Today, the most advantageous design solution is the combination of metal and wood. Such products have an excellent appearance, while being characterized by high durability, as well as a variety of colors and stylistic solutions. The sophistication of metal elements, especially forged with the sophistication of natural wood, is a winning move for a modern interior.

In this article, we will look at how to sheathe an iron staircase with wood to get a beautiful and durable structure.

Metal staircase with wood cladding in a modern interior

The staircase is an indispensable attribute of any building that boasts a height of several floors. Today staircases are made of various materials: wood, metal, plastic, glass, etc. However, staircases made of wood and metal continue to be the most popular in all houses, representing not only aesthetically attractive, but also the most durable materials.

Recently, combinations of these two materials have become very fashionable, which have significant advantages.

- Excellent performance and long service life compared to wooden counterparts.

- Less weight when compared to solid metal structures.

- Majestic appearance.

- A wide variety of design solutions.

- The metal gives the stairs strength, and the wooden steps and railings are safer and more comfortable to move.

- Wooden stair treads provide excellent soundproofing of the metal structure.

Choosing a material

Now let's talk about how to sheathe the stairs in the house. Today, wood is not in short supply, and various types of wood are offered to your attention, the price of which can vary significantly. Such cladding can be both the most budgetary and cost-effective option, and the most expensive if you decide to use elite types of wood with exquisite carvings in your decoration.

Advice! In order to save money, you can only trim the treads with wood, leaving the structure "open", that is, without risers. In some cases, this option will be the most advantageous from a design point of view.

Wood cladding of stairs involves the use of materials such as oak, walnut, beech, cherry, ash, pear or mahogany.

Let's look at them in order:

- Oak. Probably everyone has heard that oak has high strength and durability, it is a heavy and dense material that is very often used in loaded structures. In addition, it is characterized by a fairly wide range of colors: from pale yellow to red-brown tones.

Advice! When making a staircase from oak, keep in mind one feature of this wood: over time, it darkens, acquiring a noble color. Therefore, if you want to successfully "fit" oak into the interior, choose a product of lighter shades than necessary.

- Ash. No less durable than oak. The wood has a pronounced texture and a noble, slightly grayish tint. A great option for stairs in a classic interior.

- Beech - a symbol of elegance, as it is characterized by a homogeneous texture and attractiveness. Wood is durable and is often used to imitate mahogany.

- Exotic breeds. Often metal staircase sheathing is carried out by rare, exotic wood - teak, wenge, merbau, etc. And this choice is very easy to explain, since such wood has a very wide color palette: from yellow tones to reds, browns and blacks.

In addition to their excellent appearance, these stairs are very strong and durable.

Risers are often made from spruce, fir or pine. Due to their low density, these types of wood should not have wear resistance in order to install them as treads, but they are quite suitable for risers.

Pine, for example, has high performance characteristics, and its low density allows you to do it yourself. In addition, its use is also dictated by economic considerations, because the cost of pine products is much cheaper than hardwood counterparts.

Advice! The strength of the wood is significantly reduced due to excess moisture. Therefore, before work, it is necessary to dry the tree until the moisture level indicator drops to an acceptable value - 12%... Otherwise, during operation, you may encounter swelling of wood products.

Features of the cladding of metal staircases

At the moment, the most popular are two types of cladding:

- Partial, in which wooden treads are attached to the metal steps. At the same time, the rest of the structure, including the railings, remains metal.

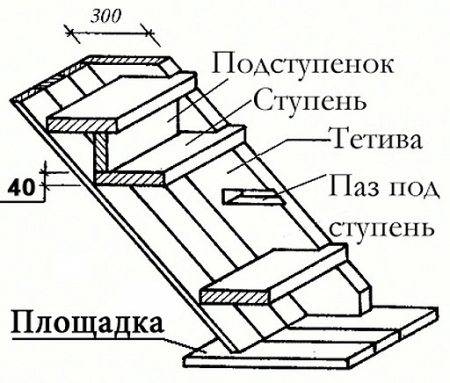

- Full, which involves the implementation of the whole range of works related to the wood sheathing of risers, treads, railings and under-ladder space, with imitation of stringers or bowstrings. As a result of the correct implementation of such work, you get a ladder with a solid metal core, which is indistinguishable from a wooden one.

Finishing technology

Staircase sheathing is carried out in several stages. Instructions:

- At the first stage of work, it is necessary to choose the design of the stairs and decide on the method of sheathing the frame. That is, you will only sheathe the treads or carry out a complete finish.

- Now you need to decide on the type of wood used for cladding.

- Next comes the preparation of the elements and details of the cladding. For this, the array is adjusted to the dimensions of the frame. In the simplest version, a hand saw for wood and a large file will suffice.

- Take careful measurements of all structural elements.

- After that, you need to transfer the measurements to the wood.

- For the markings, cut out the details of the steps from the wood.

- If you decide to produce full cladding, then the next step is to choose the most suitable type of balustrade. In addition to the protective and supporting function, the step barriers are a rather effective decorative element of the staircase structure.

Advice! Railings can have different sections, so you should choose the most comfortable shape for your palm.

It is very important to consider the spacing between the balusters. Usually it is from 150 to 220 mm... However, if there are small children in the house, then it should be reduced. up to 90 - 100 mm.

- Securing wooden elements. The easiest way is to use self-tapping screws for this.

- We drill holes in the metal frame at the points of attachment of the elements.

- Using self-tapping screws, we fasten the wooden cladding to the frame.

- The self-tapping screw can be screwed in so that the head is 5 mm deep into the wood. Then the attachment point can be closed with a wooden chopik.

- We attach the balusters to the treads with self-tapping screws. We strengthen the railing on top of the balusters.

Conclusion

In this article, we looked at how to sheathe a staircase with wood. Transforming the look of a sturdy metal structure is much easier than you might think.The main thing is to choose the right wood and make clear markings.

In the video presented in this article, you will find additional information on this topic.