How to calculate the base?

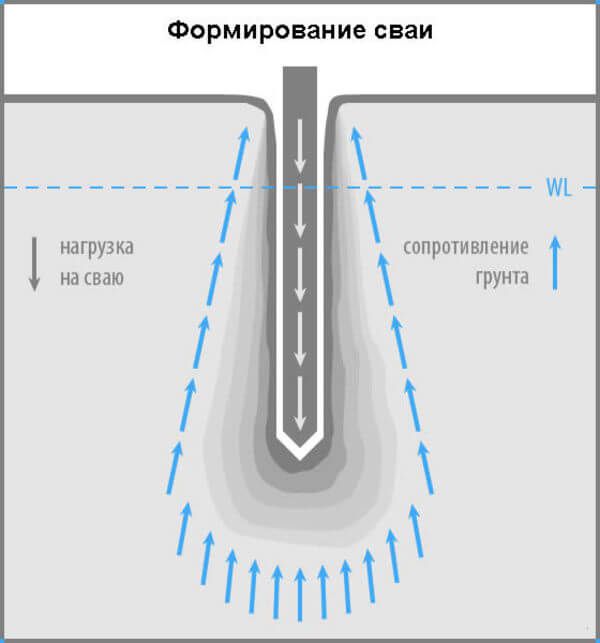

The calculation of the pile-driven foundation is carried out according to the total load and bearing capacity of the pile.

The load is determined by summing the weight of the house, roofing system, snow and wind loads, property and other factors that increase the pressure on the supports.

The bearing capacity of a pile is the sum of the soil resistance at the bottom of the trunk and along the sidewalls.

The total weight of the house is divided by the bearing capacity of one support - the number of piles required to form a pile field for this building is obtained.

IMPORTANT!

Calculation of the foundation is a complex engineering task that must be performed by experienced, trained people. Self-calculation can cause deformation or destruction of the house, so you should not take risks. At a minimum, an online calculator can be used, but it will also require exploration data for the site.

Advantages and disadvantages

Before installing the structure, you should familiarize yourself with the positive and negative aspects of the issue and study the important performance characteristics.

The pluses of the foundation made of reinforced concrete piles should include

- A positive result of construction in problem areas (with the exception of rocky ground)

- Rapidity. The structure can be installed within a day, while the traditional method of erecting a foundation requires at least 7 days. After that, you can immediately carry out the construction of load-bearing structures (the monolithic base allows you to continue work only after 3-4 weeks).

- Minimizing construction and earthwork materials.

- All-seasonality. It is possible to form a foundation on driven reinforced concrete piles at any time of the year, regardless of climate and weather.

- Duration of use. Reinforced concrete piles under the foundation are very wear-resistant and are able to withstand any weather disasters. The term of their suitability can be about one and a half hundred years.

- Strength. Reinforced concrete piles for the foundation, in the construction of which metal rods are used, are characterized by the ability to transfer multidirectional loads, which is a necessary quality in unstable areas.

The foundation on driven reinforced concrete piles has only a few drawbacks.

- The possibility of subsidence or curvature of the foundation. There is always the possibility of an unreliable characteristic of deep soil, since it is not possible to consider a multi-meter layer.

- The obligatory use of expensive specialized equipment for the installation of piles.

- The lack of a basement and basement room is a real inconvenience that people who have decided to build a foundation on reinforced concrete piles will have to face.

Views

The classification of supports of this type can be carried out based on several criteria. In general, all reinforced concrete piles are divided into 2 types - frames, poured with concrete directly at the construction site and analogues, manufactured in the factory.

The type of piles in some way depends on their device - the installation technology. So, piles, which are poured directly after installation into the ground, can be mounted by driving in with hydraulic hammers, by means of vibration deepening, or by indentation technology under the influence of static (constant) pressure.

Depending on the design features, reinforced concrete piles are divided into several types.

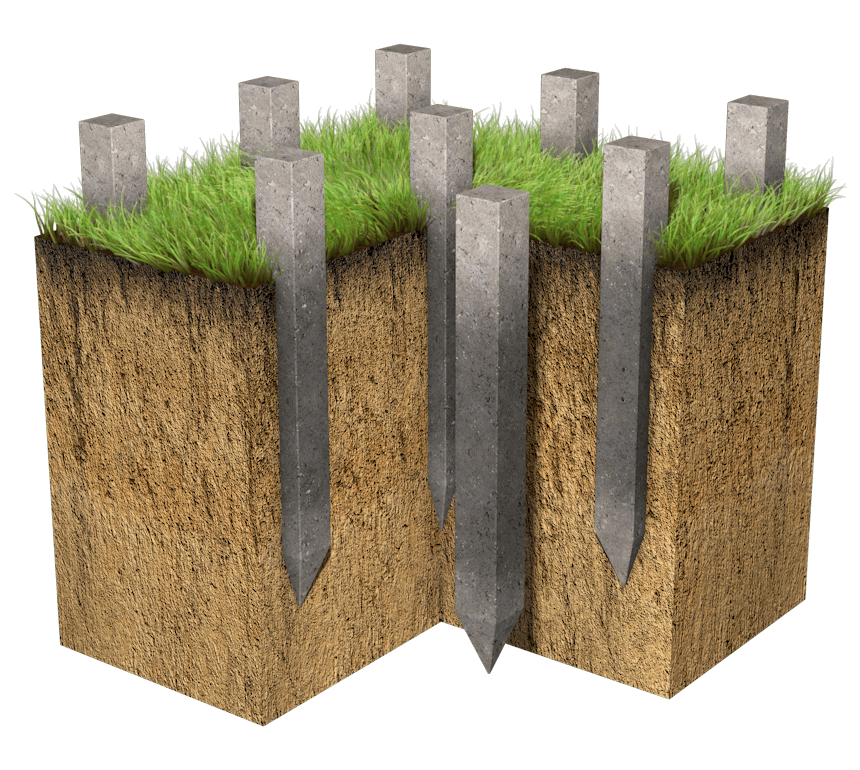

Monolithic

They represent a solid support with a rectangular or square section, although piles with a round, trapezoidal or T-section, the size of which is 20-40 mm, are possible.The bottom end is pear-shaped, it can be sharp or blunt. Such supports are not hollow, so no holes need to be made to submerge them in the ground. The technology of hammering or vibration pressing into the soil is used. They are widely used in civil engineering, they are also in demand in the construction of a private house (wooden, block, frame).

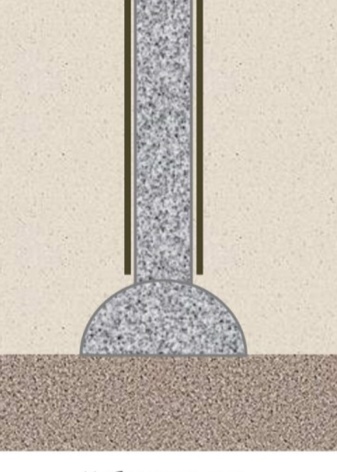

Hollow (shell)

It looks like a shell, for immersion in the soil of which a well is preliminarily prepared. The support can be round or square, but the latter still has a circular cross-section. Hollow supports, in turn, are divided into solid and composite (they consist of several elements that are assembled immediately before immersion).

Printed

But it is also mounted by immersion in a previously prepared recess.

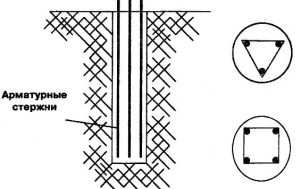

Depending on the type of reinforcement, reinforced concrete piles are of the following types:

- supports with non-tensioned longitudinal reinforcement with transverse reinforcement;

- Supports with prestressed longitudinal reinforcement with or without transverse reinforcement.

If we talk about the shape of the cross-section of the piles, then they are round (hollow or solid), square, square with a round cavity, rectangular. It is unacceptable to place supports with a square cross-section in permafrost soil. Even with a slight thawing, the pile will roll and the building will skew. In regions with increased seismic activity, structures with a circular cross-section should be used.

Allocate one-piece and prefabricated structures. The second ones consist of several segments, which makes it possible to increase the height of the product. The segments are fixed by welding or by means of a bolt connection.

How to make foundation piles

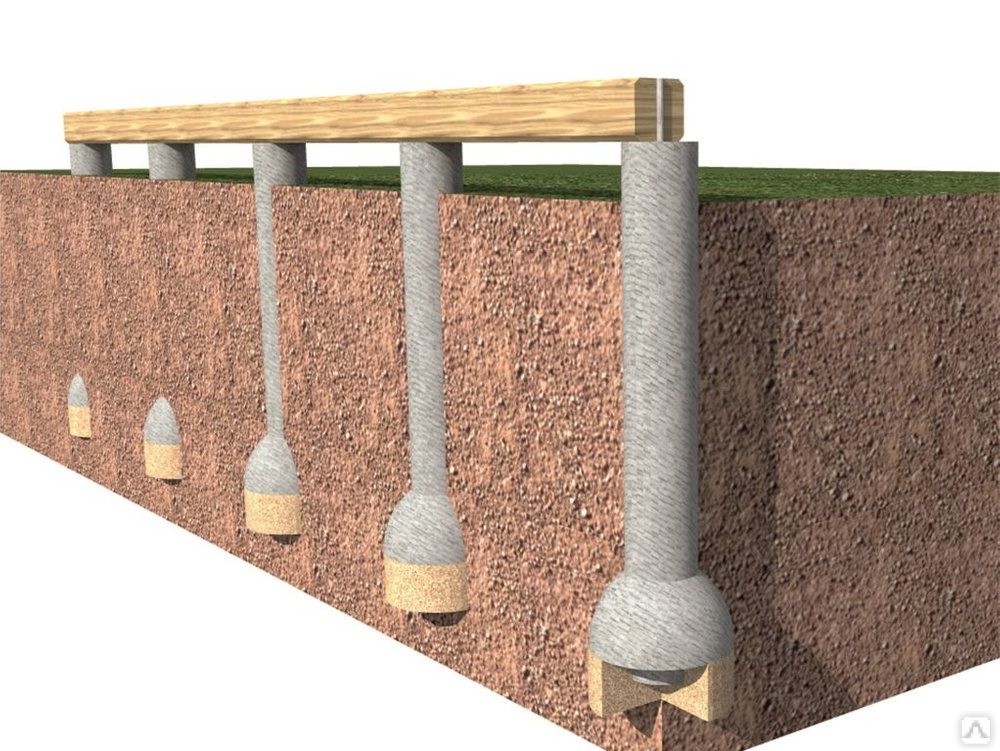

Fill piles

Fill piles

It is easy to make the foundation of reinforced concrete piles by yourself

It is only important to adhere to the basic calculations:

- barrel sizes;

- gaps between trunks;

- reinforcement parameters;

- concrete grade;

- stacking frequency.

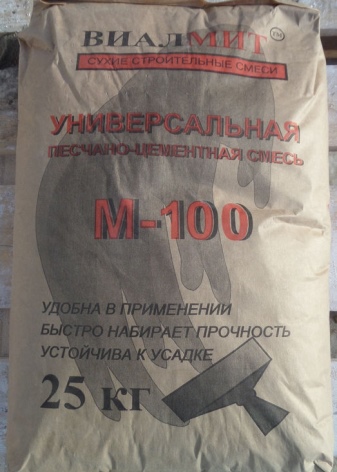

Concrete mix

Preparation of concrete mix

Preparation of concrete mix

Pile foundations are often installed in hostile environments. For this reason, concrete is needed for them strong, resistant to "chemicals". This property of concrete affects the durability of the pile.

The concrete grade should be consulted with experts who, after studying the soil, will recommend appropriate additives to increase stability.

Possible concrete composition:

- cement grade 7001 h;

- sand 1.5 hours;

- crushed stone 2.5 hours;

- water 0.5 h.

Preparation of a place for a foundation

Before starting the installation of the piles, the site is being prepared:

- remove tree roots, topsoil;

- mark the location of the foundation with cords;

- determine the levels of trunks above the surface;

- mark the axes of the piles.

Concreting and reinforcement of piles

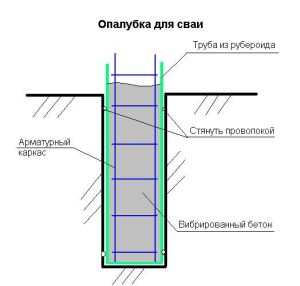

After preparing the holes for the piles, "pipes" are rolled up from the roofing material, which must correspond to the wells in the coverage, and the length is 20-30 cm deeper than their depth.

After preparing the holes for the piles, "pipes" are rolled up from the roofing material, which must correspond to the wells in the coverage, and the length is 20-30 cm deeper than their depth.

At the top, the "pipe" needs to be made stronger, from 2-3 layers of roofing material, and tightened with a strong wire. This end will be the top formwork. Then the "pipe" is carefully driven into the well.

If there is some water at the bottom, it is not a big deal. But when water fills a quarter of the well, it needs to be pumped out.

Formwork

Pile formwork

Pile formwork

The setting of concrete takes place on the first day after the preparation of the mixture

And for the strength to be maximized, it is extremely important to preserve the "cement milk" in the concrete mass. It should not drain into the ground, because then the specified concrete strength cannot be achieved.

In case of freezing of the soil surface, the heaving forces will act on the rough surface of the pile stronger if it was formed without a "pipe".

When the wells are prepared, a reinforcement cage will be needed. For this purpose, you can take 3 rods of six-millimeter diameter reinforcement for each pile shaft. They are fastened with transverse beams at intervals of 50-60 cm.

Vertical rods are brought out above the piles below the height of the grillage by 2-3 cm.

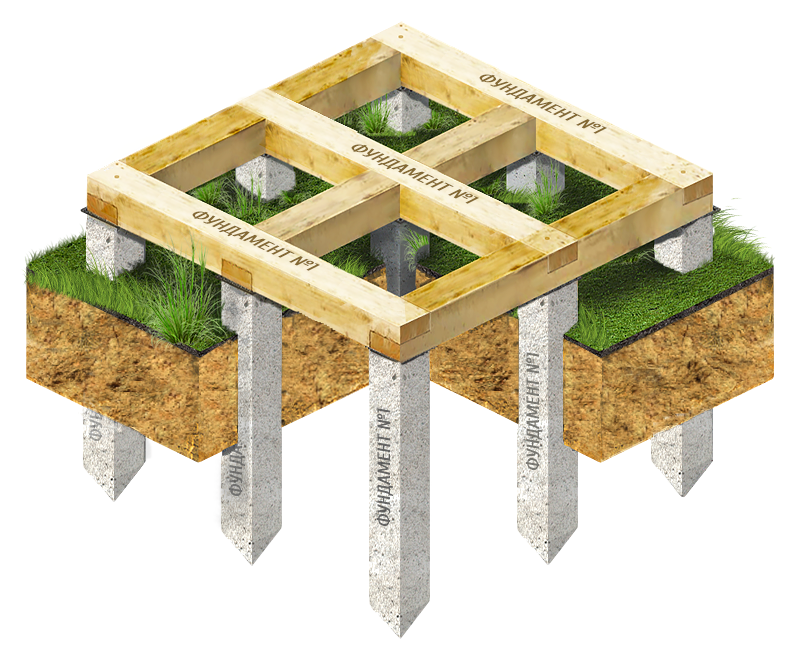

Grillage device

Arrangement of a bored pile foundation with a recessed grillage

Arrangement of a bored pile foundation with a recessed grillage

For the device of a grillage for a light house, it is recommended to observe the following parameters:

- height - from 30 cm;

- the width is equal to the width of the basement, and if it is not there, the width is equal to the thickness of the walls of the 1st floor, but not less than 40 cm.

Cutting the grillage with pipes is unacceptable. The deviation of the pile from the vertical is determined by a plumb line. It should not be more than 5 cm.

During the assembly of the grillage, you need to carefully fix the elements on the pile heads. If the grillage beam is replaced with load-bearing reinforced concrete lintels, they are fixed to each other by welding with reinforcing bars.

After assembling the grillage, all seams and joints are filled with cement mortar or concrete.

Grillage application

The grillage is an element of the foundation structure that connects the piles into a one-piece structure and provides a support for the load-bearing components. According to some reviews, you can do without it. However, the base on driven reinforced concrete supports with a grillage is more reliable and stable than in a situation without it.

According to the manufacturing method, reinforced concrete and metal are distinguished.

To obtain the first, the solution is poured into a previously prepared formwork with a built-in and fixed reinforcement cage.

To make a metal grillage, metal-rolling products are used, such as an I-beam, a rail, a channel. They are placed on supports clogged in level and welded to iron rods that are visible outside the supports. The components are fastened by welding or bolts.

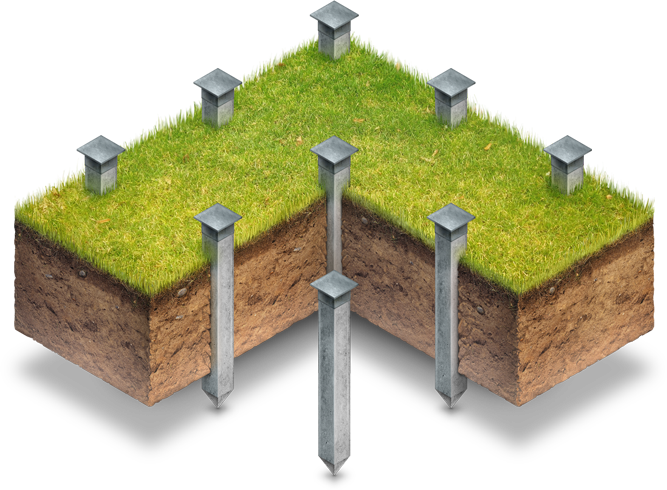

There are three types of grillage:

- hanging. Located at a considerable distance from the soil, there is an uninsulated void under the floor. It is used in the construction of temporary buildings: baths, attics, small summer cottages. In this case, the use of mini reinforced concrete piles is allowed.

- shallow. It sinks to a shallow depth into the ground. They cannot act as a support, they are used as a means of protecting the space under the floor, buildings from unfavorable climatic conditions, changes in the movement of air masses;

- recessed. To create it, they dig a trench similar to a tape base. It is an extra support for the building, strengthens the foundation on piles, ideally matches the construction of a solid year-round premises.

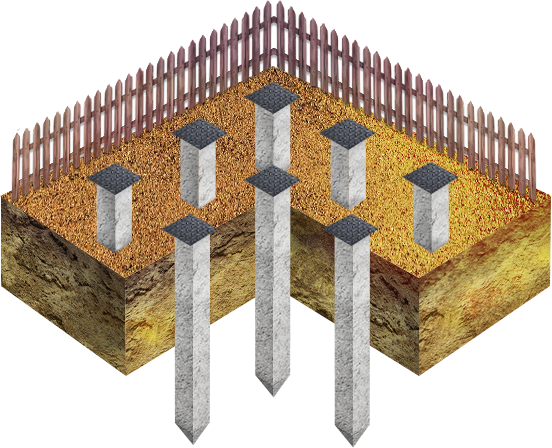

Types of piles

When building premises with a small number of floors, frame houses, it is possible to use such types of supports.

- Reinforced concrete. Most widely used. They are available in any landscape, a large number of firms specialize in both the production and installation of piles. The operational period ranges from 50 to 150 years. Differences are possible according to certain criteria:

- supports with tensioned and non-stressed metal rods;

- types of section: round, square, tee and hollow;

- shape: prismatic and cylindrical;

- structure: solid and assembled;

- base: widened, chained or hollow.

- Wooden. They are very popular in the construction of log cabins and frame structures on a wooden base. Their degree of reliability is lower than that of the previous ones, so they can only be created from certain types of wood. Recommended for use on heaving soils. The above type of supports, as a rule, are made from cedar, oak, larch, and other hard species. Supports made of wood with a diameter of 20-40 cm and a length of three to 8 meters are used. When applied on hard ground, it is necessary to use a shoe - a steel cap with a strapping, which is attached to the bottom of the sharpened end of the pile. Weather conditions, climatic changes, soil characteristics have a huge impact on the performance of wooden poles. If all the rules are observed, the service life is at least 50 years.

- Steel.There is a wide range of materials for the production of this type of pile: rails, channels, pipes, etc. They are used infrequently, as a rule, for temporary structures or utility structures. The approximate period of operation is 40 - 60 years.

Limitations in the use of the pile foundation

The process of collecting identity data

The process of collecting identity data

This type of foundations also has drawbacks, or rather restrictions that impede their use.

Reinforced concrete foundations should not be used in horizontally unstable soils, because the building will not be resistant to overturning.

When building such a foundation, problems arise with the base.

It is necessary to fill the space between the piles, as in a columnar base.

This requires additional funds.

The video demonstrates the driving of reinforced concrete piles IZH-3-38-C1 (C2) C-08 without formwork

Peculiarities

Reinforced concrete piles (RC) are a reinforcing cage that is poured with concrete. The length of the finished product can be from 3 to 12 m.

Reinforced concrete piles are used when organizing a foundation using driving technology. Their use allows you to strengthen the base and reach solid soil layers.

Visually, they represent bases with a round (hollow or filled), square section. They differ in diameter and height, which determines the bearing capacity and scope of application. In addition, the strength indicators depend on the concrete grade used. The higher it is, the more reliable the elements are.

To create reinforced concrete piles, cement is used, the brand strength of which is not less than M100. Not only the compressive strength of the pile depends on the performance characteristics of concrete, but also frost resistance and moisture resistance. The last parameters for concrete grade M100 are F 50 (that is, the structure can withstand up to 50 freeze / thaw cycles) and W2 (water column pressure) - 2 MPa. The weight of the support is determined by its dimensions, and also depends on the density of the type of concrete used.

Usually, more dense concrete grades M-250, M-300, M-400 are used. The frost resistance of such products reaches 150 cycles, and the water resistance coefficient is at least 6.

Due to the increased resistance to the possibility of driving piles to great depths, their use becomes possible on moving soils (including in the zone of increased seismic activity), on clay, heaving and weak soils, in water-saturated and swampy soils.

Reinforced concrete piles can be used not only as the foundation of the foundation, but also used to prevent the pit from crumbling, strengthening the soil and the existing pile foundation. For this, reinforced concrete supports are immersed at a short distance from the existing structures, performing the function of a second pile. In addition, with additional strengthening of the foundation, the type of support under consideration can be carried out beyond the existing foundation and connected with it through beams.

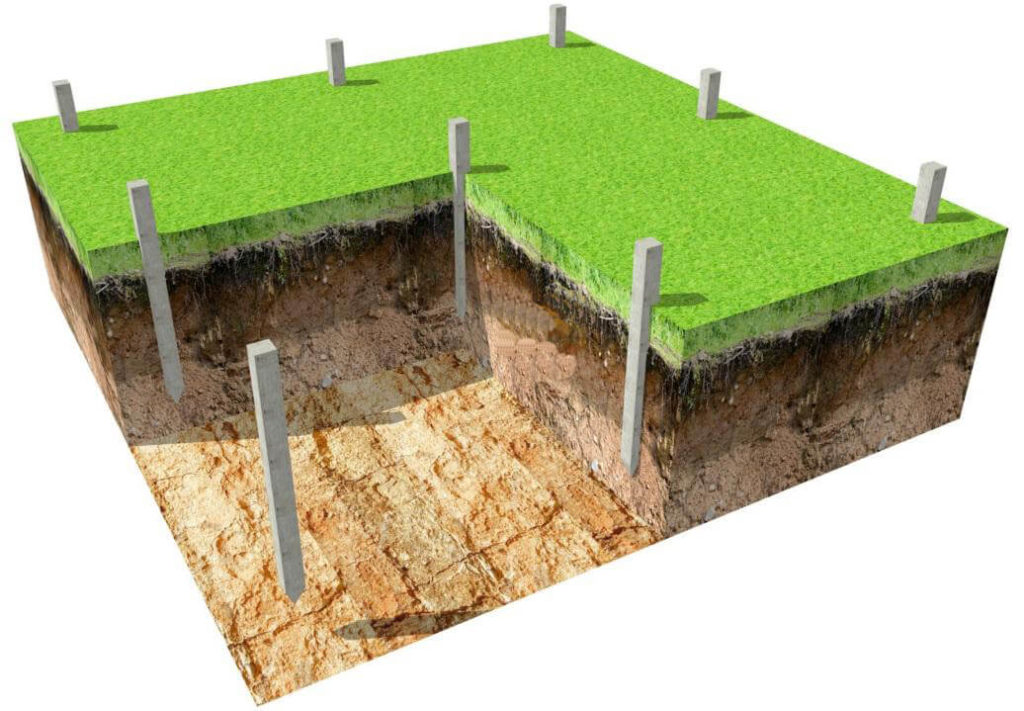

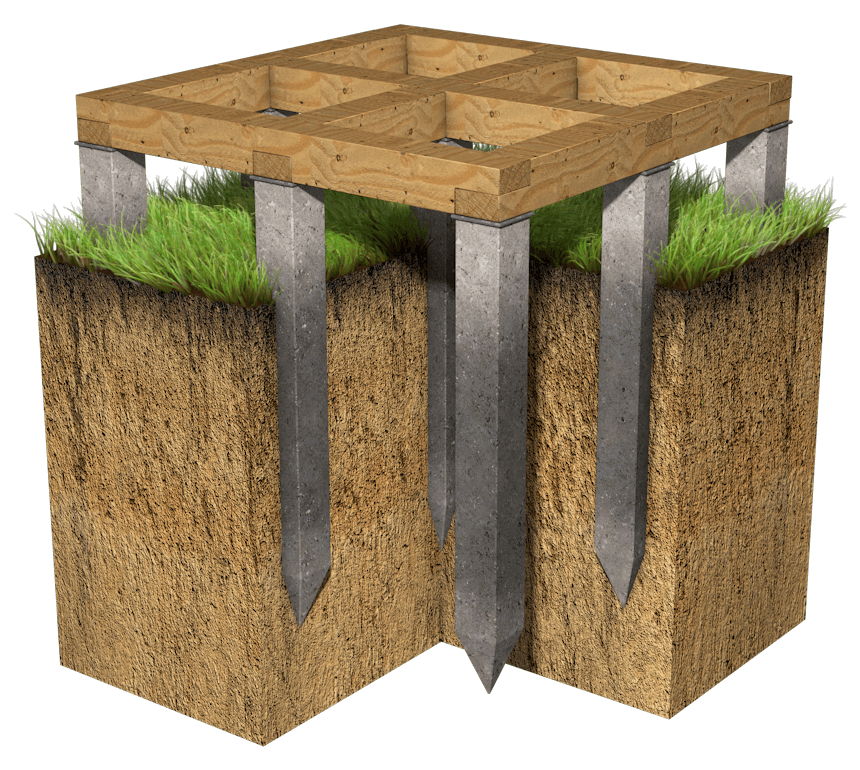

Varieties of foundations erected on reinforced concrete rods

Foundation on RC piles

The type of base chosen depends not only on the quality and characteristics of the soil on which the building will be built. I choose the type of foundation depending on the severity of the building and on its configuration:

- The foundation can be supported by single members. This is possible when constructing buildings with columns.

- The strip base requires the installation of piles around the entire perimeter of the excavation.

- Shrub - deepening several rods into the ground in one place. This design is designed for the construction of buildings requiring reinforcement of support under individual elements.

- "Field" is a foundation, the creation of which is necessary for the construction of objects with increased load. In this version, reinforced concrete piles are located both along the perimeter and throughout the entire area of the pit.

Such structures can be buried, located on the surface of the ground or towering on it.

The durability of the rods is directly related to the quality of the concrete used to create them. Therefore, the ideal option is industrial concrete, the preparation of which is carried out taking into account the most important indicators such as compressive strength, limiting water pressure, frost resistance.

Technical characteristics of reinforced concrete piles

Reinforced concrete piles of various sizes

Most of the parameters of pile shafts are determined by the grade of concrete used in their manufacture.

For example, the grade of concrete characterizes the strength of the trunk. The concrete grade numbers show the ultimate compressive strength.

In the production of reinforced concrete piles, concrete of B7.5 and higher class is used. The lowest compressive strength is determined for this type of concrete.

The indicators of frost resistance and moisture resistance of piles are determined in the same way. They appear on the type plate after the letters "F" and "W". For example, for concrete grade B7.5, these parameters are equal to more than 50 cyclic freezing / thawing (F50) and a pressure limit of 2MPa of water (W2).

The mass of reinforced concrete shafts is primarily determined by their volumes. And the larger they are, the greater the weight indicators.

The positive qualities of reinforced concrete piles of any type include:

- duration of service (If the foundation was erected without violating the technology, the piles will last more than 100 years without repair);

- high strength (reinforced concrete piles can withstand the mass of even multi-storey panel buildings);

- stability (the barrel is driven into a depth, which allows it to lean on the ground of high bearing capacity);

- the possibility of using supports for construction on difficult terrain (The pile part of the foundation base can be constructed from supports of different lengths.)

Pile field for the foundation for the construction of a two-story brick house

Pile field for the foundation for the construction of a two-story brick house

The foundation on reinforced concrete piles is made in the area where the soil is problematic, and the building needs to be built. In an area with such soil, only reinforced concrete piles will ensure the stability of the building, transferring the load to stable layers.

Reinforced concrete pile foundations for a block building have many advantages over other types of foundations.

If we compare the construction of a columnar foundation with others, then the device of such a foundation under a house from blocks is much more technologically advanced.

The pile foundation assumes the drilling of wells of a given size, the installation of reinforcing rods in them, and pouring them with concrete.

The big advantage of this method is the ability to drill wells with a hand drill.

Advice

Piles are produced by large factories or production workshops at construction firms. As a rule, the products of the former have a lower cost, but factories prefer to cooperate with wholesale buyers.

If you need a limited number of supports, it is best to contact the workshop at a reputable construction firm. As a rule, here you can order piles at least by the piece, but their cost will be higher. This is due to the fact that small companies cannot build up their power, therefore they increase their own revenues by increasing the price list.

Choosing piles is better than domestic production, since they are manufactured in compliance with the requirements of GOST.

Usually the price of a pile depends on its length and cross-sectional dimensions, as well as the brand strength of the concrete used. The lowest cost is possessed by three-meter structures with a square section, the side of which is 30 cm.

As a rule, the larger the batch of purchased concrete products, the lower the cost of one unit of goods. When registering a self-pickup, a discount is also provided in most cases.

You will learn more about reinforced concrete piles in the following video.

Installation types

The method is determined based on the indicators of geological research and design features of the planned structure.In order to adequately share the gravity, reinforced concrete supports on the foundation are lowered to the level of the location of a solid stable layer. The following types of installation are allowed:

Hammer. The most commonly used method. The supports are installed using a device with a hydraulic or pneumatic hammer.

- The indentation method (constant pressure is applied).

- Vibration deepening. Instead of the extracted layer of earth, hollow support-shells are located, concrete is poured in.

Reinforced concrete piles for construction are poured using the following techniques:

- Bored. A formwork is installed in a pre-drilled hole, metal rods, concrete are placed.

- Buroinjection. It consists in the supply of concrete under pressure into the drilled hole, followed by the installation of metal rods.

- Ground-cement In the drilled hole, a mixture of cement and soil is poured. The cement capacity and reliability of such a support are 2 times lower than that of a cement-concrete one.

What soils are driven piles used on?

Before starting the construction of a country house, to guarantee the reliability of the foundation and the entire structure, it is necessary to carry out geological surveys of soils in the building spot. Geology at the construction site makes it possible to understand the composition of the soil, its plasticity and stability, the level of groundwater, the bearing characteristics of the layers, etc. You cannot accept the type of foundation and develop a project without a geo-foundation, based only on the design of the house. Without soil research, it is impossible to understand how this or that type of foundation will work and what its reliability will be

Most people do not understand the importance of this procedure and treat geology as an additional unnecessary procedure, referring to the foundations of neighbors that have been standing for more than one year or to the geology of neighboring sites. We have repeatedly encountered cases when the geological conclusions in neighboring areas differed significantly.

There was a case in our practice in the cottage village "Martemyanovo" in the Moscow region, when in the neighboring areas in one case, according to the conclusion of geology, 3-meter piles were passed, and in the other only 5-meter piles.

Driven piles work well on almost all types of soil: sandy soils, clay, loam, sandy loam, etc. The only exceptions are peat soil types. These cases are considered individually. Sometimes, there are peat lenses, their pile can pass and abut against stable bearing layers of the soil. Based on the conclusion on the soils and the project of the house, the designer calculates the loads and determines the parameters of the piles (section, length) and the step between them. A project of a pile field is being developed, according to which driving is subsequently carried out. An important factor is the individual characteristics of the site - the relief of the site in the building spot. Before starting the design of the foundation, it is imperative to inspect the site, determine the height differences in the building spot. At large drops, different pile lengths are often used, for example, in the high part of the relief there are 3-meter piles, and in the lower part of the 4-meter.

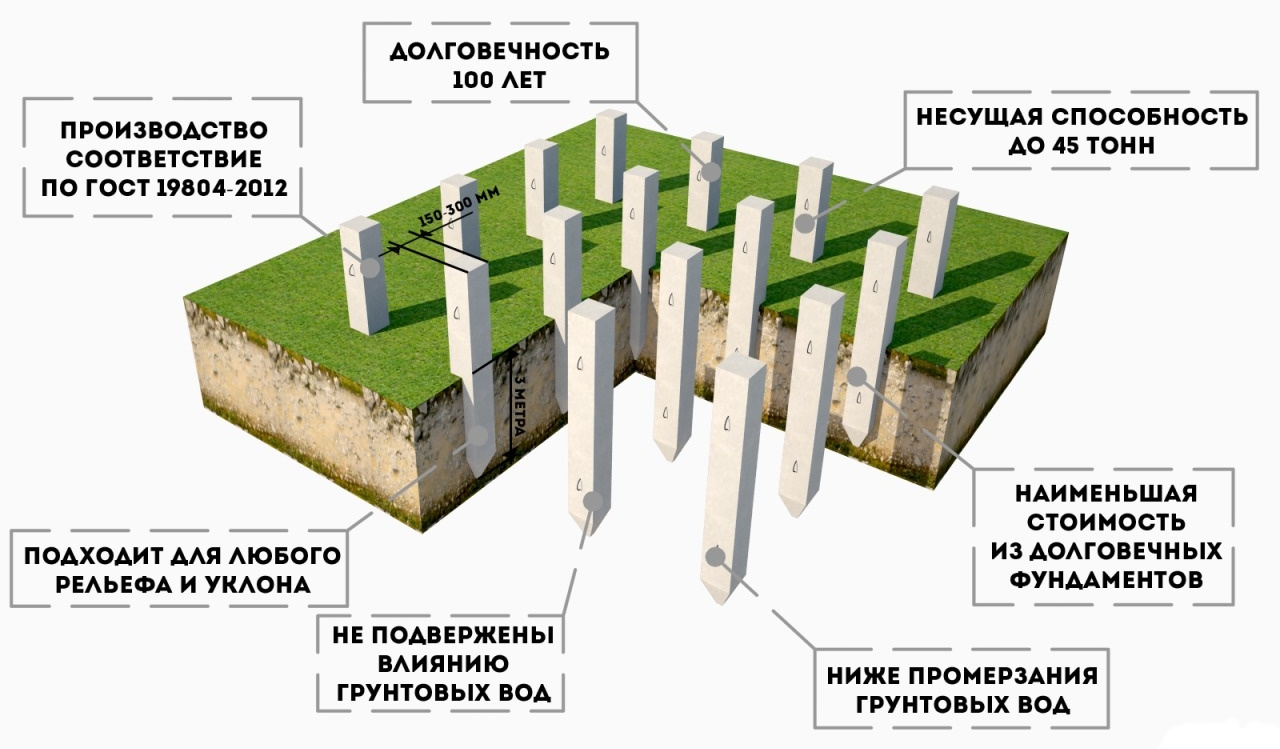

So what is a driven pile?

A standard driven pile is a reinforced concrete product that has a structure in the form of a reinforcing cage made of load-bearing reinforcement with a cross section of 10 mm with a tie bar with a cross section of 5 mm and pouring concrete with a strength class of B22.5 (grade M300). Each type of pile is marked. For example, marking C30.15-3 is a 3-meter pile with a section of 150 mm

At first glance, it may seem that there is nothing easier than making a reinforced frame, putting it in a mold and pouring it with concrete, wait a little - and the driven pile is ready. Yes, today mini-productions appear more and more often, which produce various reinforced concrete products, including piles.But a driven pile is a special type of reinforced concrete structures, the technology of its manufacture includes, without fail, a steaming cycle after pouring concrete. The piles are steamed in special chambers. Without a steaming cycle, with a very high probability, when the concrete is gaining strength, the standards required by GOST will not be achieved. Accordingly, such products may not be suitable for use in construction. Far from every production can afford a steaming chamber, because we are talking not only about the chambers themselves, but also about an increase in the number of production cycles and the complexity of the steaming process itself.

Many times we have encountered poor quality piles. Reinforced concrete piles, like any reinforced concrete products, are subject to state certification. Therefore, before buying piles, be sure to make sure that the manufacturer has a quality certificate for the piles and be sure to ask for a quality certificate for the batch of piles when purchasing them.

The pile, manufactured in compliance with all technological processes, has a long service life - more than 100 years.

Types of foundations for building a house

The design and construction of a house, as a rule, begins with its foundation. As you know, the cost of building a foundation is often half the cost of the house itself.

A foundation is a part of a structure that transfers the load from its above-ground part to the base. The foundation is laid below the freezing point of the soil. This is necessary so that when the soil buckles, no deformation of the structure occurs in the winter.

An example of a finished pile foundation

Foundations can be conditionally divided into six groups:

- slab;

- tape;

- pile;

- pile-grillage;

- columnar;

- continuous.

When choosing a particular type of foundation, it is necessary to take into account the characteristics of the soil and its ability to heave. Heavily soils include clay soils: clay, loam, sandy loam, because such soils retain moisture well. When freezing, due to the formation of ice, the soil rises, it begins to swell.

In heaving soils, with a significant depth of freezing, the installation of columnar foundations is especially effective. In horizontally moving soils, the use of columnar foundations can lead to pushing it out of the ground, raising and overturning the entire structure.

House project with an attic on a pile foundation

If the terrain on which the building is installed has an uneven surface, in order to avoid its lateral shift, a prerequisite is the installation of a rigid reinforced concrete cushion between the supports.

The most common and reliable is the strip foundation. When building a private house, it is worth listening to the feedback of specialists, because the strip foundation may not always be applicable.

The pile foundation will create a solid structure that is independent of the movement of surface water.

What kind of foundation is applicable for a given area, the calculation of its depth, as well as the selection of the necessary building materials, will be helped by experienced specialists.

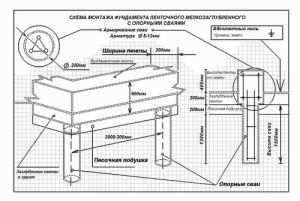

Scheme for the installation of a pile foundation