In this article, we will consider an affordable and understandable way of how to build a staircase without assistance, saving on the construction team. To do this, you do not need to take any courses, all the necessary information will be presented below, and divided into several sections. The main thing is not to try to skip any stage, the sequence is very important in the editing process.

The first stage is preparatory

Before starting the installation of flights of stairs, in particular, to start calculating and purchasing materials, you should decide on what, in fact, we will make the structure from.

- Of course, the simplest and most affordable option is to make a wooden staircase with your own hands. This option combines both price and quality, as well as practicality.

- It is simply impossible to make metal structures at home, but the frame can be ordered from any organization, the final cost will be slightly lower than in the case of a wooden staircase. On the other hand, you will have to spend money on the manufacture of steps.

Note! The estimate for the installation of a metal staircase includes welding work - it is because of them that a problem arises with the installation of the structure.

- Reinforced concrete stairs are too massive, for such products it is necessary to provide a place in advance and prepare the base. There are no special problems in the construction of reinforced concrete structures, but they need to be finished, and they look pretty massive in the interior.

Agree, the best option is to buy boards and, using a jigsaw, do all the procedures. In this case, you can install a modular staircase, that is, make several parts, then connect them together.

Required materials and tools

Calculation of materials will not take you much time:

- To calculate the number of steps, you need to determine the height of the stairs. This indicator will be equal to the size from the floor of the first floor to the floor of the second floor, taking into account the flooring. A board with a thickness of at least 40 mm should be used as a building material for load-bearing beams and steps. It is also important to choose the angle of inclination of the structure to determine the length of the support; according to standards, the range from 30 to 45 degrees is considered acceptable.

For your information! There are certain standards that can be followed, for example, for the height of the riser (vertical dimension from step to step), optimally 180-220 mm. As for the depth and width of the tread itself, 800-900 mm in length is optimal for free ascent, and no more than 350 mm deep.

- We will use wooden blocks for the fence. If the initial racks must be "strict" and reliable, then decorative fillers can be used for internal filling. It is better to buy them ready-made, you still have big savings, because the cost of installing the stairs does not include the call of expensive construction teams.

Important! Do not forget that the calculation and installation of the attic staircase is carried out in a different way, for this you need to purchase at least card loops or a folding mechanism. And the angle of inclination is selected differently, as, in fact, the width and depth of the steps. Actually, like the cost of installing an attic staircase, it depends on what type of fastening was chosen.

And now, as for the tool that will be required during the work:

- The jigsaw is an irreplaceable thing.Of course, you can make cutouts using a hacksaw, but this way the work process will stretch for long hours, it is easier to rent a tool if you are not on hand.

- Drill or screwdriver.

- Hammer.

- Building level.

- Construction square.

- Roulette.

- Sandpaper, it is better to be fine-grained.

- Chisel.

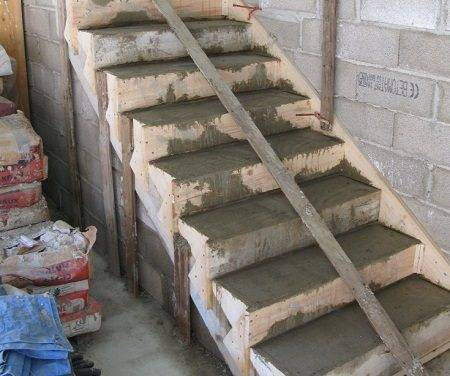

The second stage is installation

In this section, you will learn how to install and manufacture stairs on your own. We will also divide it into several parts, each will describe a specific process.

Making a bowstring and stringer

- First, you need to install an uncut beam in the place where the stairs will be located.

- Measure the bottom corner using a construction square and tape measure - transfer the angle between the floor and the support to its surface. In the place where the ladder is adjacent to the wall, appropriate actions are taken.

- Saw off excess parts with a jigsaw.

- Sand them well with sandpaper.

- As for the kosour - knowing the depth of the tread and the height of the riser, we transfer all these dimensions to the surface of the bearing support. You should get a lot of triangles that are sawn off with a jigsaw.

- The bowstring for the stairs is made in a different way, initially steps (tread) are marked on the surface of the beam, after which the grooves are selected with the help of a chisel.

Note! In the event that you decide to install metal stairs, then do not forget about the most important thing - observing the horizontal plane for welded risers. The appearance of your design depends on this.

Installation of bearing supports

- Installation of a flight of stairs begins with securing the beam.

- The first step is to attach a metal corner to it from the inside.

- Mark the holes on the floor and on the wall to which the support adjoins.

- Drill holes of the required diameter with a drill.

- Secure the beam with an anchor bolt and a wrench.

Important! If the floor is wooden, then it is enough to screw 3-4 long screws into the wood, or drive nails into it. The difference is that nails will loosen over time, due to everyday use, and the threads of the screws will hold the fasteners securely.

Fastening steps and risers

Let us repeat and recall that - if you use risers, then they should be installed first of all on the stringer, but last of all on the bowstring.

- Since the ladder is wooden, it does not require preliminary drilling, so the first step is to attach the vertical bar to the stringer.

- Screw in two wood screws on each side with a screwdriver so that the caps are slightly recessed.

- Place the tread on the vertical notches.

- Screw four self-tapping screws through the step, two on each side. It is also advisable to drown the hats.

- Using sandpaper, treat all facial surfaces to remove chips and clues.

For your information! In the case of a bowstring, the steps are fastened through the support, the fasteners are considered visible, so either use putty or use hidden fasteners. These are wooden dowels that are driven into the holes in the steps and bowstring, only this will require a more reliable beam, for example, thick 60-80 mm.

Installation of the fence

Now we start fixing the railing:

- First of all, we fasten the supporting supports, which are located at the very beginning of the staircase and at the end. And if the length exceeds 2 meters, then the stand is additionally attached in the center. The fastening element is the same anchor bolts as for the installation of the beam.

- The next step is to mark the location of the balusters. The required distance from the edge is 40 mm.

- It is best to attach them to dowels and PVA glue, so you need to drill only halfway in the steps.

- Glue is poured into the holes and the dowel is hammered. All excess glue should be removed immediately.

- The same holes are made in the lower part of the baluster, in the center.

- The support is stuffed onto the dowel.

Note! Before installing the balusters, a cut should be made on them, repeating the angle of inclination of the stairs so that the angle of the railing does not differ from the main structure.

- When all the uprights are in place, the handrail can be attached. If you use glue, it is better to fix small slats on the supports (on self-tapping screws) and make grooves in the handrails, this will be more reliable. If you don't want to bother, then just screw the screws at an angle.

Here, in fact, is the whole instruction. As you can see, the manufacture and installation of stairs for your home is not such a difficult and overwhelming process, the main thing here is to comply with all the requirements and use high-quality fasteners. You just have to make a decorative stage - finishing the finished structure.

Reminder! If you paint wood, sand the surface as thoroughly as possible so that it is smooth before and after painting.

Output

A staircase with installation usually takes up a significant part of the budget, which is laid down for the interior decoration of a residential building. Therefore, the saved installation cost of stairs, which you were able to install yourself, will help you acquire more important things from the highest quality materials.

Or you can spend money on the arrangement of the erected structure, for example, install additional lighting for the staircase. In the video presented in this article, you will find additional information on this topic.