The creation of flights of stairs is a very demanding process, which requires accurate calculations from the performer, accurate execution. In this case, it is necessary not only to build a solid and practical structure, but also to give it an appearance in accordance with the interior of the room.

Many people think that the manufacture of fire escapes is no different from the products located inside the house and connecting two floors, but in fact these are completely different processes.

Creation of flights of stairs

First of all, you need to understand that there are many varieties of these designs. They differ from each other in their appearance, material of manufacture and installation features. At the same time, the manufacture of a staircase from wood is significantly different from the creation of concrete or metal staircase structures.

However, in order to understand and study in detail the basics of installation and construction of such structures, you need to master only one method. It consists in the manufacture of concrete flights of stairs with the installation of forged fences on them and the subsequent sheathing with wood. So you can not only get the necessary knowledge about the construction of stairs, but also master the work with different types of materials and their combinations.

Project

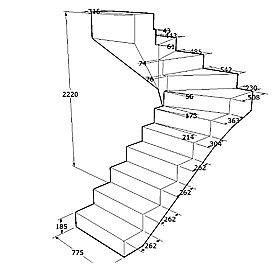

For any construction and installation, it is necessary to develop a specific action plan and create a design drawing.

It is necessary to indicate the methods of connecting various parts and their dimensions.

- Usually, the manufacture of steps for stairs is carried out in accordance with certain rules, which imply a certain angle of inclination of the product and the height of the steps.... However, real professionals in the project indicate those parameters that will ideally fit a specific design, creating convenience for all family members, even if it violates certain limits of the recommended dimensions.

- If you plan to manufacture a spiral staircase, then in the project it is imperative to display the method of its attachment to the base of the room and to the interfloor floors.... This can be useful not only during the installation of the structure, but also during the construction of the building itself.

- Separately, you should pay attention to the combination of various types of materials.... To do this, think over the location of special mounting elements or strips in advance. This is also displayed in the project with an indication of the types of fasteners.

- In fact, in the product drawing, it is necessary to indicate all the required dimensions, individual parts and methods of their installation..

Advice!

If you do not have the skills to create your own projects, then you can use ready-made developments.

This will significantly save time and prevent mistakes when working on your own.

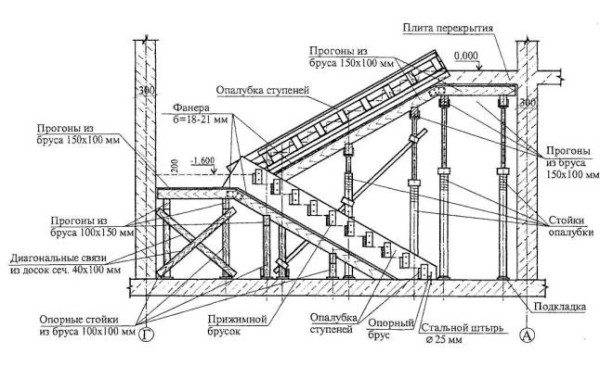

Formwork and reinforcement

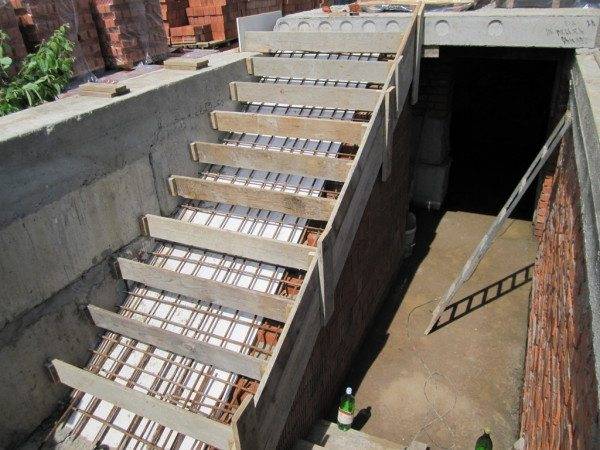

- When spiral staircases or simple flights of concrete are made, the formwork is created from plywood. At the same time, a film is placed on its bottom, which prevents cement from flowing out of the fresh solution along with the liquid.

- It is worth remembering that after pouring with concrete, the entire structure will have a rather large weight, which means that it must be strengthened with pre-prepared supports. This must be done even if it is planned to fill in the columns in addition to the flight of stairs.

- After the formwork is installed, metal fittings are placed in it. At the same time, to maintain a certain space between plywood and iron, you can use special pads.

- The standard production of flights of stairs involves their binding to the supporting structures. Therefore, in some places, the ends of the reinforcement are mounted in the masonry of the walls or simply hammered into them.

- You also need to take care of the method of installing the fences in advance. To do this, in the places where the edge of the staircase will be located, part of the reinforcement is taken out to the top. As a result, small metal pins will be located on the concrete steps, to which the fence can be attached.

Advice!

It is best to knit reinforcement together with a welding machine.

So the structure will get the rigidity it needs.

Fill

First of all, you need to understand that the cost of making a staircase directly depends on the price of work and material. That is why, in order to save money, the pouring process should be combined with the creation of floors or a reinforcing belt. In this case, it is better to use a special vibrator for better distribution of the mixture over the formwork and removal of air bubbles from it.

After the solution is poured, it is covered with a film and allowed to harden. To speed up this process, you can put pieces of rags soaked in ammonia solution under the polyethylene. This is mainly used in production, but it is also suitable for private construction.

It is worth noting that the installation instructions recommend continuing work only after a few weeks after pouring. This time is necessary for the concrete to gain the required strength.

Advice!

If, during pouring, small cracks in the formwork are found through which the mortar flows, then they should be repaired.

For this, ordinary plasticine is suitable.

Installation of fences

Usually, the technology for making stairs from wood involves the installation of fences with the help of special fasteners and grooves made in the details. However, this design must combine several materials, which means that each of them must be mounted in accordance with its technical characteristics.

Forged and metal products can be welded to pieces of reinforcement left in the concrete in advance. Wooden elements are connected using self-tapping screws or special impact dowels. Some craftsmen independently develop special connecting assemblies to facilitate installation.

Thus, it can be understood that the main tool for making the stairs will be needed at this stage. However, do not forget that the product must be correctly positioned in space, which means that all work must be done using a water level, a plumb line and a meter.

Advice!

The installation of handrails and stair railings is an important and responsible process on which the safety of users depends.

Therefore, it is necessary to approach it with knowledge of the matter and appropriate preparation.

Finishing work and cladding

The standard production of a fire escape at this stage involves the application of a protective coating. It must protect the structure from environmental influences. However, interfloor products require a completely different approach, which is focused on giving a certain appearance.

First, the concrete structure is sheathed with wooden panels or special clapboard. It can be mounted using impact dowels or glue. Usually the price of such an attachment is low, but there are also special connecting elements that are quite expensive, but they make the whole process twice as easy.

After the sheathing has been completed, the entire surface can be covered with a protective material. For metal, enamel or special paint is used, and varnish is well suited for wood. They can be applied by hand with a brush or spray.

Output

In the video presented in this article, you will find additional information on this topic. Also, based on the text set out above, we can conclude that the manufacture of flights of stairs is a rather laborious process, the complexity of which depends on the choice of a specific type of material and design. Moreover, the cost of the final product is sometimes directly related to its appearance or design.