Design, construction and finance

Staircase structures, of course, require a thorough calculation, and then assembly experience. Nevertheless, the calculation does not present any difficulty - the geometry of the 7th grade of the school, and the assembly, if the ladder is modular, is not much more complicated than the assembly of a children's constructor "for giants".

There are, however, stairs, during the construction of which one cannot do without specialists under any guise. These specialists are welders, and the ladders are iron. But, the paradox lies in the fact that it is this apparent complexity that provides us with additional options for choosing, both the complexity of the structure itself and its design, and hence the cost.

All 5 known types of stairs are subject to iron stairs.

Types of stairs

With some reservations, you have at your disposal the same 5 commonly used types of stairs:

- On kosoura. This is the most common type of staircase construction. Unless in the interior of residential premises, you can increasingly find structures on one middle stringer.

- On the bolts. This type with iron stairs is not used so often, it requires fastening from the base, the wall, first of all, increased strength. Moreover, the constant impact of chaotic pressure on the wall structure over time will inevitably lead to its deformation and destruction.

- On the casing. But this type, if you clarify that it is often called in a simple way - a spiral staircase, on the contrary, is very common in the gland. Moreover, you can not be afraid to make a big mistake and say that the most successful and attractive designs of iron stairs are spiral ones.

- Folding and retractable ladders. These are also called attic, and already speaks for itself - the vast majority of such stairs are made of iron.

- Combined. This type, as a combination of the first three, is quite common and is often the result of rigorous calculation and the desire to adapt to the existing character of the room.

Advantages

Iron stairs play on the natural advantages of this material, including:

- Excellent resistance to external adverse influences from the atmosphere, temperature drops mean nothing for iron. Although here it is necessary to take care of proper anti-corrosion treatment. But anti-corrosion is such a well-developed science that it cannot be an obstacle before deciding on the construction of an iron staircase.

- The ultimate strength of the material and its resistance to mechanical stress. This advantage is so obvious and out of competition that it is one of the main tempting factors when choosing a material for a staircase. Iron staircase steps will never begin to sag or creak - this very useful nuance should attract fans to return home long after midnight, so as not to wake up the family or to hide the time of their arrival from them.

- Simplicity in operation. And this is again the merit of the material. True, we mean that his unpretentiousness in food does not mean that now you can fry potatoes every evening. The unpretentiousness of the iron does not mean that you can completely forget about the maintenance of the stairs. On the contrary, calm but constant monitoring of fasteners and welding will be required.

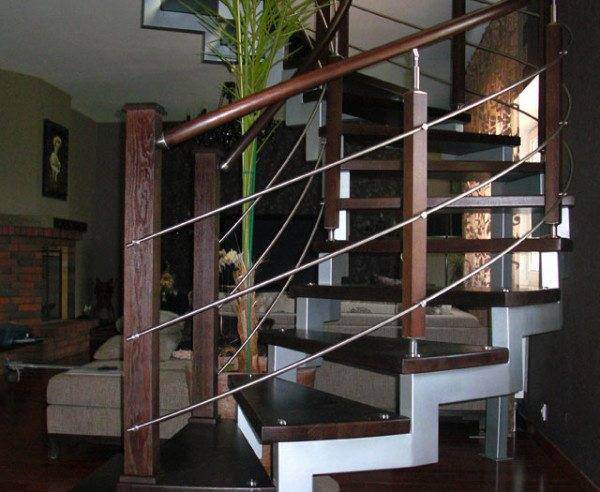

- Material flexibility and a huge number of ready-made proposals. And hence the incredible design finds.This is not to say that such stairs are "lighter than fluff", but the fact that they are akin to the air that surrounds them is undoubtedly. This apparent ease in creation, that the structure is iron, is the main mystery of iron stairs.

- Material availability. Indeed, there has never been a problem with the availability of metal, as well as with the availability of means for processing it.

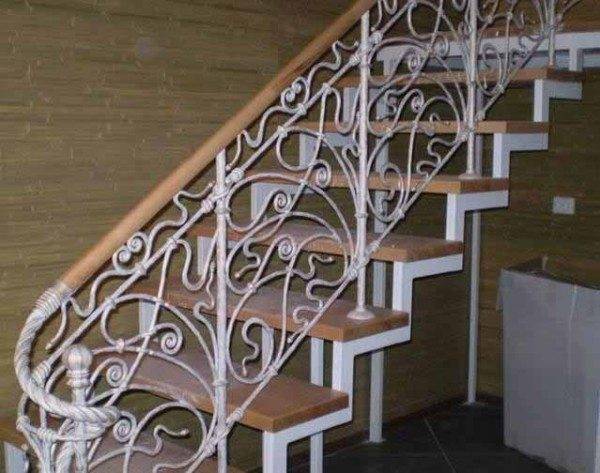

- Extensive experience in working with the material. They say that the art of furnace craftsmen is becoming a thing of the past, the real masters of this fine brick science are leaving. But the masters of working with metal are somehow not diminishing, on the contrary, new workshops for the artistic processing of metal are constantly emerging.

- As a consequence of accessibility and great experience - very low price of the initial blanks, and of the entire work as a whole. Although forging, after all, we take out the brackets. Forging is still in the price range and belongs to the highest price range of work.

disadvantages

In fairness, we will show the "bright" side of the issue, in other words, when choosing iron stairs, you need to keep in mind the following pitfalls:

- The first thing that is obvious is that iron structures are heavy, therefore, they require special attention to the foundation and interfloor ceilings. The severity of the entire structure, most likely, will force you to abandon the original idea of putting such a ladder on the bolts.

- The second is the need to carefully monitor the state of the structure, especially the fasteners and welds. If necessary, the fasteners will most likely have to be tightened from time to time.

- If you have a modular iron staircase, then the amount of welding work will be small, but in all other cases, especially if the staircase is in the open air, you cannot do without large amounts of welding.

- As a consequence of the previous one, not even a drawback, but peculiarities, the impossibility of constructing a staircase with your own hands, without the involvement of welding specialists. We are talking about iron stairs, but there are a huge number of types of metals and each requires its own types of welding and its own modes. Knowledge of the features of welding of certain metals is the prerogative of professionals.

- If you do not claim any artistic sophistication in the design of your staircase, it really will be relatively inexpensive. If you are attracted to forging, then you will throw yourself into the opposite situation - you will have to fork out and very seriously.

- The last drawback is associated with our carelessness in winter, if the stairs are in the open air - the steps will certainly slide, and the railing will be horrible how cold. But we somehow learned to cope with these shortcomings, attracting our caution to the same.

Helpful advice! Maintenance of an iron staircase, if assembled with threaded connections, should become the norm for its owner. Do not think that you have to constantly run around the apartment with a wrench. But it is necessary to calmly and carefully examine all the connections. In this regard, we advise you to get yourself a professional torque wrench with control of the tightening torque. You should also be aware of these very tightening torques for your ladder threaded connections. Just tightening a nut or bolt is not enough, you need to tighten to the required torque. Fortunately, it is usually not a strict number (defined in Newton-Meters, Nm) that is given, but a whole permissible range of tightening torque - it is already easier to get into the moon than 5 kopecks on it.

Materials (edit)

For the manufacture of iron stairs, a wide variety of raw materials are used. It:

- Profile pipes - the most reliable material for spiral staircases. Pipes of completely different diameters are used, but the most common range is from 40 to 60 mm. The pipe is attached from above and below to the ceiling and floor, corners are welded to it, to which the steps and the steps themselves are then welded.

- Channel - this is already for creating a kosour.

- Corner - rather, an accessory part of a wide variety of shapes and sizes that can be used for a wide variety of purposes.

Helpful advice! Channel - a type of rolled metal that has invaded the world of stairs almost "according to Lenin" - we say kosour - we mean channel, etc. But keep in mind that not every channel is suitable for stairs - only low alloy or structural carbon steel is needed here, which allows widespread welding.

conclusions

The dream instruction reads: "If you dreamed about a staircase made of iron in a dream, this is a sign of long-term career growth." Why "long" is understandable - the very path along this structure encourages thoughts about time. Why "career", you can also guess - where there is iron, there is solidity, reliability, solidity, both in design and in relation to life. Why "growth" is understandable and so - after all, the staircase.

But in order for these three components to successfully come together, and time, and success, and rise, take the construction of your iron staircase very responsibly, attract reliable and skillful specialists. Then you somehow will not dream of a very rapid career decline, divorce, or whatever else "Freud" will notice in the unsuccessful dream construction of the iron staircase.

The video in this article will demonstrate your vision of this issue.

I built a two-story house in my dacha, when it came to which staircase to make to the second floor I chose an iron one, compared it with others, but I realized that this was the most acceptable and reliable option

The iron staircase does not look inside the house. Better all the same wooden. And there is a place for iron on the street or in some office centers. Forging looks cool in the photo, looks expensive and tasteful. But it is now expensive.