By definition, a staircase is the most complex volumetric element of a residential building. The design has been known to man for more than one century. During this time, many changes have happened to her.

If at first it was a tight and steep spiral embedded in a stone wall, now it can be a light corrugated ribbon of completely unimaginable design flying freely in space.

The staircase is the main element of the interior. That is why reliability, functionality and its appearance must be taken into account in the design process.

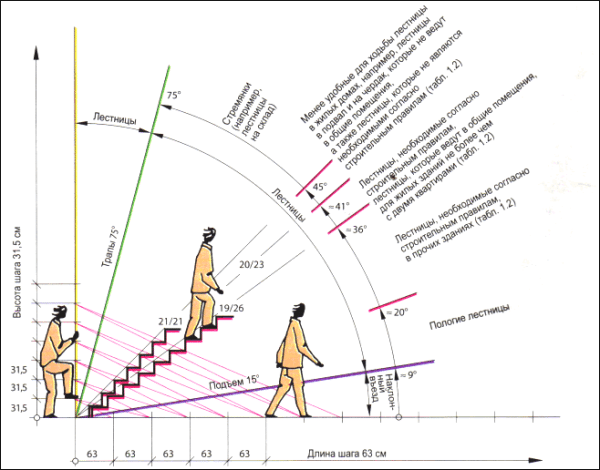

Before making stairs from wood, you need to take into account a number of factors that determine the structure of the latter, as well as its dimensions, for example:

- height;

- available area;

- the convenience of use;

- maximum design load.

The modern market offers customers a large selection of models. Therefore, in order to make the right choice, it will be useful to learn more about them.

How to choose a ladder

The stairs in the house are divided into:

- Marching... The simplest design, the most optimal option for making an object with your own hands. Such modifications are extremely comfortable to use, capable of handling heavy loads.

They are convenient for lifting large furniture to the upper level. The safety of such structures is good, this quality is especially important in cases where either children or old people live in the house. The only drawback can be considered the need to use a large area to obtain a normal slope and a comfortable height of the steps of the stairs;

- Screw... Limited space is enough for such models. They are used where it is impossible to provide a slope sufficient for a traditional ladder.

Screw system It is a more complex device than a marching structure. As the instructions say, skillfully made spiral staircases are very durable.

Note!

The steps of the newly made staircase should not slide, and the gaps between the balusters (posts in the staircase that support the railing) should be of such a size that the baby cannot crawl through them.

About the design features of home stairs

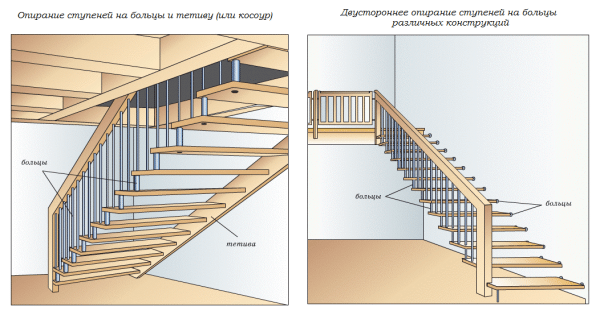

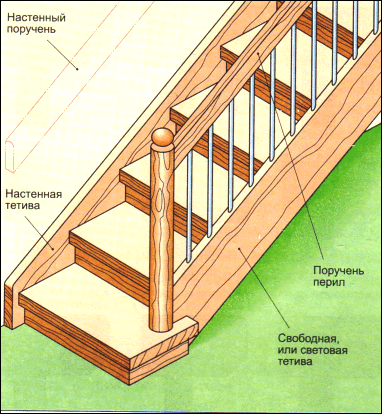

It is very important how the steps are attached to the stairs. It can be bowstrings, bolts, stringers.

The first model is equipped with two beams on which the steps are mounted. Wood or metal is used to make a bowstring. The segments are attached directly to the wall surface.

When a ladder is altered, special supports are used. This achieves greater strength of the structure.

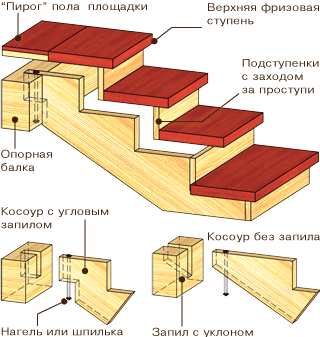

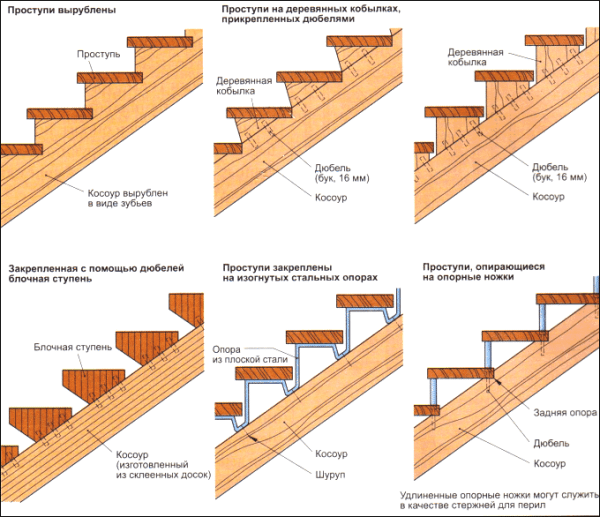

When stairs are created on a kosour (inclined bearing beam), the steps are located along the length of the run located in the lower part, the general geometry of the structure is repeated in the silhouette of the stairs.

Straight stringers have a serrated shape. The steps are mounted over the tines.

Ladder bolts, in turn, are a type of attachment by which the steps are fastened to each other.

There is a self-supporting structure, when the previous level is a support for the next step. The design of such structures is attractive and modern.

Materials that go into the manufacture of flights of stairs

The final artistic interior image depends on what material will be used to create the stairs. Wood is the undisputed favorite among today's materials.

Solid wood has tremendous benefits.

It is an environmentally friendly material, it is perfectly processed. Wood parts are warm, graceful, accessible, but flammable.

Important!

To prevent a fire, non-combustible materials are taken in the manufacture of stairs.

Marches and platforms are made of monolithic reinforced concrete, and fragments of steps and fences are “dressed” in wood.

Thus, the structure becomes sufficiently fire resistant.

The staircase, in which there is only one straight section, is the simplest product, the price of which is low. However, such designs are rarely used. The more steps and platforms, the more expensive the product.

Note!

Stairways made of oak and beech look extraordinarily impressive.

However, such facilities are available only to wealthy customers.

Conifers - pine, larch - are used for the construction of cheaper wooden stairs.

Ready-made light wood constructions must be "fit" into the design of the room. As practice shows, now it is not very difficult to do this, since many modern buildings are erected from natural wood.

You can think of a bar, a galvanized log, etc. The interior details include coniferous segments. The combination of pine needles and oak looks especially impressive.

Making stairs yourself

So, we make a staircase made of wood, consisting of steps, stringers and handrails:

- at the initial stage, the necessary calculations are made... We calculate the dimensions of the step ledge (part of the horizontal bar hanging from above the riser). With an increase in the size of the riser, the dimensions of the step decrease;

- stringers are made... One segment should be made with great care. The rest are executed according to his template.

The quality of their manufacture affects how strong, safe and durable the entire staircase will be. You shouldn't skimp on the quality of raw materials. Steps and risers are prepared in the same way;

- steps are fastened with nails or self-tapping screws... For greater strength in the process of mating, triangular fillets are used. After that, balusters are screwed to the steps, the railings are attached to them with glue (or self-tapping screws);

- so that the wood is not afraid of dampness, mold, or harmful insects, the assembled structure is processed using special means... Following this, the final paint and varnish composition is applied.

Anti-squeak

Quite often, the owners of their own houses, in which wooden spans are installed between the levels, are faced with the question - what to do if the stairs creak? Squeaking is not a characteristic sound of such devices. If it appears during installation, then the parts of the stairs are of poor quality, or the assembly technology is violated.

When a creak occurs after several years of operation, this indicates the following:

- one / several parts of this wooden device have worn out (reasons - intensive load, or insufficient care);

- structural elements rub.

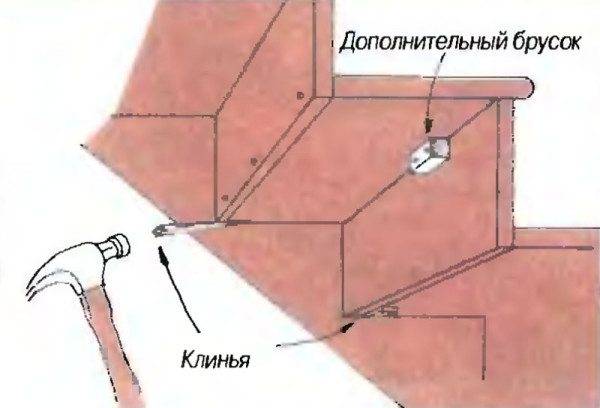

Elimination of the resulting noise occurs by repairing or replacing wooden steps of the stairs, or additional sealing of worn joints. Nails, glue, a set of wooden or metal wedges are used.

Output

Experience shows that following a simple sequence of actions, you can create a wooden staircase yourself. To do this, you need to stock up on a high-quality board, tools and patience, and analyze all the nuances before starting work. More information can be obtained from the video in this article.