Why is aluminum reinforcement made

The solution to these problems was found in the design field. The polypropylene array in the pipe is reinforced with reinforcing inserts. Materials with opposite mechanical properties were chosen: fiberglass and metal.

And the strength indicators have more than doubled - the reinforced pipes are able to withstand the pressure of hot water up to 20 atmospheres. In this way, a result was obtained that allows the widespread use of polypropylene pipes reinforced with aluminum for plumbing hot water and heating systems.

Reinforcement of polypropylene with aluminum foil deserves special attention. First of all - why is aluminum chosen? A characteristic feature of this metal is the reliable protection of the surface of products made of it with an oxide film. Aluminum patina (Al2O3) is very resistant to any oxidizing agents and chemically active substances.

Reinforcement of polypropylene with aluminum foil deserves special attention. First of all - why is aluminum chosen? A characteristic feature of this metal is the reliable protection of the surface of products made of it with an oxide film. Aluminum patina (Al2O3) is very resistant to any oxidizing agents and chemically active substances.

It can only be destroyed by mercury salts. Therefore, it is a reliable chemical protection for pipe hardening. At the same time, the mechanical strength of the products is sufficient to withstand the excess pressure from the transported liquid from the inside with a thickness of 0.1-0.5 millimeters.

Some other metals, such as gold, silver and platinum, have similar properties. But we will not seriously consider their use in the production of pipes for obvious reasons.

Features of product installation

The installation of the reinforced pipe is carried out in the same way as for the soldering of conventional polypropylene analogs:

- Cutting pipes to the required dimensions. For this, a diagram of the future pipeline is used.

- The next step is to heat the fittings and pipes using a special soldering iron.

- The softened elements are connected and held in the desired position for a set time. This results in a reliable connection.

But, there is one difference, which is the presence of an additional process. Its essence lies in stripping the aluminum layer. This is done before brazing the reinforced pipes. When carrying out cleaning, it is worth considering the location of the reinforced layer. So, if it is located outside, then the work is carried out as follows:

- Insert the reinforced pipe into the sleeve with knives.

- Turn the tool by hand several times.

- Solder the pipes.

If the reinforced layer is located inside, then the cleaning work will be carried out in a slightly different way. First of all, it is worth noting that a special tool is used for this - a facer. With its help, the elimination of the inner layer is carried out. Thus, the normal joining of the reinforced pipes is ensured.

Using this tool, you can solve the following problems:

- Delamination of pipes in the system.

- Destruction of the reinforced layer caused by electrochemical processes.

It should be noted that pipes with fiberglass reinforcement are soldered in the same way as conventional polypropylene products.

Reinforced pipes are especially popular among the population. This is due to the fact that such products have many advantages. Among them, it is worth highlighting the high strength of the material, as well as the ease of installation. You can easily build a new engineering communication with your own hands.To do this, you will need a soldering iron and a tool with which the reinforced products are trimmed.

Manufacturers overview and cost

On the Internet, you can find a lot of all kinds of ratings of manufacturers of polypropylene products. These include European, Chinese, Turkish and domestic firms. In the ratings, the following are mentioned more often than others: the German brand "Rehau", the Italian "Valtek", the Spanish FADO, the Czech "ECOPLASTIC", the Turkish "TEBO", Firat, Pilsa.

Valtec

The Italian brand Valtec offers a whole range of single and multi-layer products in various diameters. The list of brand products includes polypropylene pipes reinforced with fiberglass, aluminum foil, all kinds of fittings for heating, water supply and technological lines.

All products are adapted to heat and water supply systems operating in the post-Soviet space. A multi-level quality control system practically excludes the appearance of defective products on the market.

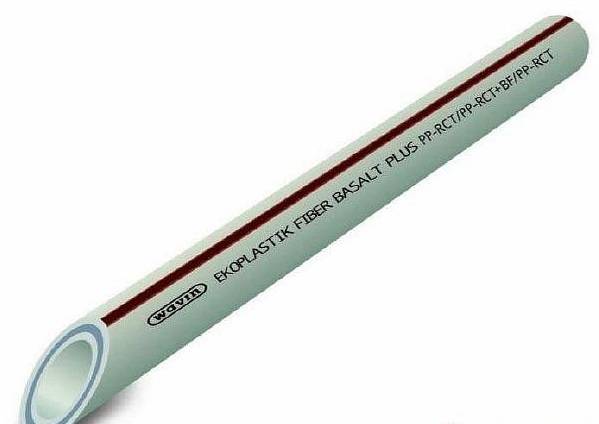

Wavin Ekoplastic

The Czech company Wavin Ecoplastic has been manufacturing plastic piping systems since 1990. All products of the company have international certification and are well known in more than fifty countries around the world.

Ecoplastic plants produce about 28 thousand km per year. polymer products, including hundreds of types of plastic and combined fittings.

Fado

The range of products of the Italian company Fado is incredibly wide and allows you to create piping systems of any complexity. In addition to the polypropylene pipelines themselves, Fado offers a full range of fasteners, connecting and combined fittings, valves, manifolds and sealing materials. All products are certified in Europe and the CIS countries.

An excellent addition to piping systems is the proprietary PP brazing tool.

Tebo

The Tebo brand, owned by Novoplast, produces engineering polypropylene systems. The main type of product is PP-R pipes and fittings.

In their manufacture, high quality raw materials from the world famous Borealis concern and Hyosang are used. All technological production processes are carefully monitored, and the very manufacture of products takes place on modern automated lines.

The lion's share of the market is occupied by Chinese manufacturers. Prices for polypropylene products can vary greatly. For example, a high-quality VALTEC PP - FIBER PN20 25 mm pipe, reinforced with fiberglass, costs about $ 6.5 for a 4-meter length, while a Chinese low-grade analogue costs half the price.

Considering the importance of various kinds of polypropylene communications, which should serve for more than a dozen years, only high-quality products from well-known manufacturers should be chosen.

About leaks, fistulas and other reviews about polypropylene

There are many horror stories about polypropylene leaks on professional construction forums. Apogee

becomes a video where a man breaks pipes on a comb, like dry rods. Any aspiring plumber or

the home craftsman will immediately disown this technology. What can I say, experienced craftsmen come to

confusion from such arguments.

The reason for such defects, oddly enough, is the savings on pipes and components. Currently

many products are sold from "basement" factories for which technical descriptions cannot be found

Note:

if you decide to use a PP-ALUX pipe, for example, from a little-known manufacturer, the data in the pressure table

and temperatures above do not necessarily apply to your brand. Nobody excuses you from learning

technical documentation from a specific pipe manufacturer

It follows from this that many "plumbers" do not bother to study the characteristics of pipes. And it can

lead to errors in soldering and installation. By the way, despite the simplicity of the technology, it needs to be done with

due accuracy, adherence to the soldering temperature and other nuances. I've seen many pipes

brazed by "shabashniki" - in the overwhelming majority of cases, the soldering is performed with overheating, the pipe is incorrect

selected for a specific task.

I had to dismantle a lot of plastic pipes and those horror films described on the network, I have not come across.

The pipes, after 5-10 years of operation, were in excellent condition, there were no cracks or

destruction of material. Most often, the places of leaks were poorly soldered connections, this despite the fact that it is correct

a welded joint is much more reliable than the pipe itself. In simple language - it's hard for me to imagine such

"Hands-on" installers. Nevertheless, there are a lot of such installers - they showed the technology, they simply said -

this completes the qualification of the employee. Hence all the ensuing consequences and problems, as well as spoiled

reputation of polypropylene.

This piece of pipe is cut from the hot water system of an apartment building. According to the customer, pipes

stood for about ten years, the date of manufacture indirectly confirms this. There were no problems, the alteration was carried out for

installation of counters. On the cut, no changes are visible in the thickness of polypropylene, on the inner walls there is a coffee-colored bloom,

which can be easily erased with your finger. The pipe from Ecoplastic is Czech polypropylene without reinforcement.

Also, polypropylene owes its tarnished reputation to marketers who are actively promoting

cross-linked polyethylene... By the way, cross-linked polyethylene is not as resistant to high temperatures as it seems from the beautiful

stories. The job of marketers is to highlight the merits and hush up the flaws of their product,

and opposite commenting on a competitor's product. It's simple, just study the technical documentation

on both goods and everything will fall into place.

We will consider soldering polypropylene separately, but for now everything. And once again I strongly recommend carefully

choose all materials for rough plumbing, beware of fakes and thoroughly approach the issue.

Rate the publication:

- Currently 3.82

Rating: 3.8 (34 votes)

About numeric and alphabetic characters in marking

A lot of both letters and numbers are applied to this material. Manufacturers usually open official websites, where, among other things, there is information on labeling and the information that it stands for. But it is best to translate these explanations into a language that would be understandable to everyone.

Pressure. The unit of measurement is kg / cm2. Designated as PN. Shows how long the pipe has been operating normally while maintaining certain characteristics.

The thicker the wall, the higher this indicator is likely to be. For example, they produce brands PN20, PN25. Such options are needed for hot water supply, heating systems.

Sometimes stripes of red or blue are also applied. This will make it clear what kind of water the future pipelines are intended for.

The marking of polypropylene pipes for heating includes data related to materials and structure. Large tables are compiled to describe this parameter. But it is enough to be aware of the basic designations in order to carry out the correct installation of heating in an ordinary building.

- Al - aluminum.

- PEX stands for cross-linked polyethylene.

- PP-RP. It is high pressure polypropylene.

- PP - Common varieties of polypropylene material.

- HI - fire resistant products.

- TI - thermally insulated version.

- M - designation of layering.

- S - icon for single layer structures.

The marking of polypropylene pipes for water supply can also indicate data that relate to:

- The presence or absence of certificates.

- Issued batch numbers, serial designation and time, and so on. Such designations can be 15 characters or more.

- Manufacturers.

- Wall thicknesses and sections.

Thanks to this information, each buyer will choose the material for water supply that meets all his needs.

Nominal pressure

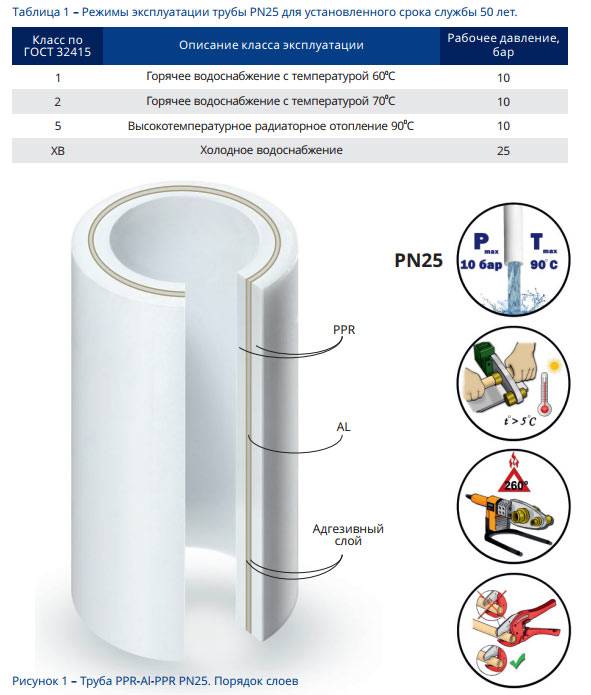

The letters PN stand for the permitted working pressure. The following figure indicates the level of internal pressure in bar that the product can withstand during a service life of 50 years at a water temperature of 20 degrees. This indicator directly depends on the wall thickness of the product.

PN10. This designation has an inexpensive thin-walled pipe, the nominal pressure of which is 10 bar. The temperature maximum that it can withstand is 45 degrees. Such a product is used for pumping cold water and installing a warm floor.

PN16. Higher nominal pressure, higher limiting liquid temperature - 60 degrees Celsius. Such a pipe deforms significantly under the influence of strong heat, therefore it is not suitable for use in heating systems and for supplying hot liquid. Its purpose is cold water supply.

PN20. Polypropylene pipe of this brand can withstand a pressure of 20 bar and temperatures up to 75 degrees Celsius. It is quite versatile and is used to supply hot and cold water, but should not be used in a heating system, since it has a high coefficient of deformation under the influence of heat. At a temperature of 60 degrees, a 5 m section of such a pipeline is lengthened by almost 5 cm.

PN25. This product has a fundamental difference from the previous types, since it is reinforced with aluminum foil or fiberglass. In terms of properties, the reinforced pipe is similar to metal-plastic products, is less susceptible to temperature effects, withstands 95 degrees. Designed for use in heating systems, as well as in hot water supply.

Service class

When choosing polypropylene products of domestic production, the purpose of the pipe will tell you the class of operation in accordance with GOST.

- Class 1 - the product is intended for hot water supply at a temperature of 60 ° C.

- Class 2 - DHW at 70 ° C.

- Class 3 - for underfloor heating using low temperatures up to 60 ° C.

- Class 4 - for floor and radiator heating systems, which use water up to 70 ° C.

- Class 5 - for radiator heating with high temperatures - up to 90 ° C.

- HV - cold water supply.

Dimensions (edit)

The sizes of polypropylene pipes vary widely. Outside and inside diameters and wall thicknesses can be found in the following table.

Reinforcement methods

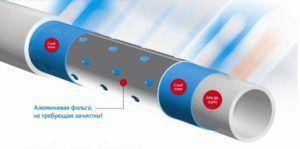

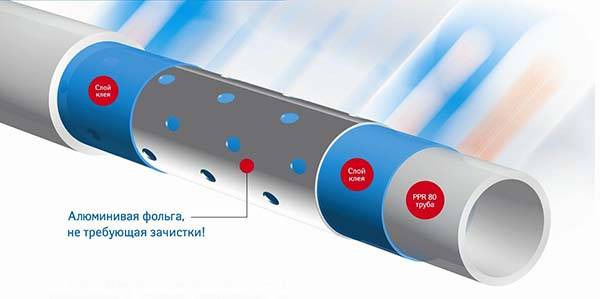

When reinforcing with aluminum, the foil is most often attached with an overlap. This technology is used by many domestic manufacturers. Of course, in recent years, the butt joint of the reinforced layer is gaining popularity. This process is performed using a special laser. When using the first method, it is necessary to strip the foil for further soldering.

Initially, solid foil was used for reinforcement. This made it possible to prevent the ingress of oxygen into the coolant, as well as to give the pipe surface smoothness. The disadvantage was the poor connection of the reinforced layer with the polypropylene. Therefore, high demands are placed on materials as well as connecting substances. This is especially true for the materials used for the construction of the heating system.

If mistakes are made during the production process, this will lead to a decrease in the performance of the pipe.So, it can be a violation of the production process or the use of low-quality raw materials. A common problem is moisture penetration through the top layer of polypropylene. As a result, water accumulates on the reinforced layer, which leads to the blowing off of the material. This significantly reduces its strength.

To avoid this result, polypropylene pipes are reinforced with perforated aluminum foil. In other words, the foil has round holes, which improves the quality of the connection of the layers over the entire area. Depending on the scope of use, polypropylene pipes can last from 20 to 50 years. In cold water supply, such materials last longer, as they function in gentle conditions.

Central reinforcement

Overlapped polypropylene pipes have some disadvantages. First of all, this concerns the installation of the pipeline. In the process of performing the work, the reinforced pipes are cleaned for welding. This refers to the removal of the aluminum and polypropylene layers. To somewhat simplify the connection of pipeline elements, manufacturers began to use central reinforcement products.

The use of such products allows you to maintain their advantages. Of course, they have some disadvantages. This concerns the stripping of pipes before welding, which will prevent contact of the reinforced layer with the coolant. If this is not done and ordinary nozzles are used for joining, then as a result, water will seep between the layers. As a result, materials are swollen.

In the process of installing the pipeline, it is necessary to perform high-quality facing of the elements. This will provide a secure and durable connection. Unfortunately, trimming pipes on an existing pipeline is difficult. This significantly lowers the quality of the connections. The only option is to use special attachments that have design features.

With the help of the nozzle, the outer and inner surfaces are heated. This is possible thanks to a special hole in the element structure. Through it, air is removed, which enters the space between the nozzle and the reinforced pipe. Also, this hole allows visual control over the heating of the pipeline element.

Glass fiber reinforcement

An alternative to aluminum is fiberglass. Reinforcement is carried out using a similar technology. The difference is that fiberglass is used instead of aluminum. As a result, the reinforced pipe consists of two layers of polypropylene, between which fiberglass is placed. It should be noted here that the layers are made monolithic, which increases the strength of the reinforced polypropylene pipe.

During the production process, the inner layer is welded to the outer and inner layers. Thus, the polypropylene is reliably bonded to the fiberglass, which prevents it from deforming. No glue is used to connect the layers of the pipe, as was the case in the previous case.

The disadvantages of reinforcing a polypropylene pipe with fiberglass include an increase in the weight of the product. But, it is worth noting that the cost of such material is somewhat lower. In addition, fiberglass does not prevent oxygen from entering the coolant. As a result, this increases the occurrence of a corrosive process on the metal elements of the system.

Why is the reinforcement of polypropylene pipes carried out?

Reinforcement of PPR pipes is the reinforcement of polypropylene with aluminum foil or fiberglass. This technology is used primarily to curb linear expansion.

Due to such a low coefficient of expansion, PPR-reinforced pipes are successfully used for hot water supply and in heating systems.

In laboratory conditions, reinforced pipes withstand the temperature of the transported liquid up to +120 ° C without noticeable deformation. In real conditions, the water temperature rarely reaches +100 ° C, therefore, PPR-reinforced pipes are the most rational solution for laying hot water pipes and heating.

In addition to restraining linear expansion, reinforcement improves two more characteristics of PPR pipes:

- Due to the denser walls, the reinforced pipe can withstand higher internal pressure than a conventional PPR product.

- The additional rigidity of the material allows it to withstand higher mechanical loads, and also requires fewer supports and fasteners (the reinforced pipe will not sag, unlike a conventional pipe).

In heating systems, it is definitely worth using PPR-reinforced pipes. When installing a water supply system, it makes sense to install such products if cold and hot water will be supplied through the same pipes. It is more rational to use ordinary polypropylene pipes exclusively for cold water.

Advantages of polypropylene pipes

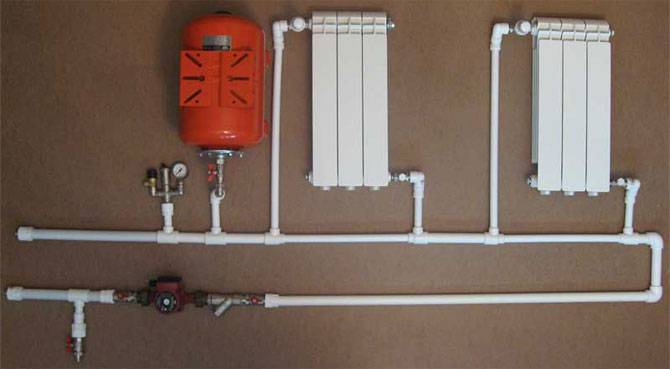

Polypropylene pipes are used to transfer the coolant from the heating center to point radiators. Experts are sure that today this particular product is the most rational. After all, it combines both technological and economic efficiency.

This is due to the fact that polypropylene heating has a number of advantages:

- The heating system assembled with polypropylene pipes does not corrode. In addition, they are neutral to the effects of many aggressive media and are able to withstand sudden changes in coolant temperatures.

- The material has a low thermal conductivity threshold, which ensures low temperature losses of the coolant.

- Polypropylene pipes have a perfectly flat inner surface, which prevents the formation of deposits.

- The material is flexible enough to make difficult bends when laying lines. It also has excellent soundproofing properties, so the movement of water through the pipes will not be heard.

- Assembling heating is very simple, and you can save a lot. It is the ease of installation, long service life and affordability that are the priority qualities of polypropylene materials.

There are two types of polypropylene pipe reinforcement. Their construction is reinforced with fiberglass or aluminum. This technology helps to eliminate the thermal elongation characteristic of the material, minimize oxygen permeability and increase the strength of the pipes. In this case, the wall thickness decreases.

What is the difference between the two modifications?

Aluminum foil-reinforced polypropylene pipes are a multi-layer structure with an aluminum layer underneath a very thin outer layer of polypropylene. It seems to grow through it, providing a strong connection.

Such an element has high performance characteristics, but its installation is a little more complicated. The fact is that before connecting the individual parts, it is necessary to clean the reinforcing layer. This procedure is time consuming and requires certain knowledge and skills. However, the soldering of elements reinforced with aluminum foil will be much more reliable than the connection of analog products.

Aluminum-reinforced pipes show less thermal expansion. They have a strong diffusion barrier that prevents free oxygen from penetrating through the pipe walls.As a result, calcium does not precipitate, which means that the metal walls of the boiler and radiators are not oxidized.

VALTEC PP-R 100

Fiberglass-reinforced polypropylene pipes also consist of several layers. The outer and inner layers are made of polypropylene, and fiberglass is located between them. Before welding, such a structure does not need to be cleaned. The fiberglass layer also acts as an oxygen barrier, so such pipes can be safely used in heating systems.

Such products have a number of positive qualities:

- Its expansion coefficient is 75% lower than that of conventional polypropylene pipes.

- Due to this, the distance between the supports increases, which significantly reduces the cost of assembling the heating system.

- The fiberglass layer provides an increase in the service life of the heat-conducting line.

- The conductivity of the coolant is also noticeably increased - by as much as 20%.

- The thermal conductivity of glass fiber-reinforced pipes is lower than that of aluminum-reinforced pipes.

Which option should you choose?

The question is complex. If you plan to install the lines yourself, then it is better to choose fiberglass-reinforced pipes. But experts agree that the line, made of material reinforced with aluminum, will be stronger.

The installation technology allows you to use any length of material cut, which significantly reduces unplanned costs for the purchase of material and increases the economic efficiency of the assembled system.

Polypropylene pipes are distinguished by their presentable appearance, so they can be succinctly fit into any stylistic concept of the interior.