Liquid rubber foundation waterproofing process

Surface preparation

For the high-quality performance of waterproofing work, it is necessary to follow certain instructions, the first point of which is the preparation of the foundation surface.

First of all, you need to conduct a visual inspection of the surface, for which you need to remove the soil around the entire perimeter of the foundation. Most often, the work involves digging a trench around the house. Its width should allow to freely perform any work, therefore it is enough to remove the soil 1 meter wide. As for the depth, there is only one option - the bottom of the trench should be on the same level with the bottom of the foundation.

Next, they begin to inspect the surface and identify all its defects. The existing dirty places are put in order, while the existing old waterproofing layer is also removed. To do this, you can use a special scraper, solvent and rags.

To completely clean the pores of the material from which the foundation is made, additional processing is carried out using a sandblaster. After that, the surface is washed with a low concentration hydrochloric acid solution.

If, upon examination, mold or fungus is found on the surface, then an antiseptic solution is performed.

To seal the entry points into the foundation of various communications, polyurethane foam is used. Cracks and potholes on the surface of the foundation must be sealed with cement mortar and covered with a layer of primer. These actions help to increase the adhesion of the surface to the waterproofing material. The drainage system at the foot of the foundation also requires attention, you need to carefully inspect and make sure its integrity. In places requiring repair or replacement, appropriate work should be carried out.

The preparation of the foundation for applying a layer of waterproofing should be approached very carefully, this will avoid additional laborious actions.

Waterproofing application

It is very important to understand that you cannot apply liquid rubber to the surface of the foundation in wet and cold weather! This applies to all methods of applying liquid waterproofing. If manual application is expected, then a brush or roller should be prepared, and the waterproofing material should be diluted with water before application

If the waterproofing is sprayed, then a special pneumatic installation is purchased. You can also use an airless spray unit. All components of the waterproofing material are mixed in the apparatus that will be used for work

If manual application is expected, then a brush or roller should be prepared, and the waterproofing material should be diluted with water before application. If the waterproofing is sprayed, then a special pneumatic installation is purchased. You can also use an airless spray unit. All components of the waterproofing material are mixed in the apparatus that will be used for work.

When choosing a method for applying liquid rubber to the surface of the foundation, material losses must be taken into account. To do this, you should know the following:

- The loss factor for manual application is 1.1.

- When using an airless spray unit, a factor of 1.25 is applied.

- Pneumatic spraying requires a factor of 1.4.

- If the surface has a complex shape, then the coefficient will be 1.6.

When manually applying liquid rubber, repeat the process several times over the entire surface until the required waterproofing thickness is achieved.Other application methods require less labor, since one layer of liquid rubber is sufficient. In general, the water protection must have a thickness of at least 2 mm. If the base of the foundation is located at a depth of 5 to 10 meters, then the layer of protection is increased to 4 mm; for deeper foundations, waterproofing is applied with a layer of up to 6 mm.

Liquid rubber is applied first in the lower part with a gradual rise upward.

To check the quality of the waterproofing protection, you can make a small incision on the top of the material and try to lift it. The separation of small pieces of rubber indicates high-quality insulation, if the rubber comes off in a strip, then the waterproofing process must be repeated again.

Penetrating waterproofing

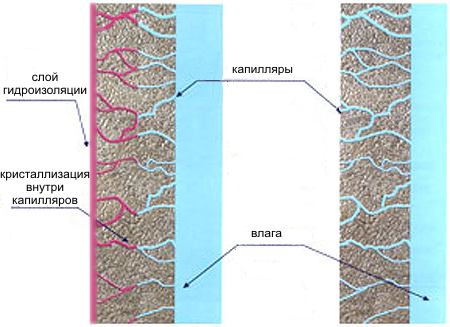

Penetrating foundation waterproofing is used to protect concrete structures. Since the liquid, penetrating into concrete, solidifies when exposed to low temperatures and destructively affects its integrity, it becomes necessary to waterproof this building material.

Penetrating waterproofing action

A waterproofing mixture is covered with concrete, when it gets into the voids and pores of the building material, a chemical interaction occurs between the active elements and the cement, during which waterproof crystal-like solids appear, which push the liquid out of the concrete and completely cover all kinds of voids and microcracks.

Application area

This method is used to protect the foundation from negative water impact, for waterproofing basements, as well as swimming pools, containers for filling and storing liquids, structures designed for wastewater treatment, as well as, if necessary, isolation from water of wet premises of residential buildings.

Waterproofing technology

Liquid waterproofing of the foundation cannot be carried out without preparation. Before starting to apply the waterproofing layer, some preparatory work should be done:

- Clean the entire surface area from all kinds of debris, sand, dust, dirt and grease stains.

- To clean the surface and open the capillary pores of concrete, sandblasting should be carried out, and then wiped with a solution of hydrogen chloride - HCl (the solution is prepared in a ratio of one to ten).

- If there is mold on the surface, then the top layer should be cleaned, and then treated with an antiseptic.

- It is necessary to grind the grooves with a depth of 25 mm at the points of registration of the materials. Increase cracks in concrete up to 2 cm wide and more than 2.5 cm deep using a spatula.

- Provide impermeability (sealing) of internal communications.

- Moisten the concrete surface before applying the insulation.

Depending on the manufacturer's instructions, a waterproofing mortar should be prepared. The mixture can be applied with a spatula, wide brush or spray gun. For clarity, we present a video on applying Penetron liquid penetrating waterproofing:

When waterproofing a brick surface, the following steps must be followed:

- Drill holes, cylindrical indentations, with a drill with a radius of 12.5-16 millimeters at an angle of 45 degrees. Maintain a 25 mm spacing between recesses and a drilling depth of two thirds of the masonry thickness.

- Moisten the surface with water and fill the grooves with cement-sand mortar.

- After the mortar has set, re-drill the holes and apply a waterproofing layer to the surface.

Some of the most common and high-quality materials for waterproofing surfaces are Penetron, protective coatings Gidroteks and sealants for waterproofing Aquatron-6. They meet all existing requirements and quality standards and ensure the proper functioning of building structures and the performance of the protective and insulating functions of coatings.

General production rules

A bitumen-polymer coating is applied with special sprayers with a gasoline or electric drive.

For the production of high-quality waterproofing, two builders are enough. You don't need to have specialized skills to do simple things. The work usually does not take more than one working day, up to 2000 m² are covered per day. Liquid rubber can also be applied to a damp surface (not wet!), Which significantly reduces the duration of the waterproofing process. The coating dries from 4 to 24 hours. The duration of drying depends on the ambient temperature: the higher it is, the faster the performance of the bitumen-polymer composition is achieved.

Liquid rubber is equally easily distributed over the horizontal and vertical surfaces of the foundation, capturing the adjacent areas and creating a monolithic coating. To spray the composition, you will need special equipment, for example, RХ-27, to which two containers with liquid rubber and a hardener are attached.

Liquid rubber can be applied not only by spraying, but also in other ways. The filling material is intended for horizontal surfaces. The waterproofing layer is formed by pouring and uniform distribution. Also, the bitumen-polymer composition can be applied with a paint bone, brush or spatula. But guaranteed high-quality and fast insulation is achieved using a special spray of domestic / imported production.

Attention should be paid to the conformity of the equipment used with the purchased liquid rubber. Foreign suppliers of raw materials recommend the installation of the same manufacturer

But domestic equipment is more versatile: RX-27 and RX-28 with an electric drive or RX-33 gasoline technology allows you to work with liquid rubber from TechnoNICOL, Rastro, Stream, Liquid Rubber Russia, Daclar.

Advantages and disadvantages of a liquid waterproofing agent

The material has truly unique properties. The following advantages deserve special attention.

- Rubber waterproofing can provide a secure connection to almost any surface. In this case, the quality of adhesion is completely independent of the wear of the coatings.

- The material penetrates into all damages and cracks, precisely repeating their shape. This distinguishes waterproofing rubber from other materials that are thicker.

- The considered waterproofing agent provides reliable protection against corrosion, because there are no joints or seams on such a coating.

- The high level of elasticity allows the material to serve for a long time without deformations and tears.

- Rubber waterproofing is completely safe for health. Even in the heat, no harmful substances are released from the material.

But, like any building material, rubber waterproofing has its drawbacks. The most significant ones are as follows:

- To apply the material, a special device is required, which can be dangerous if used improperly. Therefore, an experienced professional should work with liquid rubber.

- The composition is quite expensive. Not everyone can afford to spend this amount one time.

- Rubber waterproofing may require an additional coat of paint. It should be remembered that water-based or silicone-based products are suitable for this purpose.

- The waterproofing device using viscous rubber is characterized by a not very attractive appearance. Therefore, this material is not very often used in the field of private construction.

# 1. What is Liquid Rubber?

Liquid rubber has recently appeared on the market for waterproofing materials, so not many people know what this coating is made of. To begin with, the material has nothing to do with ordinary rubber.If rubber, familiar to all of us, is made on the basis of rubber, then liquid rubber is a product of bitumen processing. Latex and other modifying additives, stabilizers, polymers and water are added to it. As a result, a two-component system is obtained, an emulsion, the properties of which make it possible to use it for high-quality waterproofing. It is united with ordinary rubber only by its black color and the ability to self-repair after minor damages, punctures, deformations - according to this indicator, the material bypasses all traditional rolled counterparts.

It is more correct to call the material sprayed seamless waterproofing, but this name did not take root among buyers, apparently due to excessive complexity. Many manufacturers insist on the same name, but the concept of liquid rubber continues to be used in the domestic market. By the way, they tried to produce something similar in the USSR in the 70s, but the quality of bituminous raw materials was low, so the material did not become widespread.

Liquid rubber does not allow water to pass at all, which is largely ensured by the complete absence of seams. That is why the material is actively used for waterproofing foundations, roofs, pools, basements, ponds, bridges, as well as for anti-corrosion treatment.

Dignity

When compared with solid analogues, they are inferior to it in a number of indicators:

- Good adhesion (adhesion) even in the absence of a bonding primer.

- Simplicity, speed of application.

- Hygroscopic composition, solidity. Lack of seams, cracks.

- High tensile tear resistance. Resistant to one-time mechanical stress.

- Environmental friendliness, harmlessness. When heated, it does not emit harmful substances.

- Possibility of renovation. No dismantling required, spot repairs on site.

- Complex surface treatment. The only condition is an increased thickness of the layer at the joints, the use of reinforcing tapes.

- "Cold" application. The waterproofing agent is ready for application.

- Durability - over 20 years. During operation it does not lose its properties. Ossification is technologically acceptable with long-term use without violating the technical properties.

- Wide temperature range of use - from -60 to +90 ° С.

- Most formulations have good UV resistance.

- Many samples can be applied to untreated surfaces in high humidity.

Roller application

Roller application

Liquid coating types

According to the method of surface treatment, liquid roofing material can be bulk, paint and spray.

Filling technology

The self-leveling coating requires the technician to operate manually. He needs to treat the base for a liquid roof with two compounds: first with a bitumen emulsion, and then, after it has dried, with a primer. As a result, a film with a thickness of 1 to 2 cm should form.

The filling technology of the liquid roofing device requires the master to pour the composition from a bucket in portions

It remains to gradually fill the prepared area with liquid waterproofing material, forming a layer of 2 or 3 mm. The layer of the self-leveling coating will turn out to be even if it is distributed over the roof area with a construction roller. It is recommended to apply another layer of liquid material on top of the hardened polymer-bitumen mixture.

Self-leveling technology allows you to make the treated surface perfectly flat, but it is completely unsuitable for waterproofing pitched roofs.

Video: liquid roof filling technology

Dyeing technology

Painting the roof with a liquid waterproofing material is performed manually after surface treatment with a primer. A mixture of rubber and water (30%) is used as the first layer. The composition is smeared with a brush or roller and left to dry for an hour if the outdoor thermometer shows a temperature of at least 20 ° C.

Even tiled roofs are painted with liquid rubber

The second layer of paint coating with a thickness of 3 mm is formed from a liquid waterproofing material, not diluted with water. The composition is smeared over the base of the roof perpendicular to the direction in which the first layer of liquid roof was applied to the surface. The paint coating is leveled with a wide trowel.

Spraying technology

The device of a liquid roof using spraying technology involves spraying the composition by means of an airless pumping device, which is capable of driving both an electric and a gasoline engine.

Spraying liquid rubber on the roof is very fast

The installation is connected to two containers at once. One of them should be filled with a bitumen-polymer emulsion, and the other with calcium chloride, which accelerates the process of solidification of the liquid coating.

The liquid rubber spraying machine has two wires carrying two different liquids that mix at the outlet of the nozzle.

Using spraying technology, liquid waterproofing is arranged on flat or, conversely, significantly inclined roofs. When irrigated, the composition is distributed ideally evenly on the surface.

Video: spraying liquid roof

- On the label of liquid rubber, information is found on how many kg of this material are per 1 m2. The area of the roof is divided by the revealed number. This is how the required amount of liquid rubber is obtained. And in order to find out how many containers of the composition are needed for waterproofing the roof, the total number of kg is divided by the amount that is placed in one container from under the material. When applying liquid rubber cold and in two layers, one kilogram is usually enough for 3 m2. But these data are only approximate, in any scenario of the waterproofing material, it is worth buying 10-15% more than necessary.

- The base for the liquid roofing device is cleaned of dust with a damp cloth or a jet of compressed air and thoroughly inspected. The debris is removed, and the revealed cracks are sealed with putty or a mixture of water, sand and cement. Further work is postponed until the hour when the roof surface is completely dry.

The roof is checked for defects and only then covered with liquid rubber

- Having chosen the hot method of applying liquid rubber, the composition is heated to 22 °, and then immediately cooled so that its temperature drops literally by 7 °. After these manipulations, liquid rubber is promptly poured and distributed over the entire roof. When applying waterproofing material in a cold state, use a wide brush or paint roller, which will help to scrupulously smear the roof and create a neat layer 3 mm thick. On hard-to-reach areas of the roof, use a spatula or a narrow brush.

In hard-to-reach areas, it is better to apply liquid rubber with a brush than with a roller.

Glass waterproofing

The next option is waterproofing the foundation with liquid glass. This type of work is less expensive, practically not inferior to rubber waterproofing. Raw materials are made by mixing a salt solution with quartz sand and soda. It is then fired to obtain sodium / calcium silicate crystals. During waterproofing work, crystals must be dissolved in water until a liquid of the desired consistency is formed.

There is a lot of information on the Internet on the use of liquid glass for waterproofing the foundation, impregnating it, but we think this idea is dubious. Because this surface will have poor adhesion to the subsequent material to be applied. And we recommend using classical methods - liquid rubber, roll-on waterproofers and all kinds of liquid formulations based on bitumen resins or polyurethane. This is our private opinion and it does not have to be the same as yours. Below we describe the technique if you still want to use liquid glass. And this is at your own peril and risk.

Liquid glass fills fine cement pores well

Liquid glass fills fine cement pores well

It is intended for filling the pores of concrete and improving its adhesion to prevent the penetration of moisture or soil into concrete.

Used in several ways:

- Coating works on waterproofing materials;

- On a concrete foundation;

- Cement-based, so-called penetrating waterproofing.

The application method is different for each method.

Dignity

Liquid glass is used in small areas

Liquid glass is used in small areas

Pros for working with this type of waterproofing:

- Waterproofing with liquid glass penetrates into all hard-to-reach areas of the foundation, where roll-up and not even close. Full penetration into micropores, whether it be a roll or concrete, which gives reliable and durable protection;

- Low price, high quality compared to alternative works;

- In addition to being water-repellent, liquid glass has anti-corrosion properties;

- Wherever there is liquid glass, there are no fungi and mold;

- Excellent adhesion to mineral substrates;

- Ease of use.

disadvantages

Before use, glass is usually diluted with cement.

Before use, glass is usually diluted with cement.

There are disadvantages when working with liquid glass:

- High speed of solidification. If you use this solution without proper experience, then you may be faced with the fact that the solution will harden and become unsuitable for work, you will have to do everything from the beginning;

- The inability to paint the surface, the paint simply does not lie on the liquid glass.

- The presence of alkali, which is harmful to human skin. It is necessary to work with this material only in special clothing and gloves.

What affects the waterproofing of the foundation

But the material used to waterproof the foundation must provide more than just waterproofing. In addition to water, other external factors and loads affect the underground part of the building, respectively, and the waterproofing of the foundation.

These are mechanical loads due to heaving of the soil. Moreover, they can increase hundreds of times with the onset of cold weather.

These are possible mechanical damage from hard and sharp fractions of backfill soil. Moreover, any even small damage to the waterproofing will allow water to penetrate into the foundation.

These are temperature drops. Moreover, in winter, on the same surface of the foundation wall, the temperature differs by tens of degrees. Upstairs - corresponds to a negative temperature outside, and when deepening - the temperature rises.

This is contact with water. Moreover, depending on the location, for example, in the lowlands, where the level of groundwater is high, water can constantly come into contact with the foundation.

This is a possible contact with aggressive chemical substances carried by groundwater.

If you use liquid rubber for waterproofing the foundation, then most of the negative impacts on the underground part of the building can be neutralized. It is possible to ensure the safety of the foundation by 100% if, in combination with the waterproofing of the foundation, other measures are applied: protection of the foundation, clay locks, drainage of the foundation, insulation of the foundation, insulation of the soil around the perimeter of the house, installation of a blind area.

More details about the various factors that have a negative impact on the waterproofing of the foundation are described in the corresponding headings of the section waterproofing the foundation.

Read in detail, article heaving of soil and waterproofing of the foundation.

Foundation waterproofing and foundation waterproofing repair

If the house is small, the foundation is shallow and there is no basement, then for waterproofing the foundation, it is enough to use a coating waterproofing. Made by hand, one-component liquid rubber is perfect for this. No special skills or knowledge is required. A bucket of bitumen-polymer mastic, a spatula or brush and two hands - that's all you need.

If the underground part of the building goes down a few meters, and it can be a cottage with a basement or an underground garage, and a multi-storey building or a business center with underground parking or a store in the basement, then the issue of waterproofing the foundation should be approached especially carefully and responsibly ...

The deeper the foundation, the higher the cost of an error. if something is missed or overlooked somewhere and the water in 3 or 5 years passes through the waterproofing coating and ends up inside the underground part of the building, therefore, it is required to repair the waterproofing of the foundation. You can, of course, temporarily block the capillaries in the concrete, through which water flows, by means of injection waterproofing, but this is a temporary solution. If you close a passage for water in one place, in a year or two it will make its way in another.

Therefore, the waterproofing of the foundation should be immediately performed with high quality, so that you never have to repair the waterproofing of the foundation. Roll, pasting materials - all this is already outdated and is used for underground waterproofing, either because it is cheap or because the performers do not know anything else and are not able to. Meanwhile, a more modern and high-quality method is liquid waterproofing of the foundation. But among various liquid and pasty materials, the most correct solution for these purposes is liquid rubber waterproofing

How to waterproof a foundation with liquid rubber

Liquid rubber reliably protects the foundation and resists all external factors and guarantees long-term operation of the building. At the same time, the cost of waterproofing the foundation with liquid rubber is not so high, if you remember that these costs are carried out once. Moreover, given that the work is carried out in a very short time and with little effort, the price for such work as waterproofing the foundation with liquid rubber is often less than that of traditional pasting materials.

Liquid rubber allows reliable waterproofing of abutments (protrusions, supports, columns, beams) on the foundation and sealing of any amount of reinforcement.

Using liquid rubber, it is possible to perform both waterproofing of lean concrete and horizontal foundation slab waterproofing and vertical waterproofing of foundation walls.

Liquid rubber has excellent adhesion to concrete, therefore, if everything is done correctly, then the entire foundation is inside a waterproof, elastic, but at the same time durable rubber bag, respectively, water access inside this bag is impossible.

Diagram of the waterproofing procedure

According to the technological features of construction, waterproofing includes work with all elements of the foundation of the building. This will create a more reliable protection of the building from moisture and extend the time of its preservation. The waterproofing procedure affects:

- the base of the building and walls;

- basement building elements, that is, not only the floor, but also the walls;

- ground floor.

High-quality waterproofing of any building begins with a properly carried out complex of construction work. They consist in the preliminary installation of a drainage system near the walls of the house. After the soil is sprinkled, it is necessary to install a blind area of the house, that is, a wide strip around the building.

For basement waterproofing, the material is applied to the foundation in three stages: two is the application of horizontal waterproofing, one is the vertical treatment. The application of horizontal layers is necessary to protect the higher parts of the house from the incoming groundwater. The first horizontal waterproofing is applied at the base of the building at the level of the basement floor. The second layer is applied in the basement above the blind area by 2.5 cm.

The use of liquid rubber for horizontal layers will allow for a seamless application, which will provide better moisture protection.In this case, the material must withstand huge loads, allowing you to protect the house from the pressure of groundwater.

Waterproofing the foundation of any building is an important stage in construction. It allows you to protect the building from external natural influences and, therefore, increase the operating time. The large number of waterproofing materials makes it difficult to choose.

The use of liquid rubber is renowned for a large number of proven advantages that significantly cover its cost. A preliminary acquaintance with the features of the material and the specifics of its production and use will allow even a beginner in the construction business to master the skills of applying.