Today's reality is such that many of our compatriots have received the opportunity to build houses on their own. Newly rebuilt houses are solid and reliable structures. Some of them have more than one or two floors; in such houses, wooden or metal stairs for the house can be installed.

Now a staircase for a home is not an unaffordable luxury item. Rather, it can be a connecting link in creating a single design image in the overall style of the house. Correctly mounted and beautiful design gives the premises a higher status, and the owner - prestige.

Installation is a complex process both technically and in terms of structural analysis. Making it with your own hands, without special knowledge and certain skills, is not difficult. In the meantime, we would like to tell you more about the types of structures and materials from which they can be made.

Types of stairs

There are many different types available for installation in private homes.

Among them are:

- marching;

- screw;

- swivel;

- L-shaped;

- U-shaped stairs.

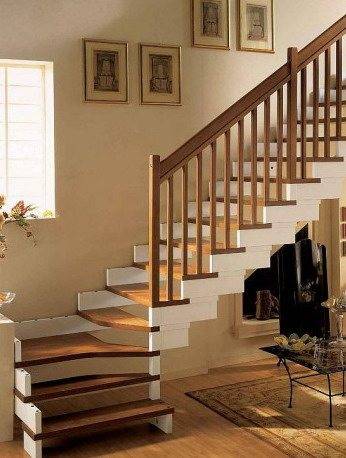

Marching stairs

This type of stairs is considered the easiest to manufacture. As a rule, such structures are mounted in low rooms. They are comfortable, relatively cheap, and look pretty good.

Are divided into:

- straight,

- swivel.

Direct flight staircase

It is mounted in low rooms (up to 3 m high), when 10 steps are enough to rise to the second level. In this case, one flight of stairs is enough. And mind you, small ladders are quite effective.

Swivel flight staircase

Such a staircase is installed in higher rooms (from 4 m or more). In this case, the flights of stairs are broken in such a way that there are no more than 10 steps in each flight of stairs.

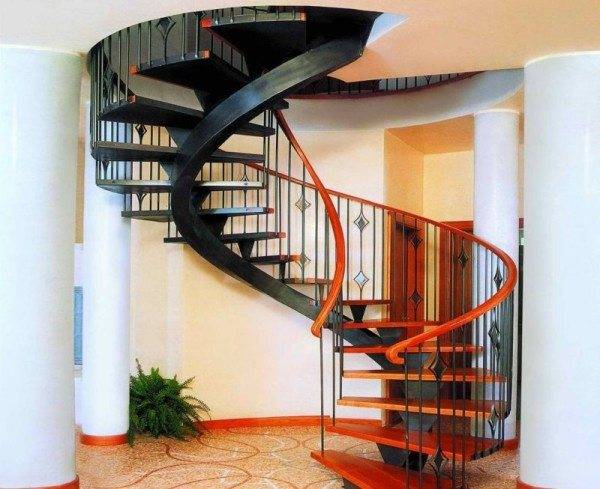

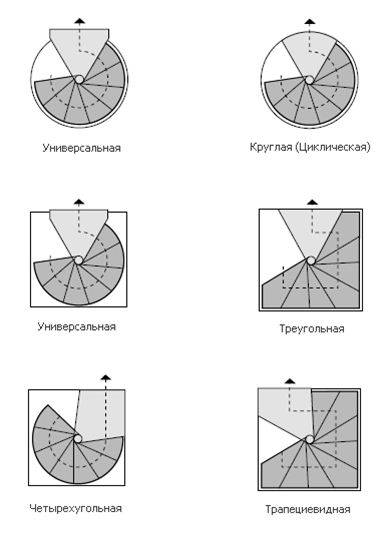

Stairs with "screw"

One of the most practical types, this design can significantly save space. The circumference of such stairs is determined by the length of the steps that make it up.

The peculiarity of structures of this type is that they are attached to the central pillar and consist only of winding steps. Thanks to this method of the device, it takes the form of a spiral.

Note!

Winder steps differ from the usual ones in that the width of their inner edge is much less than the width of the outer one.

However, do not think that these structures are only round, they can be square and octagonal.

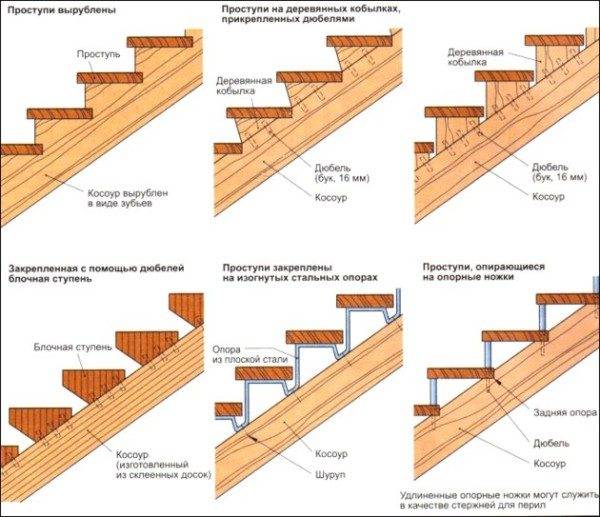

Constructions from modules

The next view is modular stairs... This type has become popular recently. Their peculiarity is that the main supporting element, here, is a type-setting kosour. This is a set of wooden or metal modules, with which the steps are attached independently, under any opening or at any height.

The height of the steps can be set individually. Thanks to the variety of shapes and textures of the materials used, they have gained well-deserved popularity.

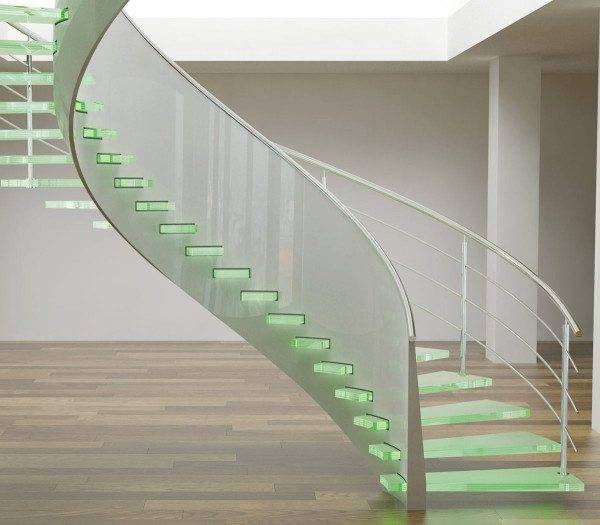

Glass stairs

This type of staircase for houses suggests something fragile and fantastic. However, glass stairs are a real reality. Tempered glass, acrylic or triplex familiar to all motorists are used for their installation.

All of these types of materials are safe and durable. They are able to withstand significant loads (up to 350 kg per square meter).

To ensure that the steps of glass stairs are not slippery, they are treated with a special coating. For the same purpose, the method of sandblasting glass is used.

Combined stairs

This is a type of stairs, during the installation of which various types of materials are used. For example, wooden ladders are attached to the base using a metal frame. Railing of combined structures is often made of glass. This gives the design grace and lightness.

Modern staircases are most often made combined. In addition to aesthetic qualities, they also differ in that the price for them is the most democratic.

Steel stairs

This is the next type that we would like to bring to your attention - steel stairs. They have a whole range of advantages over other structures of the same type. First of all, unlike wooden stairs, they are completely non-flammable.

They are quite simple to install, suitable for any style, and can withstand significant loads. Their strength is beyond doubt. In addition, they are distinguished by their durability.

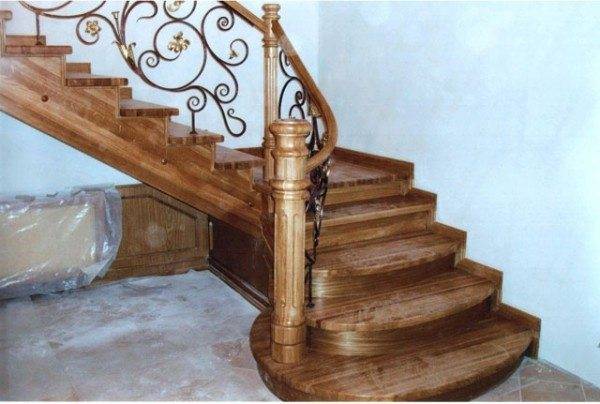

Wooden stairs

This is the most popular type, we can say that it is a classic of the genre.

Wooden stairs are environmentally friendly, comfortable, easy to install. Note that this material is one of the most affordable in terms of price.

But it should be noted that the tree burns very well. And this is the most significant disadvantage of such structures.

For the manufacture of wooden stairs used:

- Pine;

- Birch;

- oak;

- beech;

- nut;

- chestnut.

Concrete stairs

Outdoor home stairs are usually made of concrete. Concrete structures are used for descents to basements. These are solid and rather heavy structures, they are also mounted using metal frames.

Technology

Various ideas for stairs for the house can be found on our website, and their photos are presented in this article. Next, we will tell you about the basic steps for installing stairs in the house.

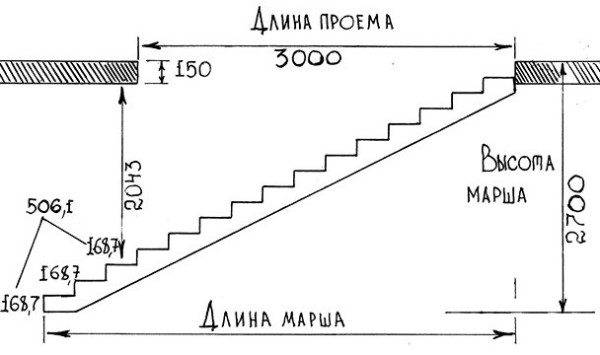

Remember that house stairs and their assembly are carried out in the presence of clear and verified calculations, the installation instructions are presented below.

Instruments

You will need the following tools for installation:

- drill and drills of different diameters;

- puncher;

- socket and open-end wrenches;

- marking triangle;

- roulette;

- screwdriver;

- screwdriver;

- hacksaw;

- fastening material.

Note!

When performing work at a height, it is required to strictly observe all safety precautions, your life directly depends on this!

Stages

The order of work is as follows:

- on the second tier, you fill the opening;

- beacons are marked on the side walls, to which the support pillars and stringers will be attached;

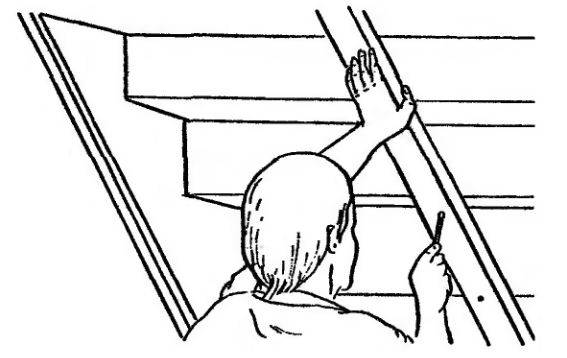

- lay the flight of stairs with the wall side down and insert the upper riser;

- then draw a pencil line along the frieze step and riser. In this case, the line should be parallel to the plane of the floor;

- the next step is to remove the first riser and frieze tread;

- then the bowstring is sawn off with a hacksaw along the outlined lines;

- then proceed to the preparation of the lower wall string. The floor line is marked on it, it should be parallel to the lower tread.

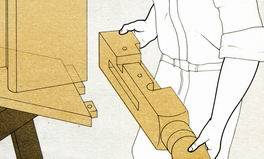

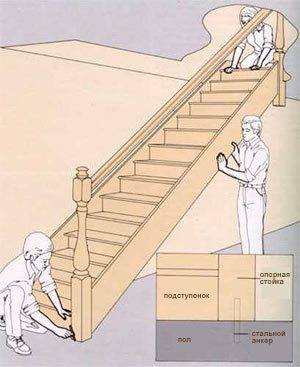

Marking the upper support post

For this:

- the top stand is placed on the workbench with the groove up;

- using a marking triangle, mark a line from the edge of the groove around the entire rack;

- then measure the length from the line under the groove to the floor surface;

- a riser is installed in the grooves and a line is marked along the trailing edge of its rib;

- in a similar way, all other steps and risers are attached along the entire flight of stairs.

Installation of handrails and support posts

The order of work is as follows:

- the flight of stairs is turned over and laid on the trestle;

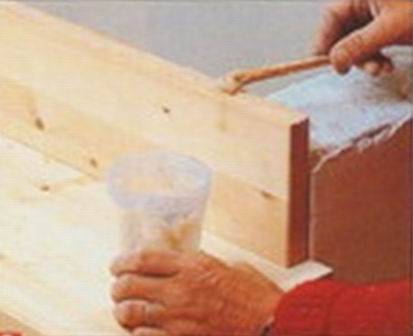

- then PVA glue is applied to the spikes in the upper part of the bowstring and support posts are inserted into these grooves;

- do the same with the upper edge of the handrail and with the lower one.

End of assembly

The procedure is as follows:

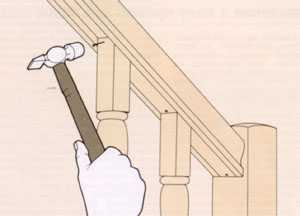

- wood spikes are hammered into the corresponding grooves on the support posts;

- the lower pillar of the support is cut off at the floor level;

- then all other risers are set on glue.

Final installation of the ladder

Completing the work:

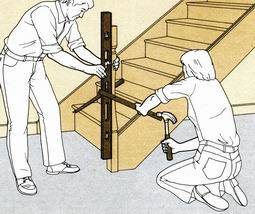

- the flight of stairs is approximately supported on the upper opening;

- fix the support post and frieze tread on the cross-beam of the opening;

- holes are drilled in the floor and in the middle of the base of the lower rack;

- insert the steel bar into the rack and place the ladder in place.

Output

Installation of stairs in your own homes, as you can see, is a fairly simple matter. This will require an assistant. Knowledge and availability of special tools will somewhat speed up the installation work, and the manufacture of stairs for the house will take a minimum of time.

If you have any questions about technology, the video in this article will allow you to find answers to any of them, take a look!