We will now analyze one of the options for making a staircase out of concrete at home, and we will also prepare the solution ourselves. That is, we will not use ready-made factory reinforced concrete marches, but we will independently mount the formwork, reinforce it and then pour the same homemade mixture there, so that the whole process will turn out to be autonomous.

Below you are offered step-by-step instructions, and also, as additional material, you can watch a thematic video in this article.

Installation work

How to make calculations

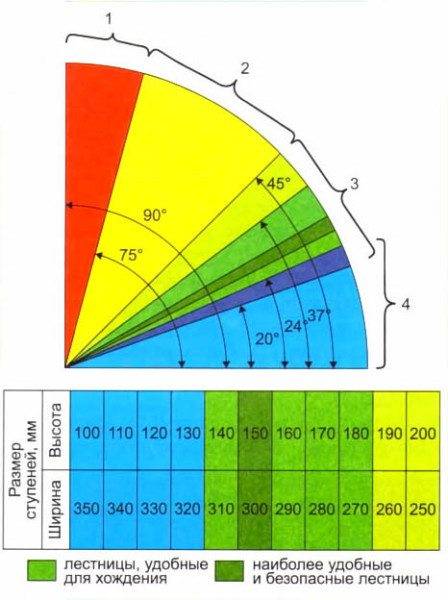

- To perform work in accordance with GOST 23120-78, you can use special computer programs, since the ladder is made in archikad, in autocad or in 3d max much faster than calculating manually, but still, we will tell you how this is done... First of all, we will pay attention to the slope, and if we talk about the most acceptable numbers, then the march can be set within 38⁰-43⁰, although, of course, everything is in your hands, and you can use another angle.

- But, nevertheless, you should pay attention to the space that is highlighted in blue on the upper diagram, it is between 37⁰ and 38⁰ - this is the critical angle... The problem in this case is that with such an inclination, it is impossible to evenly calculate the steps along the required width and height.

A warning. The slope of the span by 45⁰ will be too steep for children and the elderly, therefore, if possible, it is better to divide such marches into two and install an L-shaped or U-shaped staircase with a smaller slope.

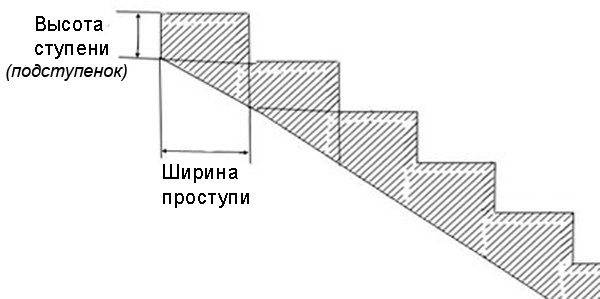

- In order for the ladder to be comfortable and safe, you need to correctly calculate the height and width of the steps of the ladder, and 60-65 cm is taken as the starting point - this is the step of a person of average height... In addition, a safe tread should be a support for 75% of the foot and, given that the sizes of the feet in people are very different, then a size of 25 cm or more is used for this.

- But we need to go out to the value of the average step, and for this we add the two heights of the riser with the width of the tread... For example, let's make the tread 27 cm wide and the riser 17 cm high. Then 27 + 17 * 2 = 61 cm - just the size that we need. Thanks to this, the step during the descent and ascent does not get lost and there is no feeling of fatigue or shortness of breath.

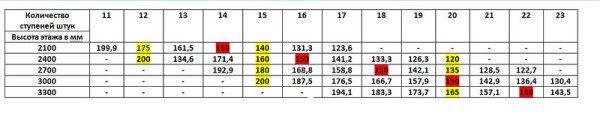

Note to the table. The numbers marked in red represent the most "convenient" sizes, and yellow for the generally accepted steps.

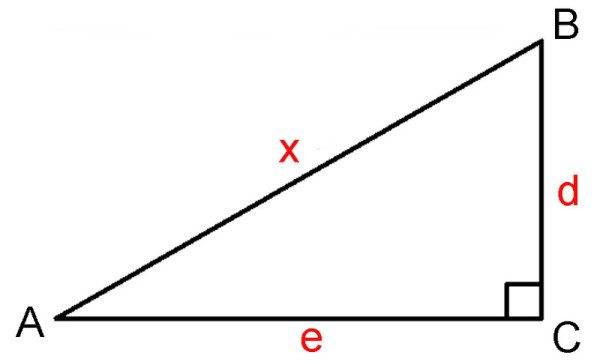

- To understand how to make a staircase correctly, you will need calculations along the length of its march, and then you can determine what steps you need.... Look at the triangle drawn above, and on its example we will learn how this value or number x is determined on the segment AB. To do this, we have to square the value of e on the segment AC and add it to the value of d on the segment CB, also squared.

- In this case, we get e2+ d2= x2, after that it remains only to calculate the square root of the value x... For example, if the distance from floor to floor (height) is 285 cm, then it will be possible to make a tread of 25 cm, and a riser - 19 cm (25 + 19 * 2 = 63). A total of 285/19 = 15 steps will be needed, then the step length will be 15 * 25 = 375 cm = e or a segment AC. Now we calculate the length of the march: e2+ d2=3752+2852= 140625 + 81225 = 221850 = x2, then √221850 = 471.009554043 or 4.72m is the length of the march.

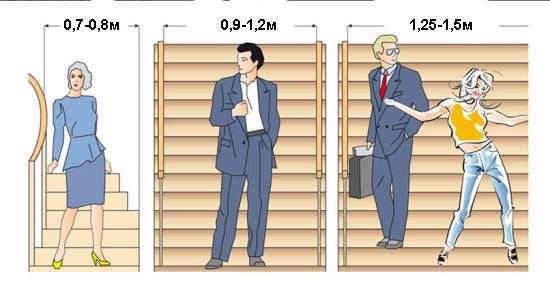

- The narrowest march can be a span from 70 to 80 cm wide, and if it is made smaller, then it will be unsuitable for everyday use.... After all, with a width of less than 70 cm, you will not even be able to climb or descend stairs with bags in hand! Such narrow spans can only be used for special purposes, for example, to the basement or to the roof, but to learn how to make an attic staircase, a separate topic is needed, and we will not consider this issue now.

- Most often, a width of 90 to 120 cm is used for spans - on such a ladder two people can miss and it is easy to carry bags along it (they will not cling to walls and railings)... But, of course, the best option is a march from 125 to 150 cm wide, although not all developers can afford this.

Recommendation. As a rule, stair rail balusters are mounted on top of the steps, and not on the side of the flight, so they occupy at least 5 cm of the span width.

Consider this when designing so that the clean passage is at least 80 cm.

Installation work

First of all, we will figure out how to make the formwork for the stairs, what materials are needed for this and how they are mounted. At the bottom of the formwork, ideally, it is best to use 10 mm thick film faced plywood - this will create a smoother concrete surface.

But, be that as it may, in some places the sheets will join, which will leave a scar on the filling, so the seams need to be sealed with tile glue (cement-sand mortar will not work - it will crumble).

After installing the pallet, you should start flanging, which can be made from the same plywood that you are currently using. In addition, boards are used for the boards (in the top photo, a board of 150 × 50 mm is used). The structure is tightened with self-tapping screws, which must be screwed in at least after 30 cm, and in some situations the step can be reduced.

But, in order to make a staircase to the second floor, it must be reinforced, and for this, corrugated reinforcement with a cross section of at least 12 mm is used. Tied (with a knitting wire) two battens with a cell of no more than 200 × 200 or 200 × 150 mm and fastened together with vertical rods with a periodicity of 60 cm.Adjust the height according to the thickness of the march so that the concrete covers the reinforcement with a layer of at least 50 mm.

If there is a wall on one side, then this can be used to give the march additional rigidity, since the concrete staircase must be made strong enough. The transverse reinforcement of the frame is driven into the wall, into the holes previously made with a perforator, and sometimes, for strength, guides from the channel are installed along the edges of the span, and then the frame is welded to them.

For handrails (balusters), according to GOST 25772-83, you need to make embedded concrete, which are connected to the frame by welding.

Now pay attention to what to make the steps for the stairs - this is the same laminated plywood and a board of 150 × 50 mm. The transverse partition (board) is fixed with self-tapping screws to the flange, but to give rigidity, they are additionally fastened with metal corners to exclude any possibility of shear.

In order to make a ladder with your own hands, you will also have to additionally secure the formwork, not sparing the material on the supports - the more, the better. There is no definite order during installation of the backs - you just need to ensure that the entire structure can take on the weight of wet concrete and not deform even by 1 mm.

Of course, a lot of material will be used for this, but do not be confused by its price, but you will get an excellent result.

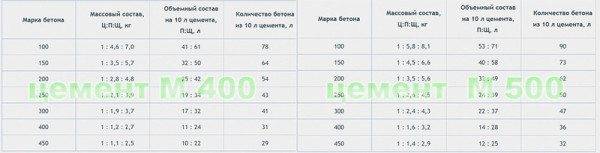

Of course, you can order the mortar at the nearest concrete site, if there is one nearby, but as we already mentioned, we have the opportunity to prepare it ourselves. Pay attention to the concrete table and use a mixture of at least M300. Pouring starts from the bottom, since the solution will slide down under its own weight.

Recommendation. In order for the march to turn out to be of high quality, a vibrator is used when pouring concrete, but if it is not there, then the solution should be compacted manually, for example, with the same handle from a shovel.

In order to calculate how much concrete you need, you can calculate the volume of the stairs (for this, find out the volume of one step (height * length * width) and multiply by their number). You can find out the amount of required ingredients from the table.

Conclusion

The formwork can be removed after 3-4 days and start grouting the steps, and the pallet can be removed a little later, you can even after 28 days, when the structure is ready for loads. Of course, it will be much faster to make marches from profiles, but we will tell you how to make a metal staircase in another article.