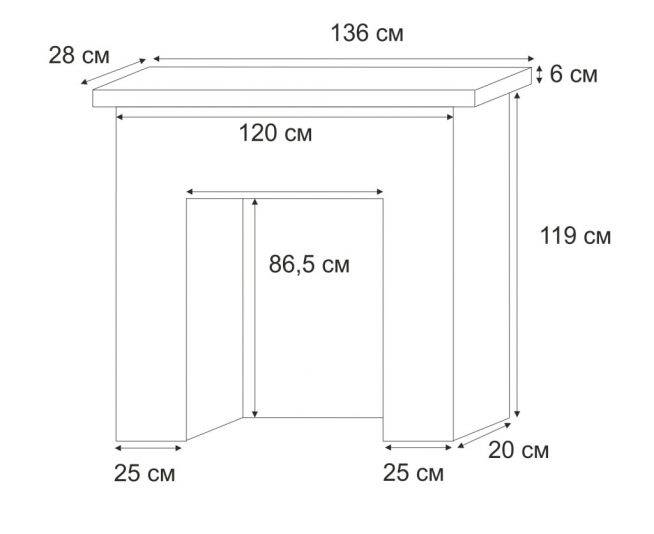

All calculations must be done taking into account the size of the place for the future bio fireplace. One of the options is shown in the drawing.

Preparatory work

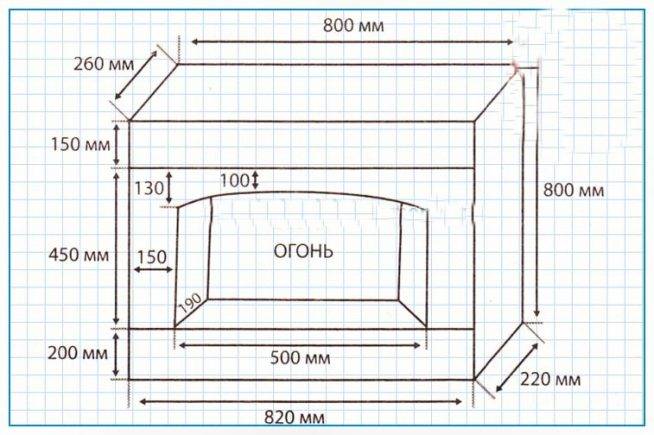

The drawing must be created taking into account fire safety

This option provides for the arrangement of the firebox

At this stage, it is necessary to decide on the size and design of the biofireplace: large or small, wall-mounted, corner or located in the center of the room. After that, a drawing or sketch is created, taking into account the fire safety of the object. When calculating its dimensions, you need to ensure that the distance from the hearth to the walls of the structure and the mantelpiece is at least 15 - 20 cm. After that, based on the drawing, markings are applied to the wall and floor.

Step-by-step manufacturing instructions

The process involves several stages: from fastening the profile to decorating the sheathed drywall

- Assembling the frame. Pre-prepared guide profiles are attached according to the finished markings. Then rack elements are inserted into them, which are subsequently fixed with self-tapping screws. With the help of a plumb line, verticality is controlled.

- Fastening the profiles to the wall using dowel-nails. In this case, the racks are additionally secured with jumpers.

- Laying insulating material into the walls of the structure. They can be compressed basalt wool.

- Drywall sheathing. To do this, you need to mark the sheets of drywall and cut off unnecessary elements using a special knife. The main thing is to make an incision on the one hand, breaking the material on the other. When sheathing the future structure, you need to screw in the self-tapping screws at a distance of 10 - 15 cm from each other. At the end of this work, plaster plaster should be applied.

- Biofireplace finishing. For this, the walls and bottom of the housing are glued with ceramic tiles, with the exception of the recess for installing the burner.

- Grouting. After it, a mantelpiece is mounted, and the structure itself is decorated with prepared decorative elements - stucco, mosaics, facing bricks.

- Burner installation. It can be purchased or made independently from a metal glass into which a wick is lowered. In the latter case, it will not be possible to regulate the height of the flame, but you will not have to pay for the factory design either.

The final step can be the installation of a forged or fireplace grate made of heat-resistant glass, which will provide an additional level of safety for the household.

Due to the bulkiness of floor biofireplaces, they are very often designed in the form of corner structures. The latter can be symmetrical or asymmetrical, when a column is installed instead of one of the rear walls near the fireplace.Their installation practically does not differ from the installation of standard outdoor bio fireplaces, with the exception of the drawing.

Outdoor fireplace

First of all, you need to decide on the installation site - it can be any part of the room. For biofireplaces, it is not necessary to equip a chimney and an air exhaust system - this makes it possible to install them even in apartments of multi-storey buildings. The design of such a fireplace can be very diverse. Since its surface will not be exposed to thermal effects, it can be made of plasterboard and galvanized profiles.

The main condition is to observe the minimum distance from the source of the flame to the walls of the fireplace. The base in which the burner will be installed must be steel.

A mounting hole is made in it. The burner can be made by yourself, or you can purchase a ready-made one. Craftsmen have adapted the so-called gastronomic container for these purposes. emkostIt is made of galvanized steel and can withstand significant temperature effects. The structure is divided by means of a corrugated partition into 2 chambers, as described above. Slots are made on the cover for combustion. A sealed filler neck is made in the fuel part.

Basalt wool is pre-laid. However, unlike factory models, this design does not have the proper level of tightness - ethanol vapors will quickly evaporate. Which of these ways to create a bio fireplace is better? It all depends on the requirements and personal preferences. It is necessary to adhere to the restrictions on the area of the room - at least 16 m² is required for 1 burner.

And if you want a large biofireplace

With large fireplaces, of course, more hassle. First you need to place the wall and cut from the drywall what you need. If the wall is not made of plaster, then hollow out the millet. Next, you need to make a frame for the fireplace - it can be the same drywall (do not forget to fix the frame).

For the assembly of large fireplaces, however, purchase a specialized fireproof box. Such a miracle is sold in specialty stores. Do not forget that between the frame and the box it is necessary to lay out refractory material, at least mineral wool. And it's better to buy a special, large burner. This option is still cheaper than buying a solid fireplace. We cover with refractory tiles or stone. You can see a photo of a biofireplace on the Internet and how to decorate it.

As you can see, it is not so difficult to make a biofireplace with your own hands, the only thing that is now always worth purchasing oil for biofireplaces. The rest of the oils are obviously unhealthy or leave a grime.

Making a fuel tank

The most difficult part of a bio fireplace is its heating elements - a burner or a fuel tank.

To make a simple burner, it is enough to fill a simple tin can with fuel. It can be easily installed in most tabletop fireplaces, but it will not be enough for more complex designs.

In this case, fuel tanks are used - special containers for biofuel, equipped with a stack or plate with holes for uniform distribution of combustible vapors, as well as flaps for closing the tank. If you are not sure of your ability to make it yourself, you should purchase a ready-made factory product, or contact a specialist.

Prefabricated containers use a special porous filler. It is impregnated with fuel and promotes efficient evaporation. Using it in homemade tanks can be problematic and not necessary.

When preparing a container, the following points should be considered:

When choosing a base material, one should give preference to heat-resistant compositions.Hardened metal will be the best choice. It combines high resistance to extreme high temperatures and good processing flexibility.

Compartments for storing fuel must be made with a thick bottom, and the firebox is made of high-strength material. In this case, the biofireplace will be as safe as possible and the possibility of deformation of the areas in contact with the flame is excluded.

In order for the fuel vapors to be evenly distributed, a mesh or a metal bar with holes is installed over the firebox.

For the convenience of ignition, a wick soaked in a flammable liquid is used. Otherwise, every time the fireplace is fired, special fireplace matches with a long wooden base must be used.

After assembly, you need to check the structure for defects.

Pay special attention to leaks. All seams must be tight, fuel must not leak

Failure to do so may result in a fire outside the tank.

It is recommended to install a flap that will completely cover the firebox. It will prevent the flow of oxygen, which means that the fireplace can be safely extinguished at any time.

Advice! Before you make a container for fuel yourself, we recommend that you familiarize yourself with ready-made solutions and take them as a basis. This will avoid many of the most common mistakes.

This video shows an example of the simplest DIY fuel tank at home:

Rules and principles for handling a fireplace made with your own hands

Safety precautions must be observed so that the fireplace does not cause a fire:

- Fuel can only be poured into a completely cooled fireplace. If you accidentally spill the compound on the floor, try to wipe it off immediately with a rag.

- Special lighters are used for ignition. With the use of conventional ones, there is a high probability of getting burned.

- The liquid itself must be stored at a sufficient distance from the fireplace, out of the reach of children and animals.

- Installation of the finished product should take place in places where there is less likelihood of fire.

- The tabletop hearth is located away from heating appliances.

- If you have chronic respiratory diseases, consult your doctor if the fumes from the fuel will be harmful to you.

In conclusion, we note that you can purchase ready-made refractory decorative elements. This will create the complete illusion of a real fireplace. Specially selected fuels can generate small amounts of steam. When buying special mixtures, it becomes possible to choose a type in which the flame will have different shades. This will allow you to get a beautiful effect and home comfort in any room.

Tools and materials

If you do not buy an aquarium, then making a bio fireplace will be cheaper.

If you do not buy an aquarium, then making a bio fireplace will be cheaper.

Eco-friendly and safe biofuel fireplaces have become popular with owners of city apartments and country houses in recent years. Large fireplaces with sophisticated design elements are created by professionals. And small products, installed on the floor or wall, are also available to home craftsmen. To do this, you need to prepare tools, materials and familiarize yourself with the operating procedure.

You will need the following tools:

- ruler;

- scissors for metal;

- glass cutter.

Materials (edit)

To make the simplest floor fireplace with biofuel, you need to purchase:

- metal box or steel sheets for the base;

- an appropriately sized rectangular aquarium or sheet glass;

- wick cord;

- metal tank (for example, a tin can);

- metal mesh;

- decorative pebbles;

- silicone sealant;

- degreasing compound for glass.

What is biofireplace

The famous wisdom says that you can endlessly look at how the fire burns. Unfortunately, making a classic fireplace in an apartment building is difficult due to significant limitations associated with the design features of the house.

But technology does not stand still, and apartment residents have the opportunity to watch live fire at home. And the biofireplace will help with this. It is a decorative fire source that uses a special type of fuel. Today there are such types of ecological fuel:

- Biogas. It is extracted from waste processing and is similar in composition to methane.

- Bioethanol. Fuel that is almost entirely alcohol.

- Biodiesel. Fuel extracted from vegetable oils and used to refuel cars.

Advice! For home use, we recommend using bioethanol. It does not have a specific smell, does not create soot and fumes when burning, and is completely safe for human health and pets.

There are the following types of biofireplaces:

- Tabletop. Small structures that can be placed on a table and enjoy an open fire.

- Wall mounted. Suspended structures that must be firmly attached to the wall. Otherwise, when it collapses, fuel spreading and the formation of a fire hazardous situation may occur.

- Outdoor. They are often equipped with casters to make it easy to move the fireplace around the house.

- Embedded. A special type of floor-standing biofireplaces similar in appearance to classic fireplaces. It is installed in a niche in the wall, which saves space. At the same time, his mobility is completely lost.

Currently, in specialized stores you can find a very wide variety of bio fireplaces, but their cost does not always allow you to make such a purchase. In this case, you should not be upset. If you have some skills in working with tools, you can make a similar fireplace with your own hands.

Making fuel for such a hearth

The fuel for the bio-fireplace is bioethanol - a colorless and odorless liquid containing alcohol and acting as a substitute for gasoline. Its main advantage is that during combustion it does not emit harmful gases and does not leave behind soot and soot. Therefore, biofuel fireplaces do not require the installation of hoods, due to which one hundred percent heat transfer is achieved. And besides, during the combustion of bioethanol due to the released water vapor, the air is humidified.

You can buy fuel in specialized stores. It comes in plastic bottles and cans. One liter of liquid is enough for 2-5 hours of continuous burning

Fuel for a biofireplace can be made with your own hands. This will require:

- Medical alcohol 90-96 degrees;

- Gasoline for Zippo lighters.

Gasoline can transform a blue laboratory flame into a living orange hotbed. You just need to mix these two components in such a proportion that gasoline is 6-10% of the volume of medical alcohol. Shake the finished composition well and pour it into a container for fuel. Fuel consumption is 100 ml for 1 hour of burning.

After igniting the fuel, for the first 2-3 minutes while the flame is small, a slight smell of alcohol is felt within a radius of several meters from the biofireplace. But as the fuel heats up, when the vapors begin to burn, and not the liquid itself, the smell quickly dissipates, and the flame becomes lively and playful.

Step-by-step instructions for the device of a biofireplace

Once the burner is complete, you can proceed to the following steps:

- the glass is fixed to each other with a silicone sealant in the required configuration. Leave to dry for a day or more.

- the burner is hidden in a rectangular metal box;

- a can of liquid fuel is placed inside the burner;

- a wick is lowered into the can with fuel;

- the burner is covered with a net and decorated with decorative elements.

- a glass screen is installed in front of the flame to ensure fire safety;

- use only special biofuels from well-known manufacturers.

In the end, you just need to light the bio fireplace and enjoy the romantic atmosphere, comfort and coziness in the apartment.

Biofireplace design

The design of fuel blocks is simple at first glance. The width and length of the combustion slot, the internal structure of the burner - absorbent material, the ratio of the volume to the size of the combustion slot - everything is clearly verified. A "self-made" fuel block may 1-simply not burn, 2-combustion may occur with pops due to carbon dioxide accumulating inside. In addition, you need to decide on the design of your future bio-fireplace and mark the product on the wall. After that, using the profile and drywall, you can assemble the frame for the fireplace, and also use self-tapping screws or dowel-nails to fix it on the wall, where your heat source will be located.

It is imperative to make all internal walls of the biofireplace double, and in order for the structure to be super reliable, a layer of heat-resistant insulating material is laid. After the structure of the frame is completed, the biofireplace must be veneered using wild stone, fire-resistant tiles or tiles, depending on your own preference. All seams that remain after facing must be treated with a special grout.

Conclusions and useful video

Important parameters when buying an eco fireplace

- Power. The more powerful the fireplace, the stronger the heat transfer

- Fuel tank size. Here you need to approach from the point of view of operating time. The longer the time of using the bio fireplace, the larger the tank. For an hour of using a medium-sized biofireplace, from 350 ml to 1 liter of fuel is consumed. Leaving fuel inside the fireplace is undesirable;

- Burner material. It can be ceramic or stainless steel.

Biofireplace is a high quality decor. He will be the main highlight in your room, which will create a unique atmosphere.